Paper suction method of folder for V-shaped box drawing type facial tissues and paper suction device using in same

A folding machine and paper pumping technology, which is applied in the field of paper suction devices, can solve the problems of cost increase, paper consumption, paper towel folding angle, etc., and achieve the effect of reducing equipment operating costs, reducing production costs, and ensuring paper cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

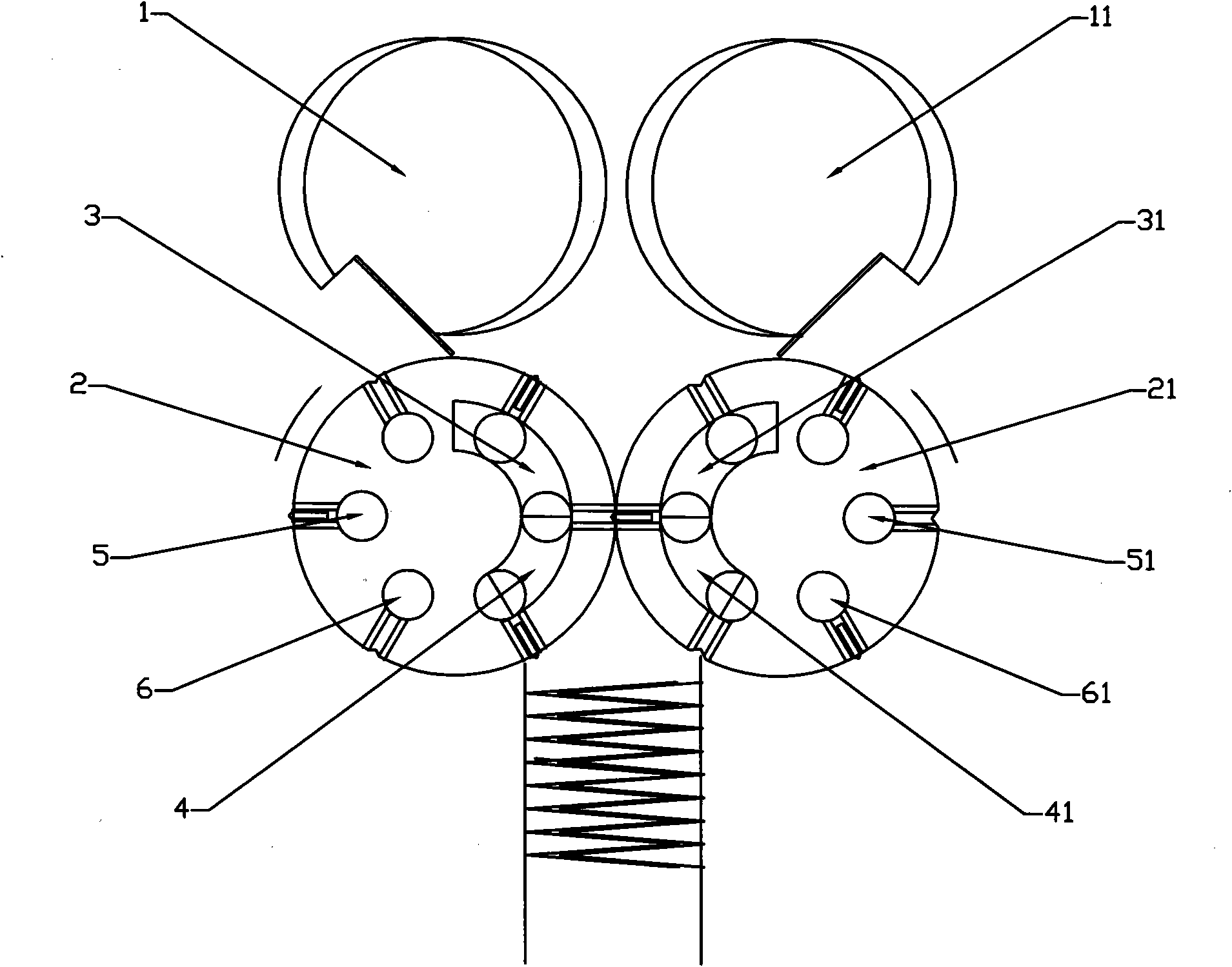

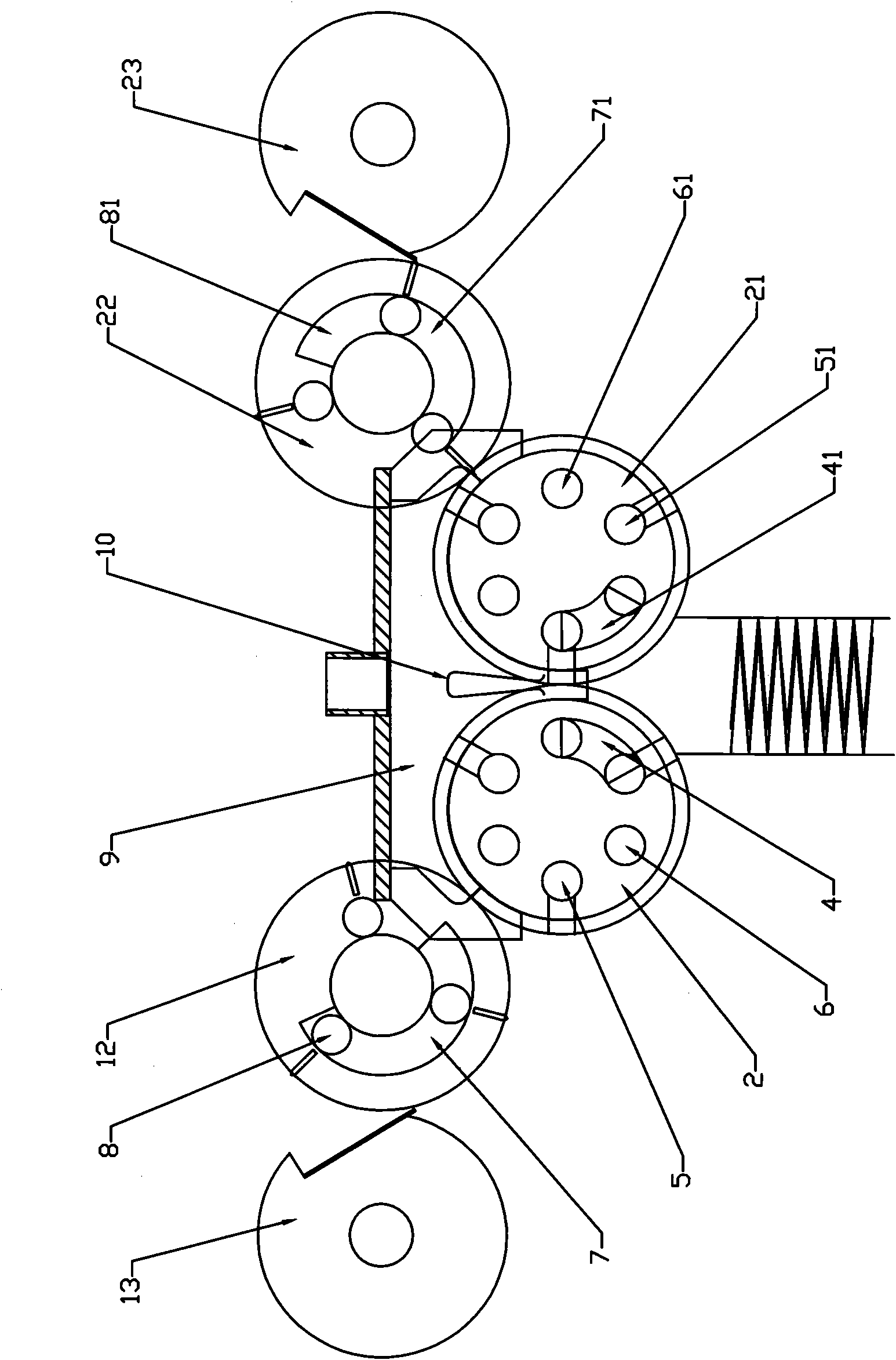

[0043] Such as image 3 , 4 Shown is a paper suction device of a V-shaped box pumping paper towel folding machine, which includes two left folding rollers 2, right folding rollers 21 and two sets of knife shafts that cooperate with the folding rollers on the horizontal plane. The knife shafts include horizontal Arrange and coordinate the fixed knife shaft 13 (23) and the moving knife shaft 12 (22) of rotating paper cutting, this moving knife shaft 12 (22) is positioned at 45 ° of folding paper roller obliquely above and cooperates with folding paper roller 2 (21) and rotates. Folding paper roller 2 (21) is provided with suction passage and the air chamber that communicates with it to form air valve, and this air valve is the air chamber that forms between the valve body and the roller surface or end face of two ends of folding paper roller, and folding paper roller The two ends have the end surfaces at both ends and the roller surfaces at both ends; a paper feeding air chambe...

