Permanent magnet synchronous motor with wide field-weakening and speed regulation range

A permanent magnet synchronous motor and field-weakening speed regulation technology, which is applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, magnetic circuit rotating parts, etc., can solve the problems of permanent magnet demagnetization, etc. Achieve the effects of increasing the direct axis inductance, good application prospects, and solving the narrow range of field-weakening speed regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

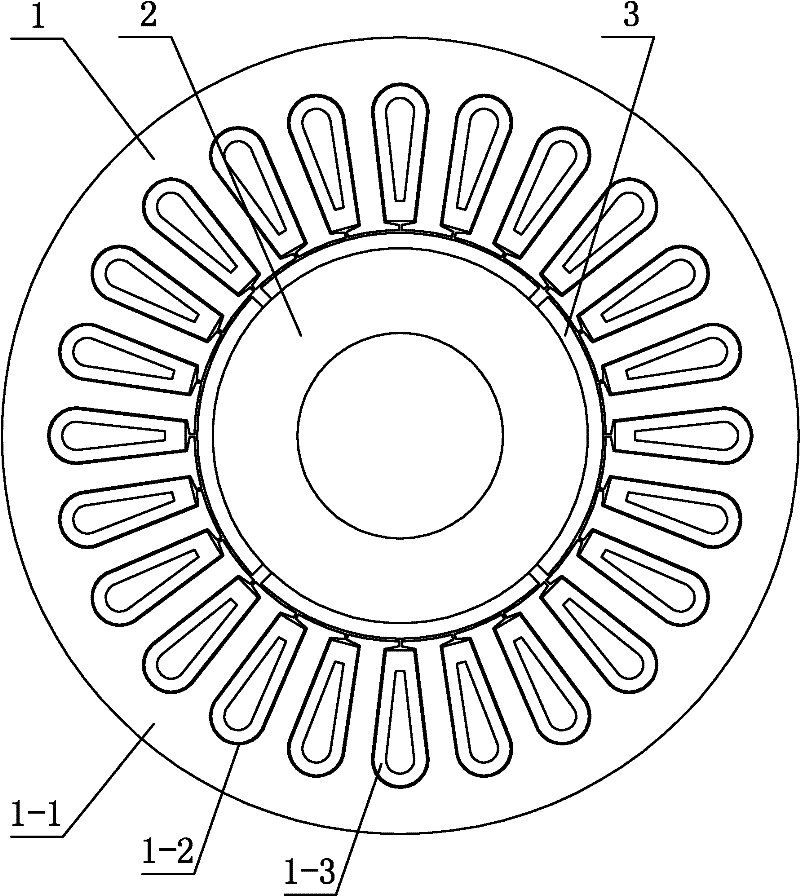

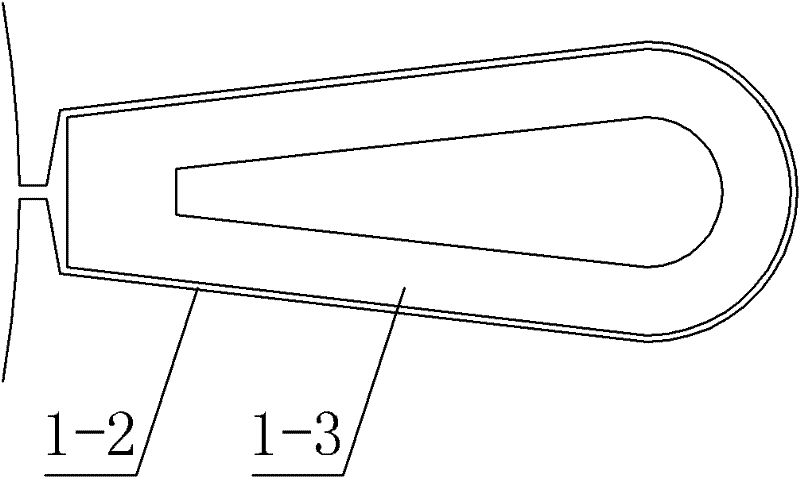

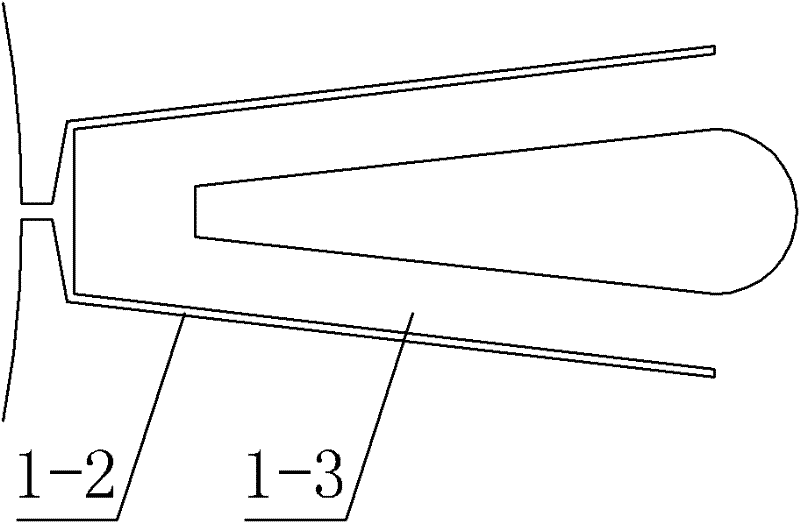

[0027] Specific implementation mode one: the following combination Figure 1 to Figure 5 Describe this embodiment, this embodiment includes a stator 1 and a rotor 2, an air gap is formed between the inner circular surface of the stator 1 and the outer circular surface of the rotor 2, and it is characterized in that: the stator 1 is composed of a stator core 1-1, a non- Composed of a magnetic isolation layer 1-2 and a magnetic sleeve 1-3,

[0028] A plurality of stator slots are evenly distributed along the circumferential direction on the inner side wall of the stator core 1-1, and the stator slots axially penetrate the stator core 1-1, and a magnetic permeable sleeve 1-3 is arranged in each stator slot, and the magnetic permeable sleeve 1 The shape of -3 matches the shape of the stator slot, the thickness of the magnetic sleeve 1-3 is uniform, and a non-magnetic isolation layer 1-2 is provided between the stator slot and the magnetic sleeve 1-3;

[0029] The rotor 2 includes...

