Method and device for detecting strain/stress of pile body by prestress pipe file field static load test

A prestressed pipe pile and static load test technology, which is applied in the test of foundation structure, sheet pile wall, building, etc., can solve the problem of rigidity changing horizontal load bearing performance, short distance between strain gauges, and failure to reflect the level of pipe piles well Bearing performance and other issues, to achieve the effect of strong operability and simple embedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the examples and drawings, but the implementation of the present invention is not limited thereto.

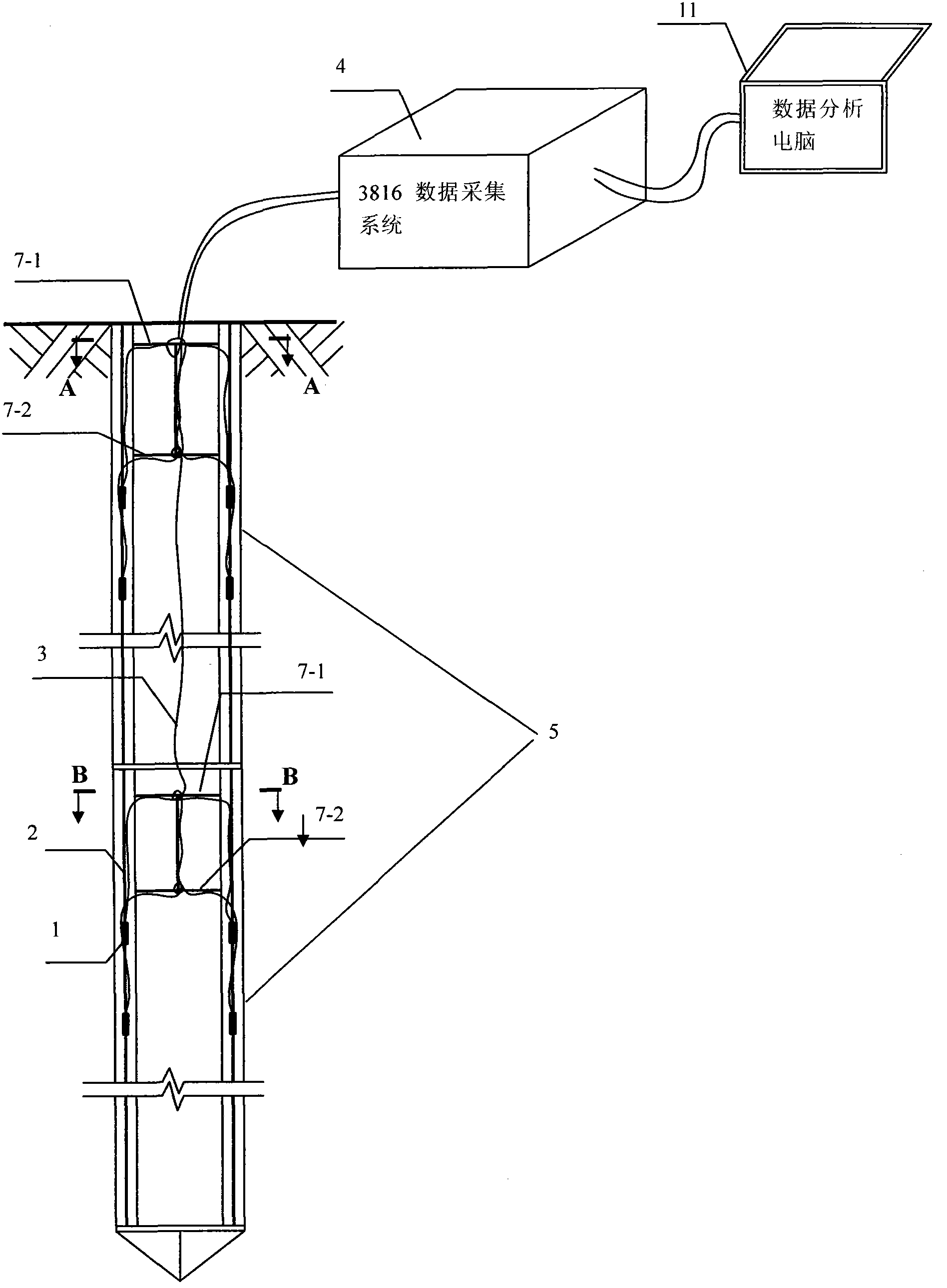

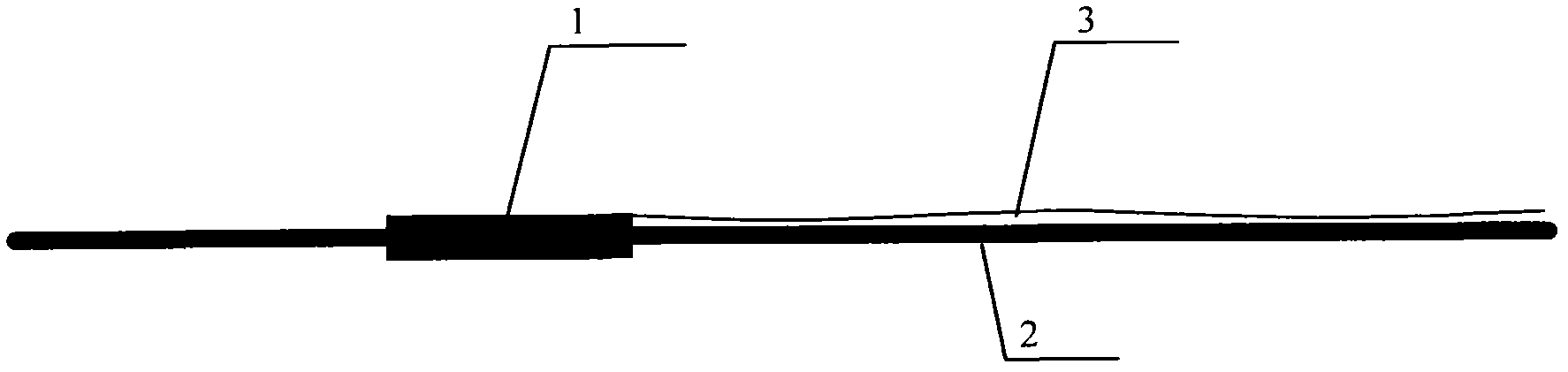

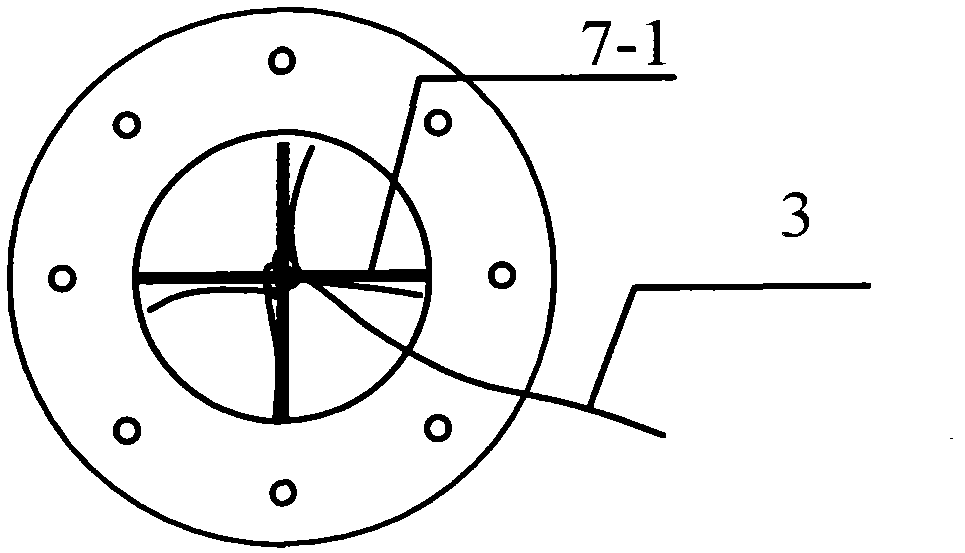

[0041] Such as figure 1 As shown, the pile body strain / stress detection device for the on-site static load test of the prestressed pipe pile includes an additional steel bar 2 with a strain gauge 1, a wire 3, a pressure sensor, a displacement sensor, a data acquisition system 4, and a computer 11. Such as figure 1 , 2 , 6, 7, 8, with strain gauge 1 (strain gauge 1 type includes resistance strain gauge, vibrating wire strain gauge or embedded strain gauge) additional steel 2 pre-embedded in each section of the prestressed pipe In the reinforcement cage 6 of the pile 5, the wire 3 connected to the strain gauge 1 is guided along the additional reinforcement 2 to the proximal end of the reinforcement cage 6 and fixed, that is, all the wires 3 of each section of the prestressed pipe pile 5 pass th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com