Patents

Literature

40results about How to "Improve driving accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

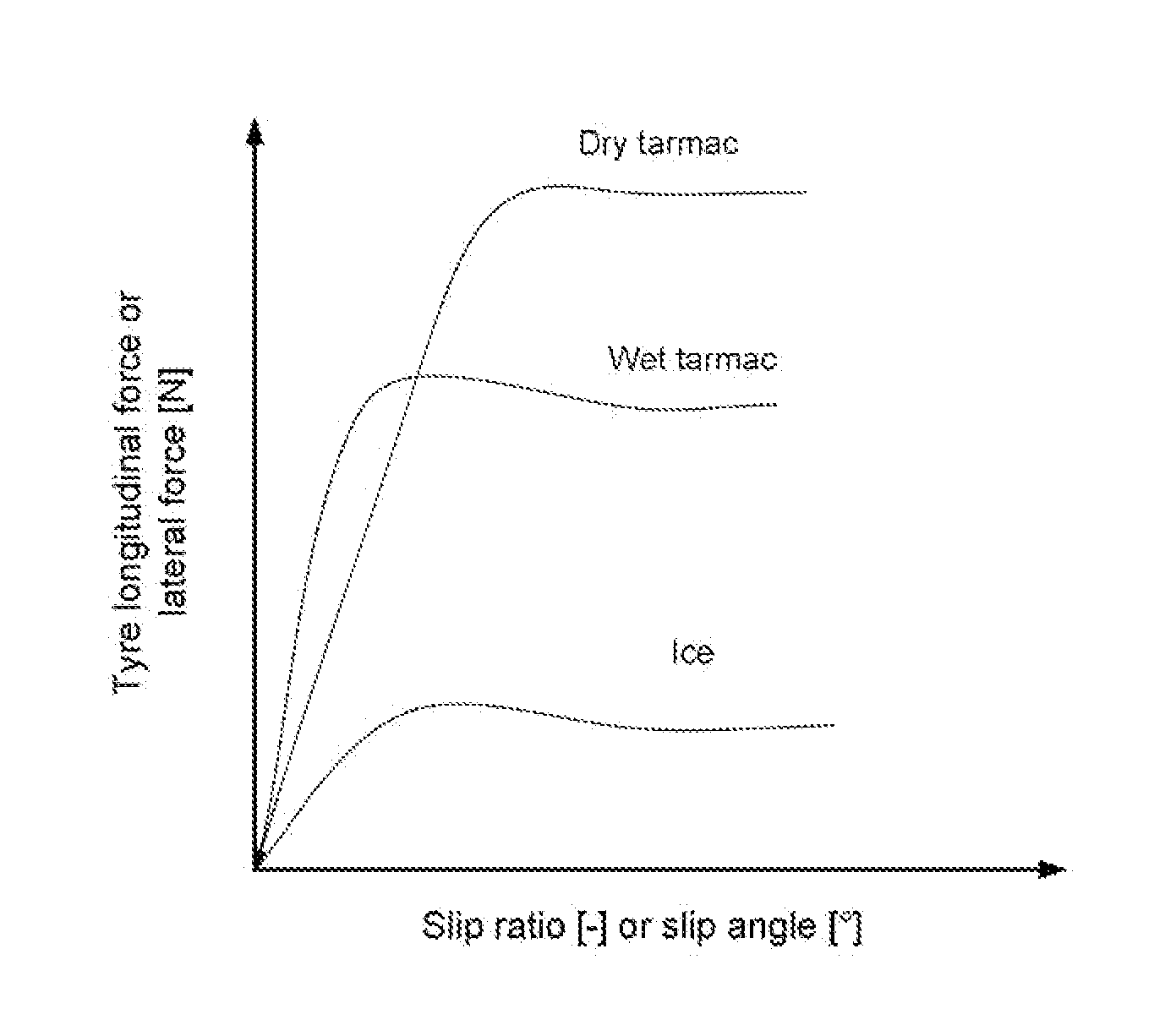

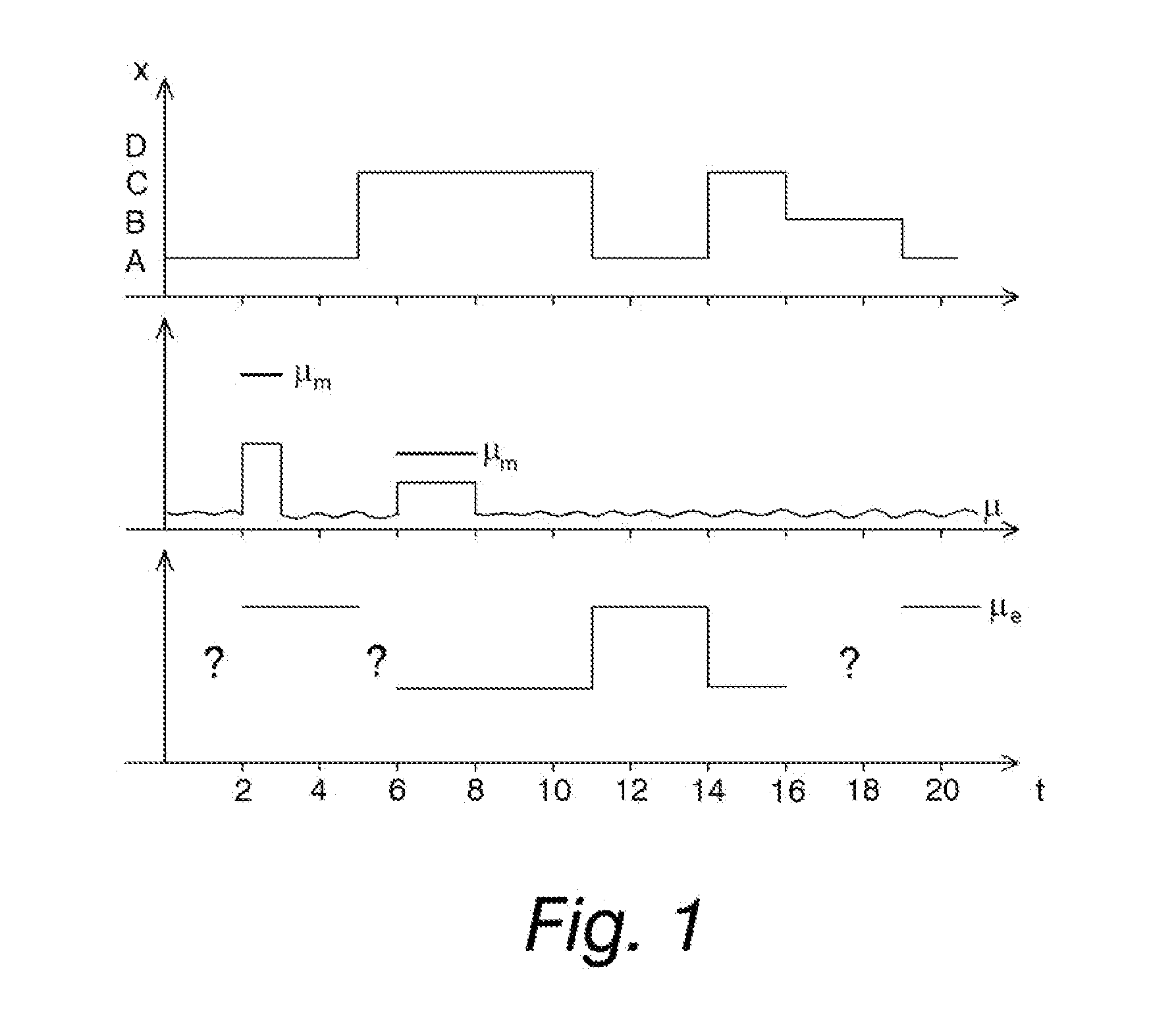

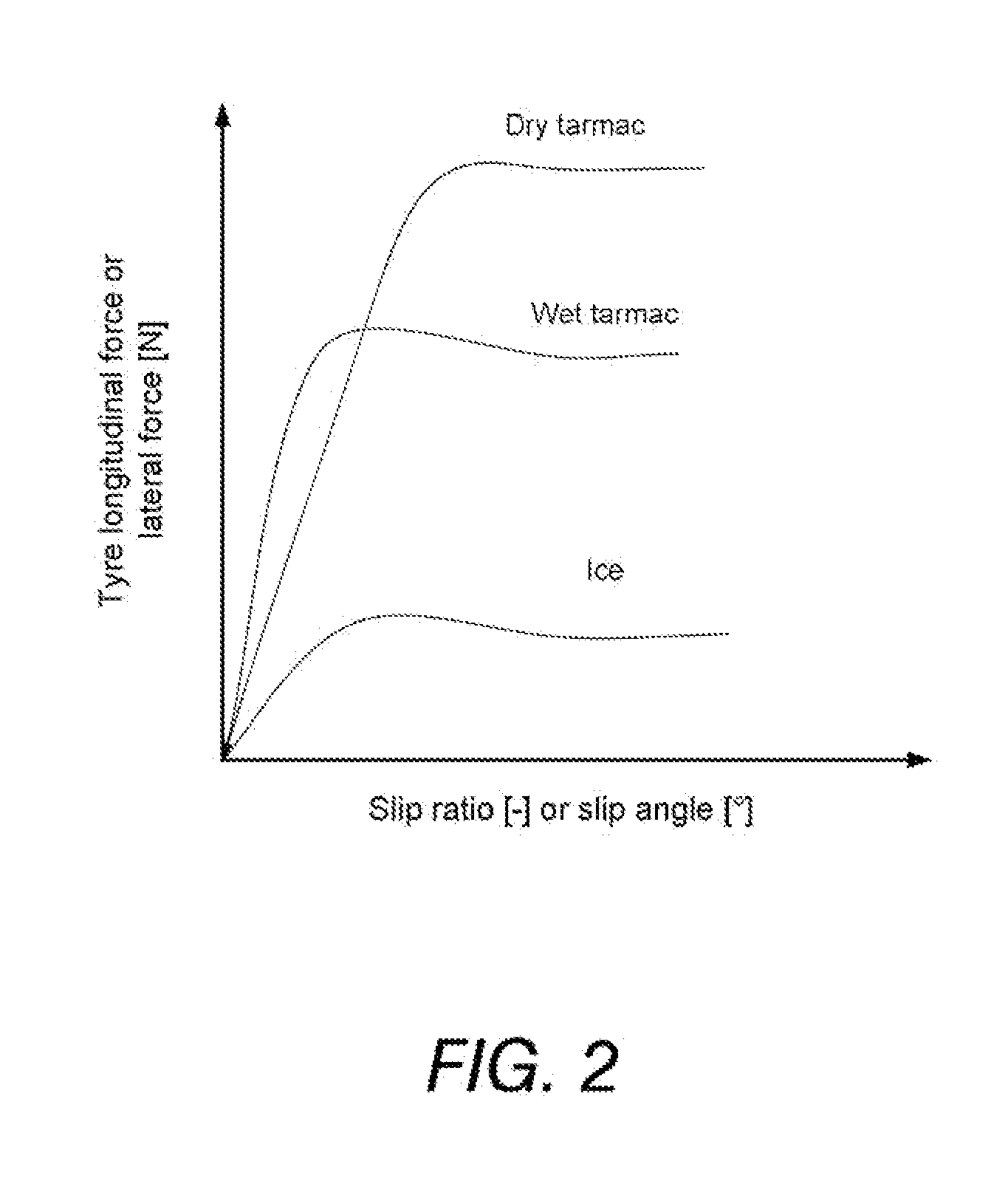

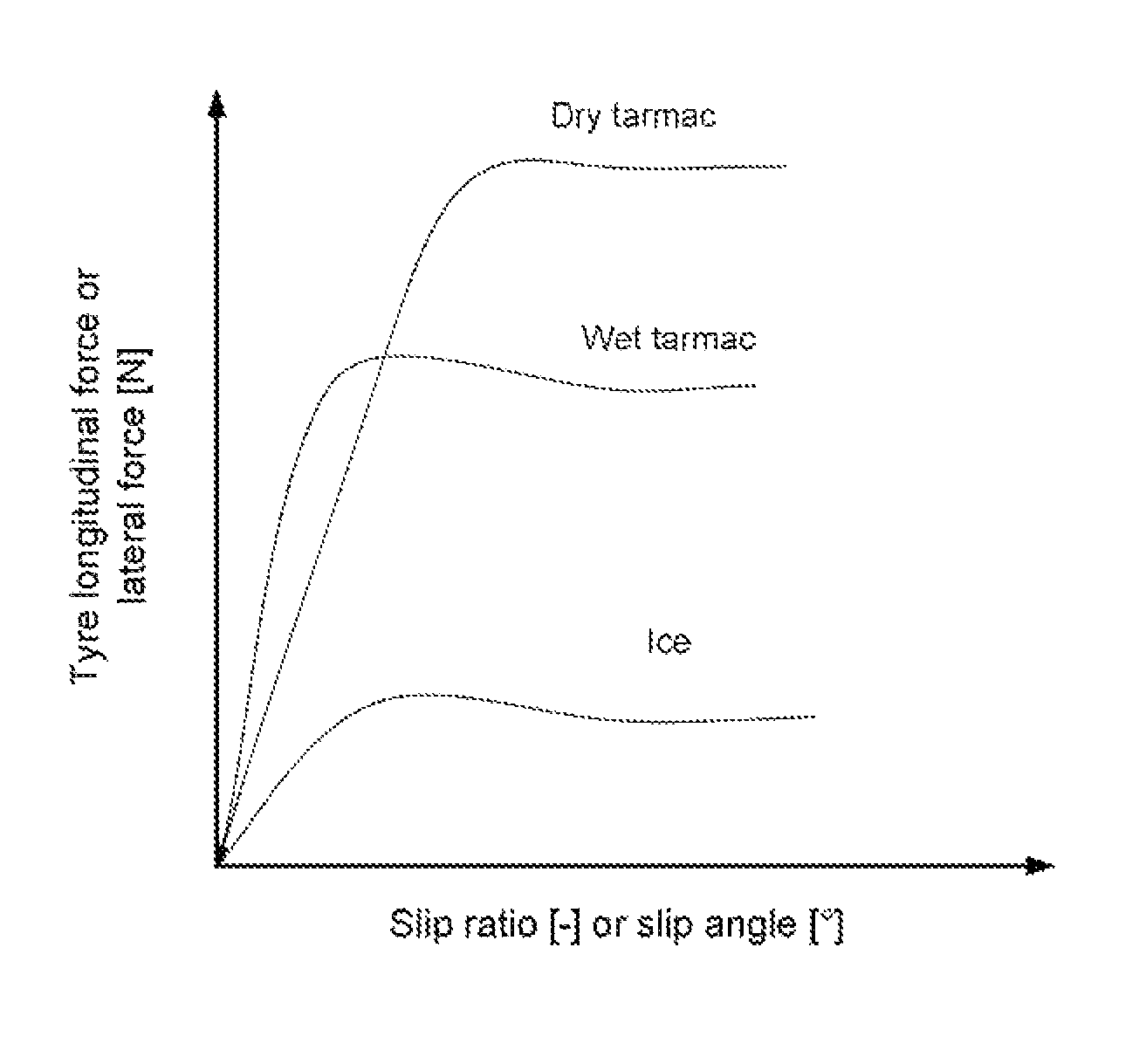

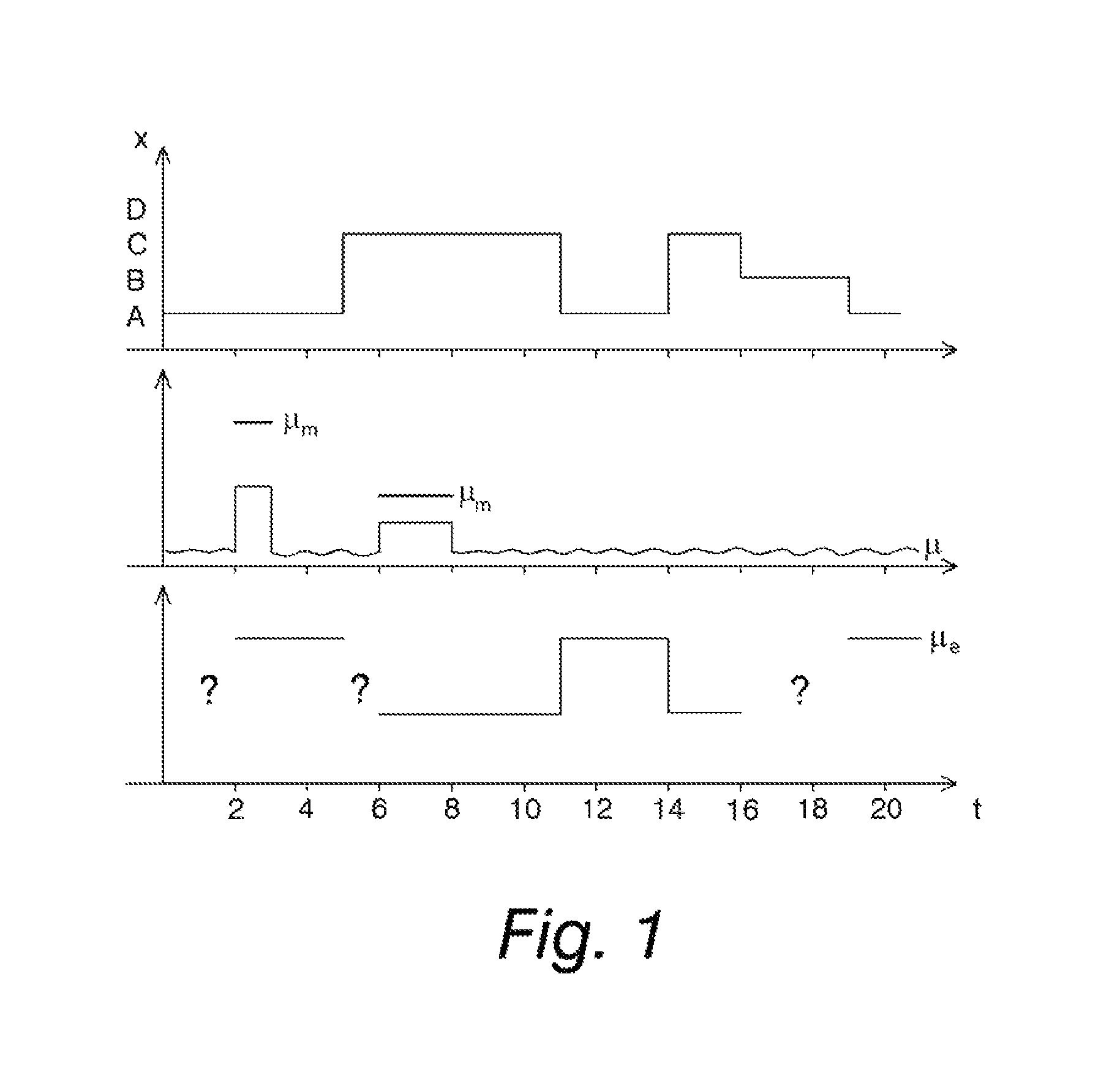

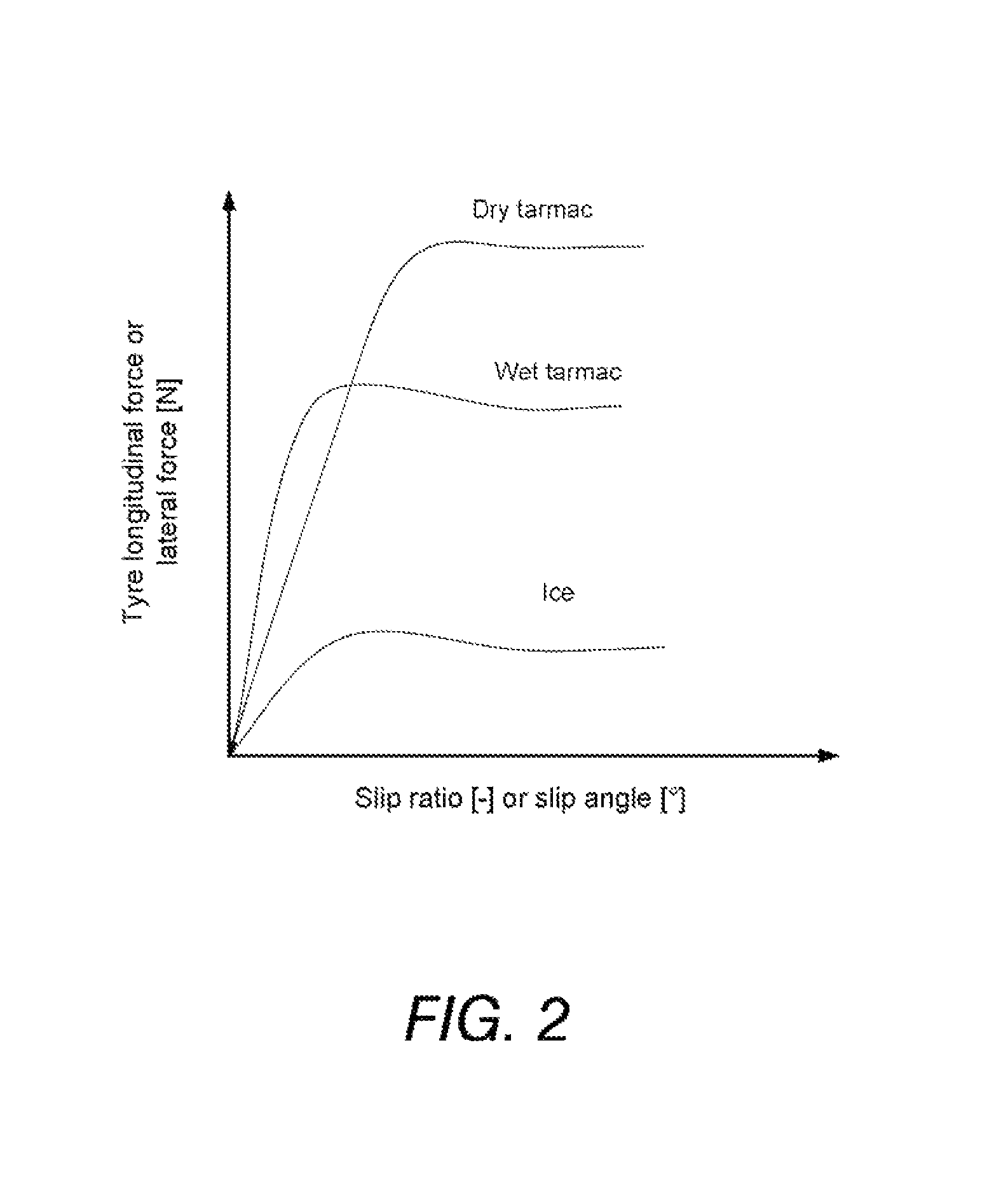

Friction estimation method

ActiveUS20110264300A1Improve reliabilityInaccurate estimationDigital data processing detailsUsing mechanical meansAutomotive engineeringEngineering

A method and apparatus for the estimation of maximum friction between a vehicular tire and a road surface via driving dynamics measurements and at least one sensor measuring the road surface, comprisingmeasuring road surface properties via a sensor;measuring the state of motion of a vehicle and a tire and concluding therefrom a momentary maximum friction coefficient when the tire is subjected to a sufficient friction force;storing a maximum friction estimate concluded from the above-mentioned measurements, along with measuring results regarding road surface properties measured at the moment of measurement;when the tire is not subjected to a friction force sufficient for measuring maximum friction, using, as a maximum friction estimate, the previously measured maximum friction estimate, such that an applied selection criterion for the maximum friction estimate is the newness as up-to-date as possible of the measuring result and a consistency of the road surface measuring result.