Embodiment 2

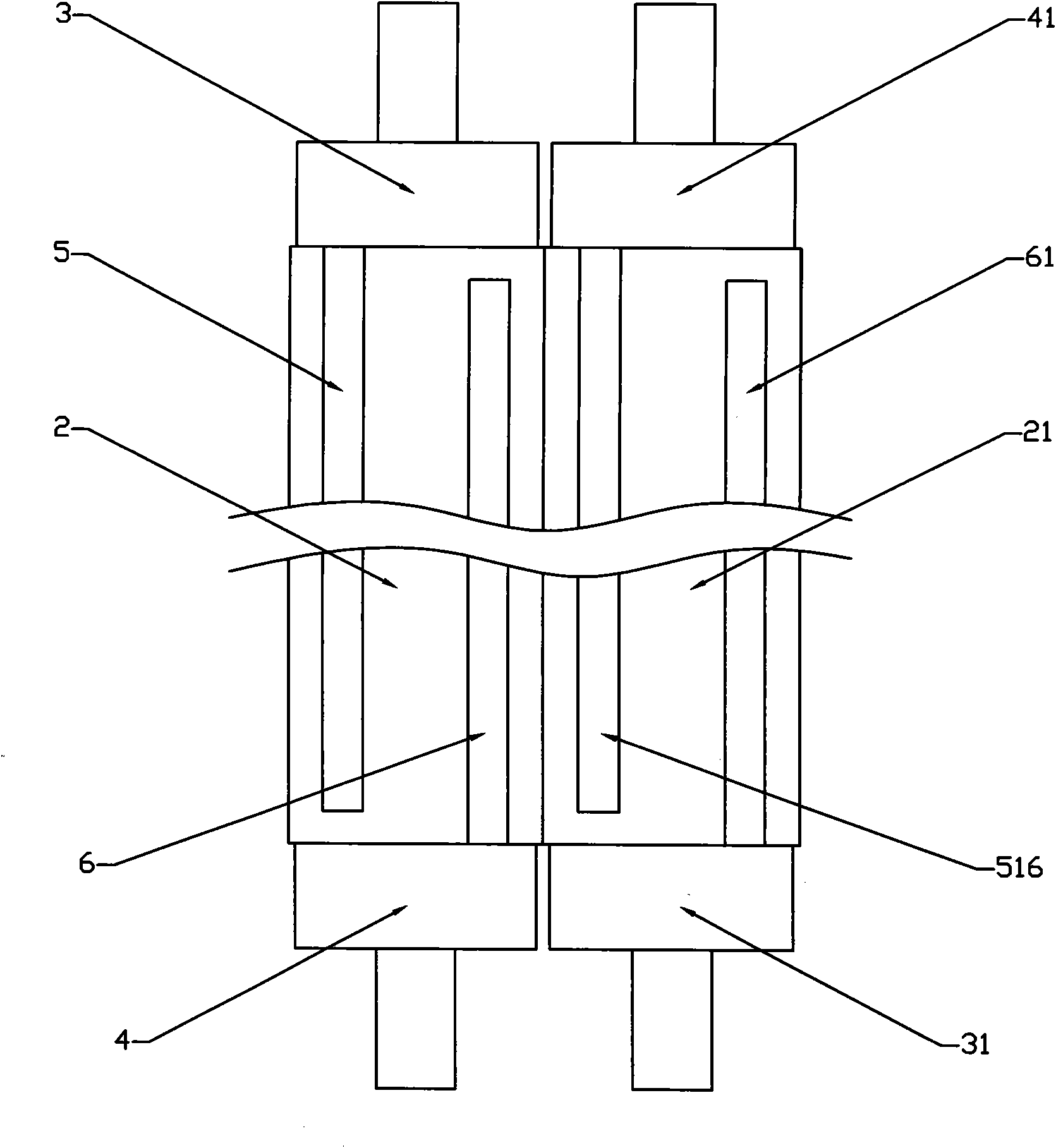

[0051] Compared with Embodiment 1, this embodiment sets the ports of the paper feeding suction channel on the end faces of the two ends of the paper folding roller, cancels the air chamber on the roller surface, and additionally sets the paper feeding air chamber, that is, the air valve; the port of the folding paper suction channel That is, the origami air valve formed by the origami suction hole and the origami air chamber is set on the outer ring of the end face of the origami roller, and the port of the paper feeding suction channel is the paper feeding air valve formed by the paper feeding suction hole and the paper feeding air chamber. The inner rings at both ends of the roller, the paper feeding suction holes and the folding paper suction holes can be arranged along the same circle, or can be arranged along two circles with different radii respectively, and the suction channel is set to penetrate through the inside of the paper folding roller along the axial direction. T...

Embodiment 3

[0053] Compared with Embodiment 1, the difference between this embodiment and the first embodiment is that both the paper feeding suction hole and the folding paper suction hole are arranged on the roller surfaces at both ends of the paper folding roller, and the paper feeding suction hole and the folding paper suction hole are respectively provided with corresponding There is an air chamber on the roll surface, which is the air valve. At the same time, the installation structure of the air valve is slightly different. The knife shaft includes the upper left knife shaft and the upper right knife shaft that are arranged horizontally and cooperate with the paper cutting. The upper left knife shaft and the upper right knife shaft are located on the Above the origami roller and cooperate with the origami roller to rotate. The paper folding roller is provided with a cutting knife corresponding to the upper knife shaft along its circumference. Its paper-absorbing method and working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com