Connection structure of vehicle frame

A technology for connecting structures and frames, applied in load-bearing body structures, upper structures of passenger cars, superstructures, etc., can solve problems such as cracks and stress concentration, and achieve the effects of reducing weight, enhancing impact resistance, and strengthening load bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

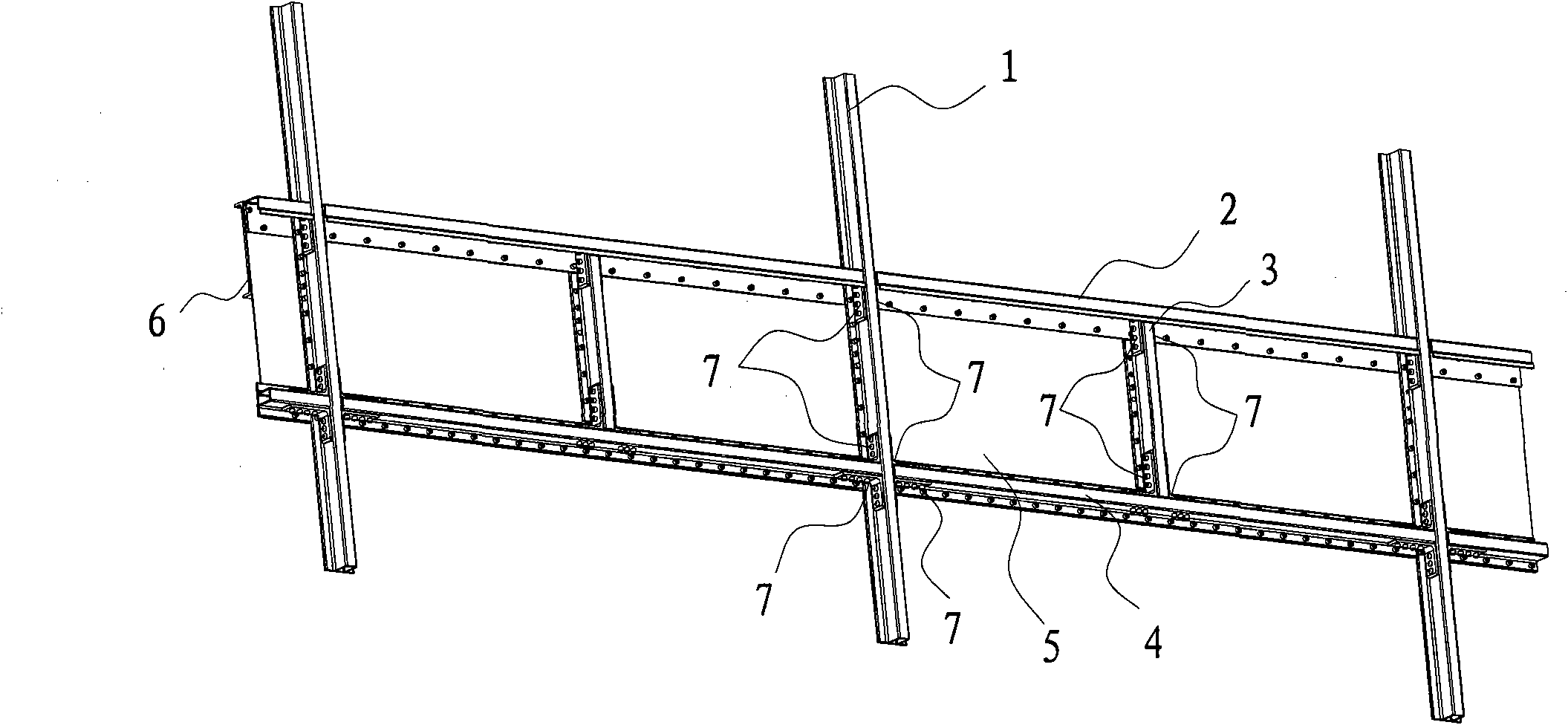