Owner:AALTO UNIVERSITY FOUDATION SR

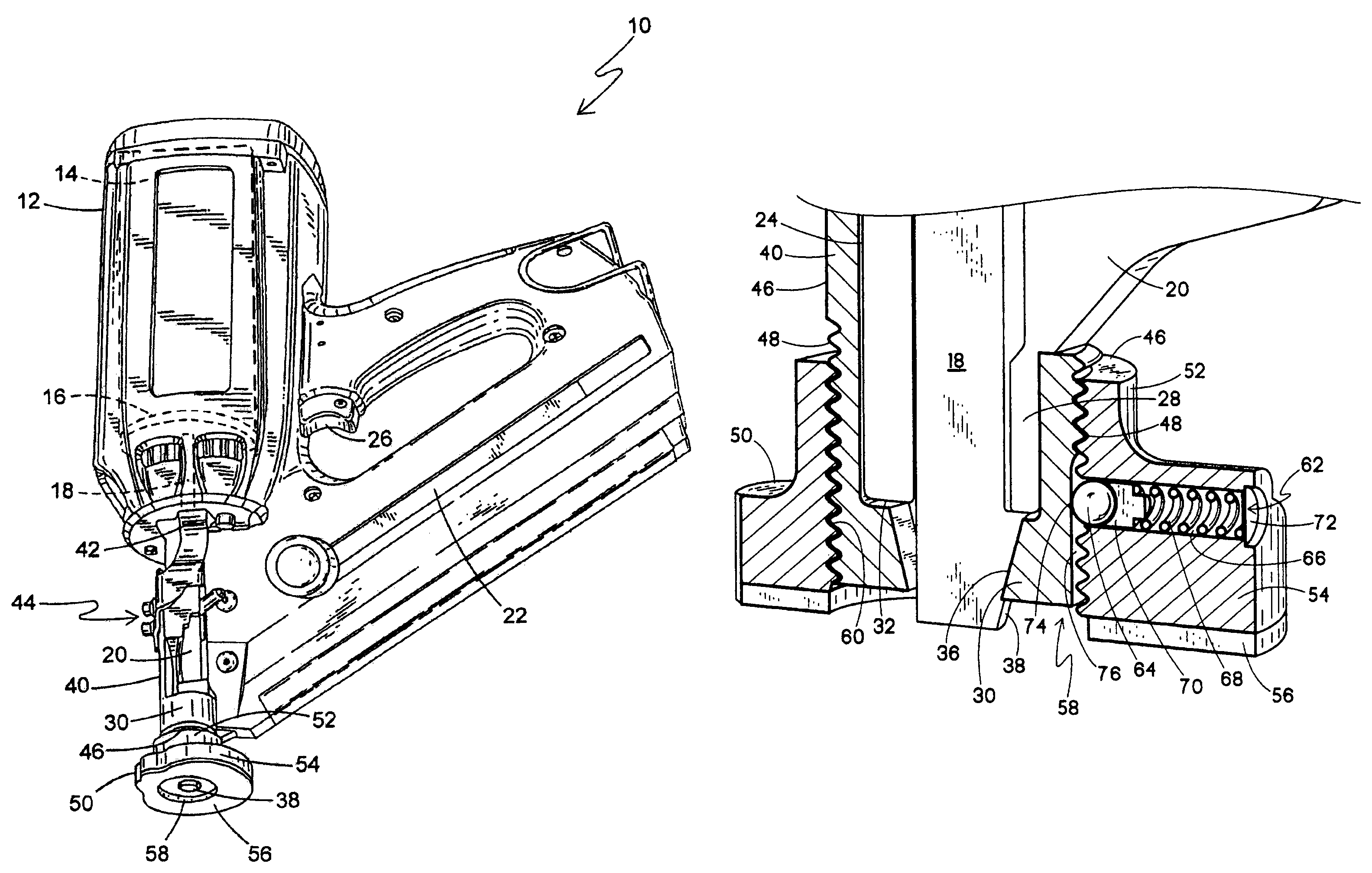

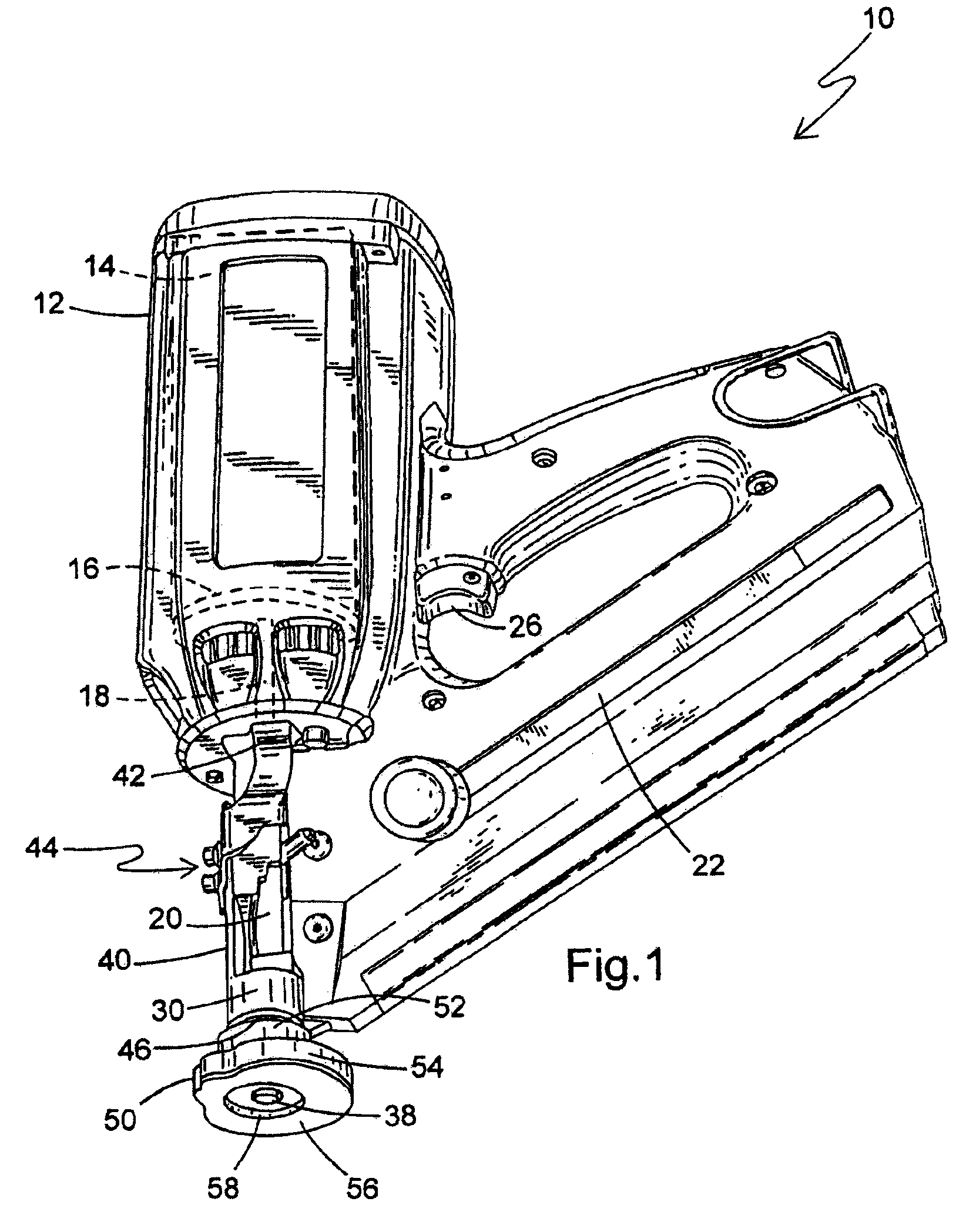

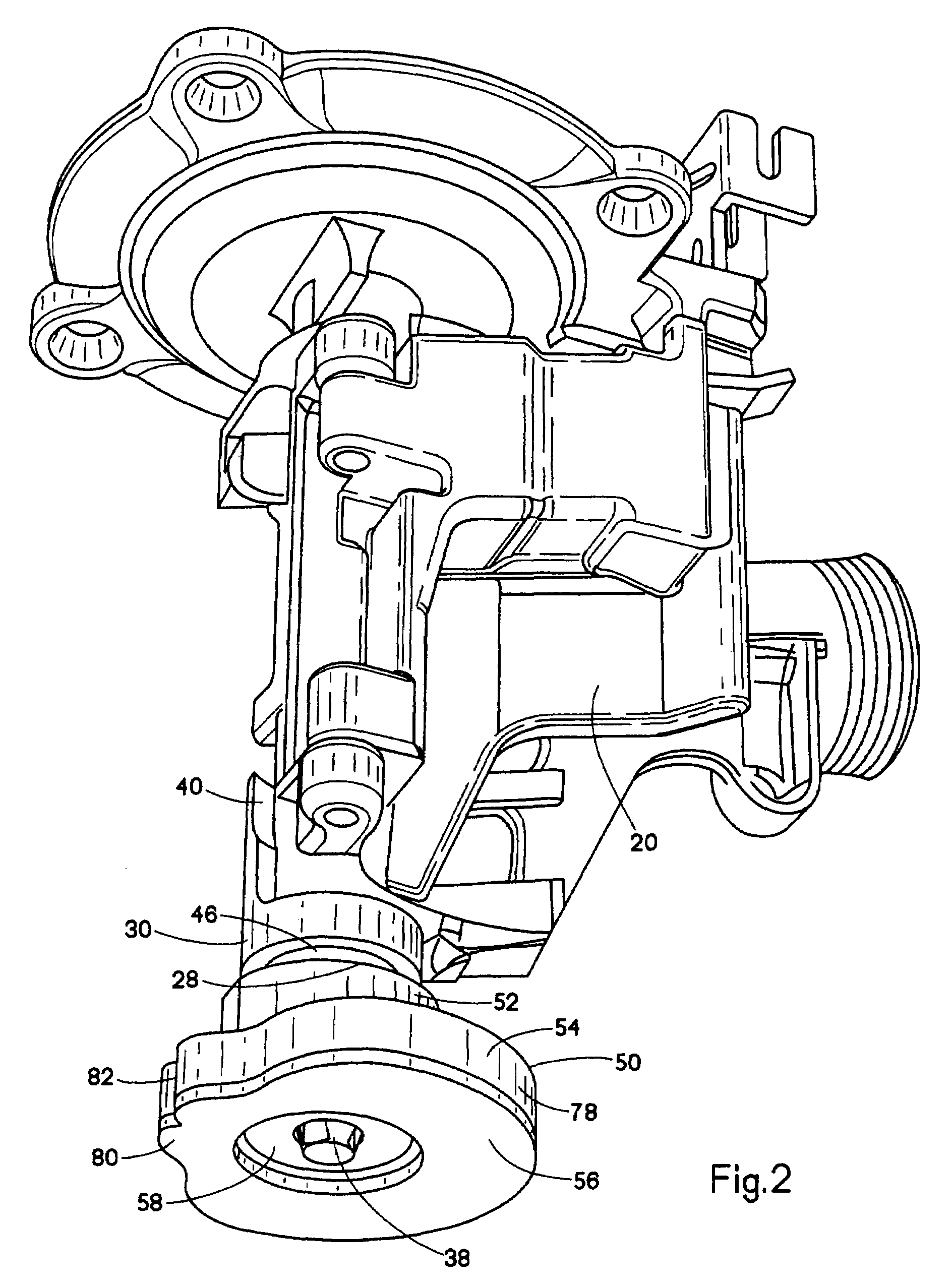

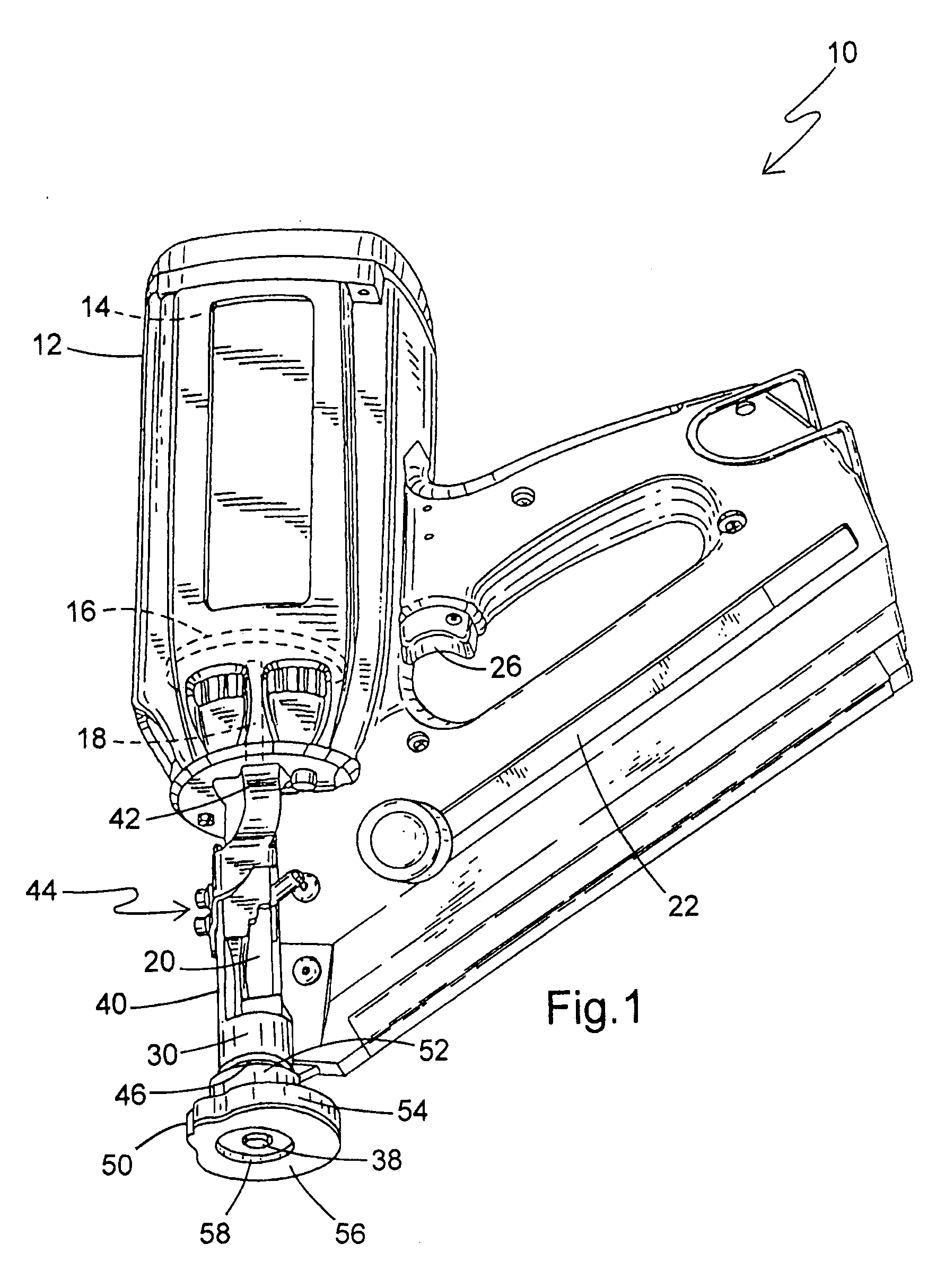

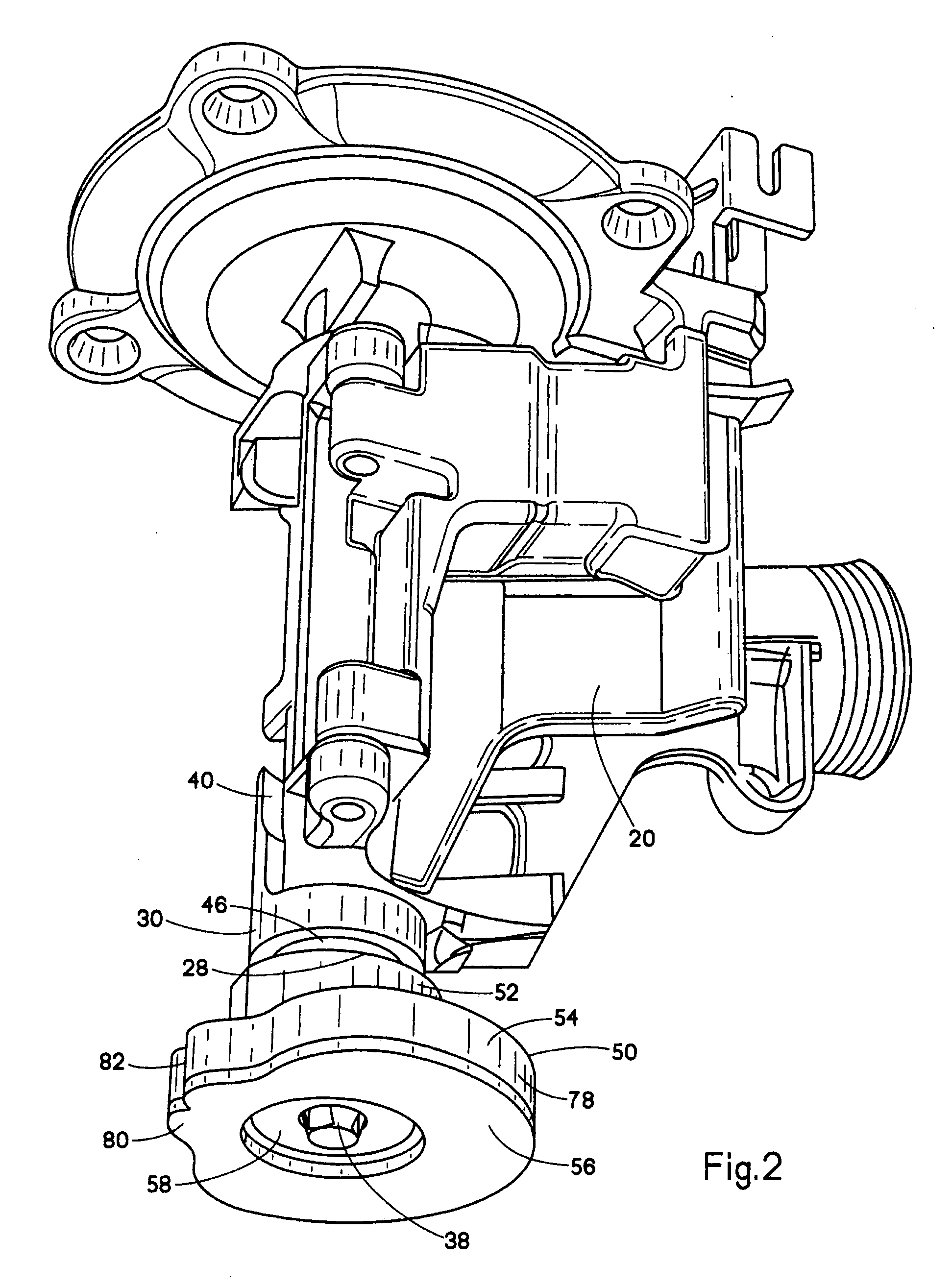

Depth of drive control with load transfer for fastener driver

InactiveUS7513404B2Improve driving accuracyIncrease awarenessStapling toolsNailing toolsReciprocating motionKnife blades

An adjustable depth of drive apparatus is provided for use on a fastener driving tool including a nosepiece defining a fastener passageway, and a driver blade reciprocating in the passageway for driving fasteners sequentially fed from a magazine into a workpiece. The depth of drive apparatus includes a depth of drive adjustment element being reciprocally movable relative to an end of the nosepiece, the depth of drive adjustment element defining a nosepiece chamber dimensioned for receiving the nosepiece and including a driver blade stop configured for receiving an end of the driver blade to terminate vertical driving motion of the driver blade.

Owner:ILLINOIS TOOL WORKS INC

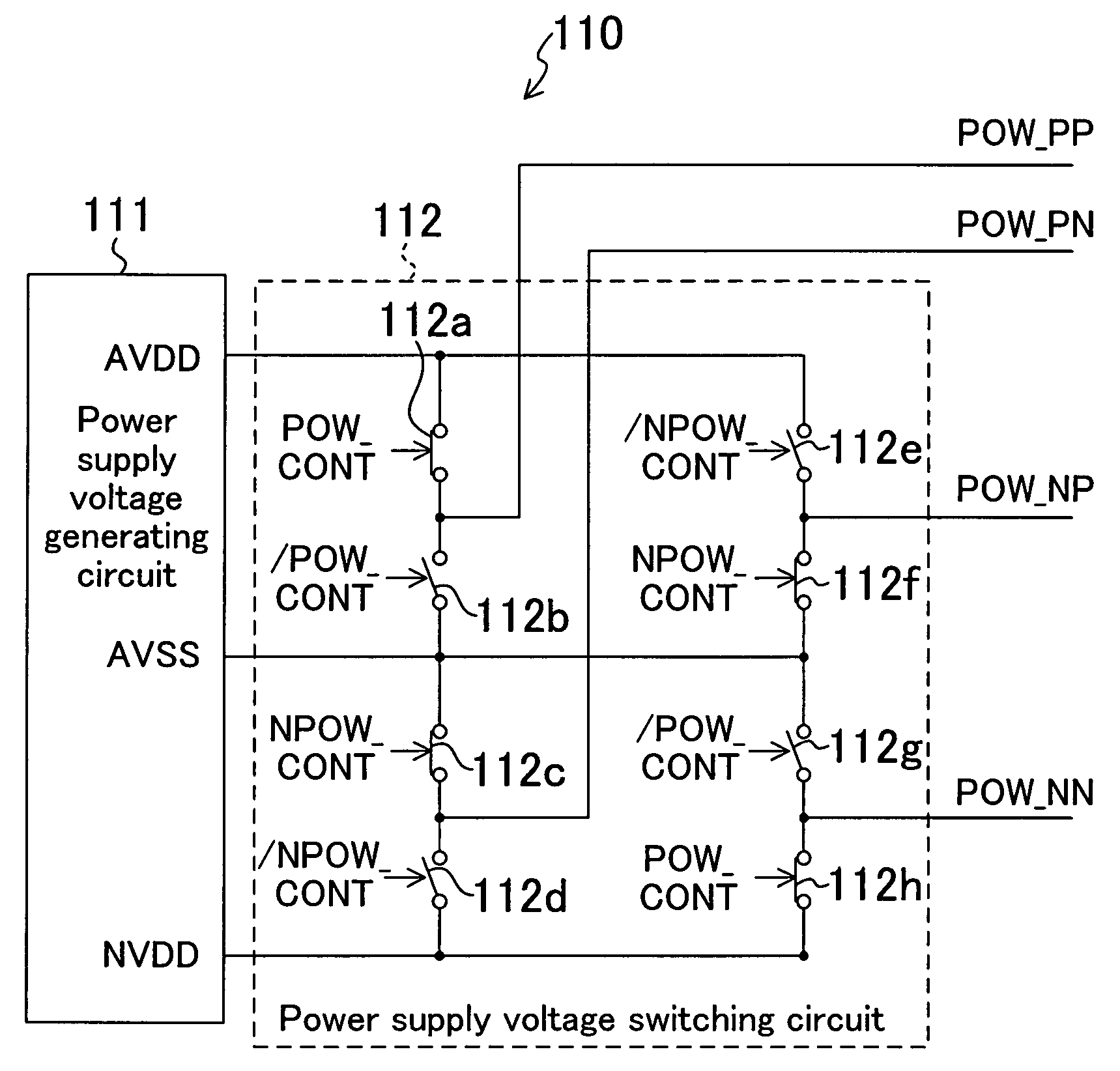

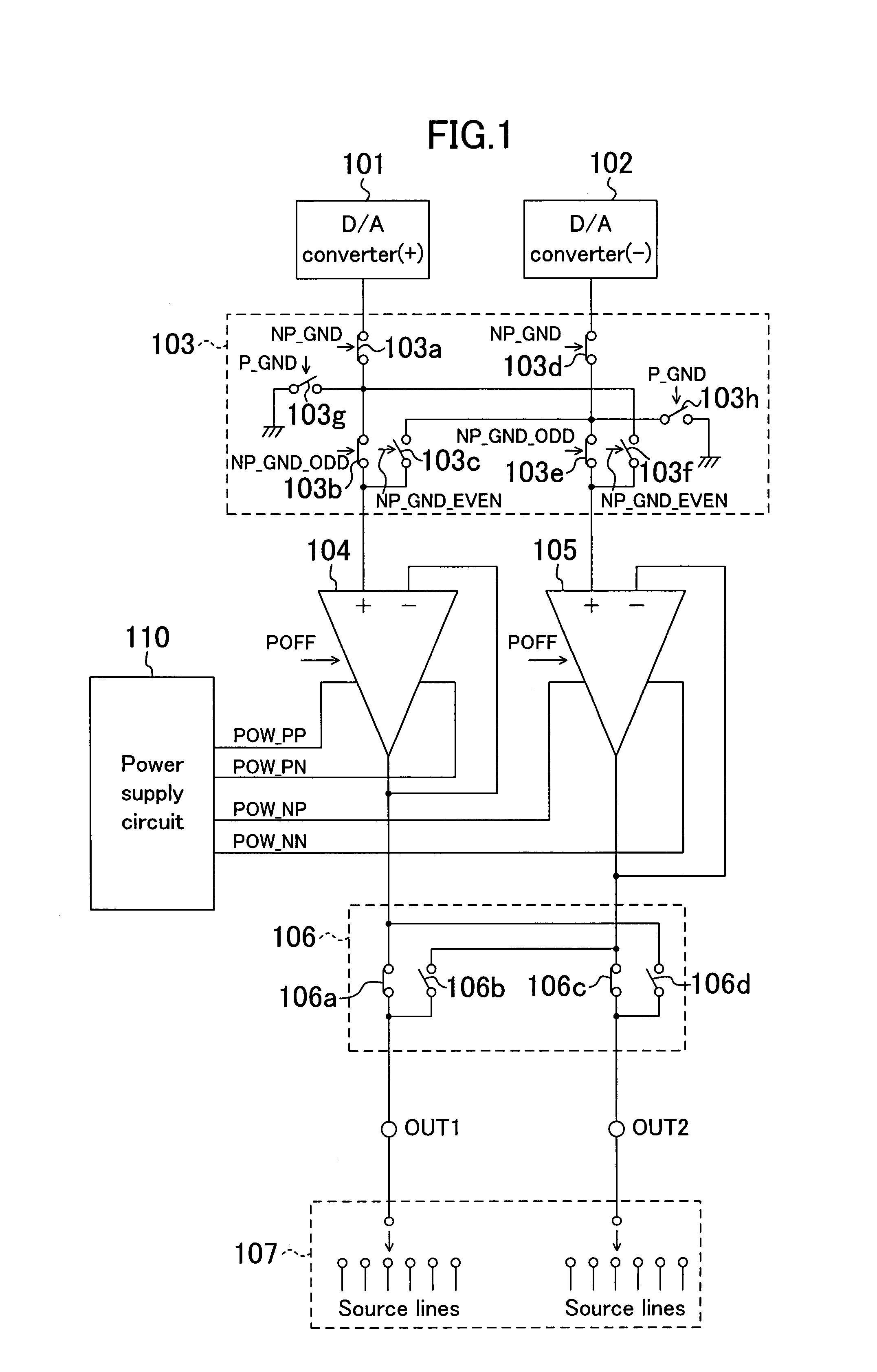

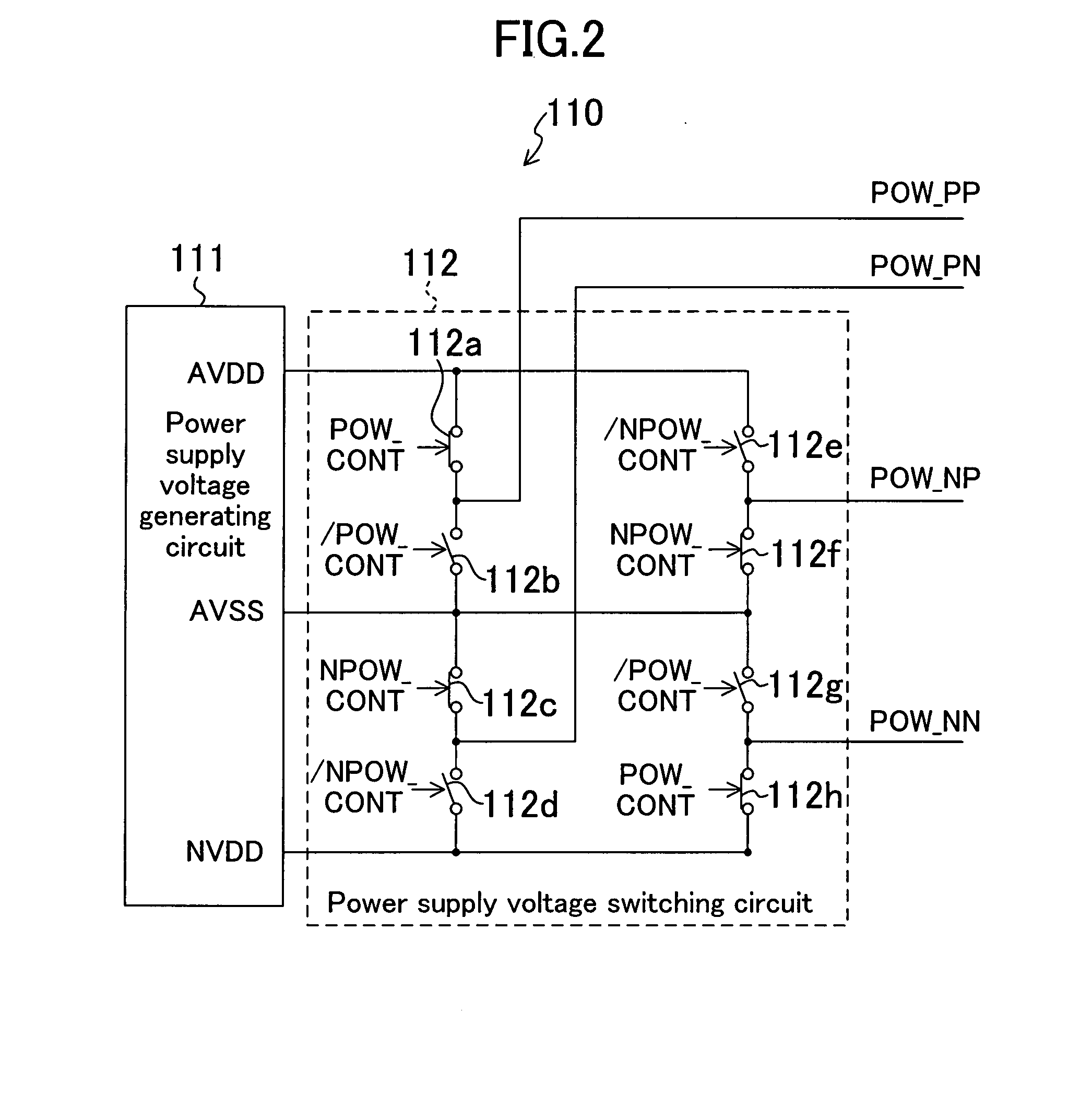

Driving voltage output circuit

InactiveUS20080089003A1Increase accuracyReduce areaStatic indicating devicesEmergency protective circuit arrangementsEngineeringAudio power amplifier

A driving voltage output circuit is provided for selectively outputting a positive driving voltage and a negative driving voltage. The driving voltage includes: an amplifier which amplifies and outputs, as a driving voltage, a selectively input positive or negative input signal; and a power supply voltage switching circuit which switches a power supply voltage to be supplied to the amplifier according to a polarity of the input signal.

Owner:PANASONIC CORP

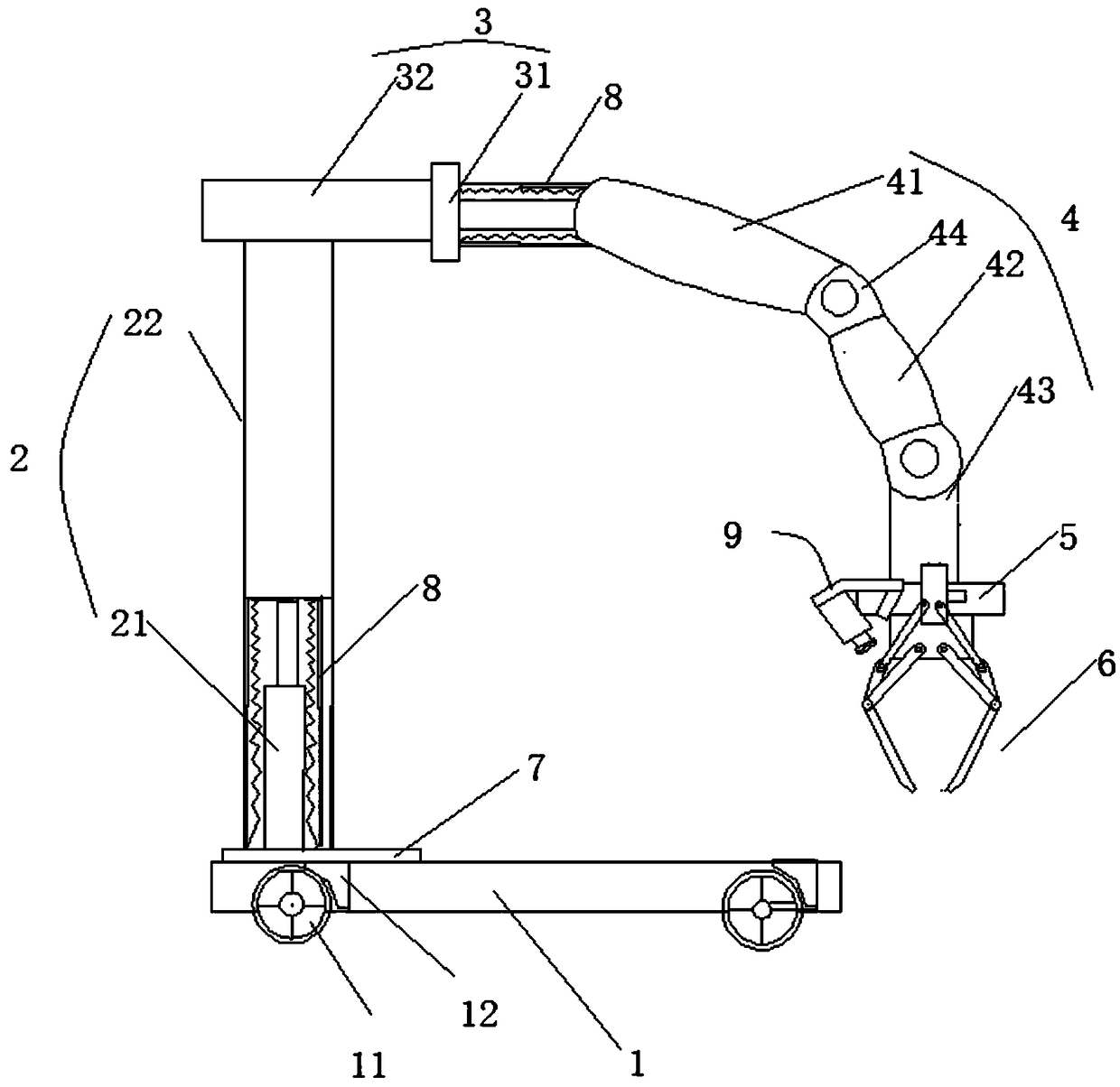

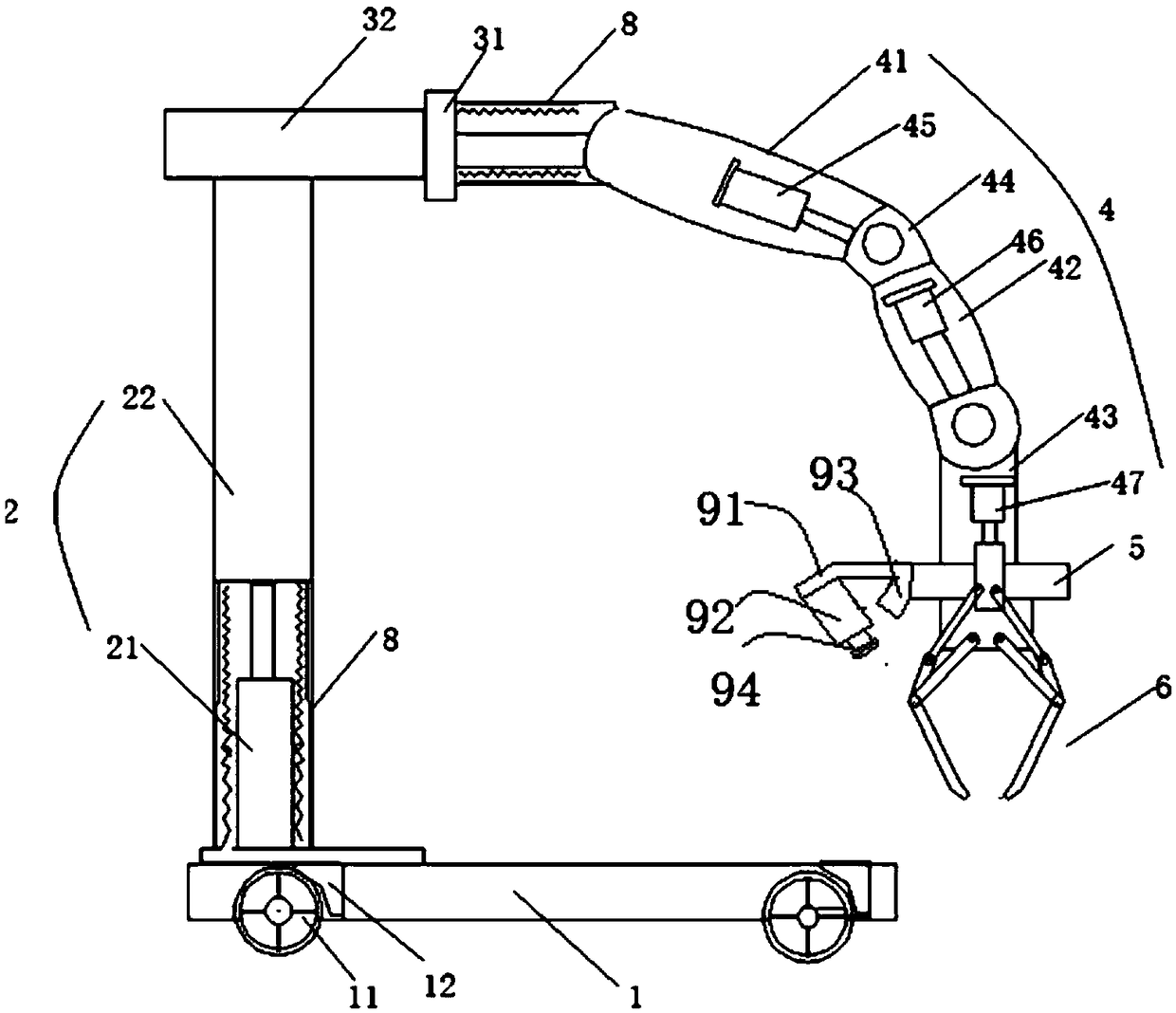

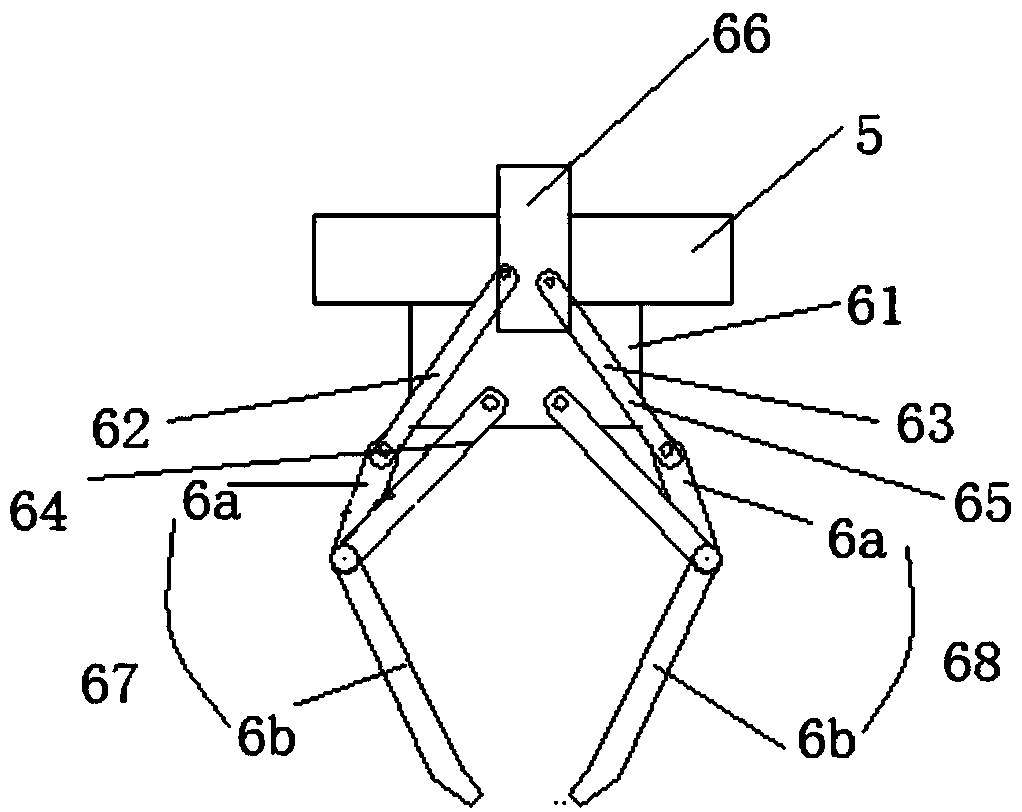

Material carrying mechanical arm capable of rotating and displacing and working method thereof

PendingCN108621119AReasonable structural designEasy to useProgramme-controlled manipulatorGripping headsEngineeringDangerous environment

The invention discloses a material carrying mechanical arm capable of rotating and displacing. The mechanical arm comprises a base, a lifting stand column, a transverse moving mechanism, a mechanicalarm, a connecting piece and a material taking mechanical claw, wherein the lifting stand column is fixed on the base through a rotating disc, the transverse moving mechanism is arranged on the liftingstand column, the lifting stand column comprises a lifting air cylinder and a supporting stand column, and the bottom of the lifting air cylinder is arranged on the rotating disc; and the mechanicalarm comprises a first mechanical arm, a second mechanical arm and a third mechanical arm, wherein the third mechanical arm is connected with the material taking mechanical claw through the connectingpiece, a first hydraulic cylinder is connected between the first mechanical arm and the second mechanical arm, a second hydraulic cylinder is arranged between the second mechanical arm and the third mechanical arm, and a third hydraulic cylinder is arranged between the third mechanical arm and the material taking mechanical claw. Through the cooperation and use of the lifting stand column, the transverse moving mechanism and the rotating disc, all-directional work of the material taking mechanical claw can be controlled, so that the automation degree in the production process is improved, manual operation of people in a dangerous environment is replaced, the working condition is improved, and the working efficiency is greatly improved.

