Method of concentrating a bayer process liquor

A technology of Bayer process and liquid, applied in the field of concentrated Bayer process liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

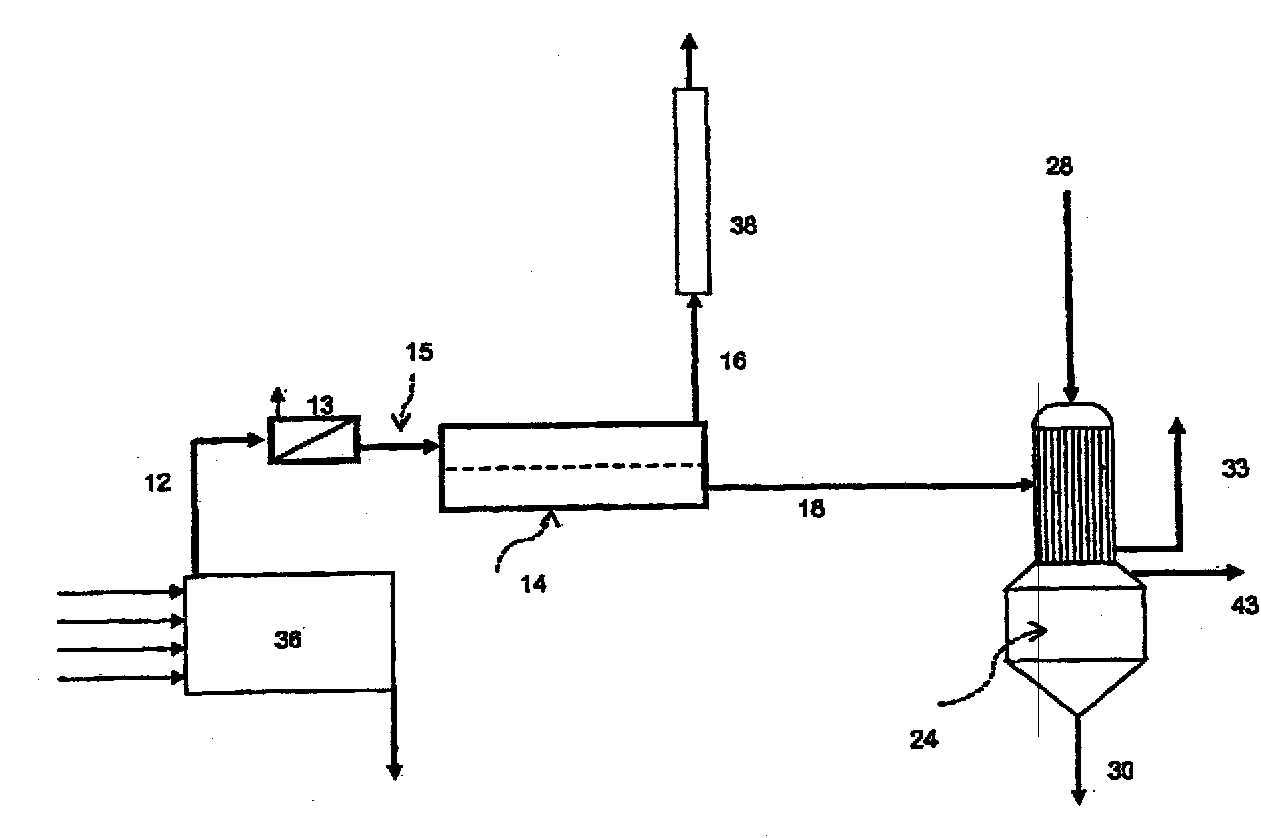

[0097] Example 1: Triple Effect Evaporation of Single Membrane Fraction and Spent Liquid

