Positive-negative integrated conveying system device of multifunctional pump

A conveying system and multi-functional technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problem of low efficiency of conveying compressed air to convey dry ash, and the difficulty of pneumatic ash removal system to meet the requirements of economy, practicality, reliability, energy saving, Problems such as pipe blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

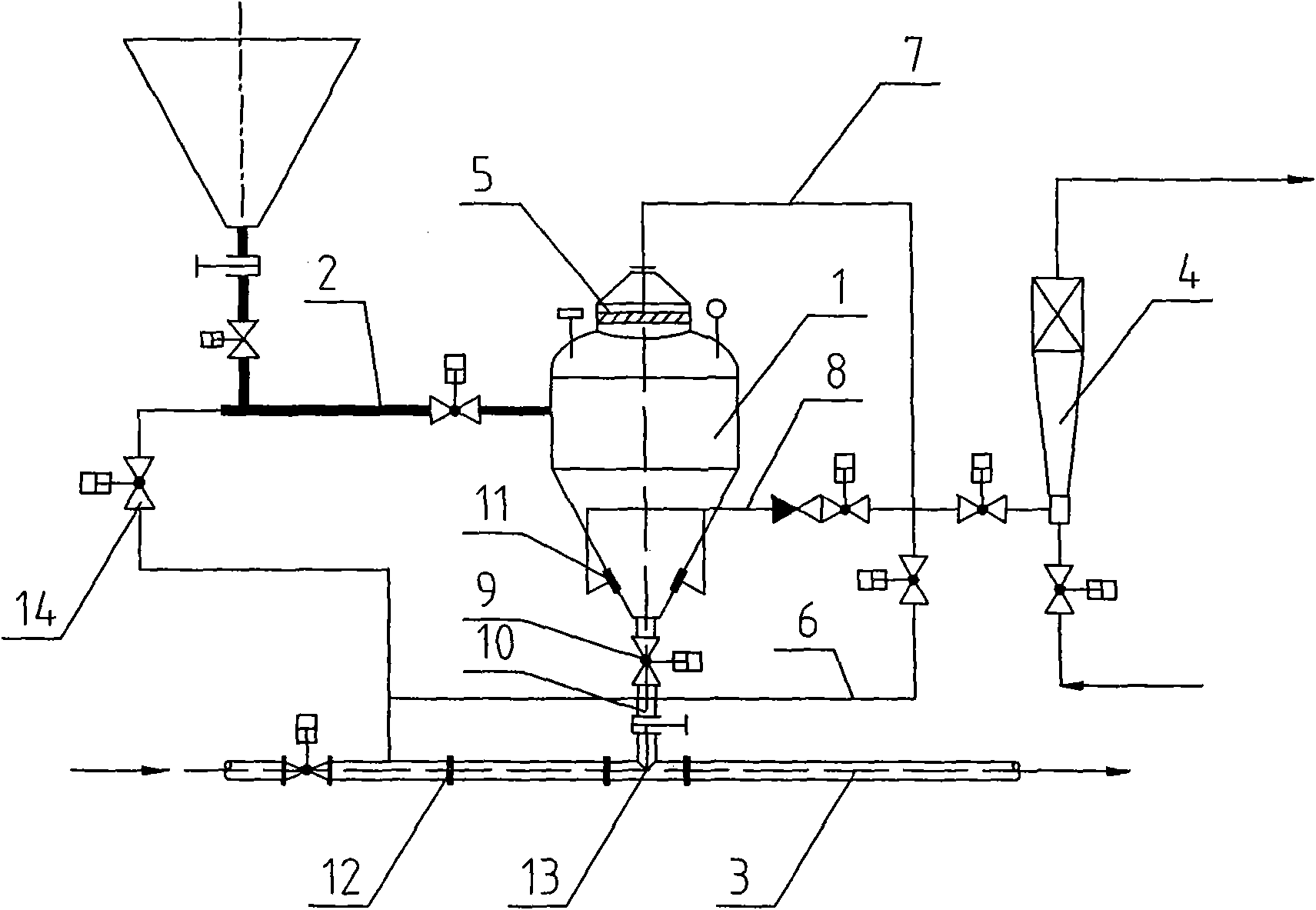

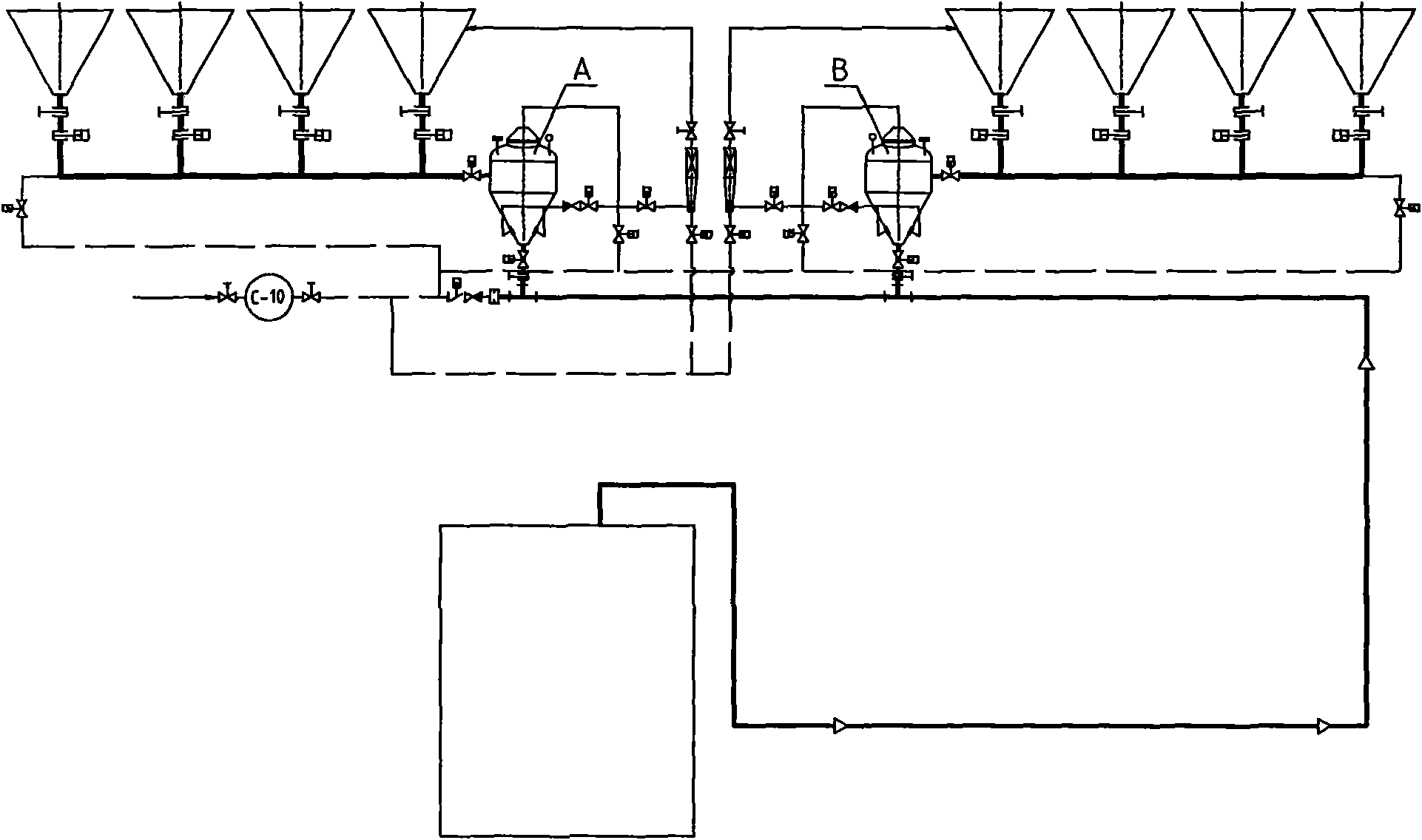

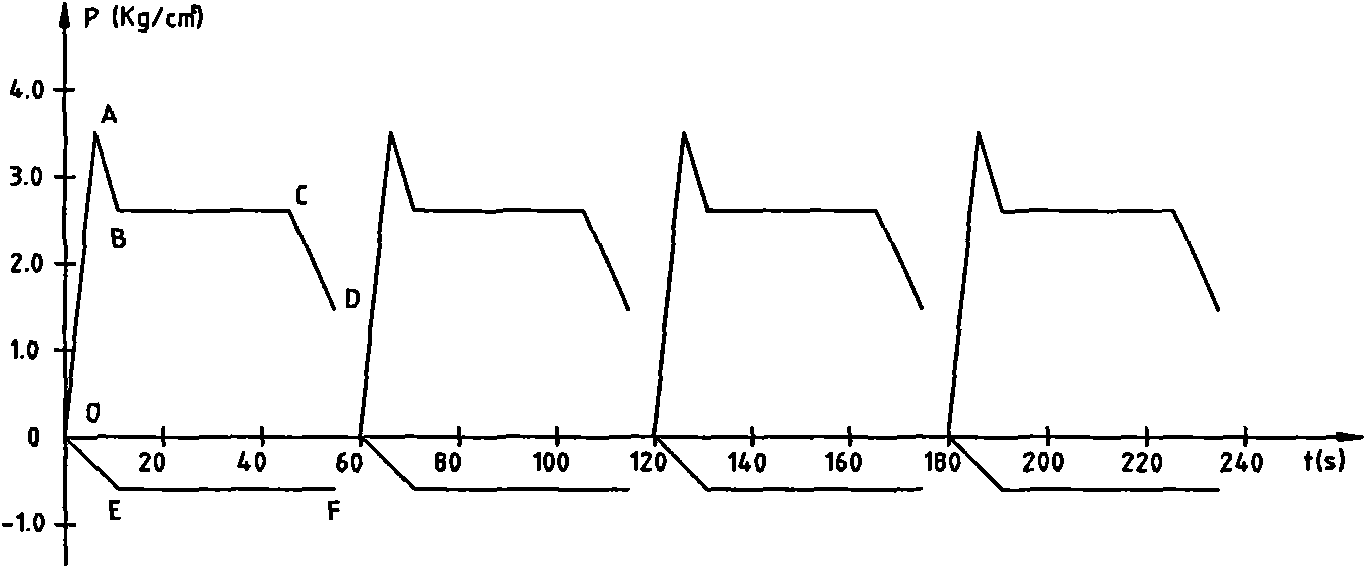

[0027] The structure of the positive and negative integrated multifunctional pump delivery system device of the present invention is as follows: figure 1 As shown, it includes a multifunctional warehouse pump, a multifunctional warehouse pump negative pressure ash loading device, and a multifunctional warehouse pump positive pressure conveying device. Filtration device 5, negative pressure ash conveying pipeline 2, positive pressure air supply device 14, including at least two lower ash hoppers of the boiler flue gas dust collector, connected with multifunctional warehouse pump 1 through negative pressure ash conveying pipeline 2, generating negative pressure device 4 The air ash filtering device 5 on the top of the warehouse pump is connected to the multifunctional warehouse pump 1, and the end of the negative pressure ash conveying pipeline 2 far away from the multifunctional warehouse pump is connected with a positive pressure air supply device 14; the multifunctional wareho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com