Owner:薛敏强

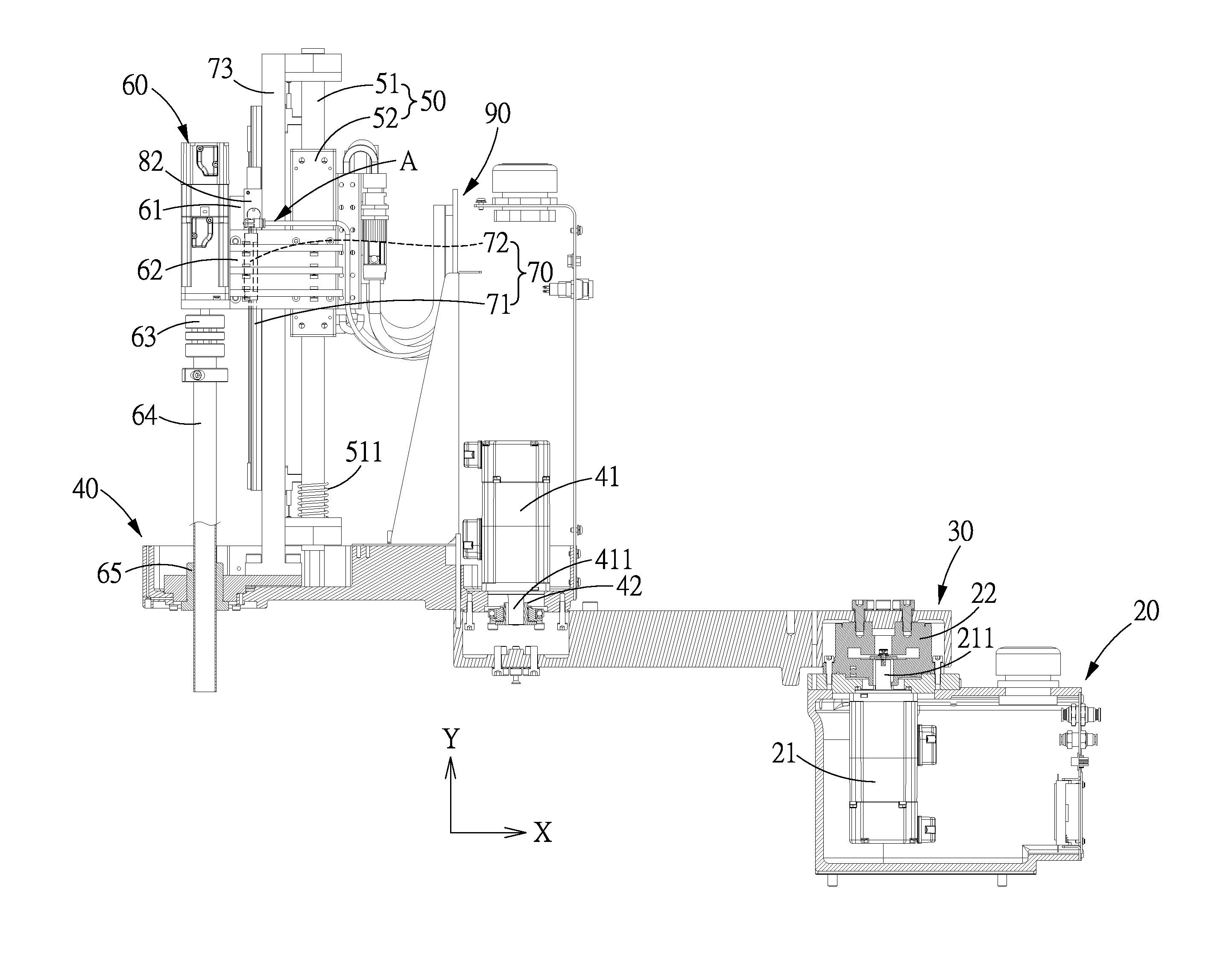

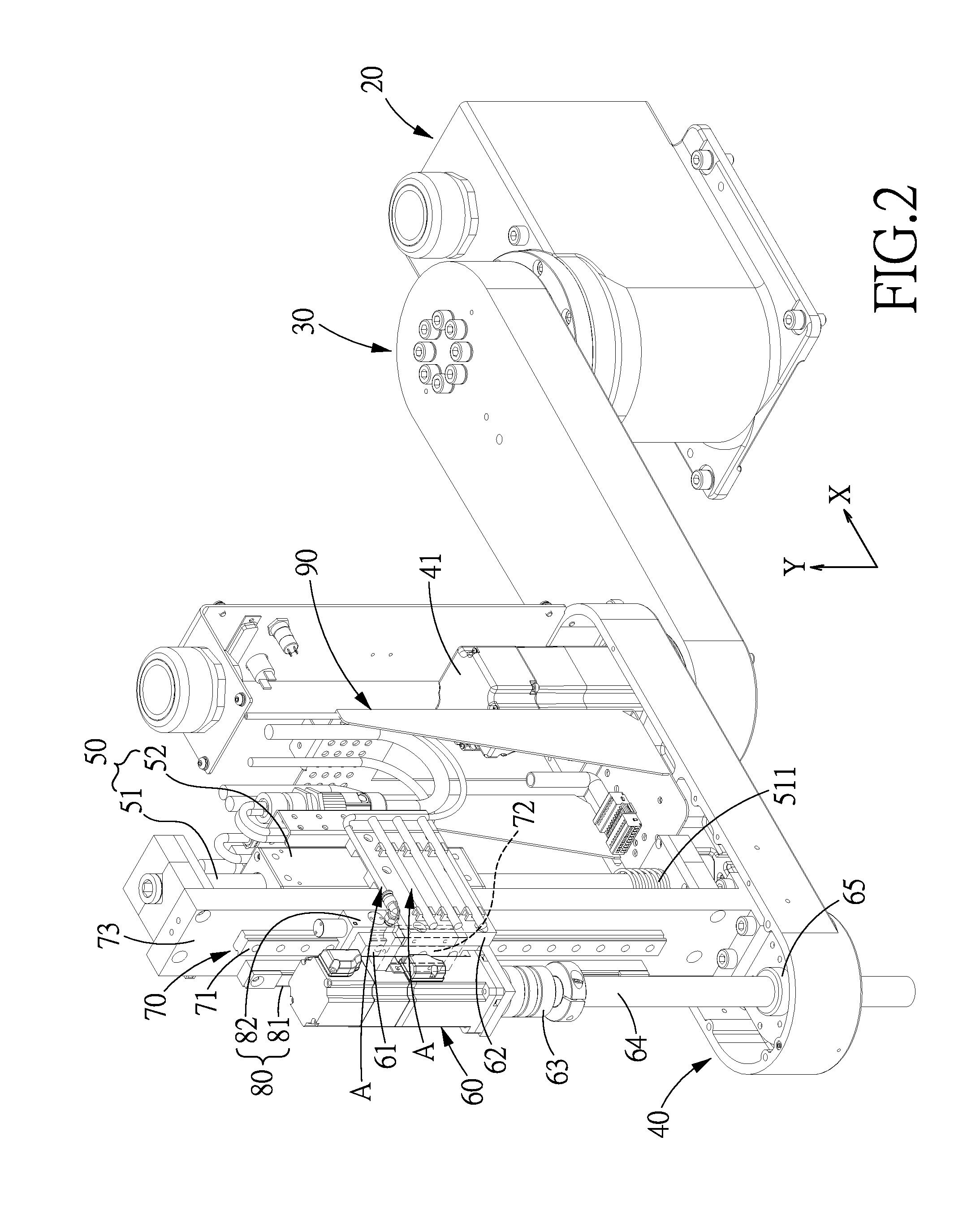

Selective compliance assembly robot arm

InactiveUS20160046020A1Improve driving accuracyImprove stabilityProgramme controlProgramme-controlled manipulatorEngineeringLinear motor

A SCARA arm includes a base, a first arm, a second arm, a third linear shaft motor, and a fourth shaft motor. On the base is disposed a first shaft motor. The first arm is connected to and driven by the first shaft motor rotate in a horizontal direction. The second arm is fixed to a second shaft motor which is connected to the first arm to rotate the second arm in the horizontal direction. The third linear shaft motor includes a linear motor stator which extends in a vertical direction and is fixed to the second arm, and a linear motor mover which is sleeved onto the linear motor stator and movable along the vertical direction. The fourth shaft motor is drivingly connected to the linear motor mover and a rotary shaft, respectively, and another end of the rotary shaft is inserted out of the second arm.

Owner:HIWIN TECH

Depth of drive control with load transfer for fastener driver

InactiveUS20080251567A1Facilitate visibilityImprove driving accuracyStapling toolsNailing toolsFastenerEngineering

An adjustable depth of drive apparatus is provided for use on a fastener driving tool including a nosepiece defining a fastener passageway, and a driver blade reciprocating in the passageway for driving fasteners sequentially fed from a magazine into a workpiece. The depth of drive apparatus includes a workpiece contact element being reciprocally movable relative to an end of the nosepiece, the workpiece contact element defining a nosepiece chamber dimensioned for receiving the nosepiece and including a driver blade stop configured for receiving an end of the driver blade to terminate vertical driving motion of the driver blade.

Owner:ILLINOIS TOOL WORKS INC

Friction estimation method

ActiveUS8666562B2Improve reliability and legitimacyImprove driving accuracyAnalogue computers for trafficAutomatic initiationsEstimation methodsSelection criterion

A method and apparatus for the estimation of maximum friction between a vehicular tire and a road surface via driving dynamics measurements and at least one sensor measuring the road surface, comprisingmeasuring road surface properties via a sensor;measuring the state of motion of a vehicle and a tire and concluding therefrom a momentary maximum friction coefficient when the tire is subjected to a sufficient friction force;storing a maximum friction estimate concluded from the above-mentioned measurements, along with measuring results regarding road surface properties measured at the moment of measurement;when the tire is not subjected to a friction force sufficient for measuring maximum friction, using, as a maximum friction estimate, the previously measured maximum friction estimate, such that an applied selection criterion for the maximum friction estimate is the newness as up-to-date as possible of the measuring result and a consistency of the road surface measuring result.

