Soil source heat pump system with heat pipe heat exchanger well

A technology of soil source heat pump and heat pump system, applied in the field of soil source heat pump system, can solve the problem of water source heat pump recharge rate of less than 50%, etc., and achieve the effects of reducing extraction, small wellhead area and large heat storage volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

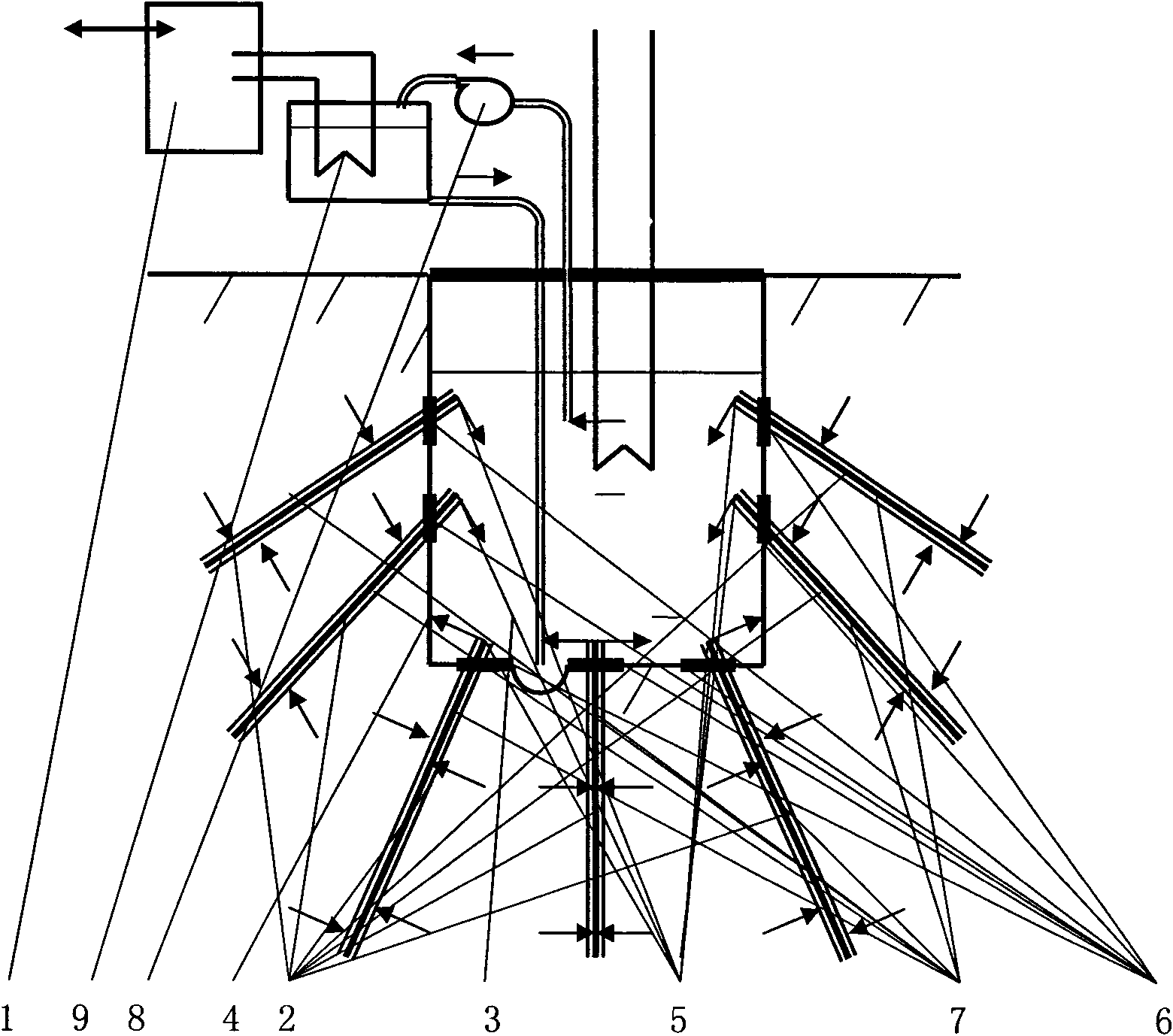

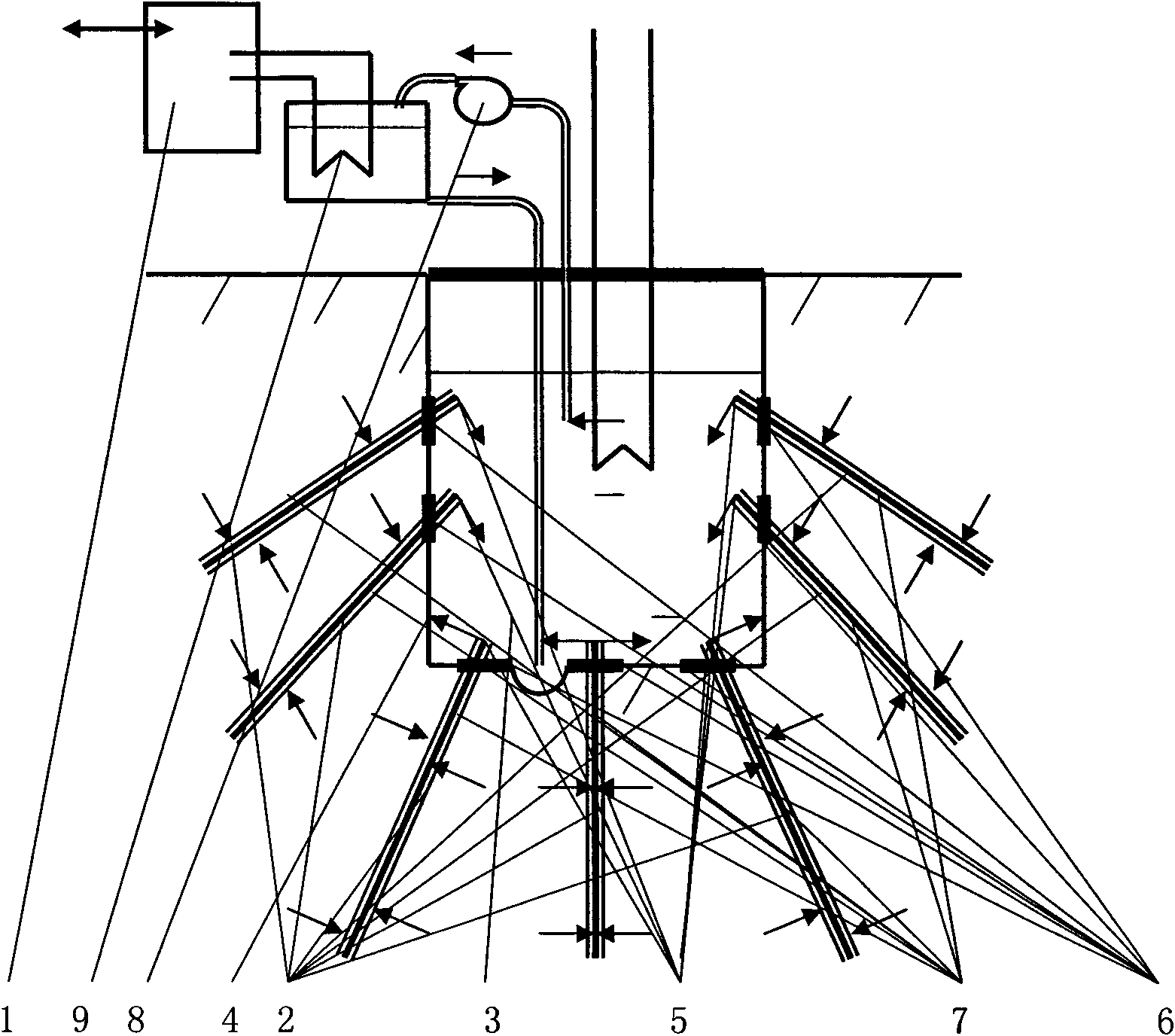

[0009] figure 1 In an embodiment, a heat pump unit 1 and a well-shaped artificial water body heat exchange well 3 with heat pipes 2 are used to form a soil source heat pump system with heat pipe heat exchange wells. Most of the heat pipes 2 arranged radially extend into the soil outside the wall 4 of the heat exchange well 3 , and the cold ends 5 of the heat pipes 2 extend into the water of the heat exchange well 3 . A rubber sealing ring 6 is lined between the heat pipe 2 passing through the well wall 4 and the well wall 4. The surface of the heat exchange well 3 and the hot end 7 of the heat pipe 2 are used as the heat exchange interface between the heat pump system and the soil, and the heat energy is conducted to the well water. The well water is pumped by the circulating pump 8 to the evaporator 9 of the heat pump unit 1 to exchange heat with the evaporator 9 and then return to the bottom of the heat exchange well 3 . The heat pump unit 1 performs work to increase the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com