Novel complex active brilliant blue dye

A technology of reactive brilliant blue and blue dyes, which is applied in the field of manufacturing new composite reactive brilliant blue and brilliant blue dyes, can solve the problems of inability to emit redder and brighter colors, appearing color spots, easy to dye flowers, etc. good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

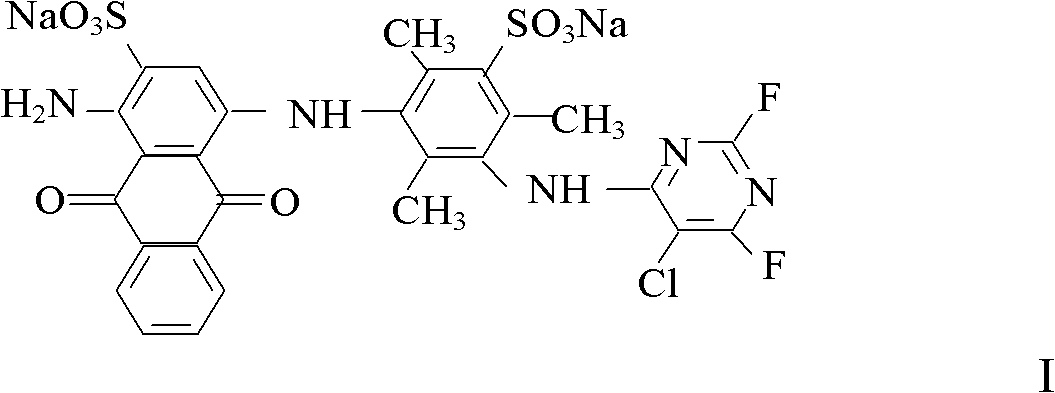

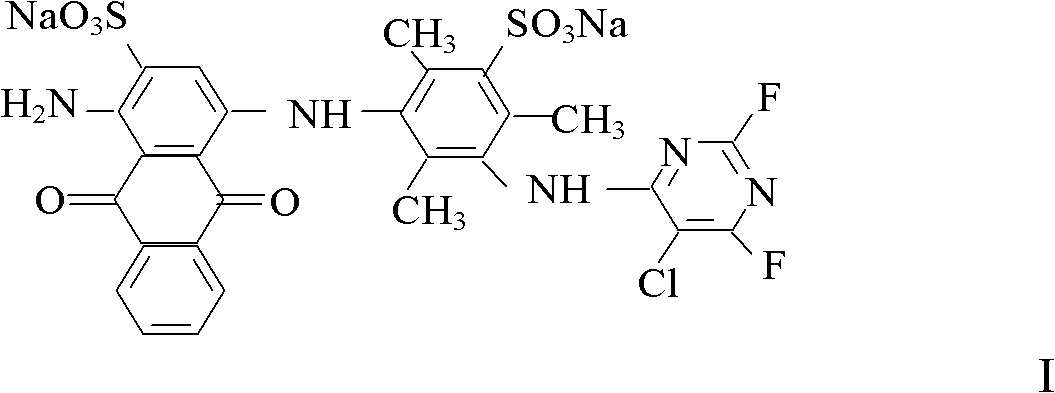

[0019] A new type of composite reactive brilliant blue dye, 1 part (mole parts) of 1-amino-4-(5'-amino-2', 4', 6'-trimethylphenylamino) anthraquinone-2,3 '-Disulfonic acid is dissolved into a 25% aqueous solution at PH5.5~7, 40°C, cooled to 0~5°C, and 1.02~1.05 parts of 2,4,6-trifluoro-5-chloropyrimidine is added in 1~2 hours, Simultaneously keep pH6.5~7.5 with 20% soda ash solution, react for 3~4 hours, add hydrochloric acid to adjust pH5.8~6.2, salt out with sodium chloride, press filter, flash dry, obtain active brilliant blue former powder ( MS: [M+H] + =723.00). The dye is red and brilliant blue, low directness, RF value 0.98, solubility (50°C) 100g / l, 1 / 1 dyeing depth. Fastness indicators: light fastness level 6, washing fastness level 4, ironing fastness Grade 4, dry friction grade 4~5, wet rubbing fastness grade 4, chlorine immersion fastness grade 3~4.

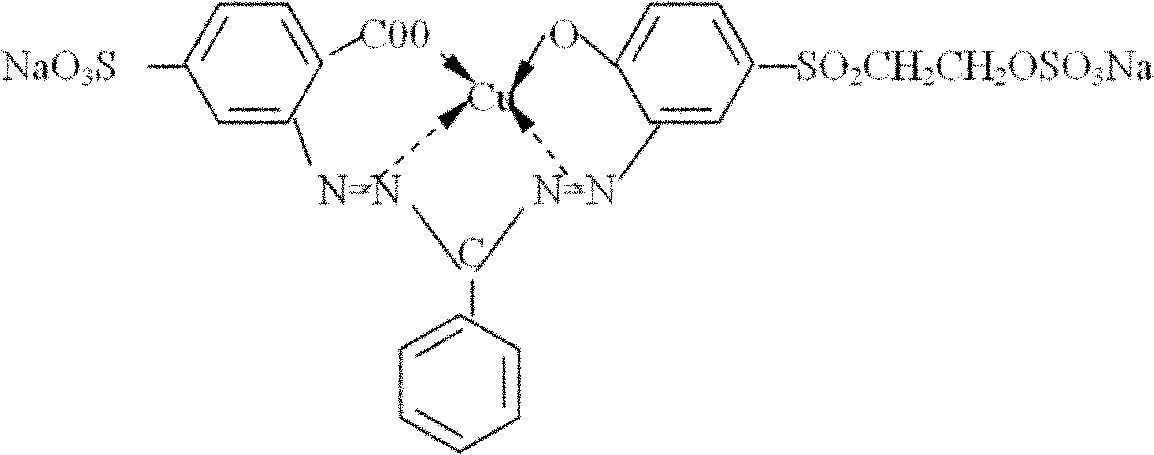

[0020] The former powder of reactive brilliant blue and C.I. reactive blue 220 are prepared by the above method,...

Embodiment 2

[0022] Reactive brilliant blue raw powder and C.I. reactive blue 220 raw powder were prepared by the above method, Yuanming powder was mixed according to the mass-weight ratio of 80:10:10, and 2% of dustproof agent FC-3 was added to standardize to obtain commercial products.

Embodiment 3

[0024] Reactive Brilliant Blue former powder and C.I. Reactive Blue 220 former powder are obtained by the above method, sodium lignosulfonate is mixed according to the mass-weight ratio of 75:10:15, and 2% of dustproof agent FC-3 is added, standardized to obtain commodity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com