Owner:AALTO UNIV FOUND

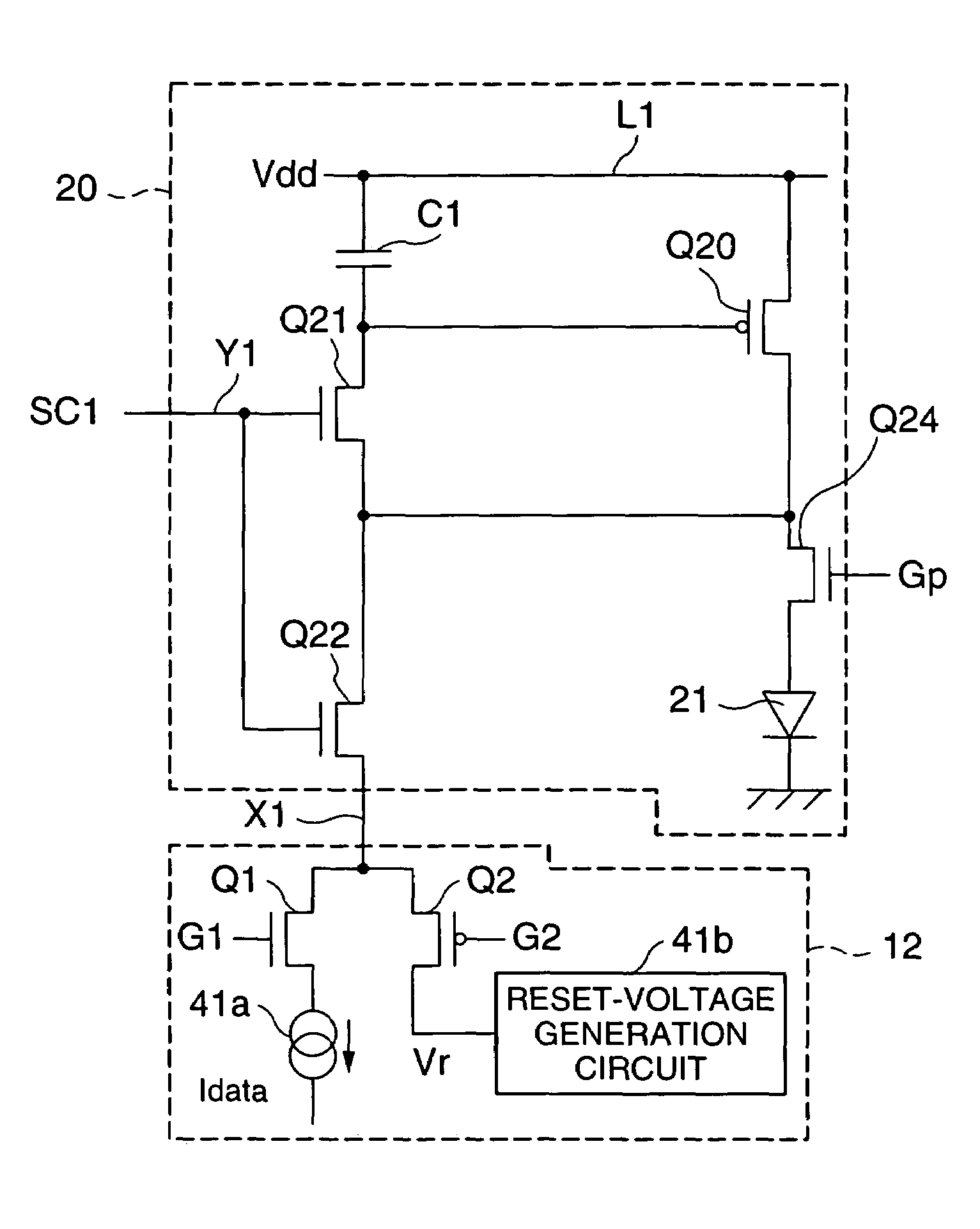

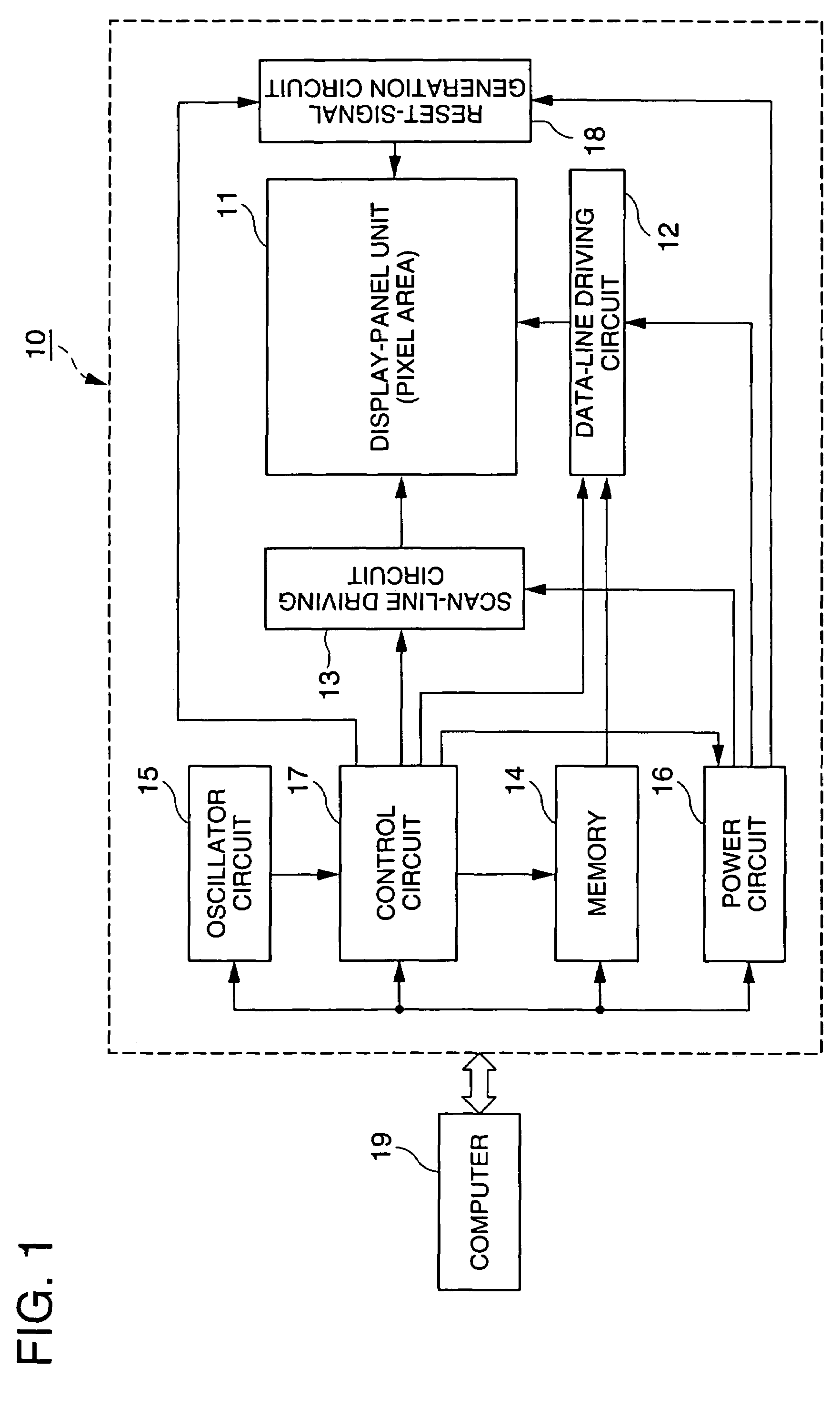

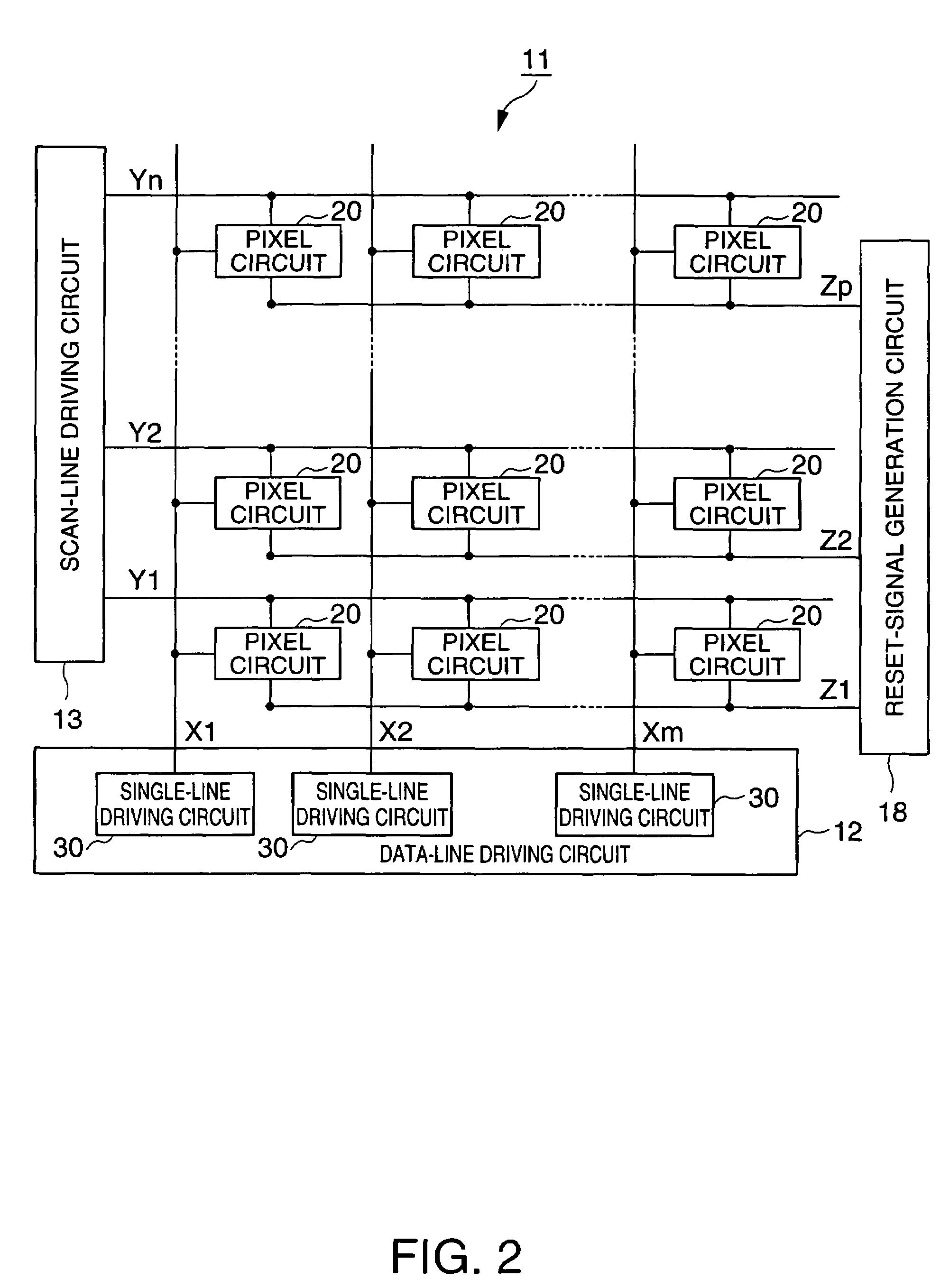

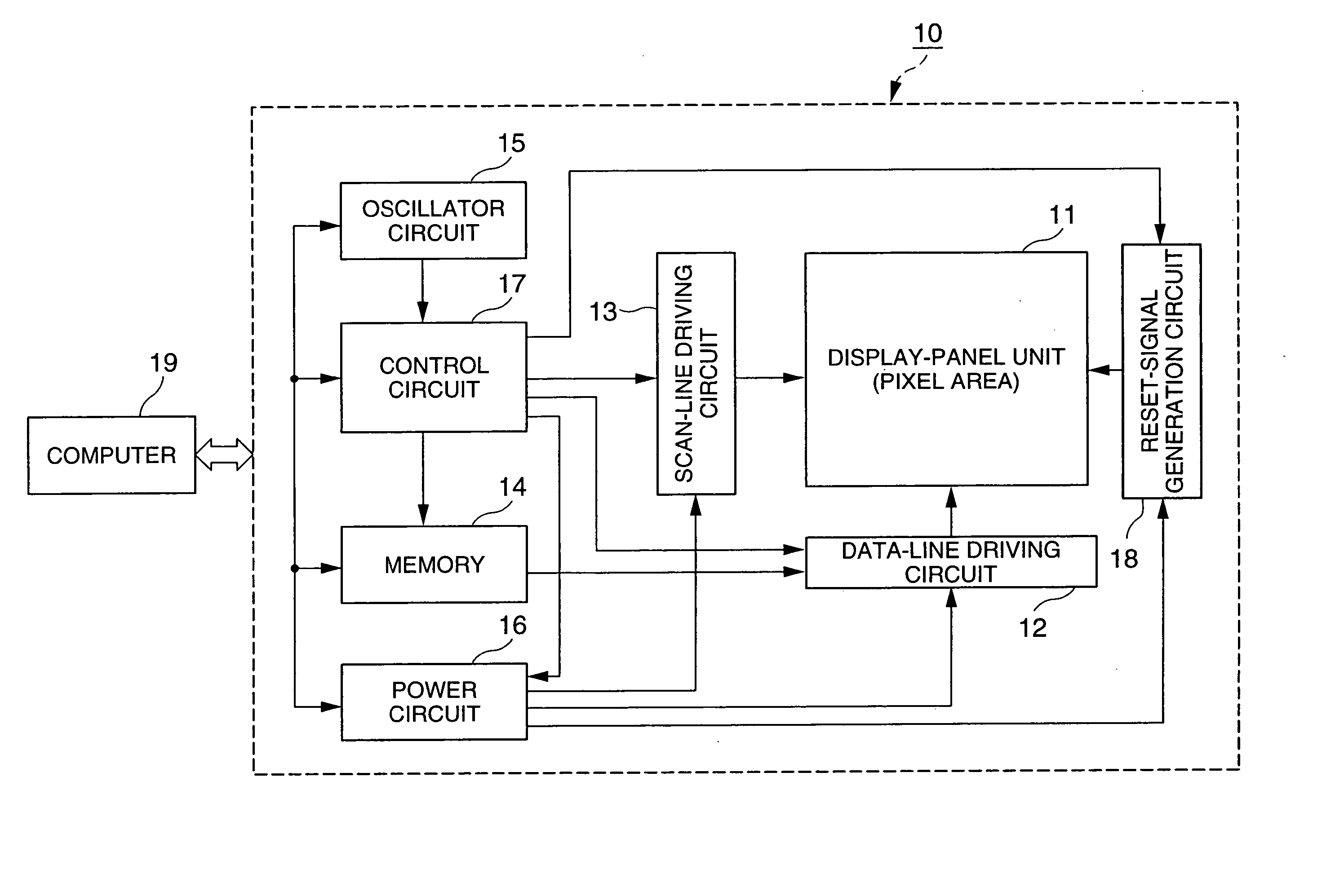

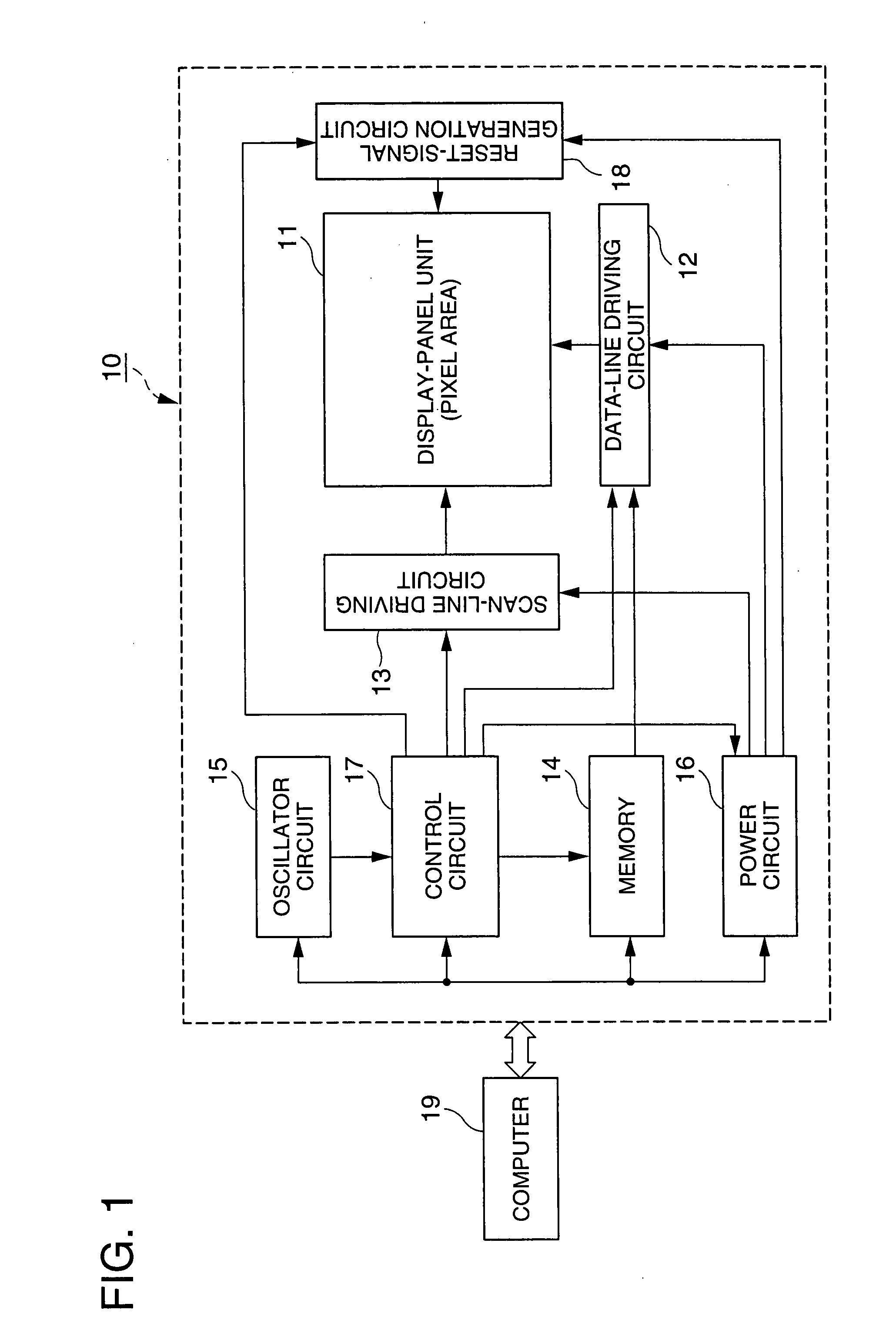

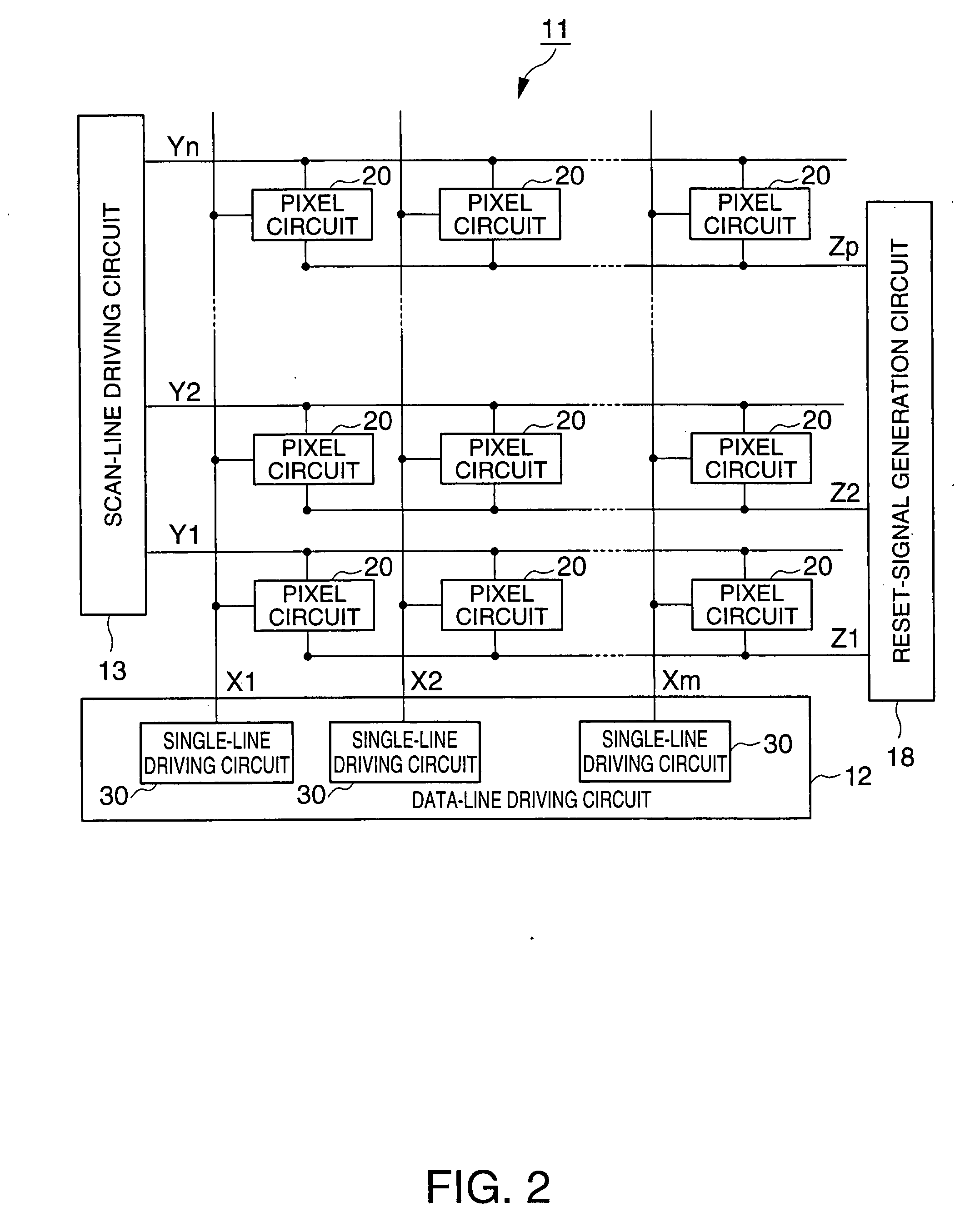

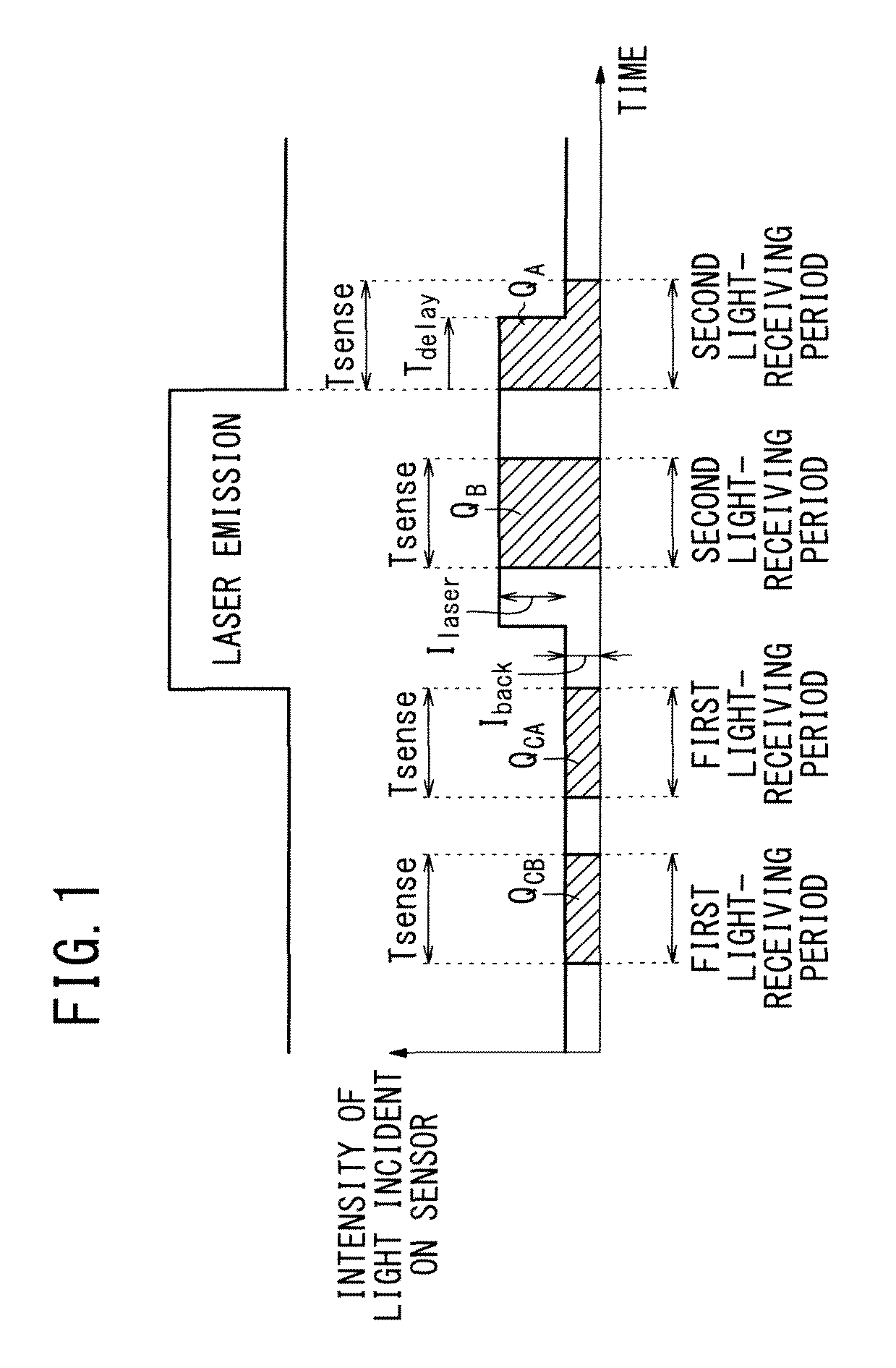

Electronic circuit, optoelectronic device, method for driving optoelectronic device, and electronic apparatus

ActiveUS7345685B2Improve driving accuracyIncrease driving speedSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOpto electronic

An electronic circuit, an electronic device, and an electronic apparatus are provided that are capable of display with good quality and reducing operation delay, and a method to drive the electronic circuit. First and second switching transistors are turned on and an operation voltage Vdx and a data-current Idata are transmitted to a holding capacitor. The conduction state of a driving transistor is set according to an electrical-charge amount corresponding to the data-current Idata held in the holding capacitor and a current that passes the driving transistor is transmitted to an organic EL element. Then, a first switch is turned off, a second switch and the second switching transistor are turned on, and a reset voltage Vr is transmitted to the holding capacitor, whereby the driving transistor is turned off and the organic EL element stops emitting light.