specific Embodiment approach 2

[0032] Specific implementation mode two: the following combination figure 1 Describe this embodiment. This embodiment is a further description of Embodiment 1. The permanent magnet 3 is a 2P block, P is the number of pole pairs of the motor, and the 2P permanent magnets 3 are evenly distributed along the circumferential direction and surface-attached on the On the cylindrical outer wall of the rotor 2. Other components and connections are the same as those in Embodiment 1.

[0033] In this embodiment, the rotor 2 adopts a surface-mounted permanent magnet 3 structure.

specific Embodiment approach 3

[0034] Specific implementation mode three: the following combination Figure 5 Describe this embodiment. This embodiment is a further description of Embodiment 1. The permanent magnets 3 are 2P blocks, P is the number of pole pairs of the motor, and the 2P permanent magnets 3 are evenly distributed in the rotor 2 along the circumferential direction. , and form a regular polygon in the circumferential direction of the rotor 2, the number of sides of the regular polygon is 2P, and the center line of the regular polygon coincides with the center line of the rotor 2, and the permanent magnet 3 axially penetrates the rotor 2, each A magnetic isolation hole 2-1 is provided on both sides of the permanent magnet 3 in the circumferential direction, and the magnetic isolation hole 2-1 is filled with a non-magnetic material. Other components and connections are the same as those in Embodiment 1.

[0035] The difference between this embodiment and the second embodiment is that the rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com