Syringe with integrally formed piercing member and luer slip

A technology for syringes and components, applied in the field of syringes, can solve the problems of time-consuming, pollution, etc., and achieve the effects of being easy to use, reducing the risk of pollution, and reducing the risk of incorrect injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

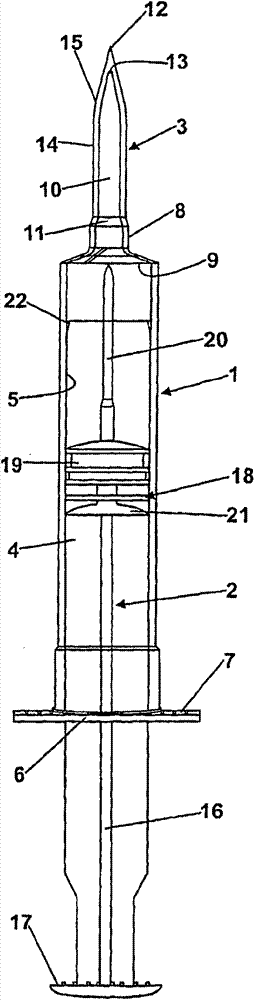

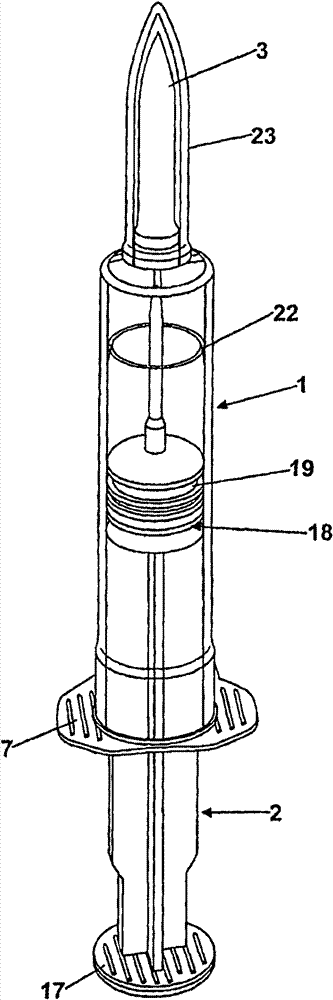

[0014] The syringe shown in the figures comprises a barrel 1 in which a piston 2 works and with which a piercing element 3 is integrally formed.

[0015] The cartridge 1 is substantially cylindrical, having a main cylinder 4 with a cylindrical inner surface 5 in which the piston 2 slides sealingly. The proximal end 6 of the barrel 1 is open and provided with a gripping flange 7 . The distal end of the barrel 1 has a reduced diameter portion 8 with a step between the main cylinder 4 and the reduced diameter portion 8 forming an inner abutment shoulder 9 . In a standard syringe, the reduced diameter portion 8 will have an open end to define the liquid outlet, onto which a metal needle will be mounted in any suitable manner. Examples of mounting are eg luer slips (which hold the needle frictionally fitted), luer locks onto which the needle is threadedly mounted, or permanent mounting secured by glue or the like. In the syringe of the invention, the reduced diameter portion 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com