Owner:BOE TECH GRP CO LTD

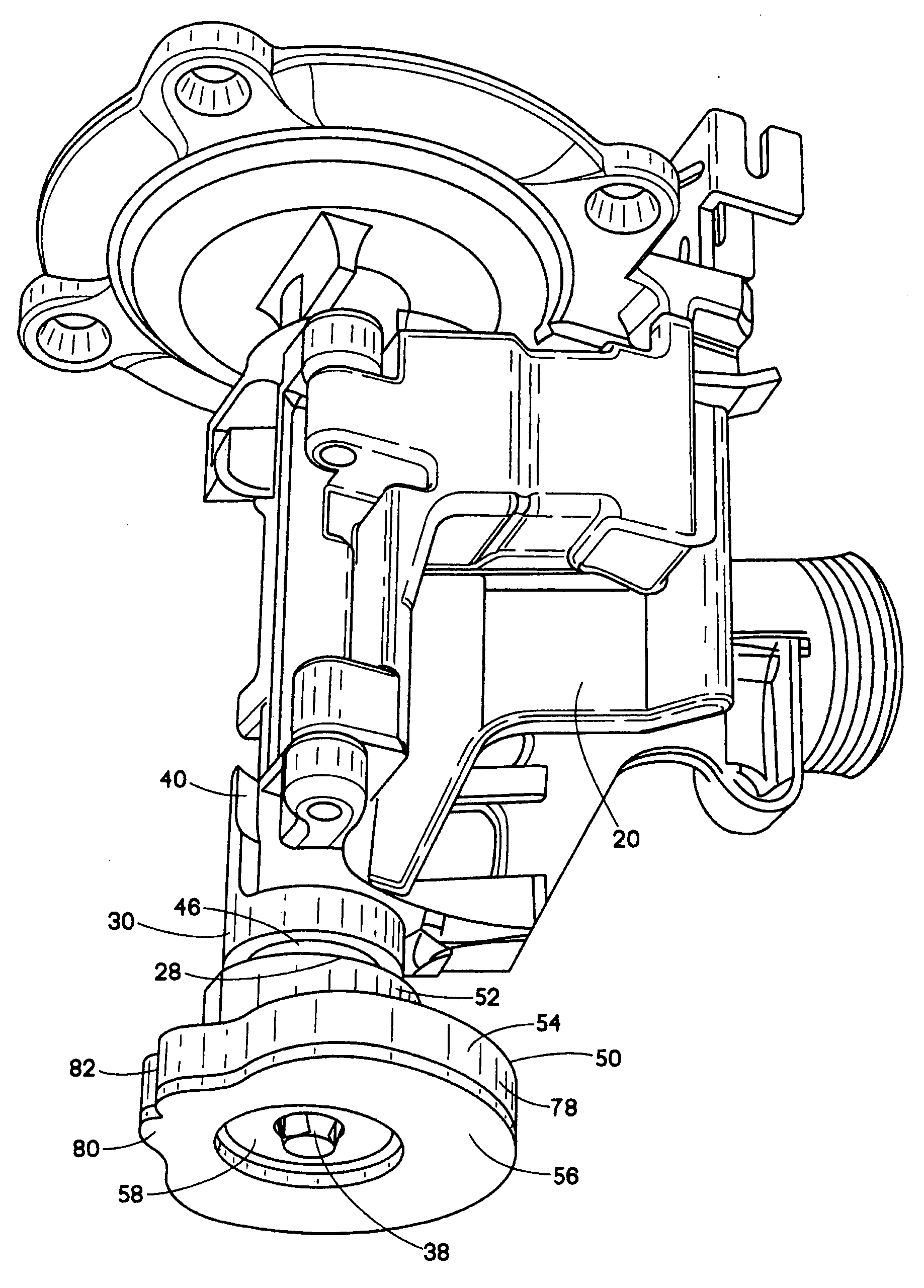

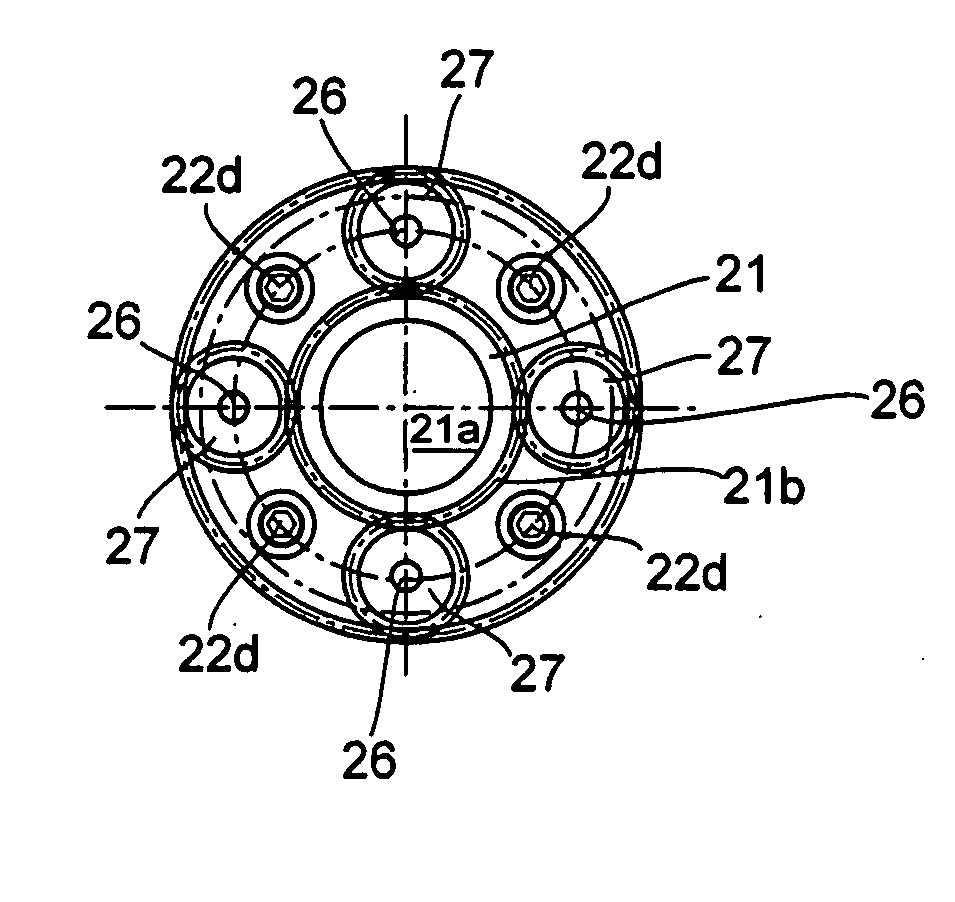

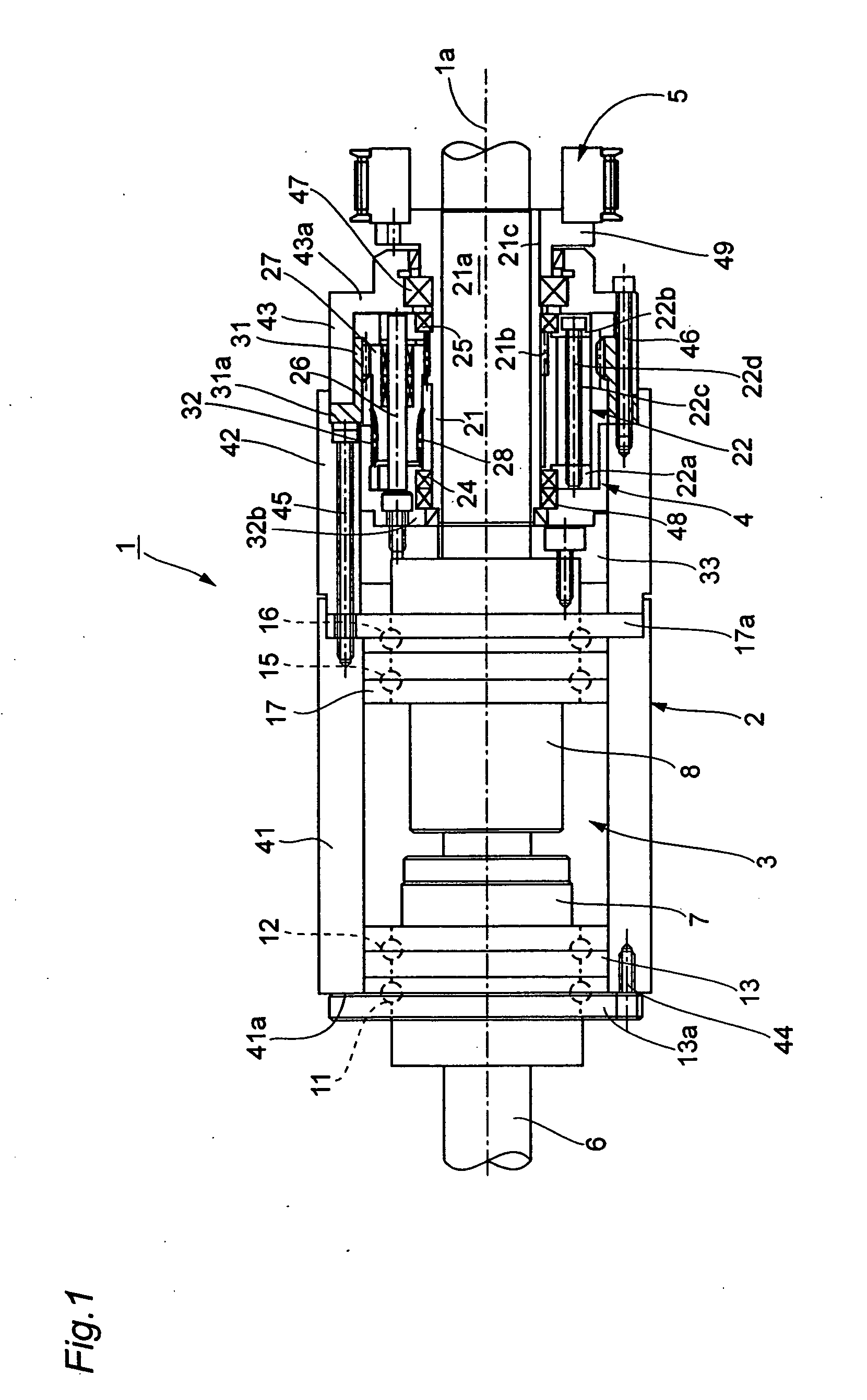

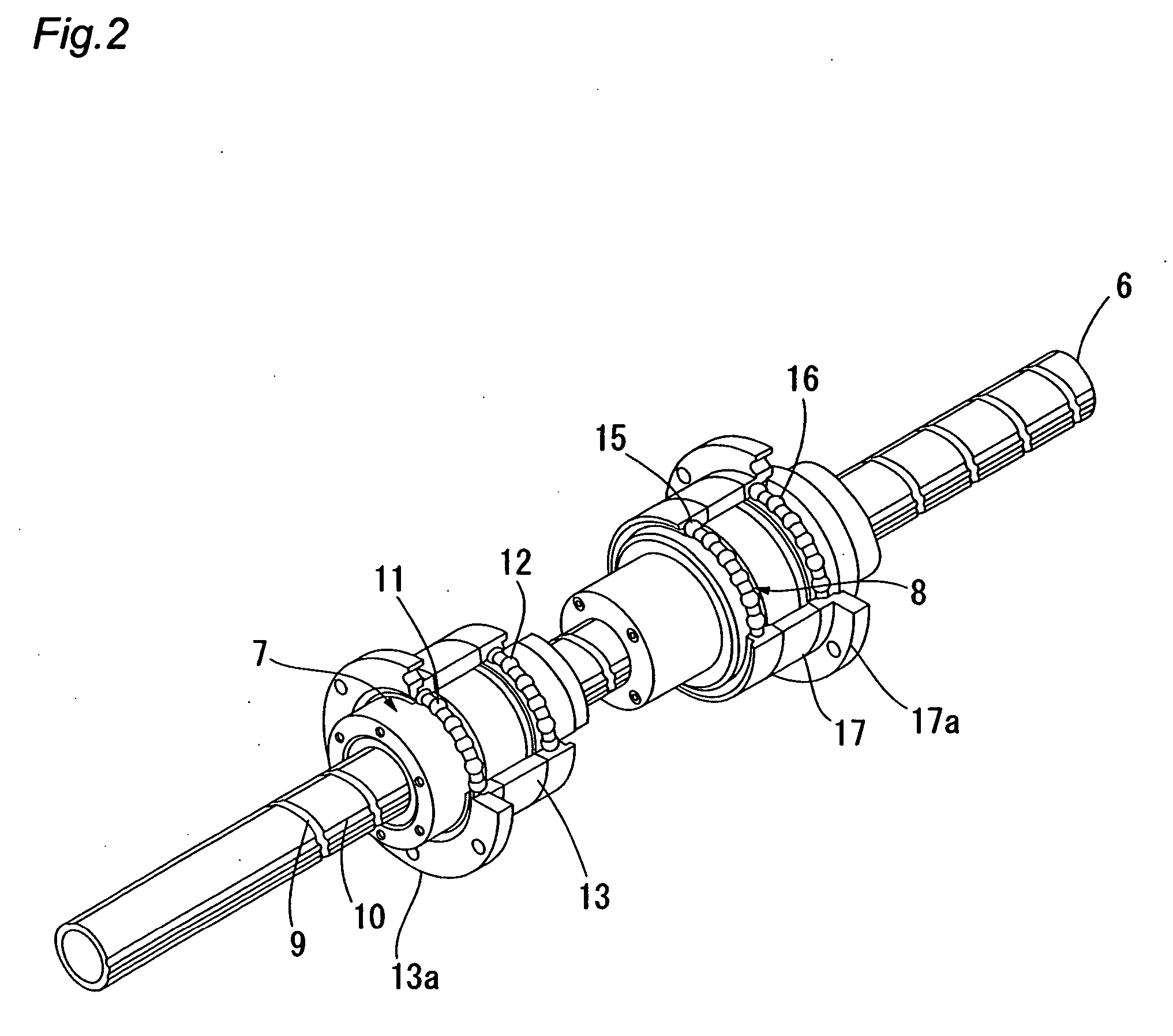

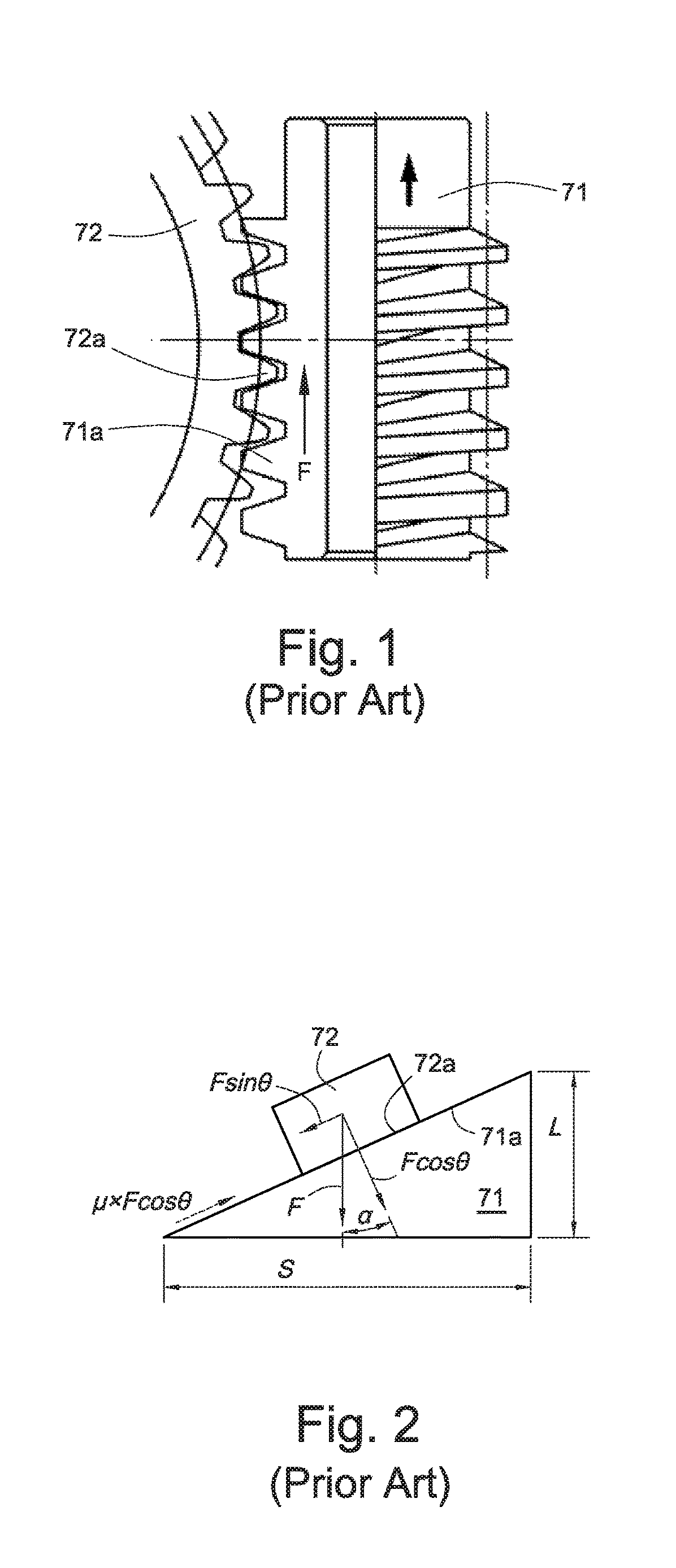

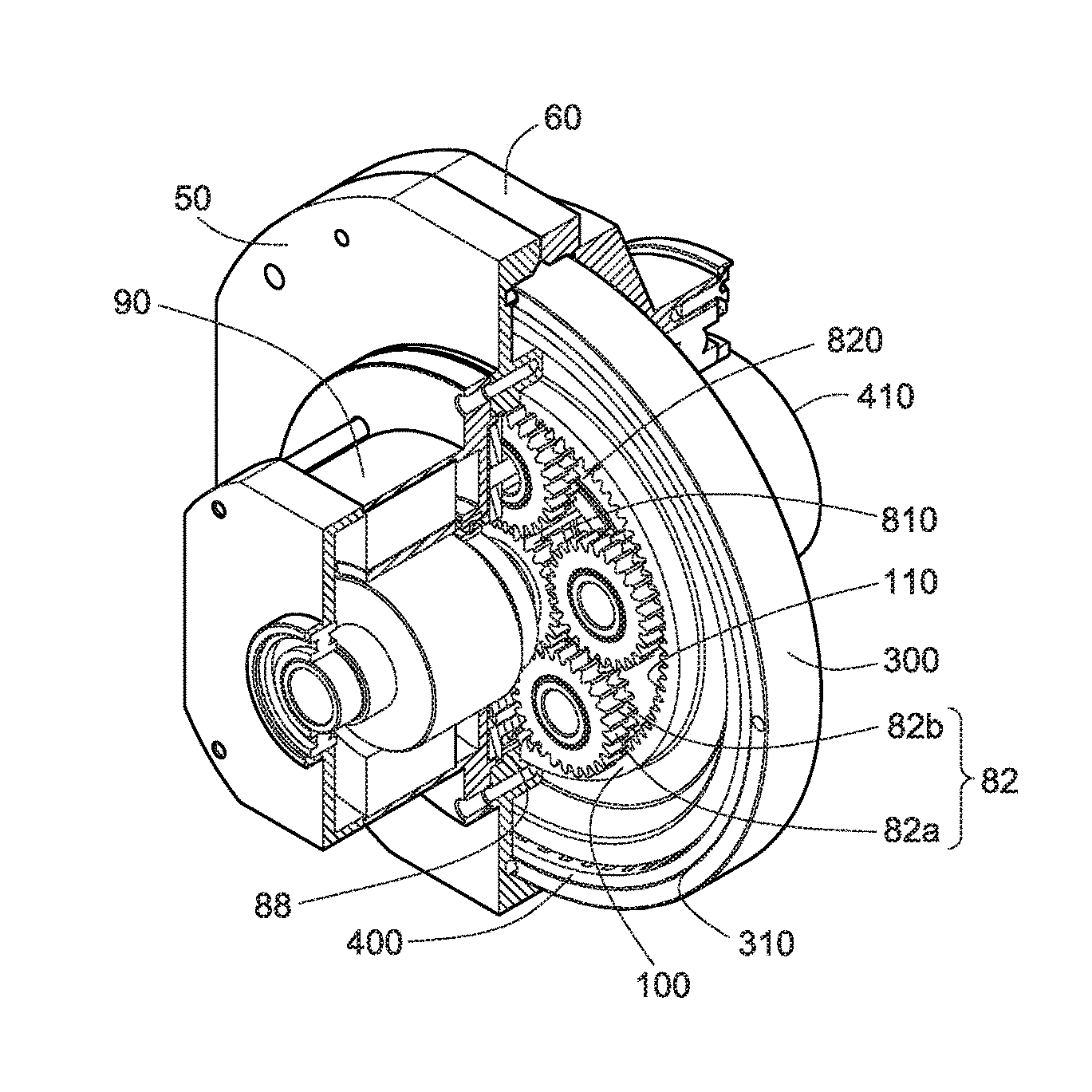

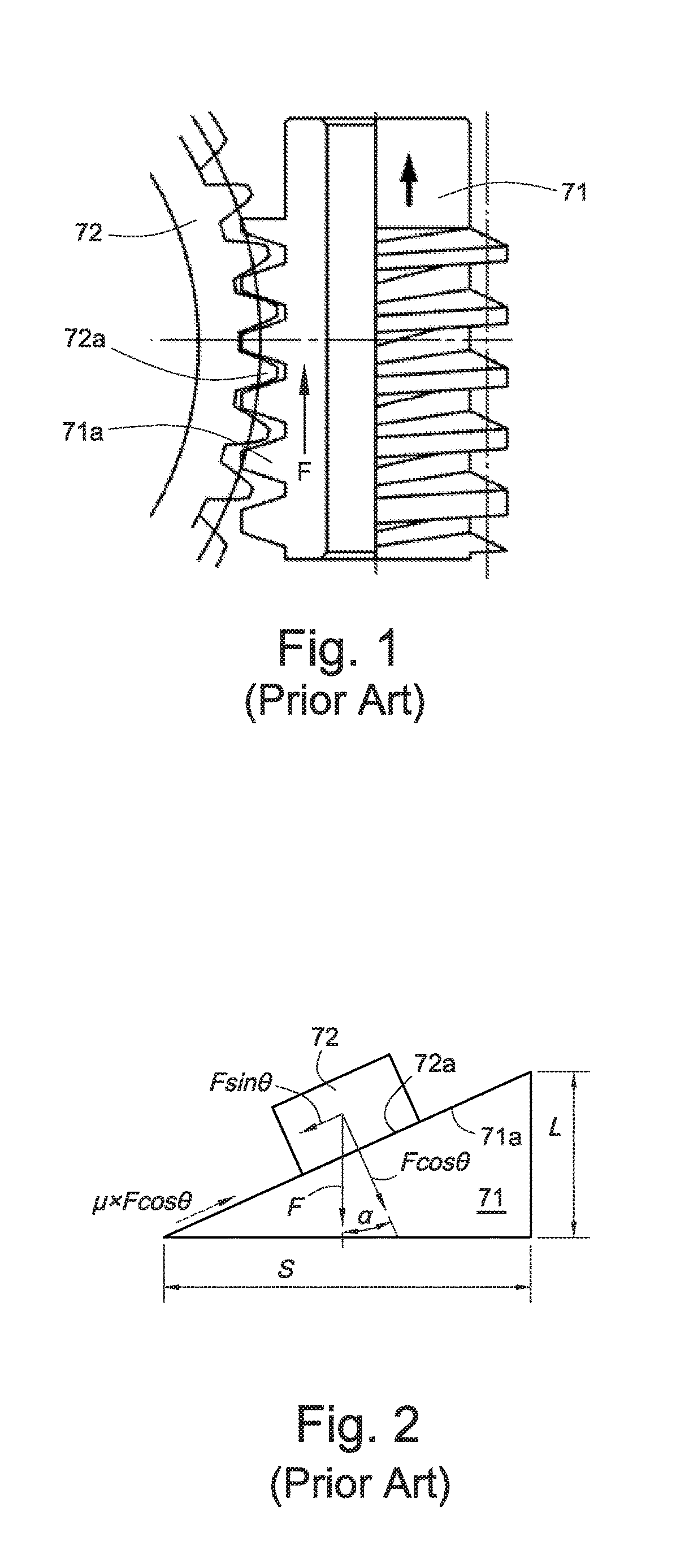

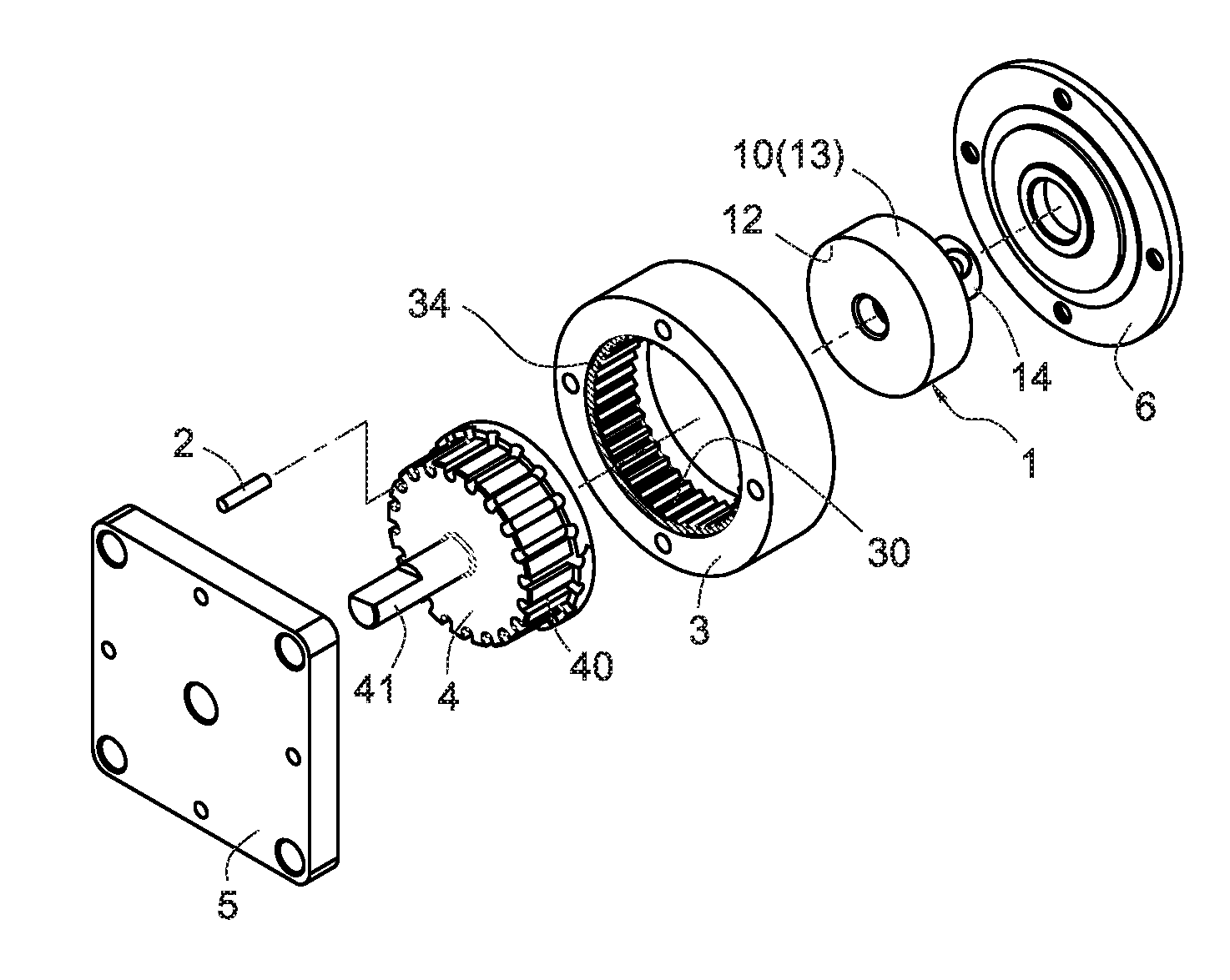

Linear movement/rotation mechanism equipped with a ball screw/ball spline mechanism

InactiveUS20050160855A1Precise positioningHigh strengthDoors/windowsToothed gearingsDrive shaftBall screw

In a linear movement / rotation mechanism, inside a tube-like housing, a ball screw / ball spline mechanism and a hollow planetary reduction gear are coaxially disposed, a drive shaft extends therethrough, and a ball screw nut, a ball spline nut, a hollow planetary reduction gear, and a driven pulley are disposed in that order along a center axis of the drive shaft. A rotational force inputted to the driven pulley is inputted to a hollow rotational shaft of the hollow planetary reduction gear, and a reduced rotation output is outputted from a rear stage internal gear. The reduced rotation output is transmitted to the ball spline nut that is connected and fixed to the rear stage internal gear. When the rotation of the ball screw nut is restricted, a feeding operation of the drive shaft is realized.

Owner:HARMONIC INC

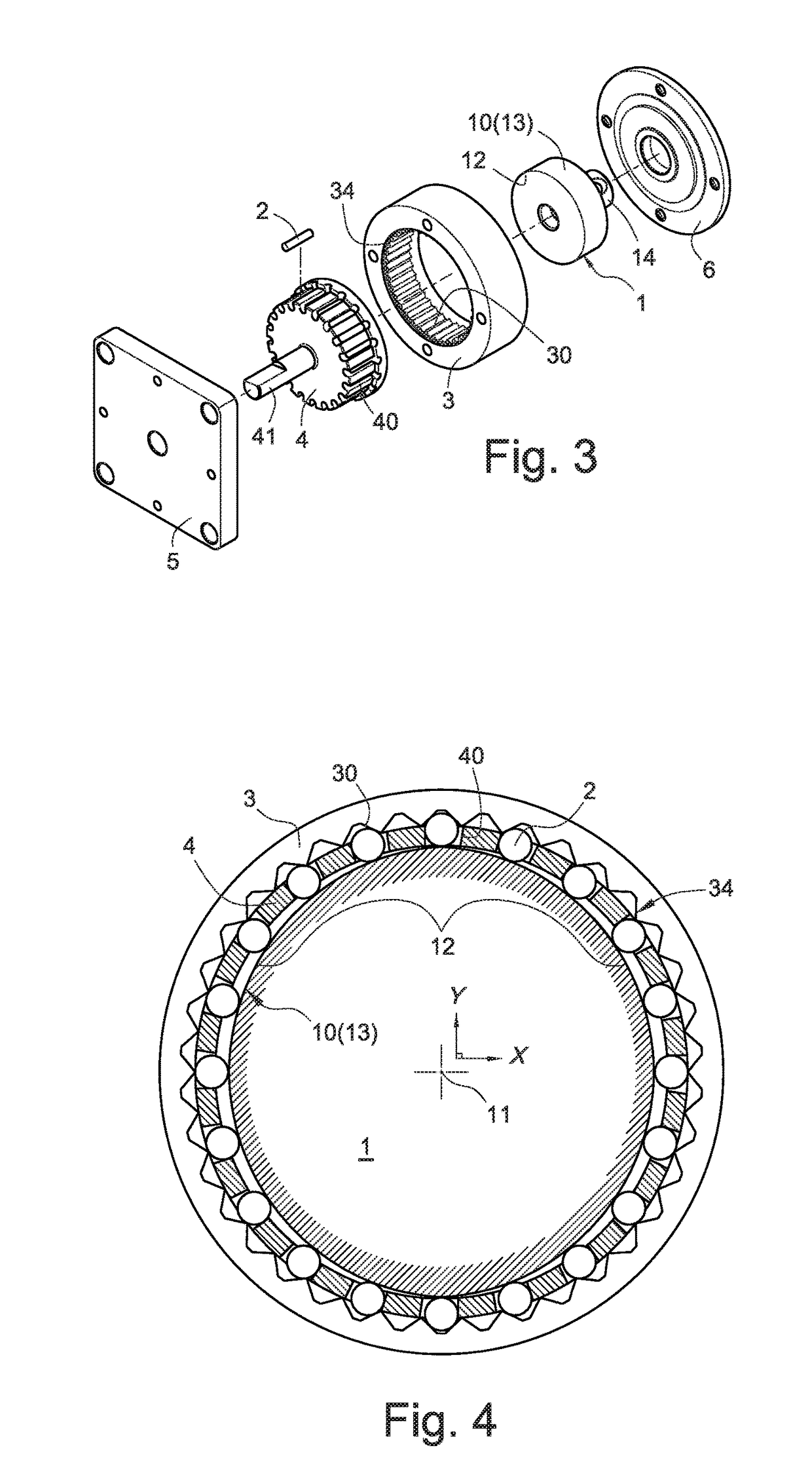

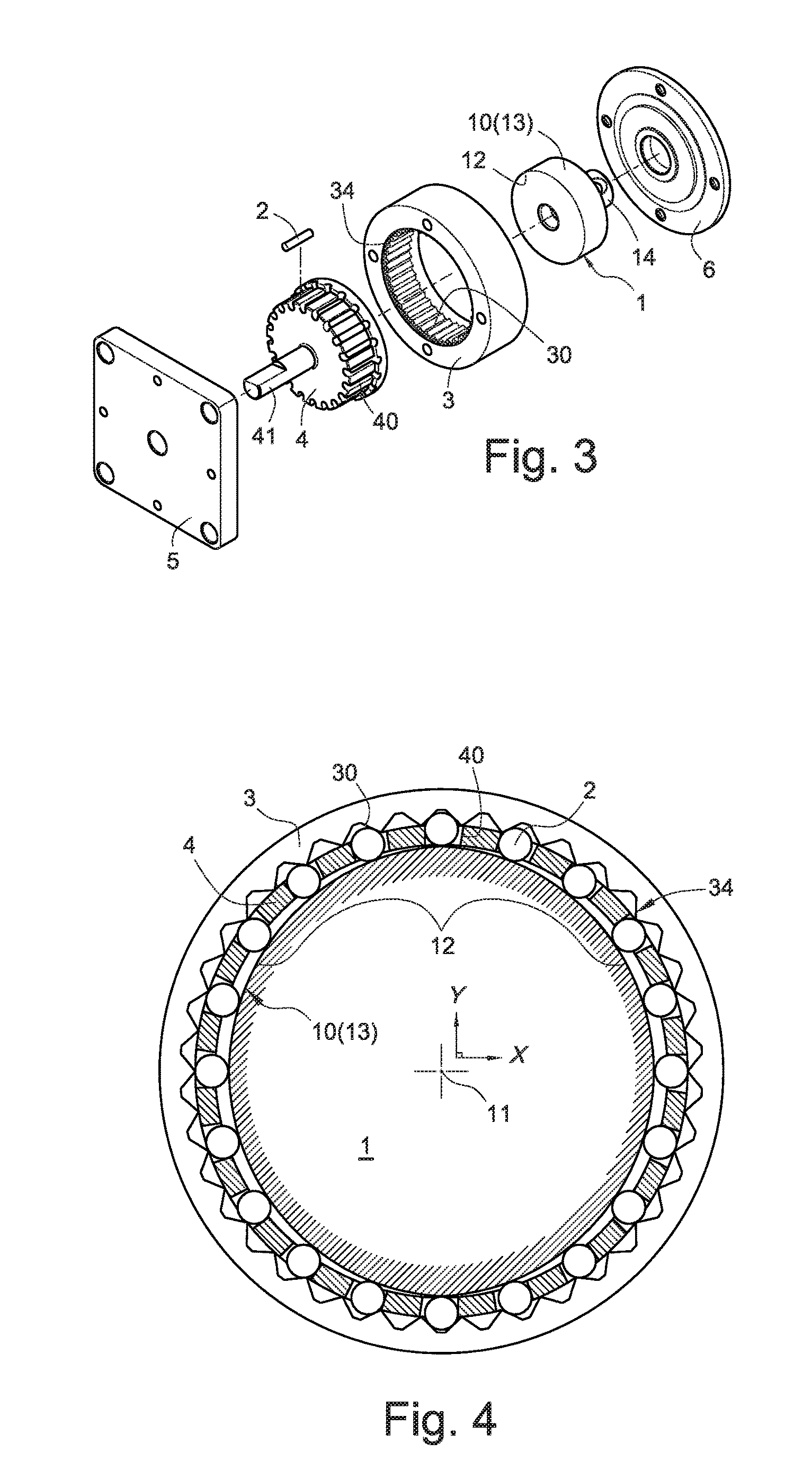

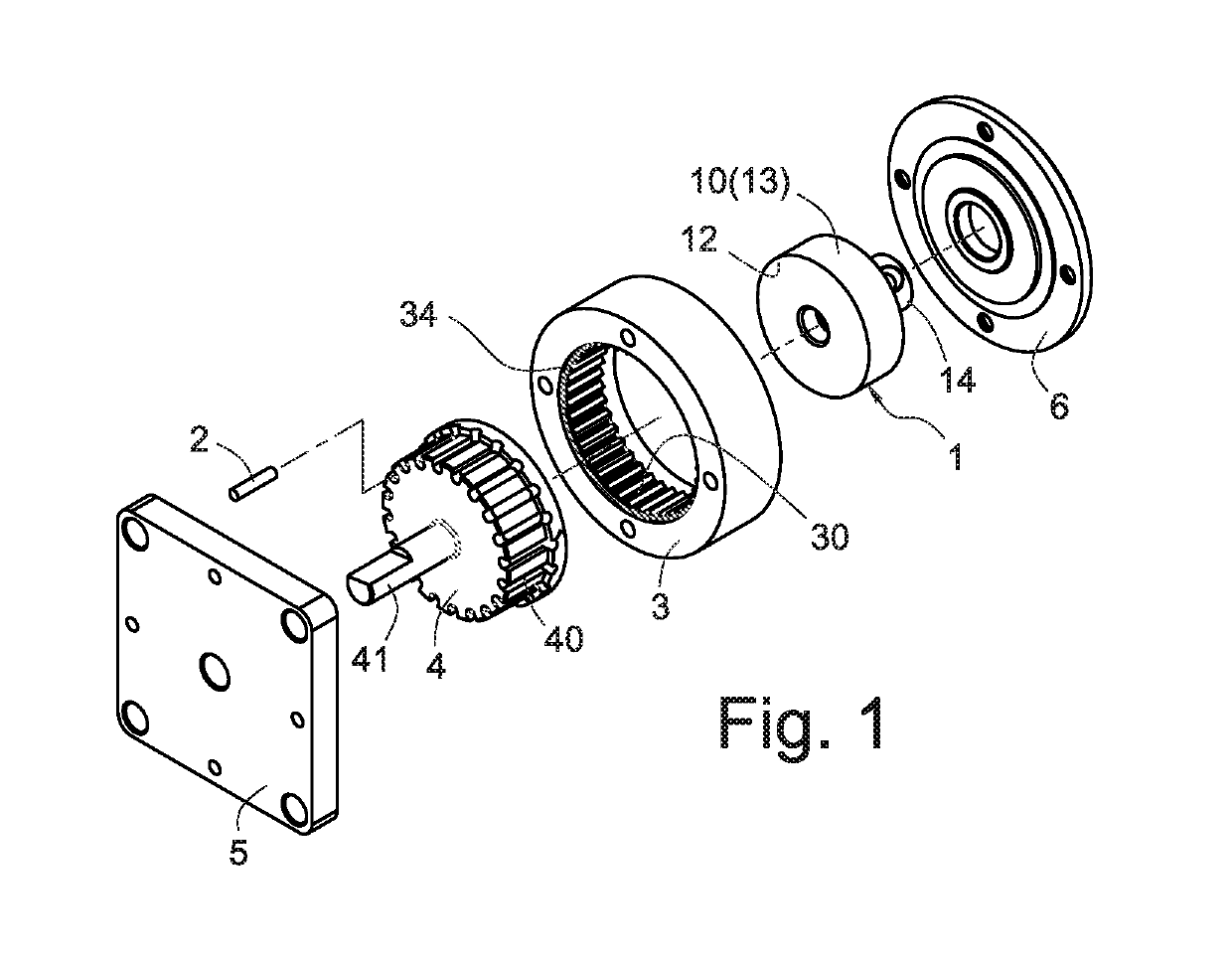

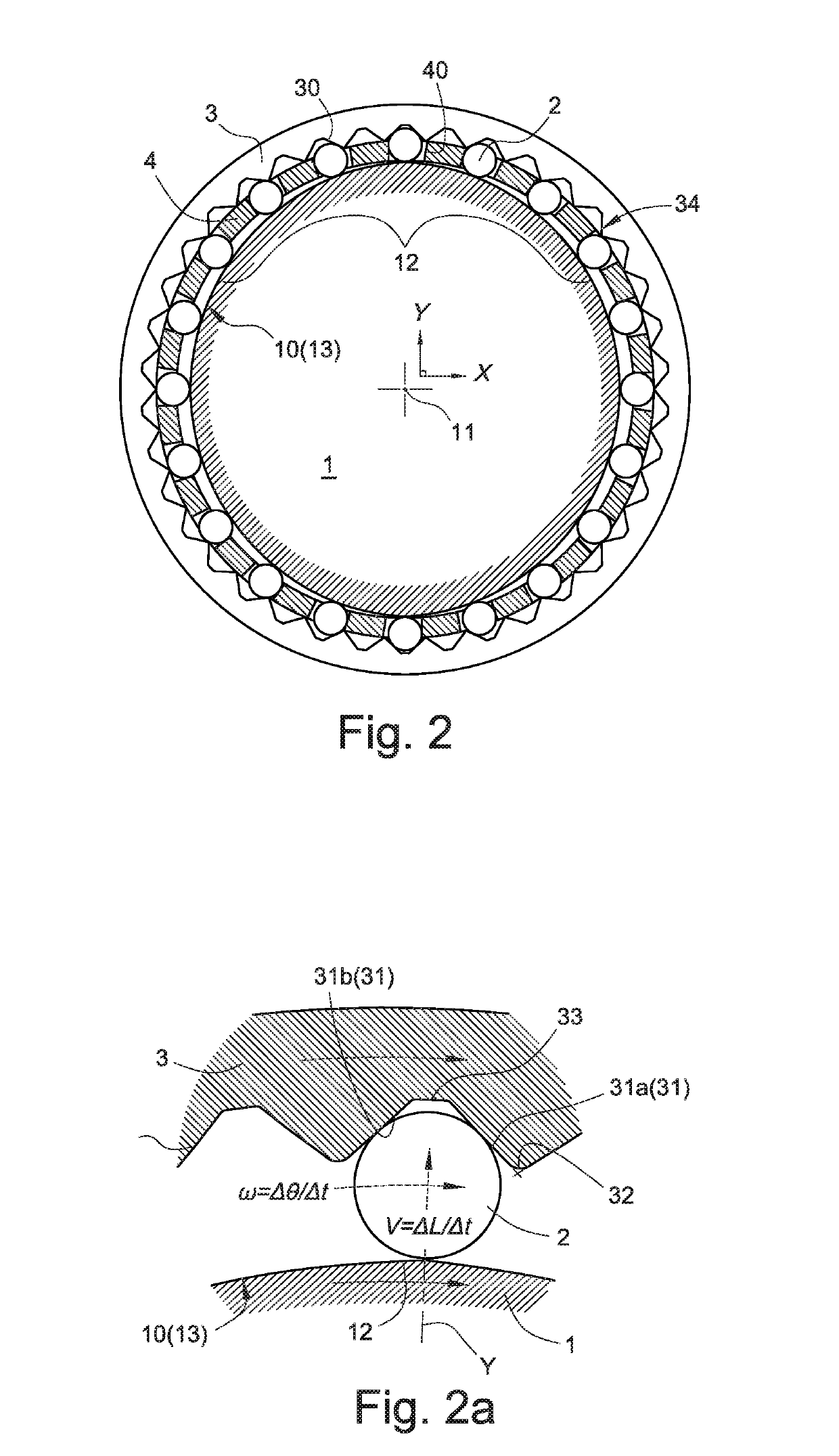

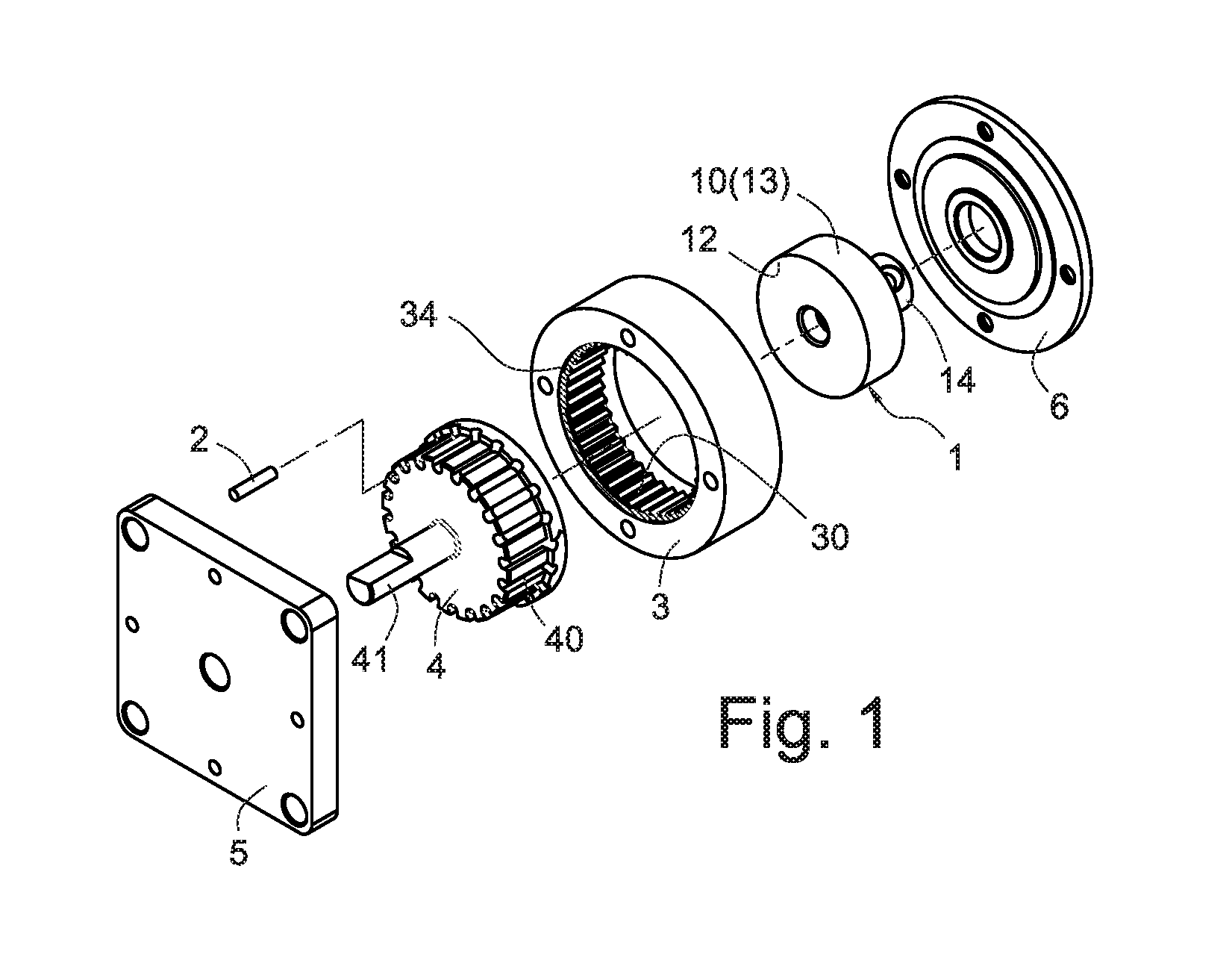

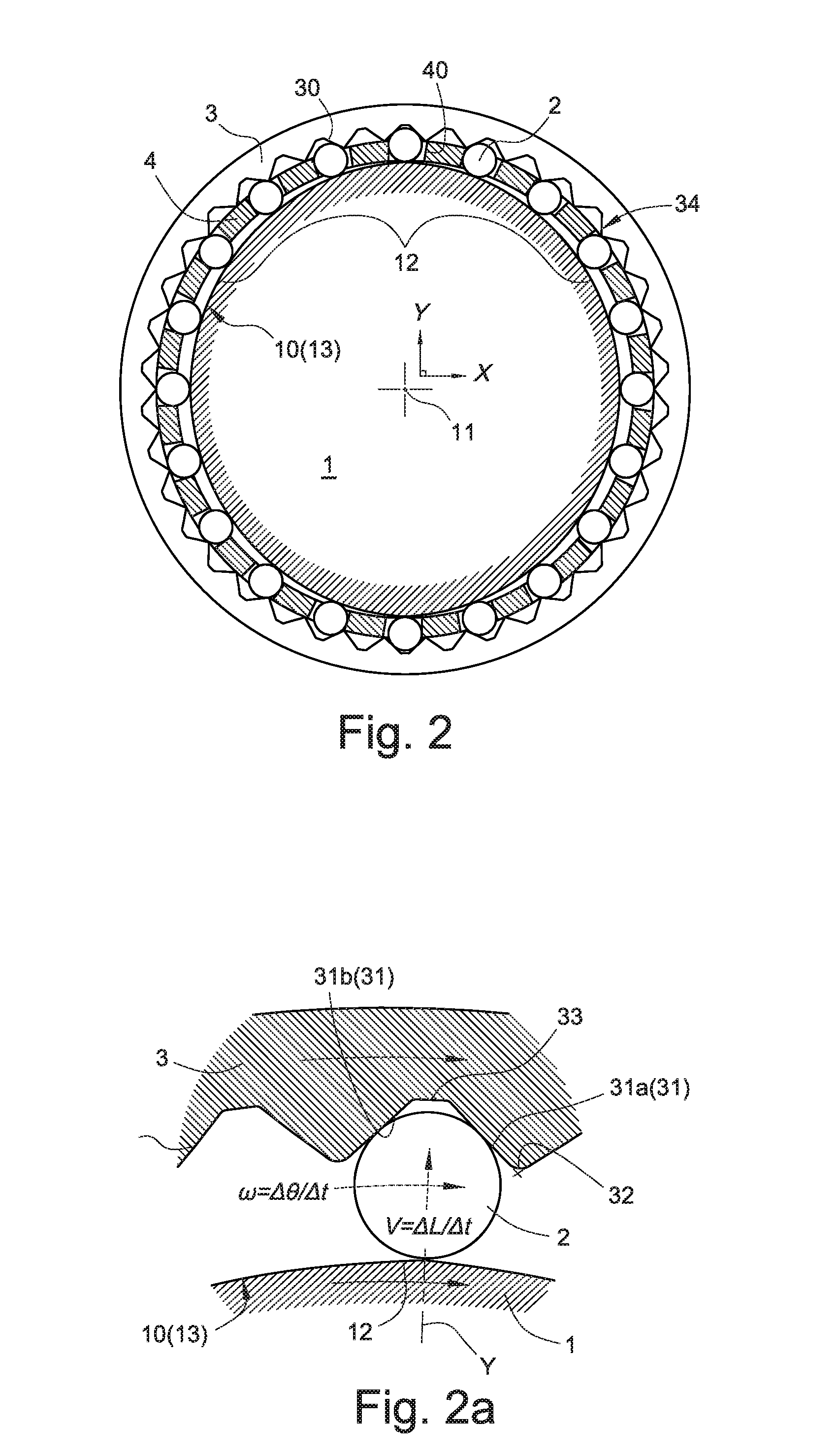

Wave speed reducer having self-locking function and compound type reducer device

InactiveUS9897189B2Improve accuracyImprove driving accuracyToothed gearingsReduction driveReduction ratio

Owner:PRODRIVES & MOTIONS +1

Wave Speed Reducer Having Self-locking Function And Compound Type Reducer Device

InactiveUS20170009867A1Improve accuracyImprove driving accuracyToothed gearingsReduction driveReduction ratio

The invention provides a wave speed reducer having a self-locking function comprising a structure for outputting driving rotation of a bearing member or a spline wheel at a specific reduction ratio which drives rollers to rotate by a cam. A designed convex arc of the cam has self-locking function of restricting the rollers to reversely rotate so as to form a compound type reducer device having a multi-reducer function by mutually combining the wave speed reducer and a planetary gear set. To solve conventional problems, poor driving accuracy at tiny rotation angle and scarcity of self-locking function for conventional reducers are improved.

