Heat-resistant all aluminum alloy conductor and manufacturing method thereof

The technology of an aluminum alloy wire and its manufacturing method, which is applied in the field of overhead power transmission wires, can solve the problems of high cost, etc., and achieve the effects of reduced overall cost, simple wire connection, and superior heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

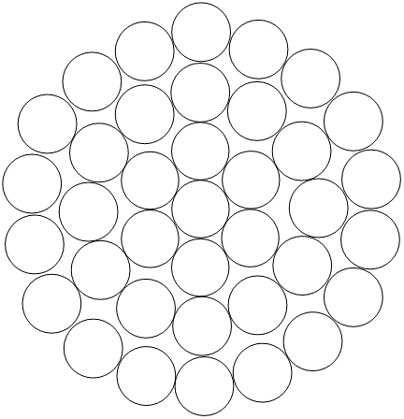

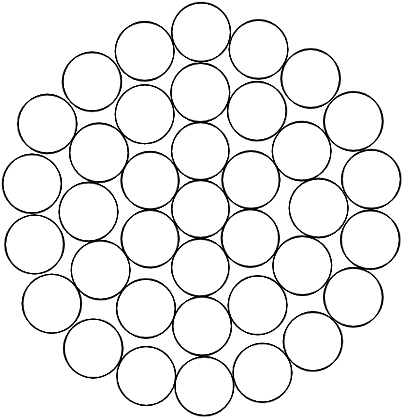

Image

Examples

Embodiment 1

[0017] Embodiment 1: Manufacture heat-resistant aluminum alloy wire according to the following specific steps:

[0018] 1. Magnesium Mg: 0.40% by weight, silicon Si: 0.05%, zirconium Zr: 0.2%, iron Fe: 0.15%, boron B: 0.001%, rare earth: 0.05%, copper Cu: <0.01%, titanium Ti , vanadium V, manganese Mn, chromium Cr < 0.01%, the rest is aluminum Al and unavoidable impurities, which are added to the shaft furnace;

[0019] 2. It takes 2 hours to raise the temperature to 730°C for refining, and stir within the range of not more than 10 cycles per minute, and the time is not less than 10 minutes;

[0020] 3. After refining and slag removal, control the temperature of the aluminum alloy liquid at 730°C and let it stand for 1 hour. Use a photoelectric direct reading spectrometer for sampling analysis and adjustment before the furnace to control the content of elements;

[0021] 4. The aluminum alloy liquid enters the aluminum rod continuous casting and rolling unit through the alumi...

Embodiment 2

[0025] Embodiment 2: Manufacture heat-resistant aluminum alloy wire according to the following specific steps:

[0026] 1. Magnesium Mg: 0.60% by weight, silicon Si: 0.2%, zirconium Zr: 0.35%, iron Fe: 0.575%, boron B: 0.1%, rare earth: 0.175%, copper Cu: <0.01%, titanium Ti , vanadium V, manganese Mn, chromium Cr < 0.01%, the rest is aluminum Al and unavoidable impurities, which are added to the shaft furnace;

[0027] 2. It takes 3.5 hours to raise the temperature to 755°C for refining, and stir within the range of not more than 10 cycles per minute, and the time is not less than 10 minutes;

[0028] 3. After refining and slag removal, control the temperature of the aluminum alloy liquid at 755°C and let it stand for 1 hour, and use a photoelectric direct reading spectrometer for sampling analysis and adjustment before the furnace to control the content of elements;

[0029] 4. The aluminum alloy liquid enters the aluminum rod continuous casting and rolling unit through the...

Embodiment 3

[0033] Embodiment 3: manufacture heat-resistant aluminum alloy wire according to the following specific steps:

[0034] 1. Magnesium Mg: 0.80% by weight, silicon Si: 0.35%, zirconium Zr: 0.5%, iron Fe: 1.0%, boron B: 0.2%, rare earth: 0.3%, copper Cu: <0.01%, titanium Ti , vanadium V, manganese Mn, chromium Cr < 0.01%, the rest is aluminum Al and unavoidable impurities, which are added to the shaft furnace;

[0035] 2. It takes 5 hours to raise the temperature to 780°C for refining, and stir within the range of not more than 10 cycles per minute, and the time is not less than 10 minutes;

[0036] 3. After refining and slag removal, control the temperature of the aluminum alloy liquid at 750°C and let it stand for 1 hour. Use a photoelectric direct-reading spectrometer for sampling analysis and adjustment before the furnace to control the content of elements;

[0037] 4. The aluminum alloy liquid enters the aluminum rod continuous casting and rolling unit through the aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com