Complex annular shed bending and twisting component and manufacturing method thereof

A manufacturing method and technology of annular cover, which can be applied to arched beams, building components, roofs, etc., can solve problems such as complex structural stress, difficulty in plate processing and component manufacturing and processing, and component plate thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

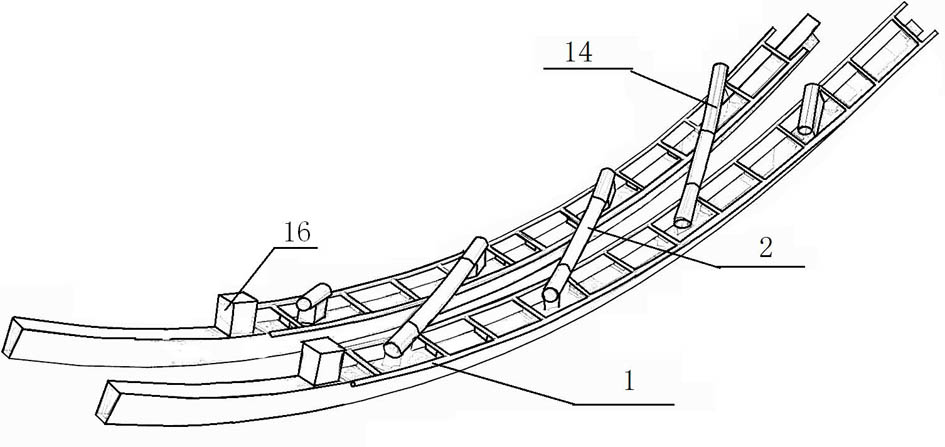

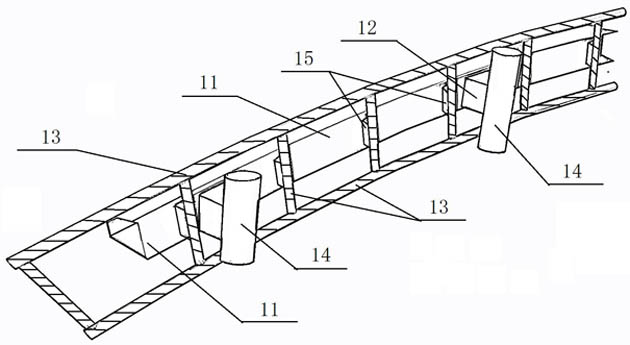

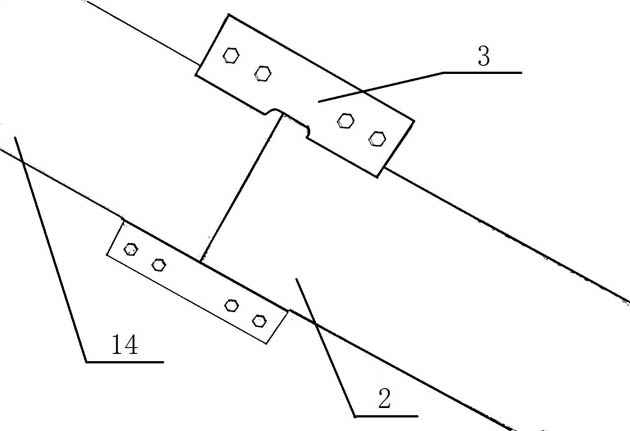

[0117] Such as Figure 1-Figure 3 The complex bending and torsion member of an annular canopy shown is composed of the canopy bending and torsion member 1 and the secondary rib member 2. Two sets of roof bending and torsion members are placed side by side, and the two ends of the secondary rib member are respectively connected to a group of roof bending and torsion members. Rods connect two groups of roof bending and torsion rods into a whole.

[0118]The canopy bending and twisting member 1 is composed of a main rib body 11, a secondary rib corbel connector 12, a curtain wall rod connector 15, a curtain wall rod 13, a secondary rib corbel 14 and a box-shaped corbel 16; the main rib body 11 is a curved Twisted box-shaped, with a trapezoidal cross-section; the secondary rib corbel connector 12 and the curtain wall rod connector 15 are box-shaped; the curtain wall rod 13 is a ladder-shaped tube structure composed of twisted round tubes; the secondary rib corbel 14 is A twisted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com