Owner:PRODRIVES & MOTIONS +1

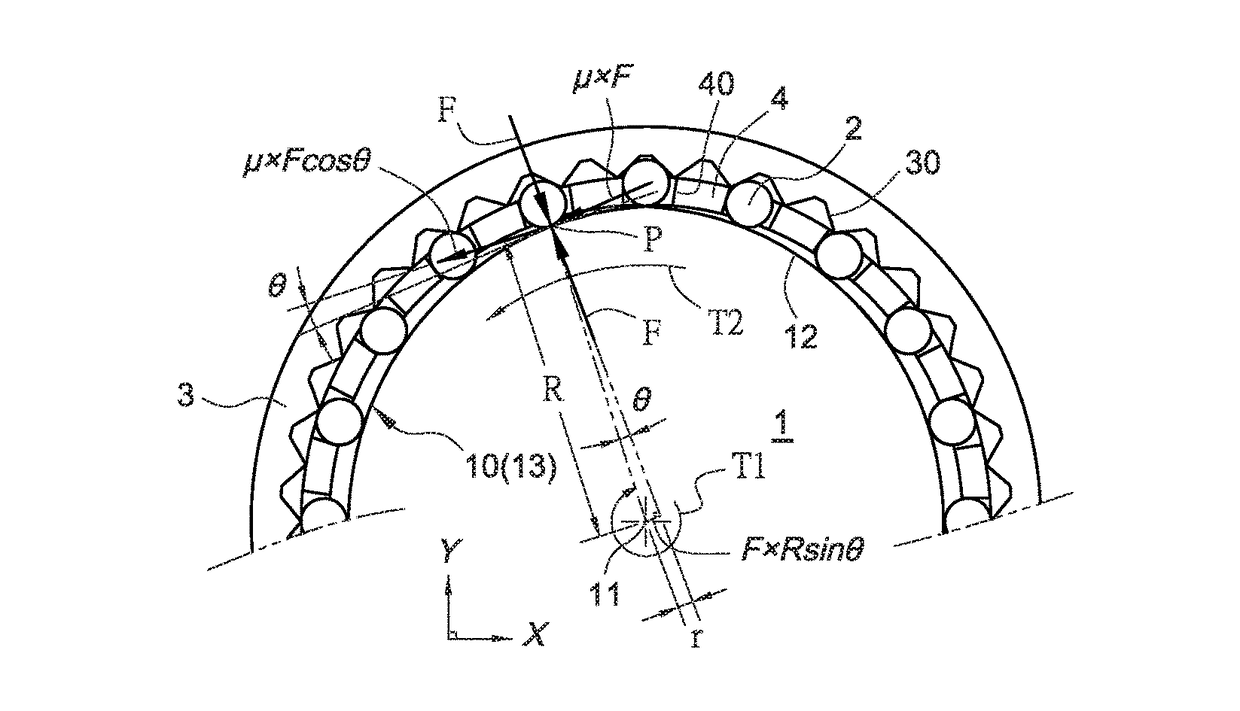

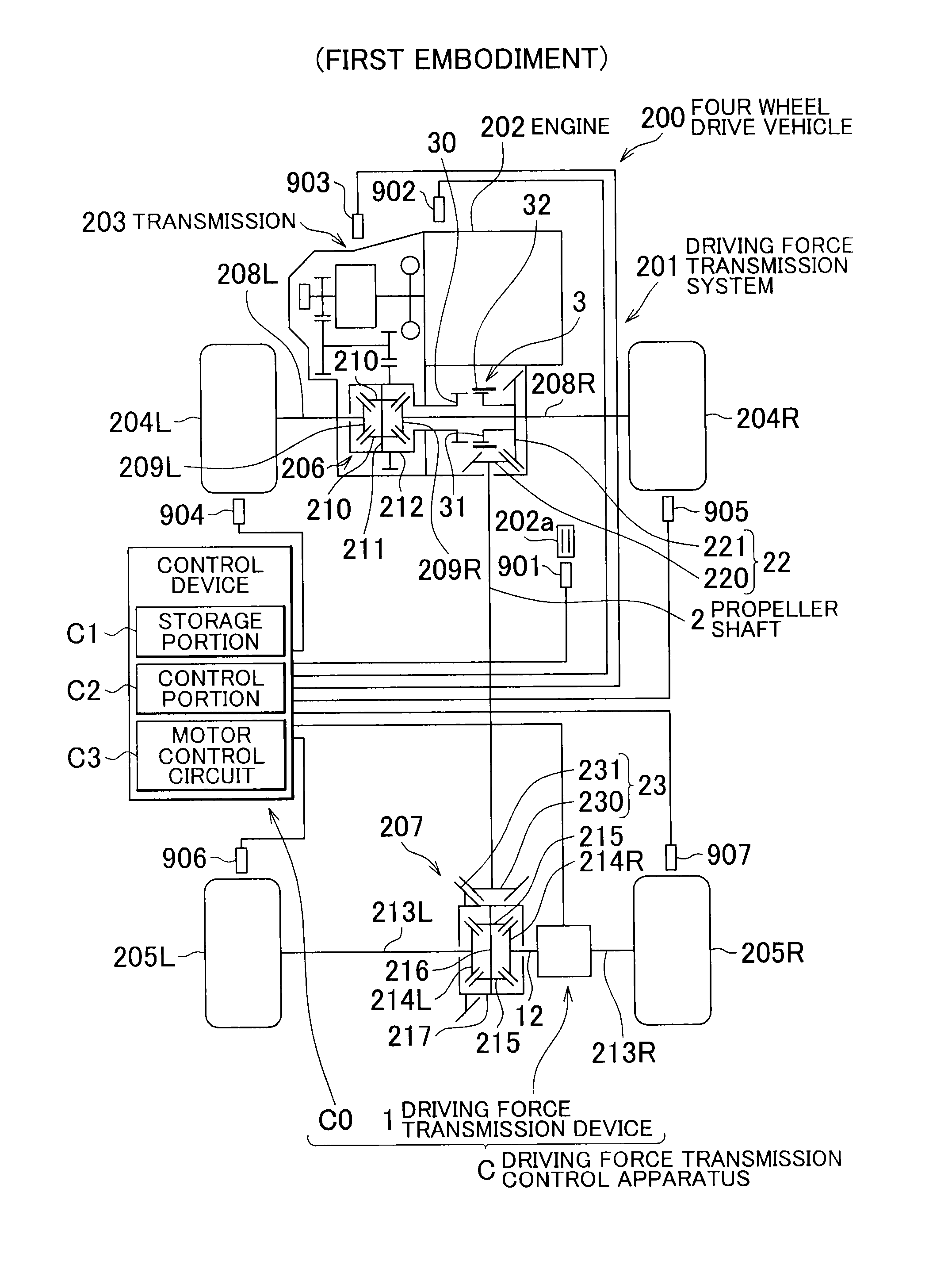

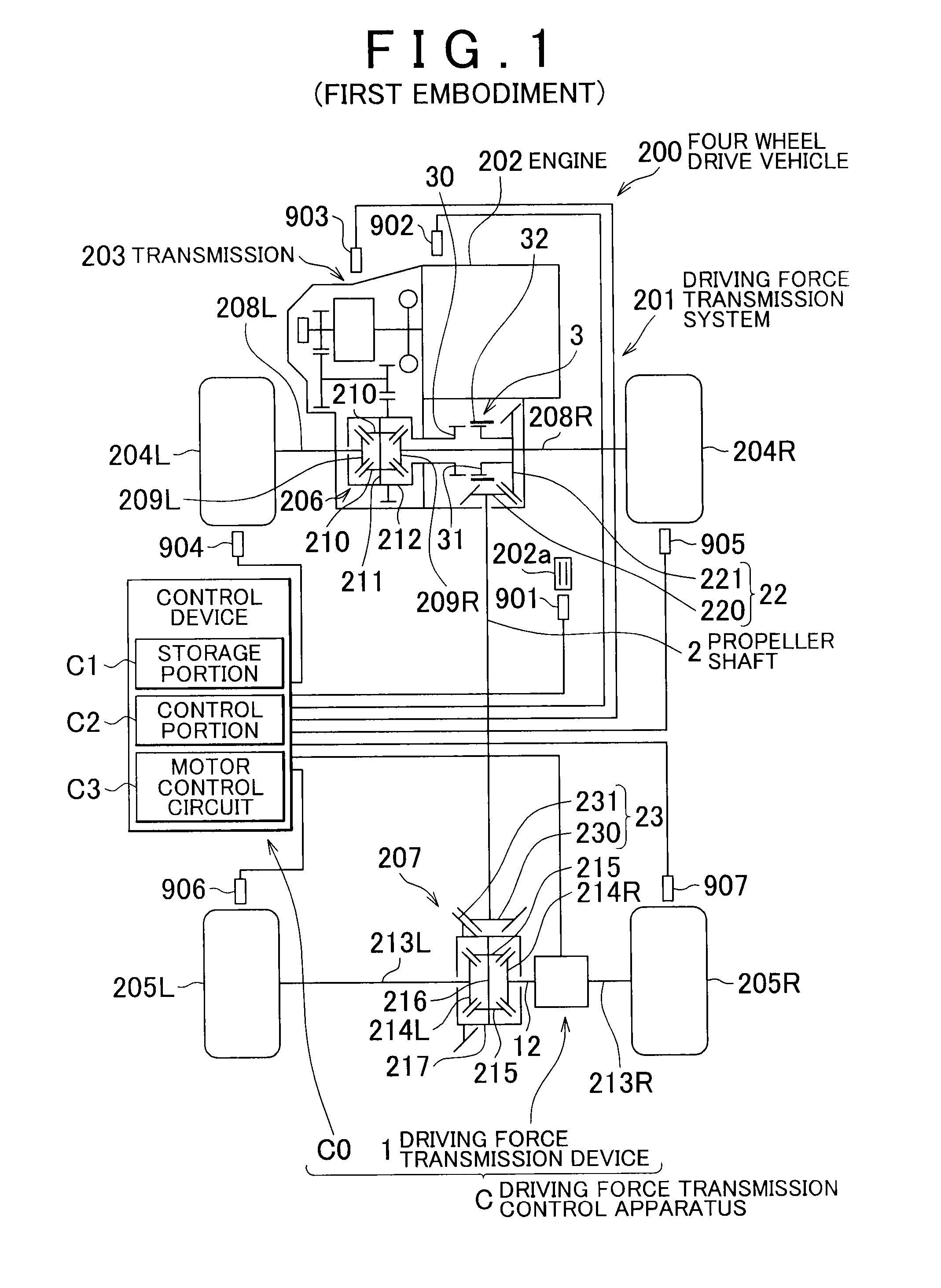

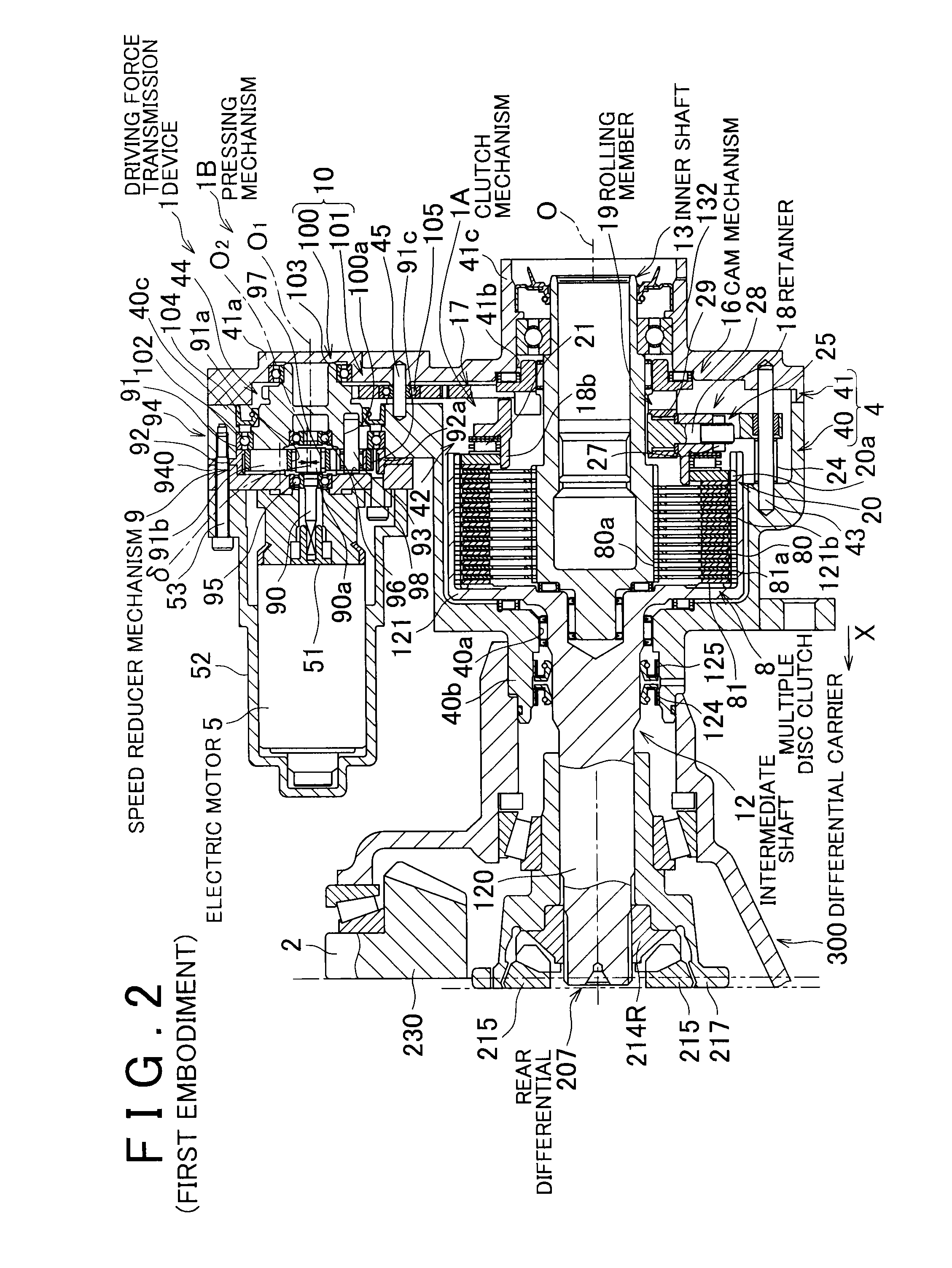

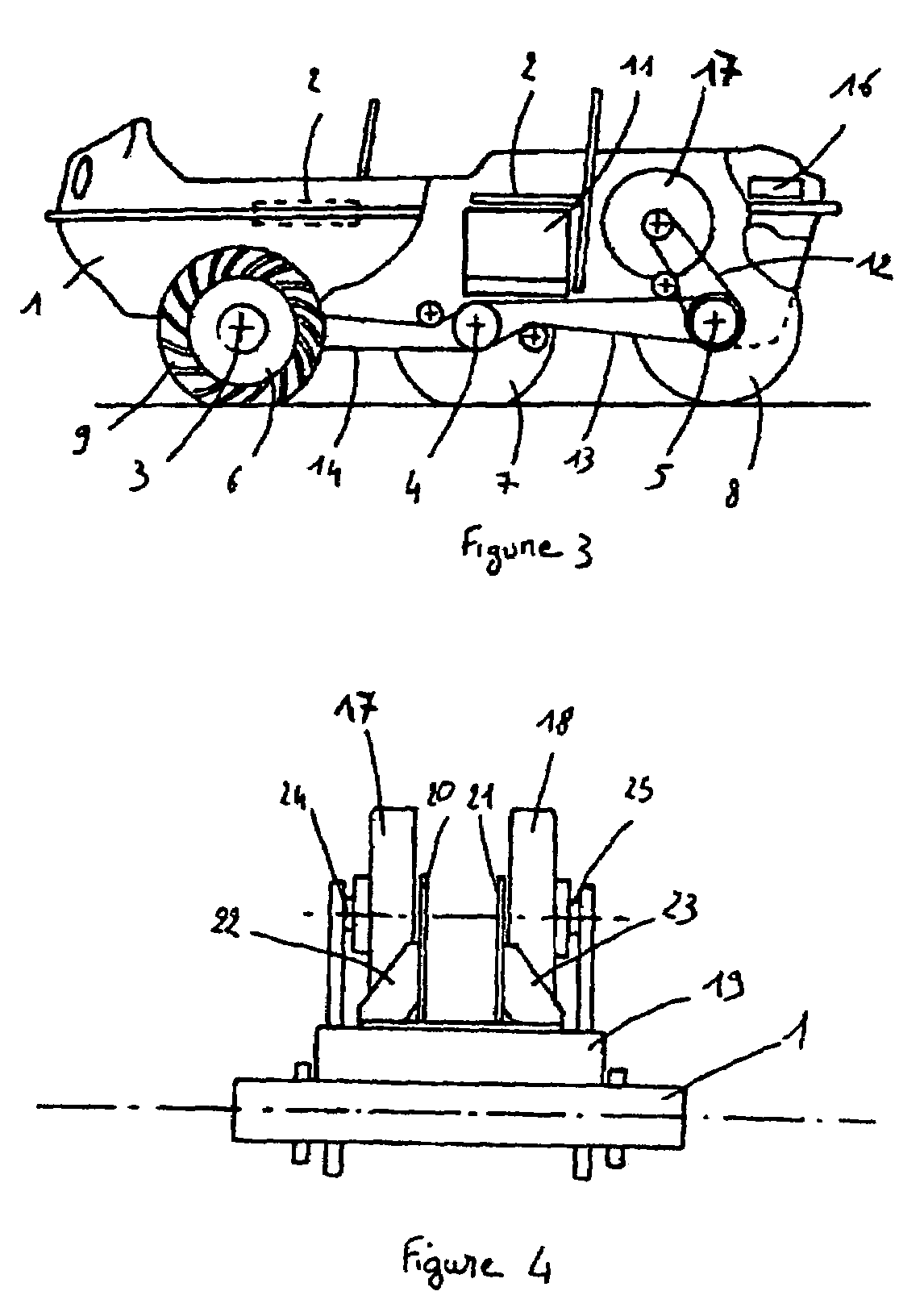

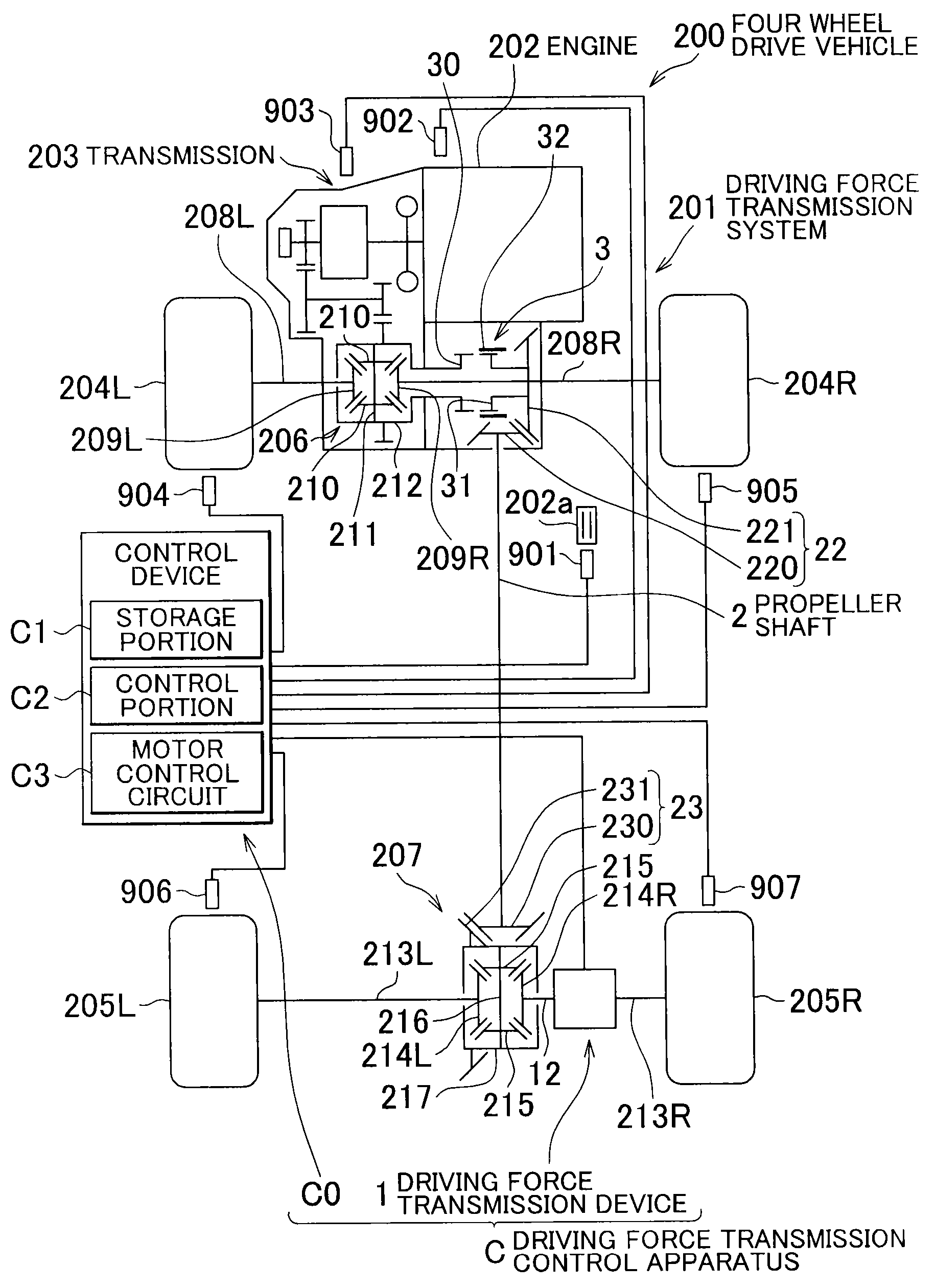

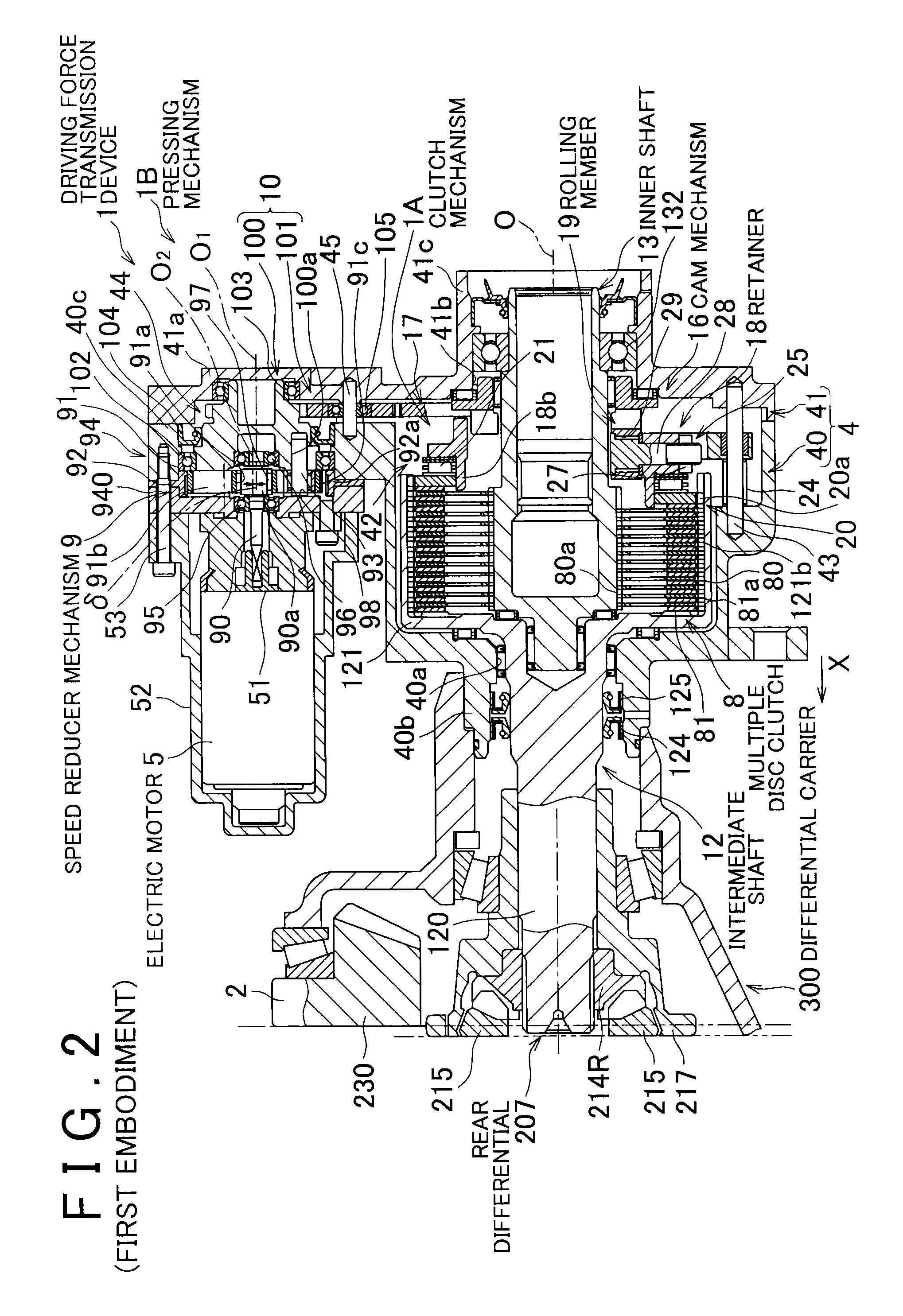

Driving force transmission control apparatus

ActiveUS20140163831A1Improve driving accuracyImprove accuracyDigital data processing detailsFriction clutchesEngineeringOperant conditioning

A driving force transmission control apparatus includes a multiple disc clutch including a plurality of outer clutch plates, and a plurality of inner clutch plates; a pressing mechanism that presses the multiple disc clutch; and a control portion that controls the pressing mechanism. The outer clutch plates and inner clutch plates are engaged with an intermediate shaft and an inner shaft respectively. The control portion makes a determination as to whether the multiple disc clutch is in a first operating condition in which the multiple disc clutch is pressed with a relative rotation speed between the intermediate and the inner shafts being equal to or higher than a predetermined value, or in a second operating condition in which the multiple disc clutch is pressed with the relative rotation speed being lower than the predetermined value, and the control portion controls the pressing mechanism based on a result of the determination.

Owner:JTEKT CORP

Electronic circuit, optoelectronic device, method for driving optoelectronic device, and electronic apparatus

ActiveUS20080068361A1Improve driving accuracyIncrease driving speedSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOpto electronic

An electronic circuit, an electronic device, and an electronic apparatus are provided that are capable of display with good quality and reducing operation delay, and a method to drive the electronic circuit. First and second switching transistors are turned on and an operation voltage Vdx and a data-current Idata are transmitted to a holding capacitor. The conduction state of a driving transistor is set according to an electrical-charge amount corresponding to the data-current Idata held in the holding capacitor and a current that passes the driving transistor is transmitted to an organic EL element. Then, a first switch is turned off, a second switch and the second switching transistor are turned on, and a reset voltage Vr is transmitted to the holding capacitor, whereby the driving transistor is turned off and the organic EL element stops emitting light.