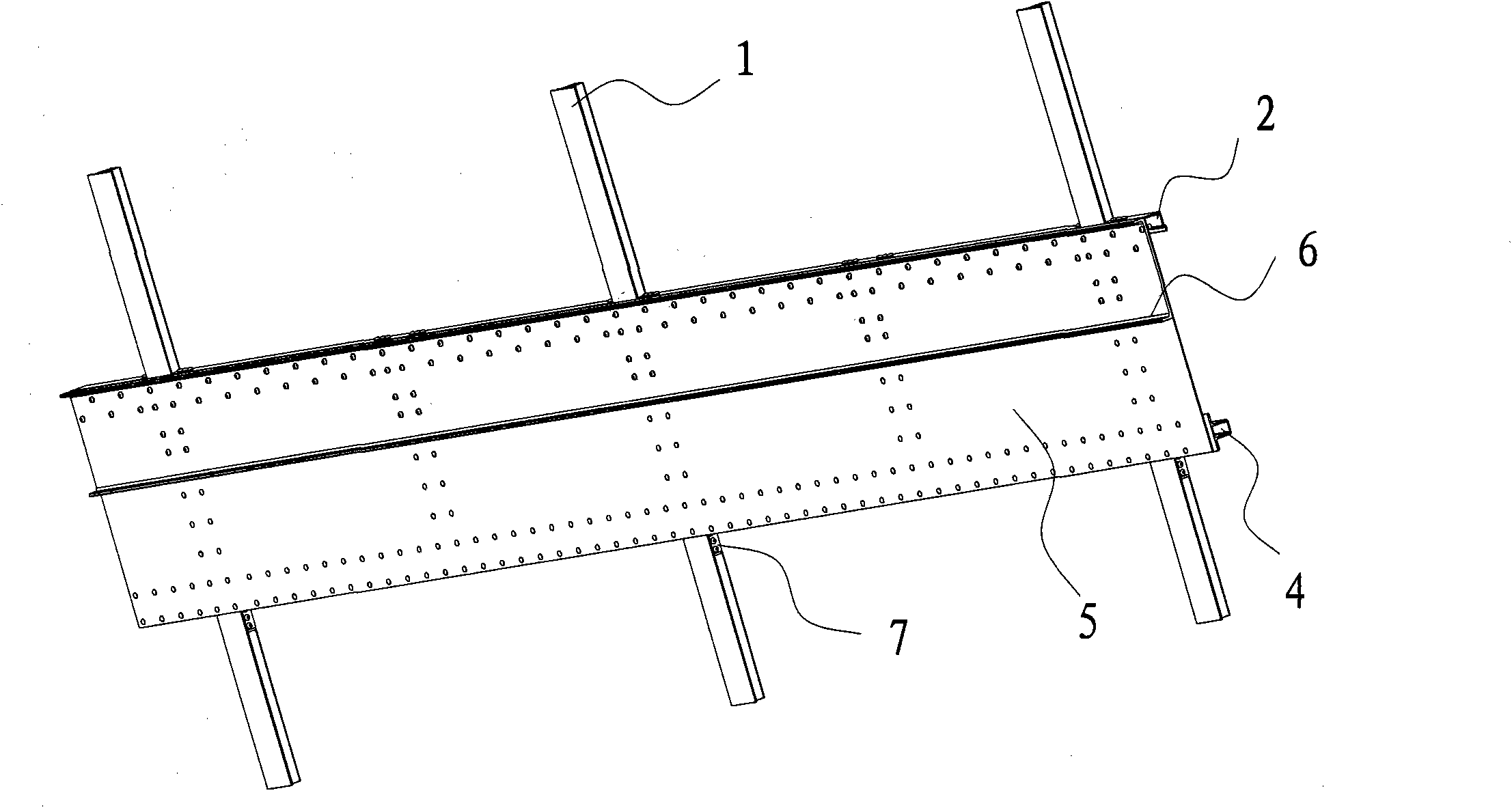

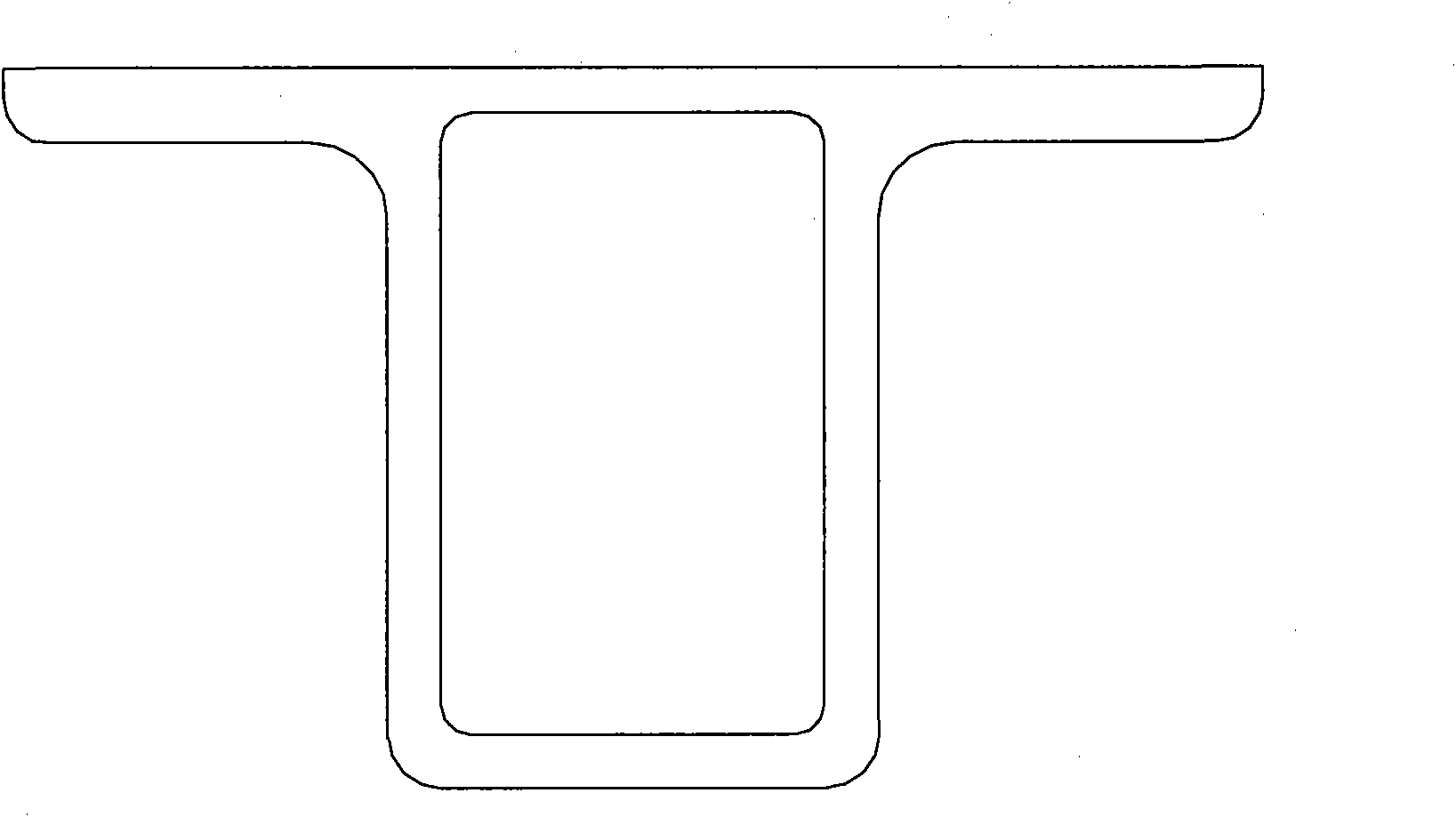

[0058] like figure 1 , figure 2 As shown, in the frame connection structure of the present invention, the end of the side window lower rail 2 is connected to the column 1 through the middle corner bracket 7, and the side window lower rail 2 is perpendicular to the column 1, and one end of the short waist column 3 passes through the middle corner. The corner code 7 is connected with the middle part of the side window lower rail 2, the other end of the short waist column 3 is connected with the middle part of the side cabin door upper rail 4 through the middle corner code 7, and the short waist column 3 is perpendicular to the side window lower rail 2 And perpendicular to the upper longitudinal beam 4 of the side ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com