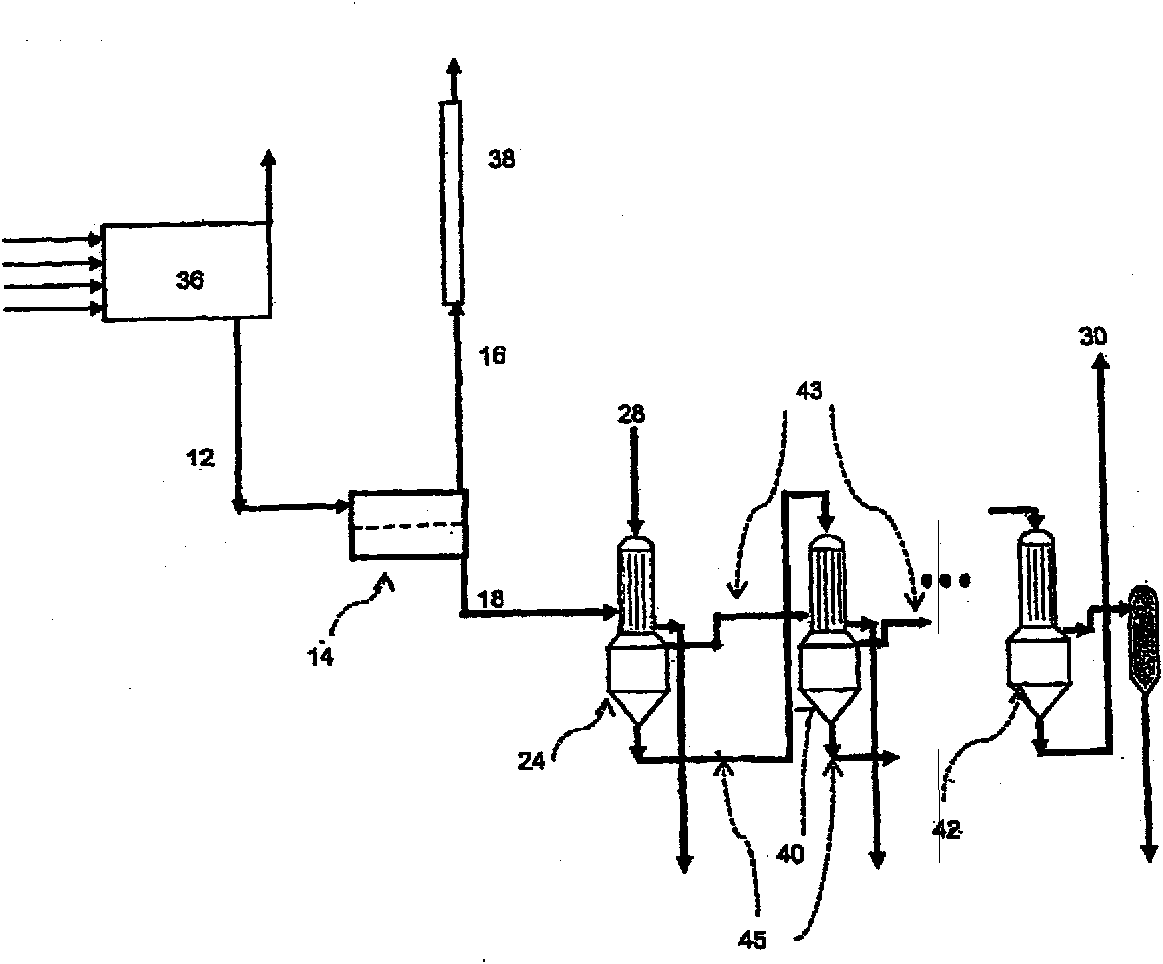

[0098] An example of the second embodiment is shown in figure 2 Among them, single-film stage and three-effect evaporation are included. In this example, calciner flue gas 12 (165°C, 41% w / w steam, 202 t / hr) from calciner 36 was passed through the membrane at a feed pressure of 2.55 bar and separated into dehydrated Stream 16 (171.5 t / hr) and steam rich stream 18 (30.5 t / hr). The dehydrated stream 16 contains goes to an expander or turbine (not shown) to recover some energy and then passes through a chimney 38; its dew point is 78°C. The 30.5 t / hr water vapor rich stream 18 is superheated to a temperature of 150°C by each available waste heat source (not shown) and sent to the first of 3 falling film evaporators 24, 40, 42 in series. The shell side of the heat exchanger section of a film evaporator. The evaporated water vapor stream 43 is compressed before being sent to the heat exc...

Embodiment 2

[0100] Example 2: Single membrane fraction, wet scrubbing with calciner flue gas, and triple effect evaporation of waste liquor

[0101] Another example of the second embodiment is shown in image 3 middle. It is basically similar to the situation described in Example 1, with the difference that the calciner flue gas 12 is cleaned by wet scrubbing 13 with water 10 before the compression system 50 (165°C, 41% w / w water vapor , 202t / hr), the compression system 50 is connected to the expander 52 for energy recovery. Wet scrubbing achieves a number of advantages including dedusting, further humidification of the membrane feed and cooling to feed to the compressor train. Stream 15 leaving wet scrubber 13 has a temperature of 85°C and a moisture content of 43.8 wt%. This stream is compressed to 2.55 bar using a compressor or booster 50 . Before feeding the membrane feed stream 17 into the membrane unit 14, the temperature of the membrane feed stream 17 is lowered by exchanging h...