Owner:BOE TECH GRP CO LTD

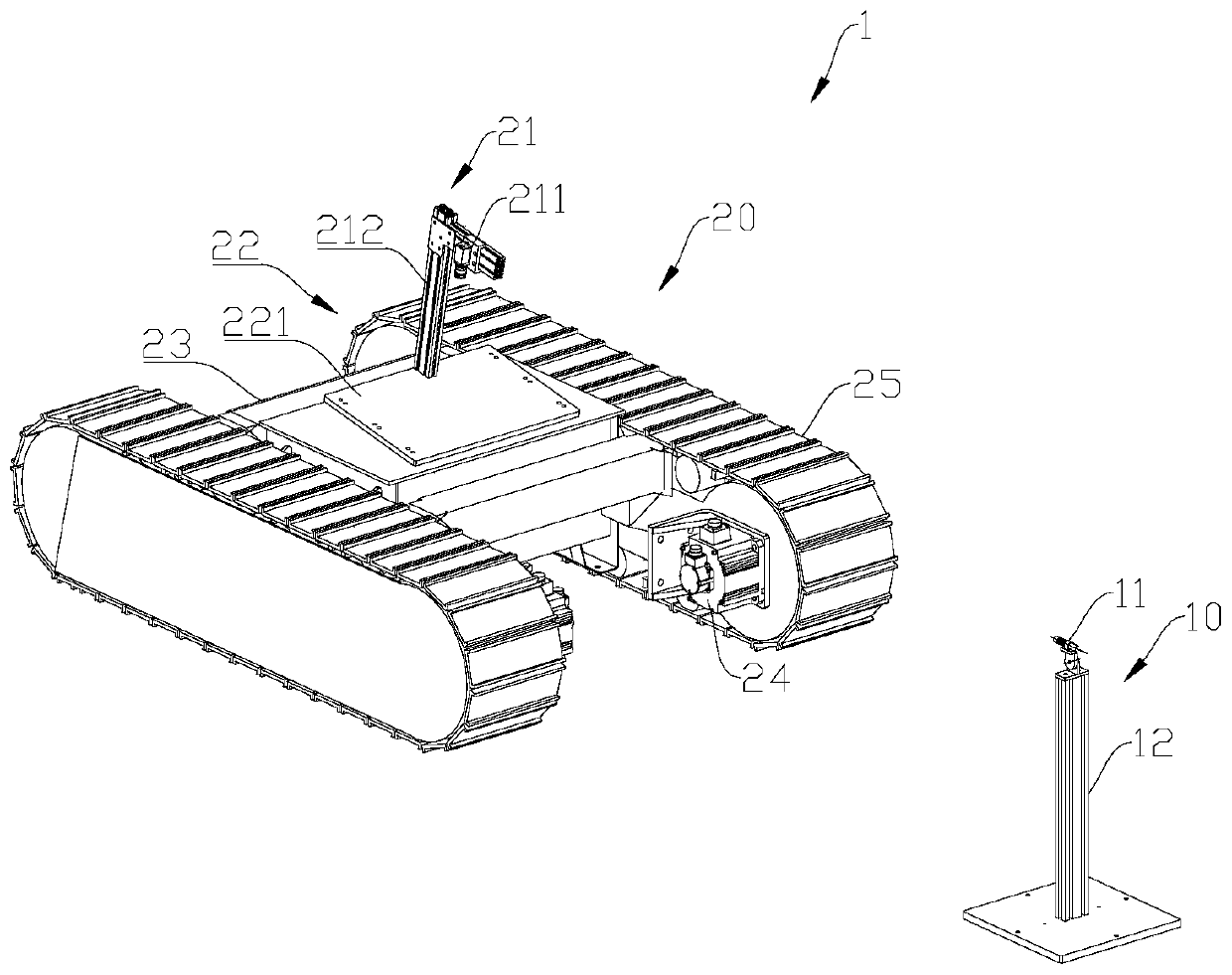

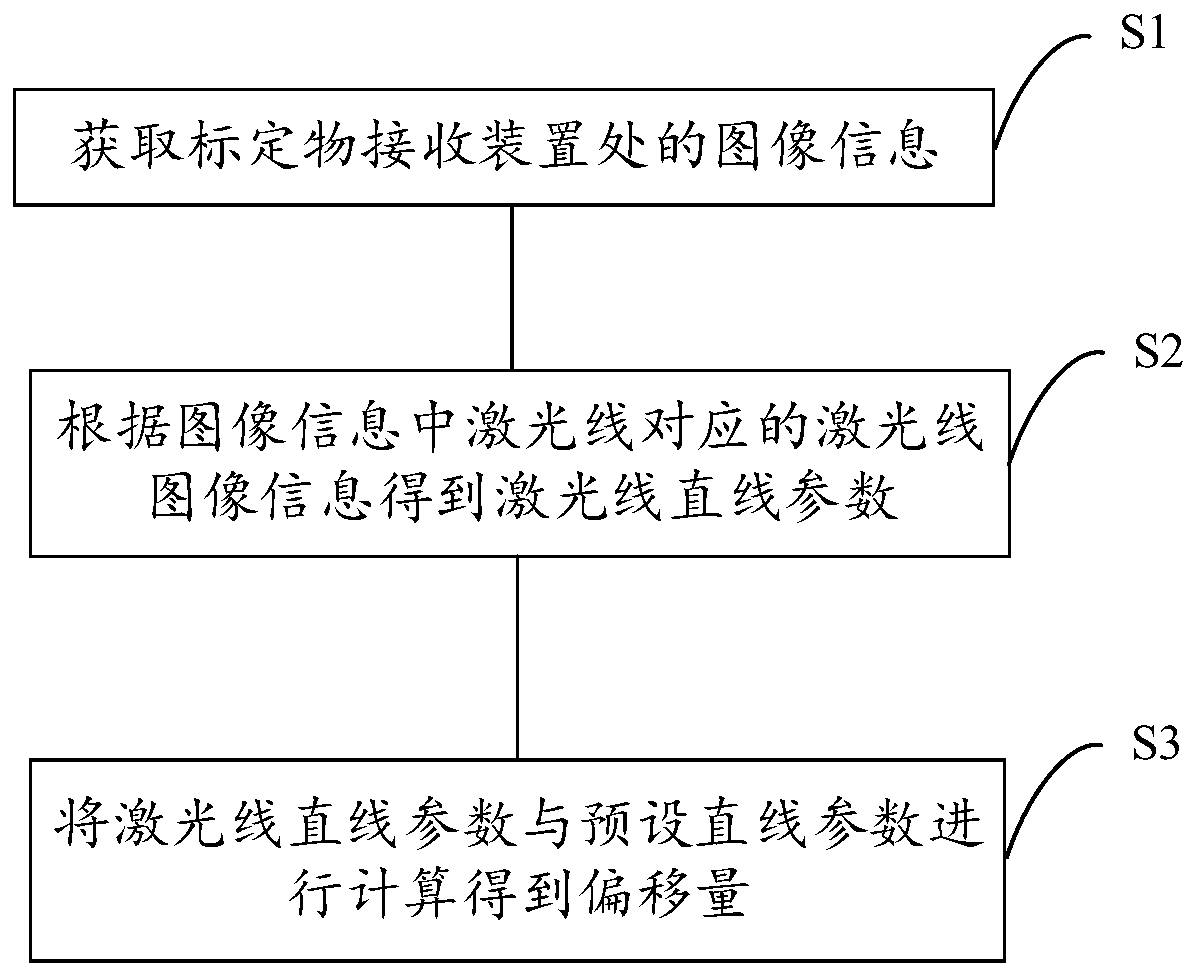

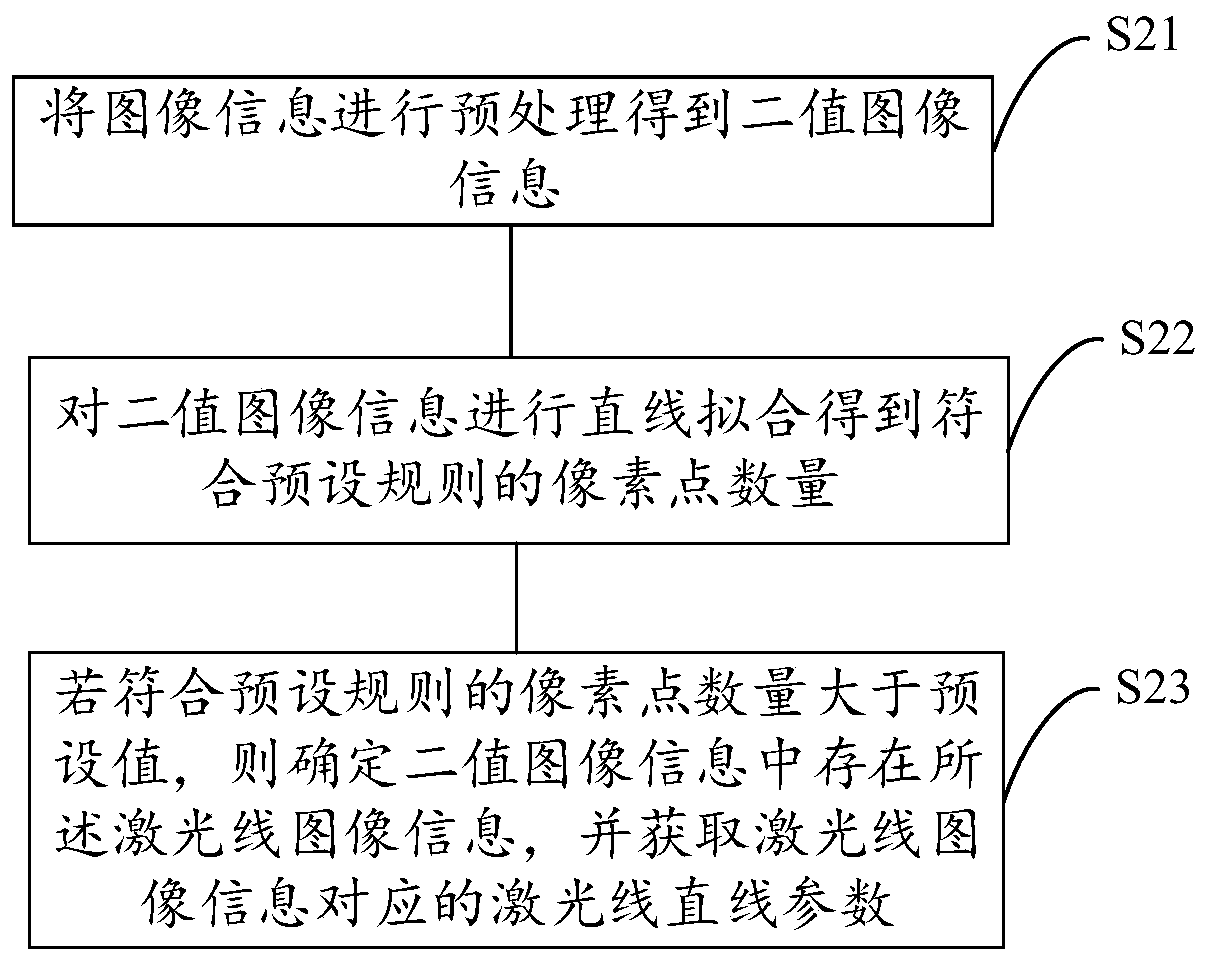

Offset calculation method and device, automatic driving control method and traveling mechanism

InactiveCN109709959ACorrect driving deviationImprove driving accuracyPosition/course control in two dimensionsElectricityVisual recognition

The embodiment of the invention, which relates to the technical field, provides an offset calculation method and device, an automatic driving control method and a traveling mechanism. The automatic driving control method is applied to the traveling mechanism. The traveling mechanism includes a visual recognition device, a calibration object receiving device and a controller; and the visual recognition device is electrically connected to the controller. The method comprises the following steps that: the calibration object receiving device receives projection of a laser line emitted by a calibration object transmitting device in a driving direction of the traveling mechanism; the visual recognition device obtains image information at the calibration object receiving device, acquires a laserline linear parameter according to the laser line image information corresponding to the laser line in the image information, and calculates the laser line linear parameter and a preset linear parameter to obtain an offset; and the controller receives the offset and controls the traveling mechanism to carry out traveling along a preset driving path based on the offset. With the automatic driving control method, the navigation accuracy of the traveling mechanism can be improved.

Owner:CHINA HEFEI TAIHE OPTOELECTRONICS TECH

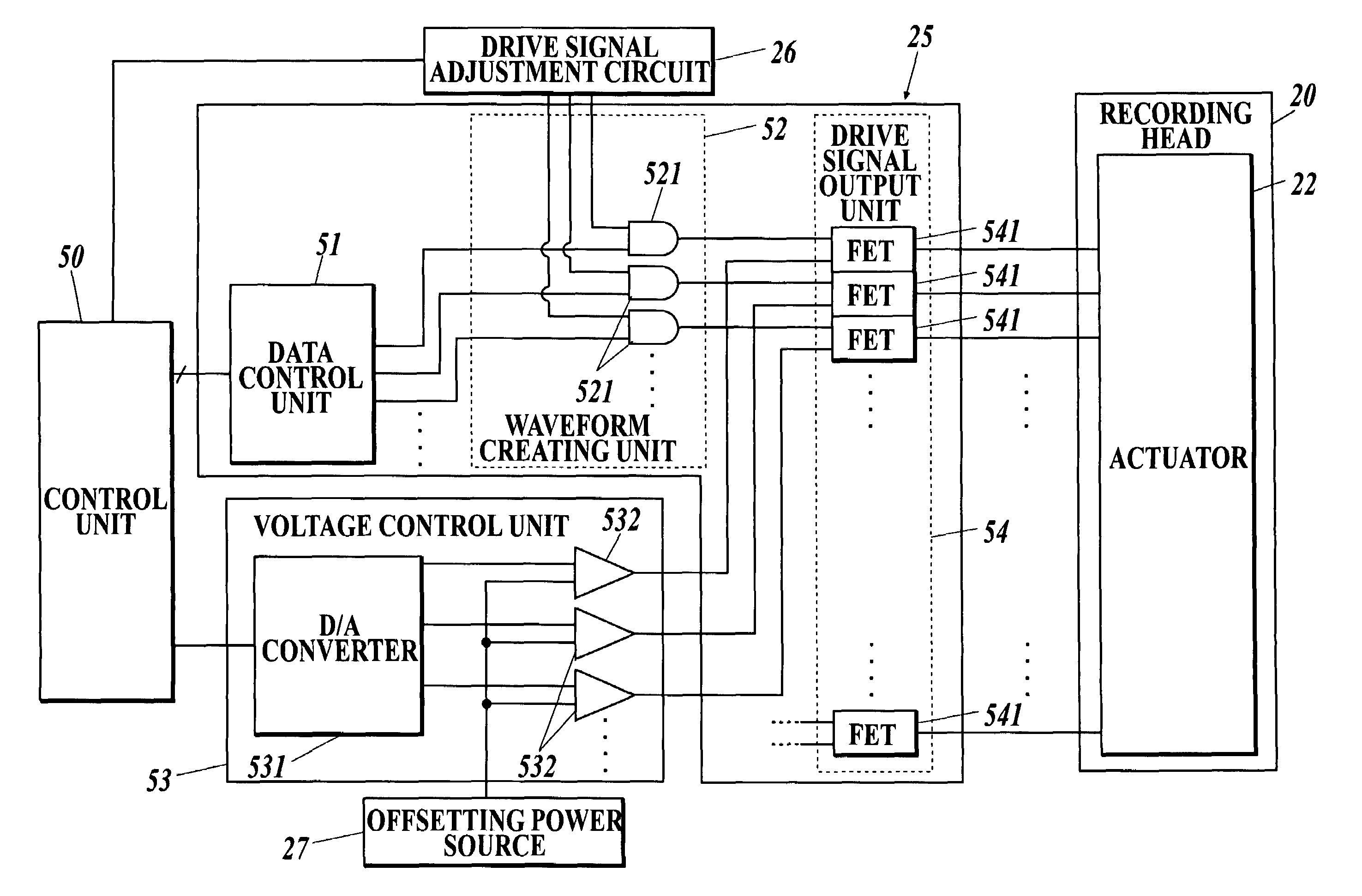

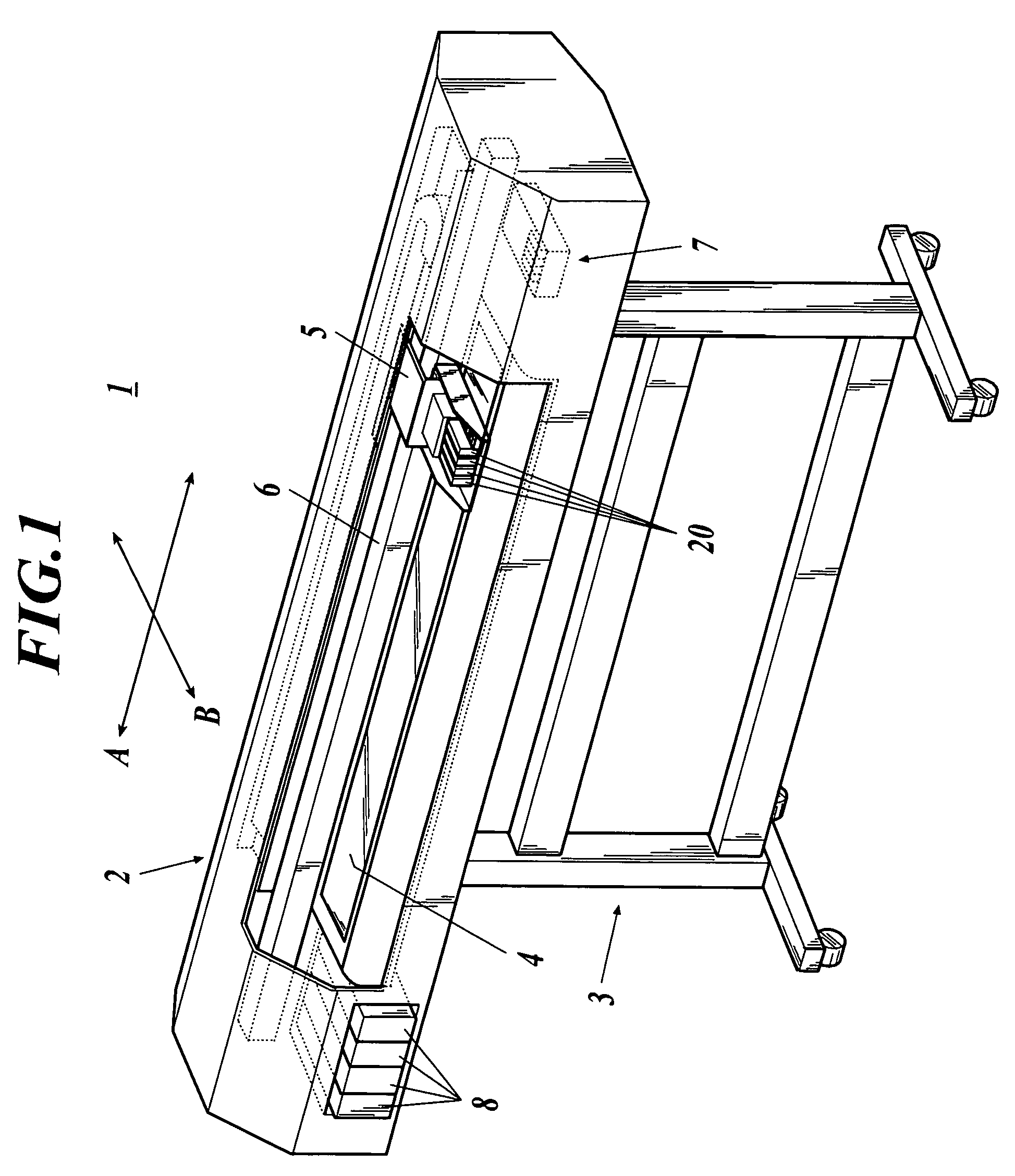

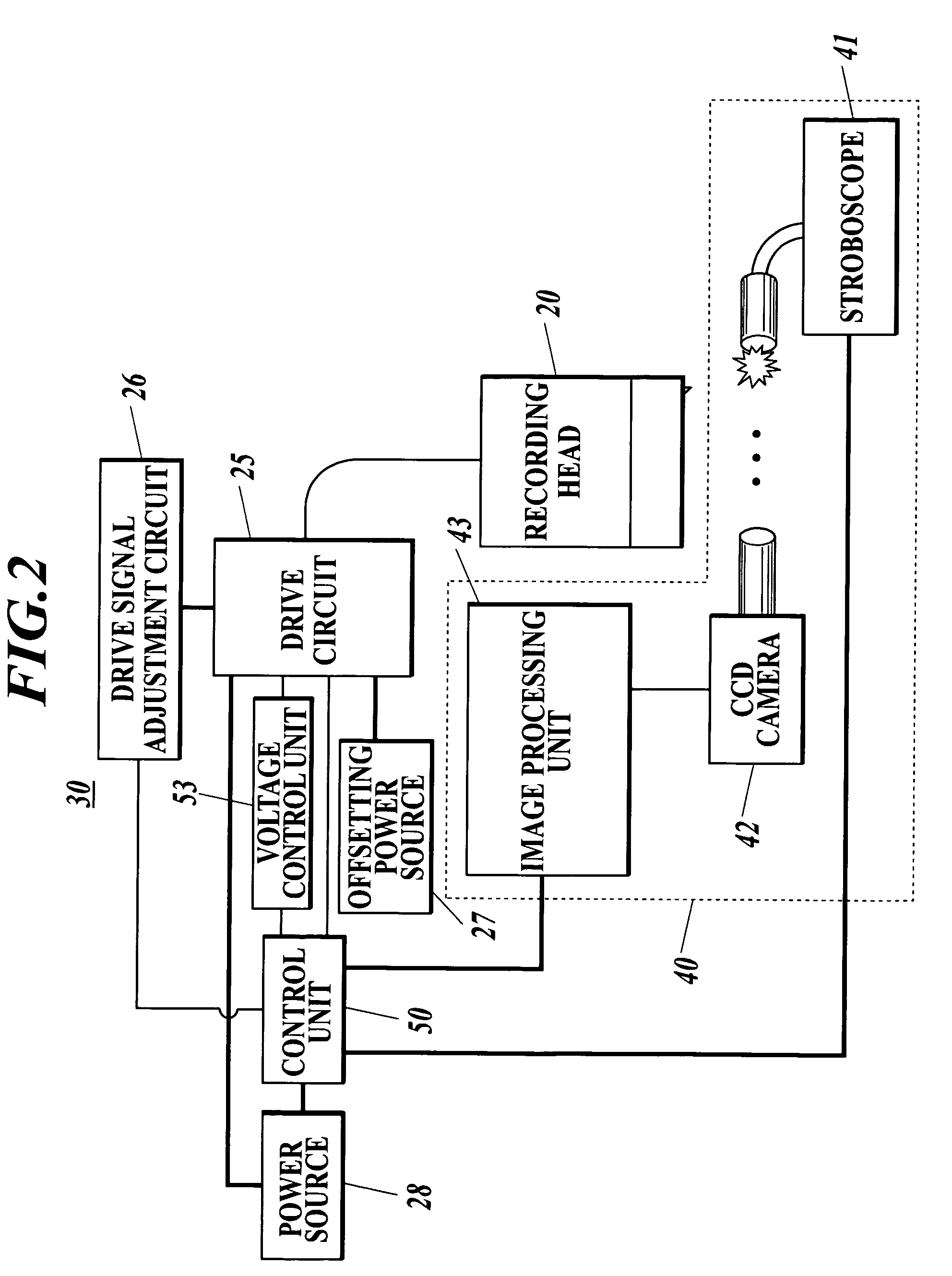

Liquid jetting device and drive voltage correction method

ActiveUS7287821B2Improve image qualityImprove driving accuracyInking apparatusOther printing apparatusLiquid jetVoltage regulation

A liquid jetting device having: a recording head including a jetting energy generating element; a drive circuit generating drive signal for the element; a liquid detection sensor detecting a jetting characteristic value of liquid jetted from a nozzle; a drive voltage adjustment unit adjusting a voltage value of the drive signal; and a controller to control the drive circuit, the sensor and the drive voltage adjustment unit, wherein the controller performs control so that the liquid is jetted, and creates a correction data from the jetting characteristic value; and the controller performs control so that the voltage value is corrected based on a value obtained by multiplying the correction data by convergence coefficient within a range from 0.50 or more to less than 1.00, and repeats correcting the voltage value until a detection result of the liquid jetted based on the drive signal after the correction becomes a target value.

Owner:KONICA MINOLTA INC

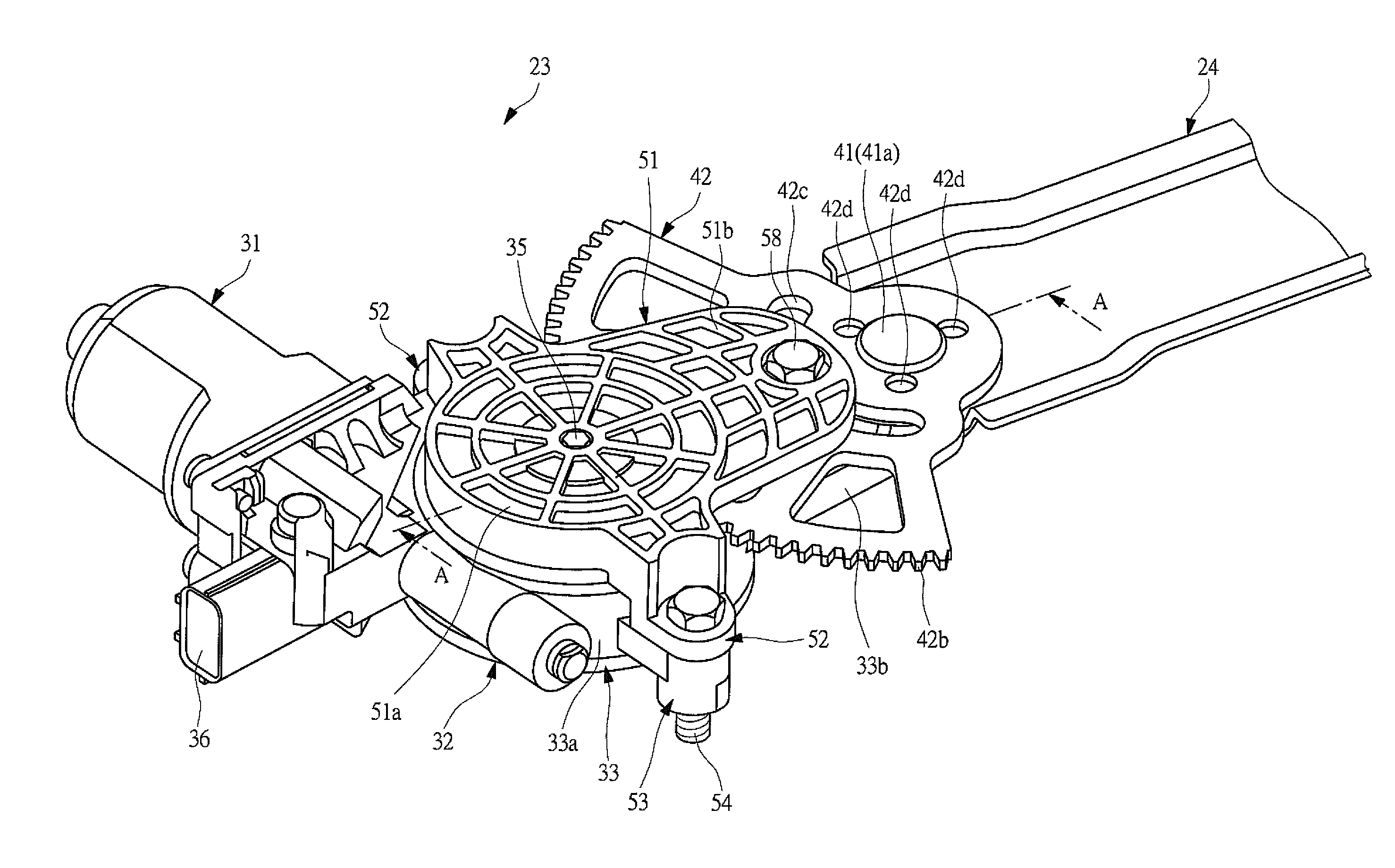

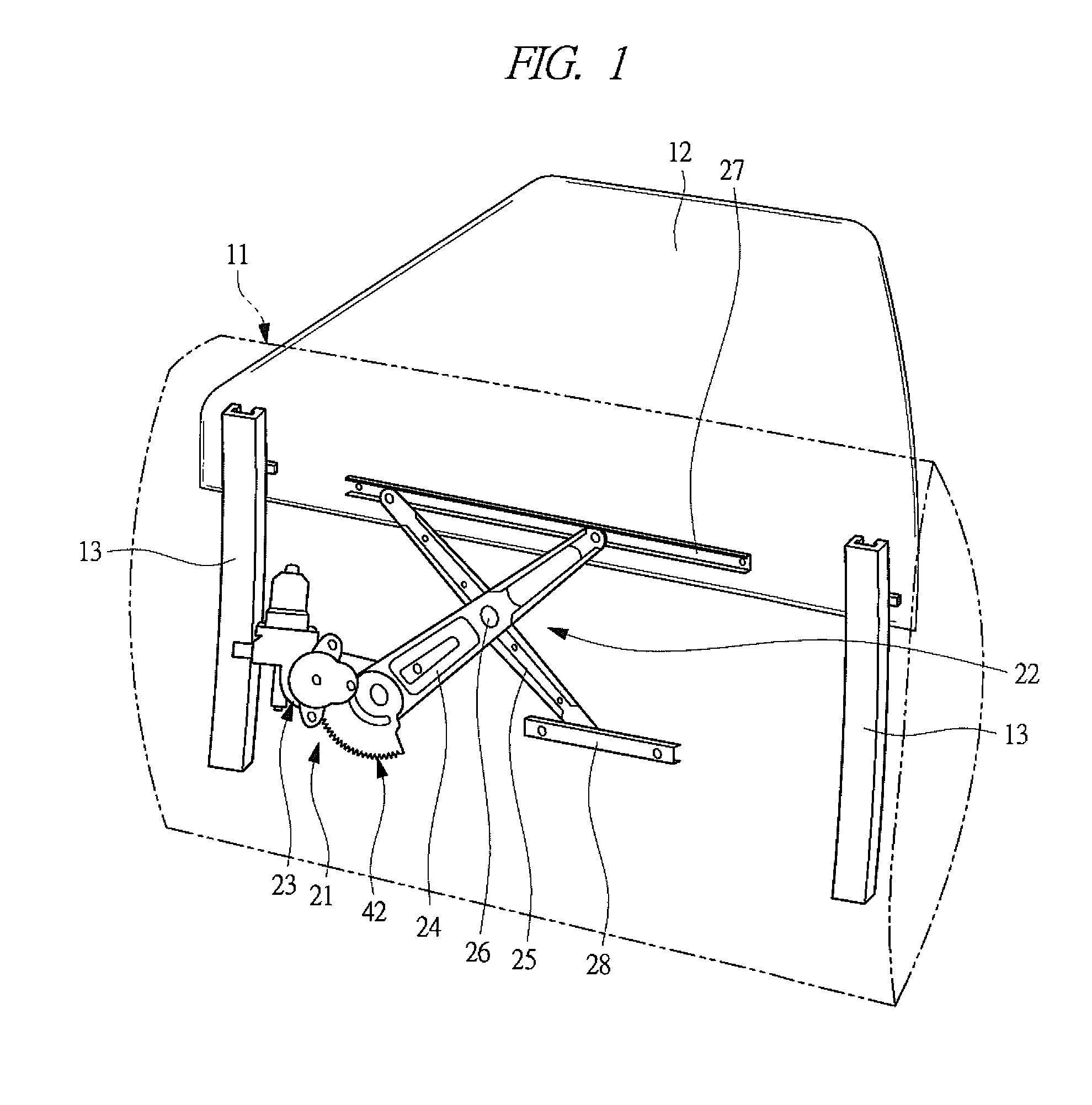

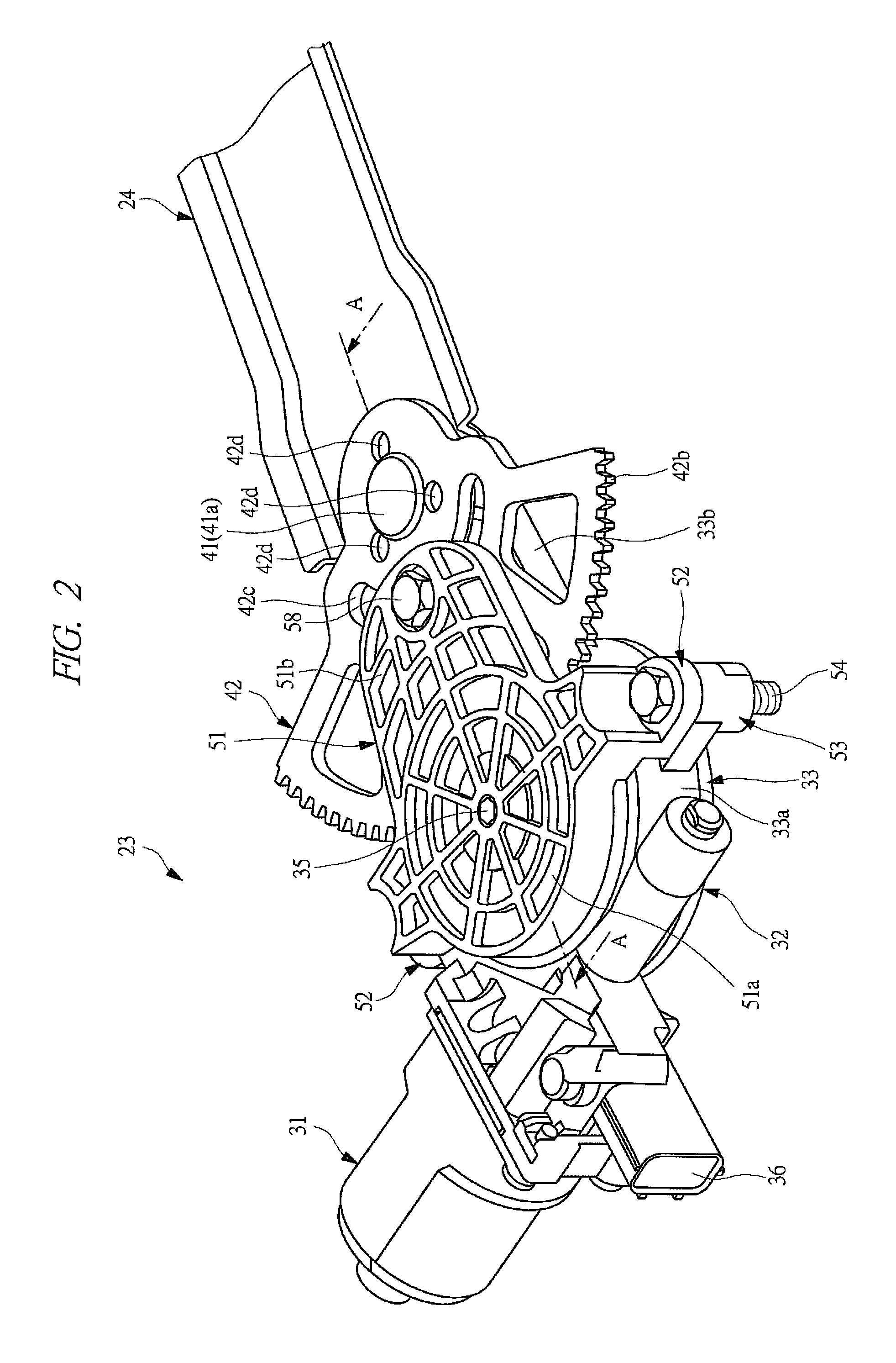

Automatic opening and closing apparatus for vehicle

ActiveUS20110023369A1Improve driving accuracyImprove accuracyMan-operated mechanismPower-operated mechanismEngineeringReducer

A speed reducer (32) including a gear case (33) is attached in an electric motor, and a pinion is provided to an output shaft (35) protruding from the gear case (33). A base portion (33a) protruding in a diametrical direction is provided to the gear case (33) and a support shaft is mounted to the base portion (33b). A sector gear (42) is fixed to a base end of a lift arm (24), and the sector gear (42) is swingably supported by the support shaft and meshed with the pinion. In addition, a groove portion (42c) in a circular arc shape is provided to the sector gear (42), and a gear cover (51) is fixed to the gear case (33) by a bolt (58) penetrating the groove portion (42c) and a bolt (54) disposed on an outer periphery side than the sector gear (42), and the gear cover (51) covers a mesh portion of the pinion and the sector gear (42) and presses the sector gear (42) toward the gear case (33).