Embodiment 3

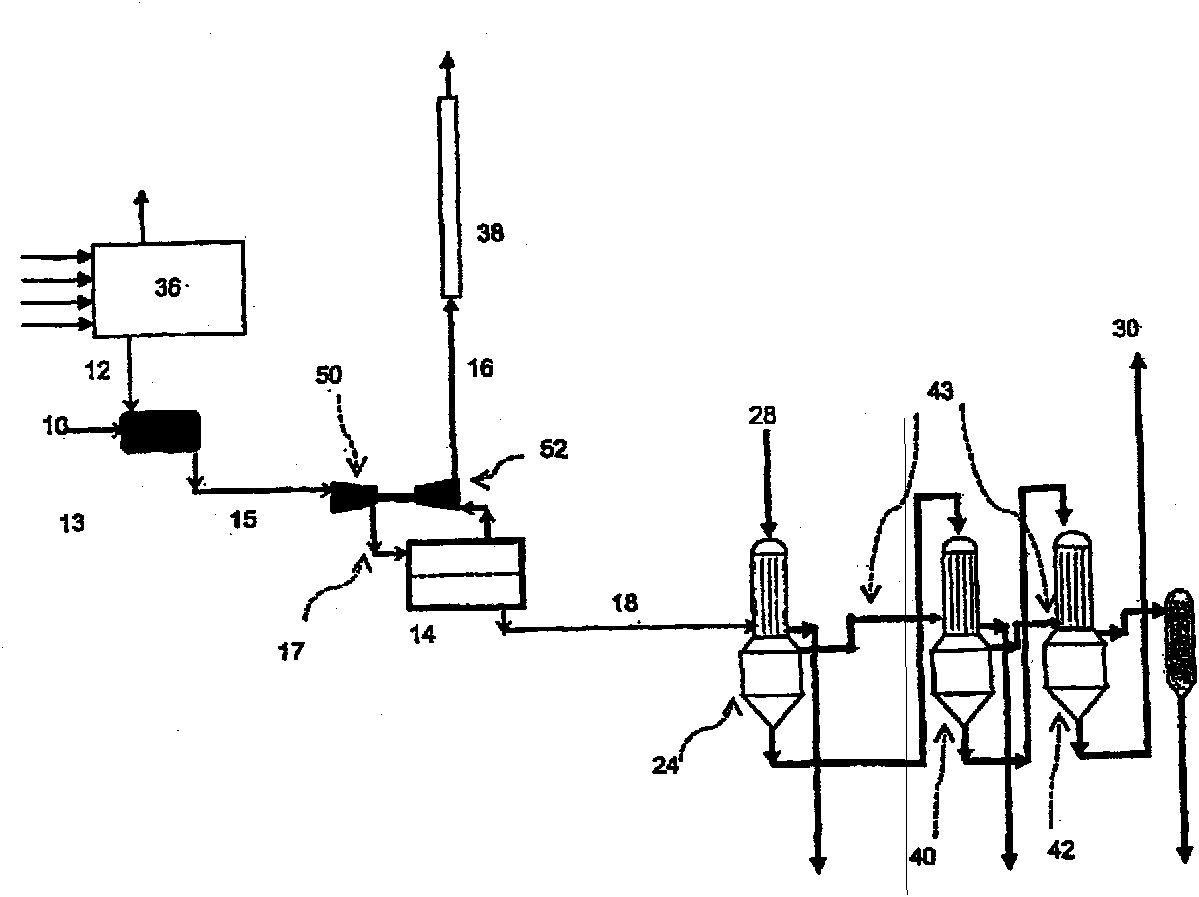

[0106] Example 3: Two membrane fractions with wet scrubbing and triple effect evaporation

[0107] exist Figure 4In the illustrated example of embodiment, the calciner flue gas 12 (165°C, 41% w / w steam, 202 t / hr) is cleaned by wet scrubbing 13 with water 10 and passed through a compressor or booster 50 compression to 2.55 bar. The temperature of the membrane feed stream 17 was lowered to 180°C by exchanging heat with the water vapor rich stream 18 to raise its temperature to 161°C prior to feeding the membrane feed stream 17 into the membrane unit 14. The flow rate of membrane feed stream 17 is 211.7 t / h.

[0108] The steam rich stream 18 from the first membrane section 14 conveys 40.3 t / h of vapor (vapoursteam) into a header arrangement (not shown) which also receives 38.8 t / h of steam in the water vapor-enriched stream 19 from the second membrane section 34.

[0109] 171.4 t / h of dewatered stream 21 from the first membrane section was passed through water quench 55 whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com