Owner:MITSUBA CORP +1

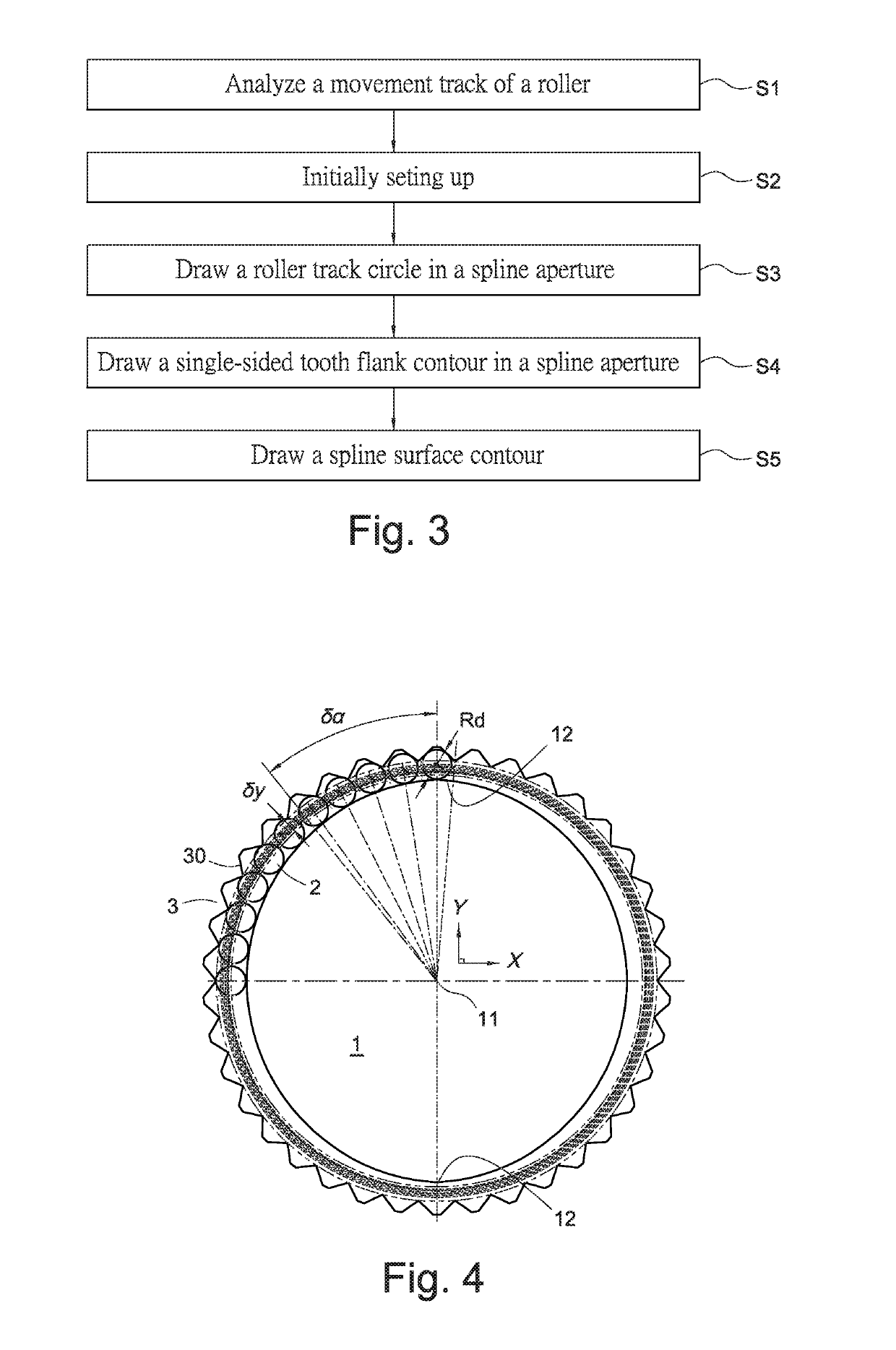

Method of designing member of spline wheel contour, spline surface contour and cam periphery of roller-type wave-motion

ActiveUS10267403B2Increased formationImprove the circumferenceGearingPortable liftingRadial motionClassical mechanics

Owner:PRODRIVES & MOTIONS +1

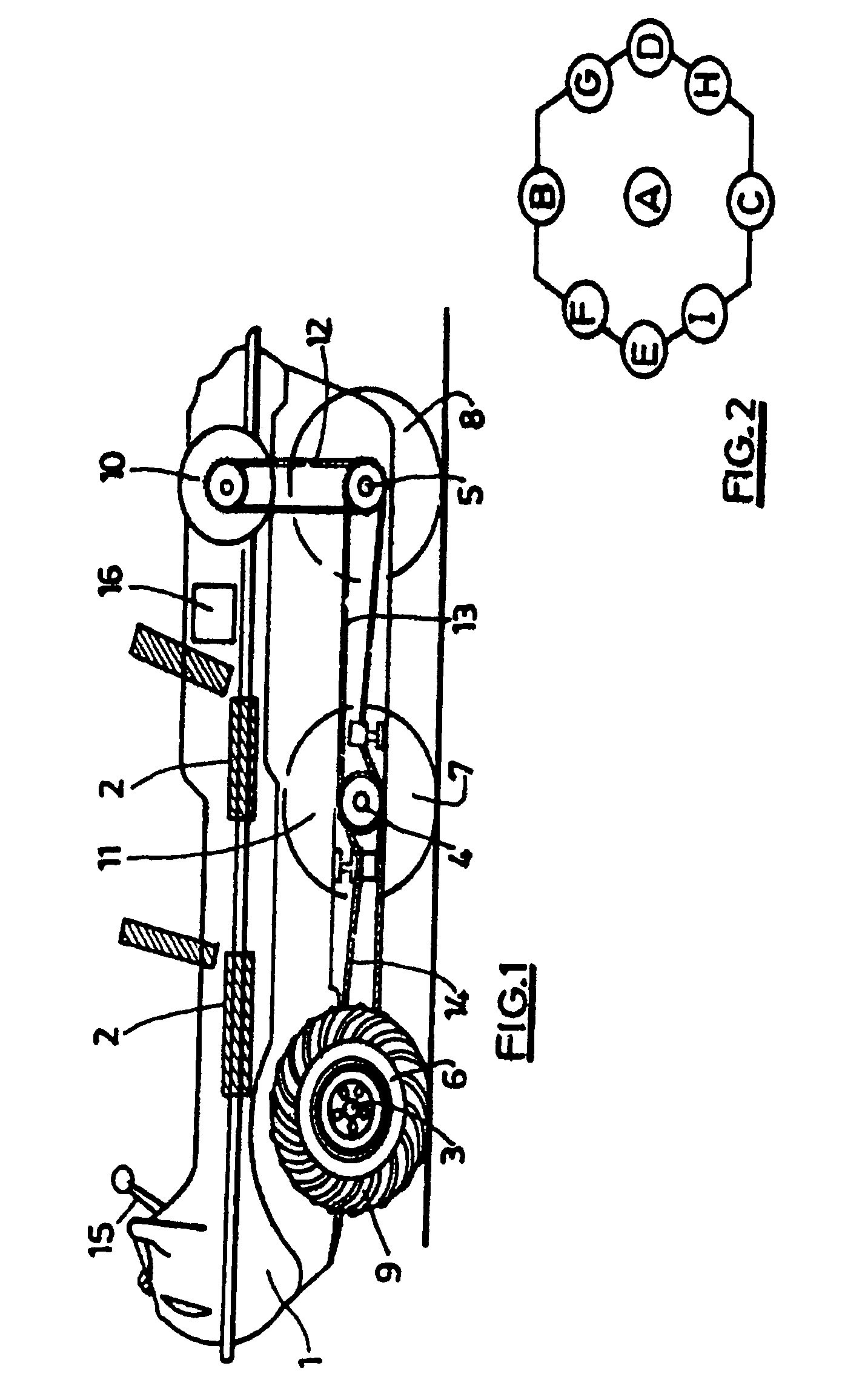

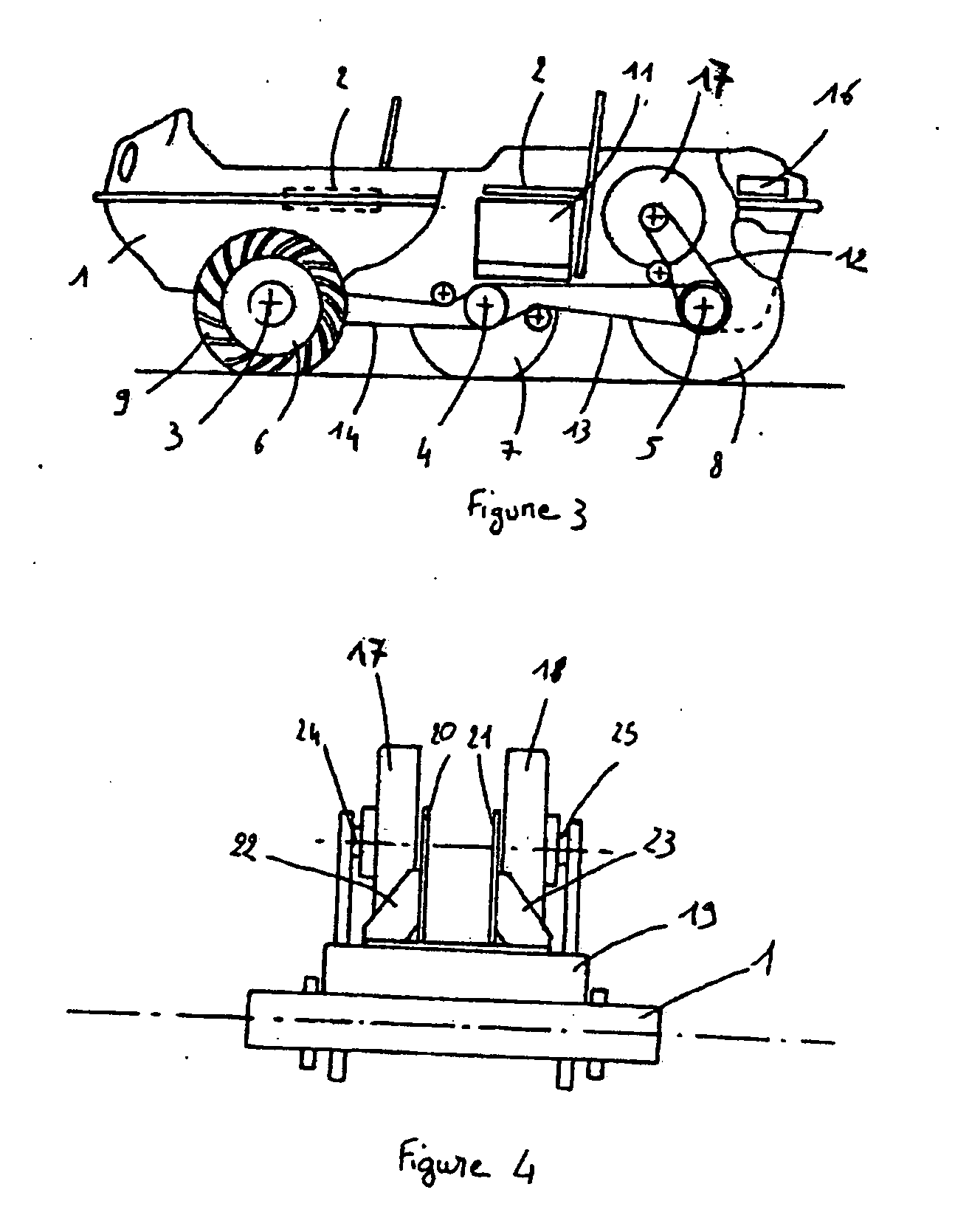

Amphibious off-road vehicle

InactiveUS7211983B2Reduce noise levelImprove mobilitySynchronous motors startersAC motor controlControl signalBuggy vehicle

Owner:HEULIEZ SA

Driving force transmission control apparatus

ActiveUS9243673B2Improve driving accuracyImprove accuracyFriction clutchesElectrically actuated clutchesEngineeringOperant conditioning

Owner:JTEKT CORP

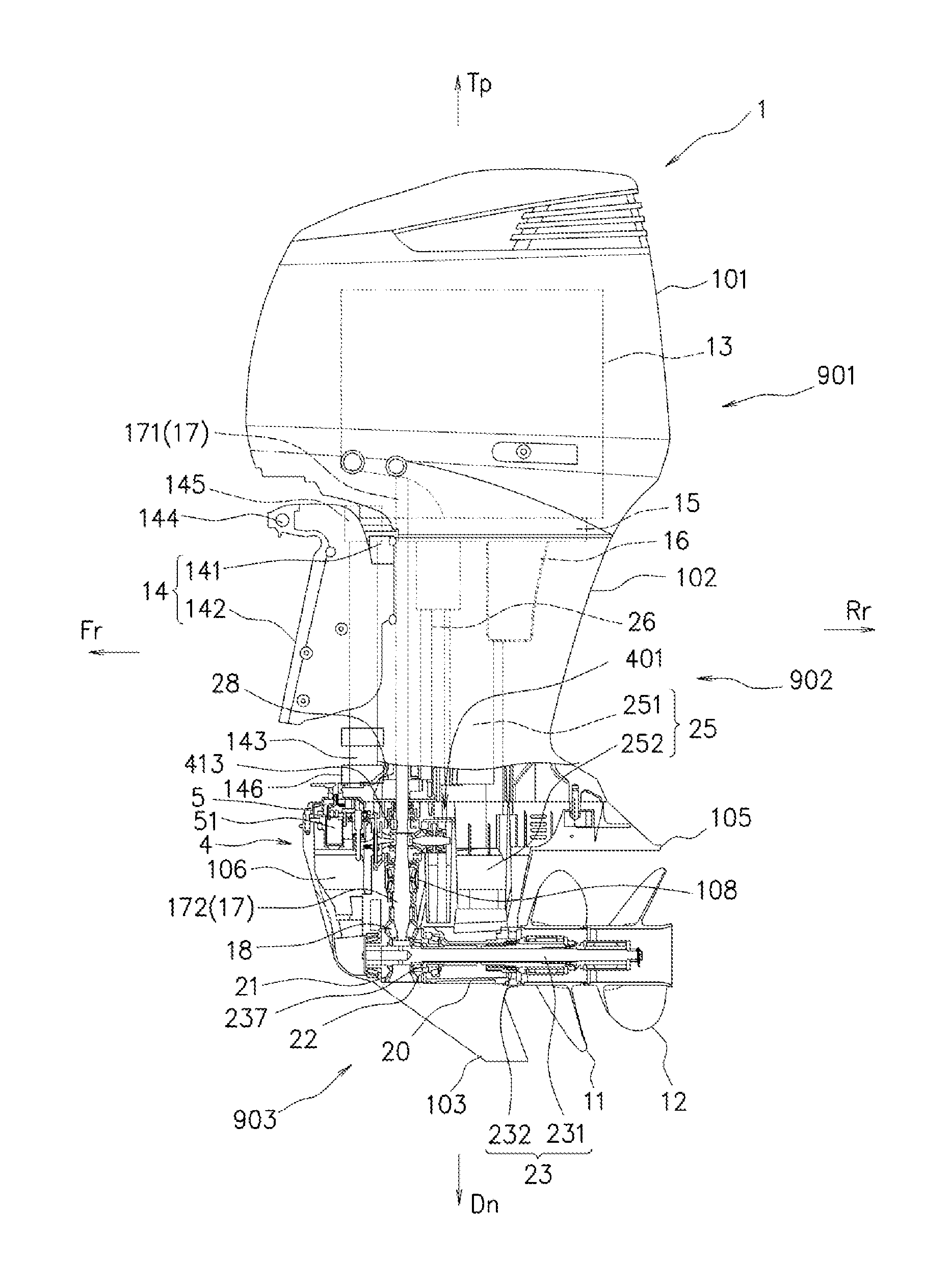

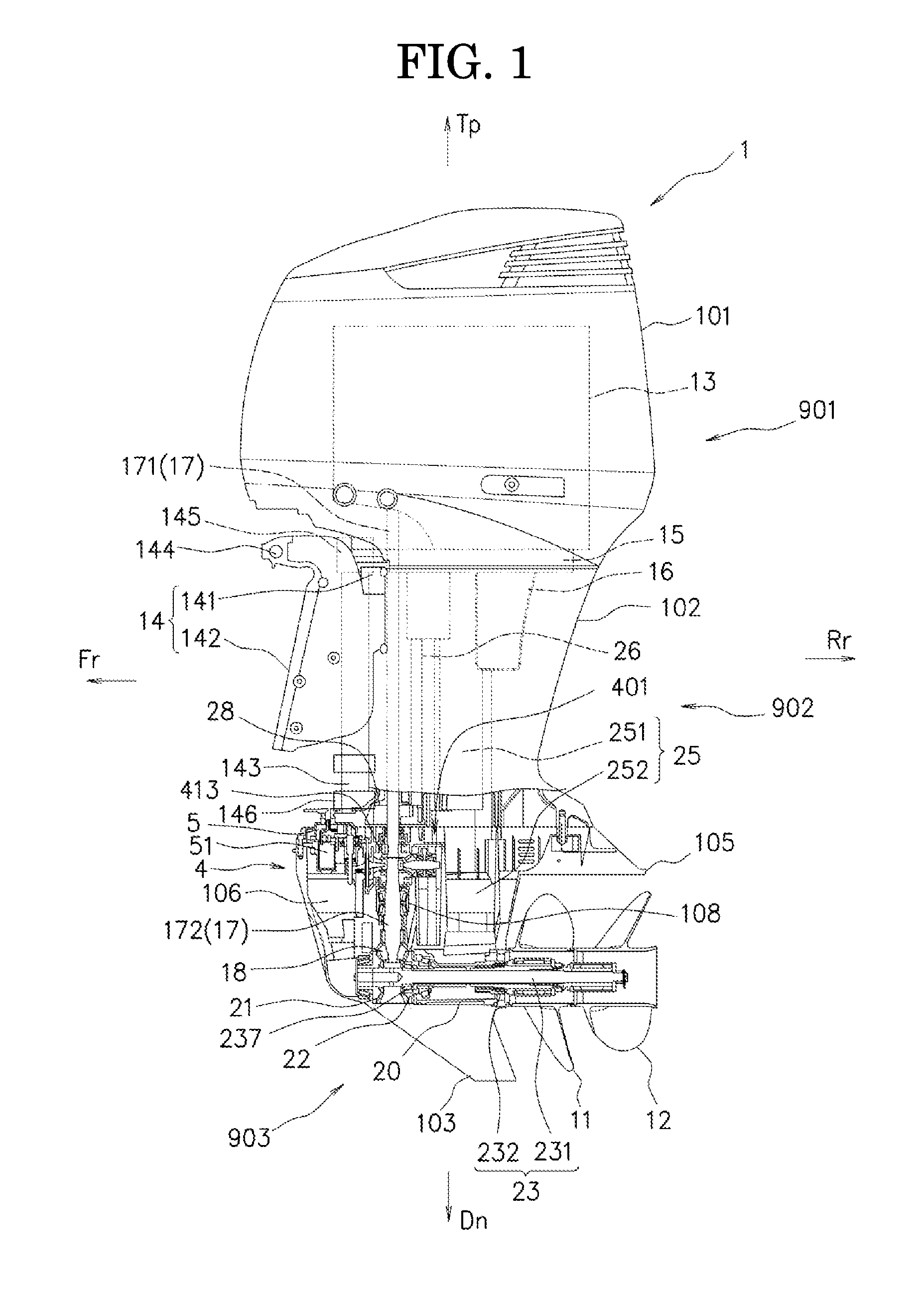

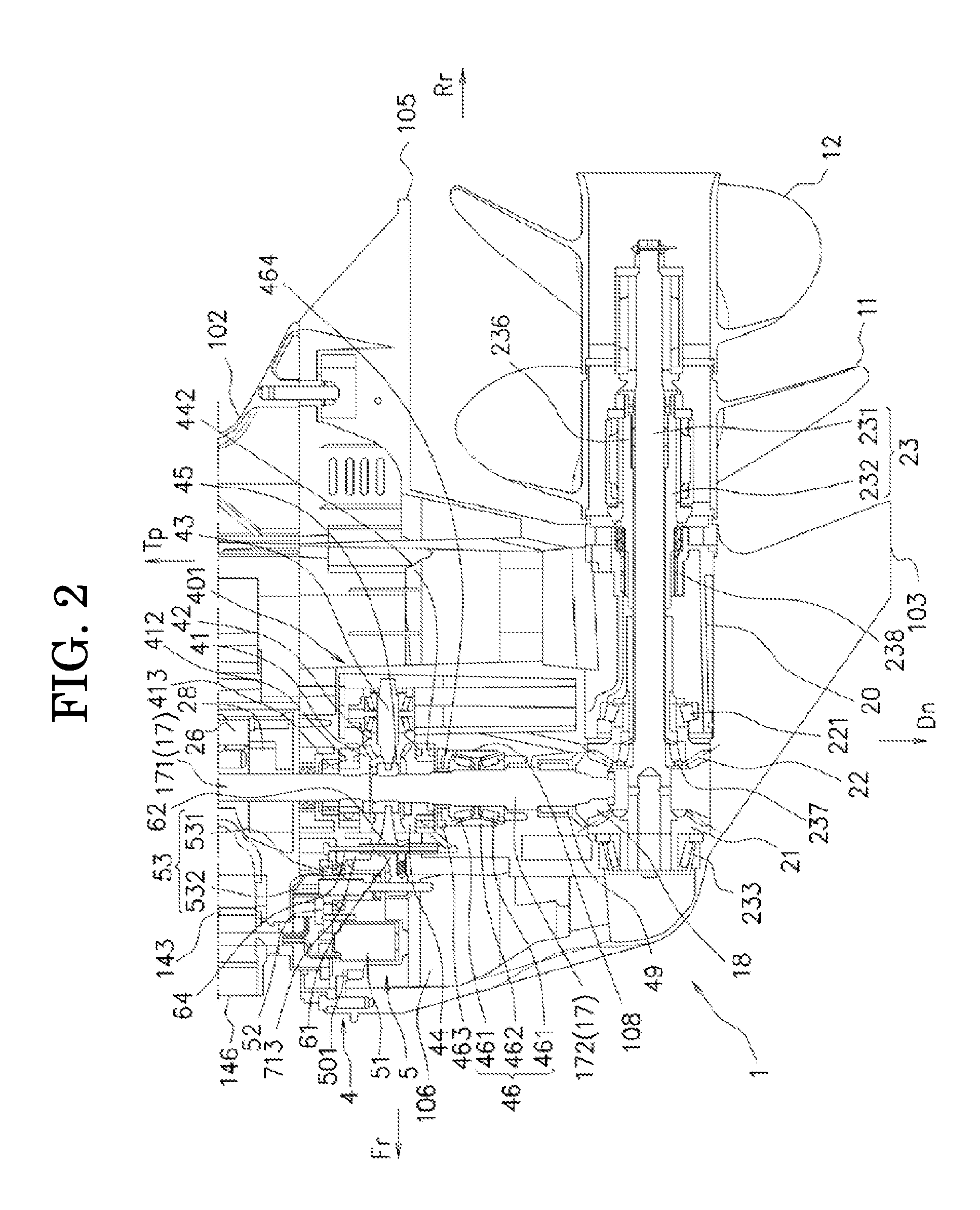

Outboard motor

ActiveUS9475562B2Improve driving accuracyPropulsion power plantsOutboard propulsion unitsLinear motionDrive shaft

An outboard motor includes a drive shaft that transmits rotational power from the engine, and a shift unit provided in the middle of the drive shaft. The shift unit has a dog clutch that reciprocates in parallel with the drive shaft, a shift fork member that reciprocates the dog clutch in parallel with the drive shaft, and a linear motion type actuator that reciprocates the shift fork member in parallel with the drive shaft. The actuator is arranged in the vicinity of the front side of the dog clutch such that the direction of the rectilinear motion of the screw shaft is in parallel with the axial line of the drive shaft, and the shift fork member is connected to the screw shaft.

Owner:SUZUKI MOTOR CORP

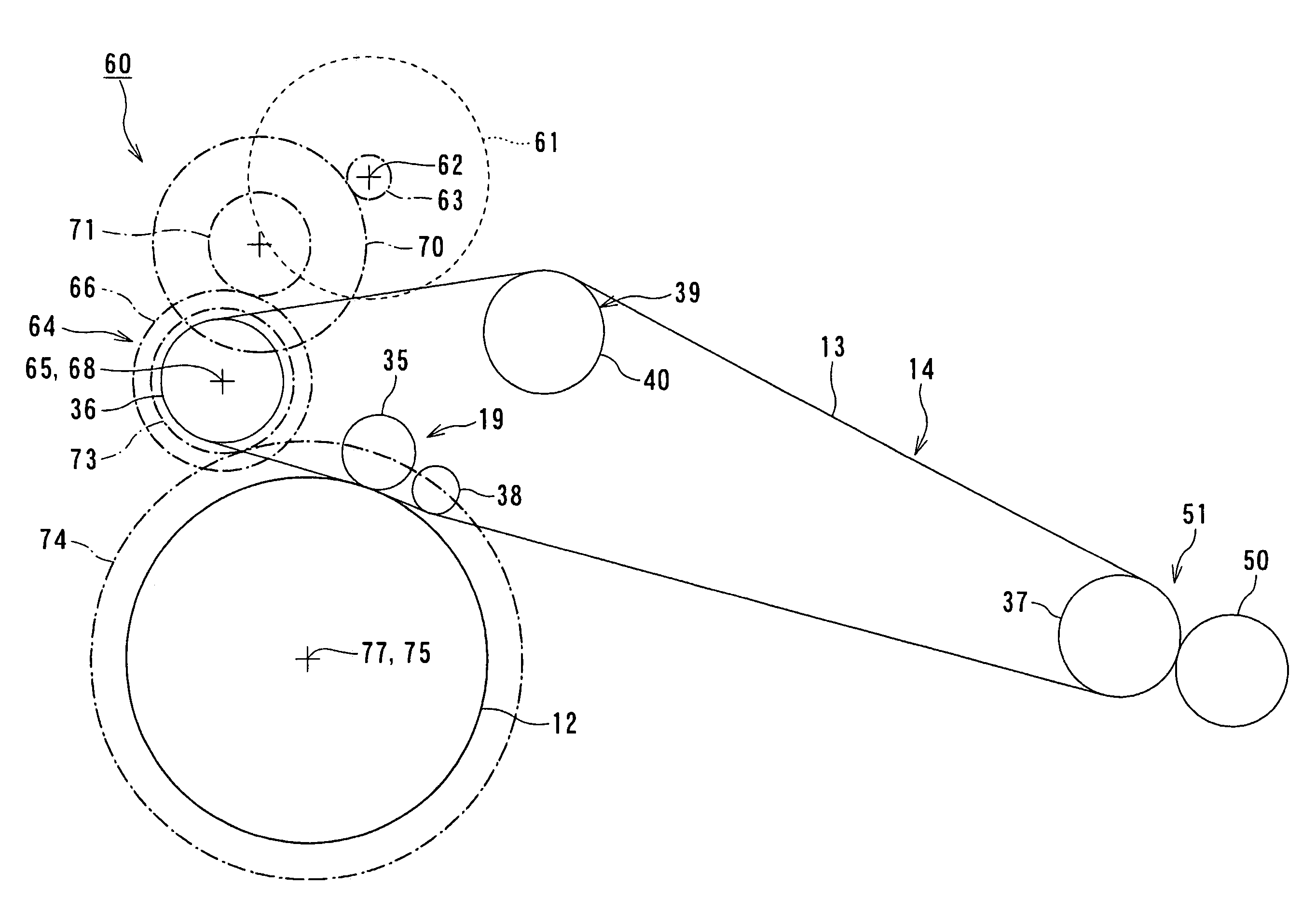

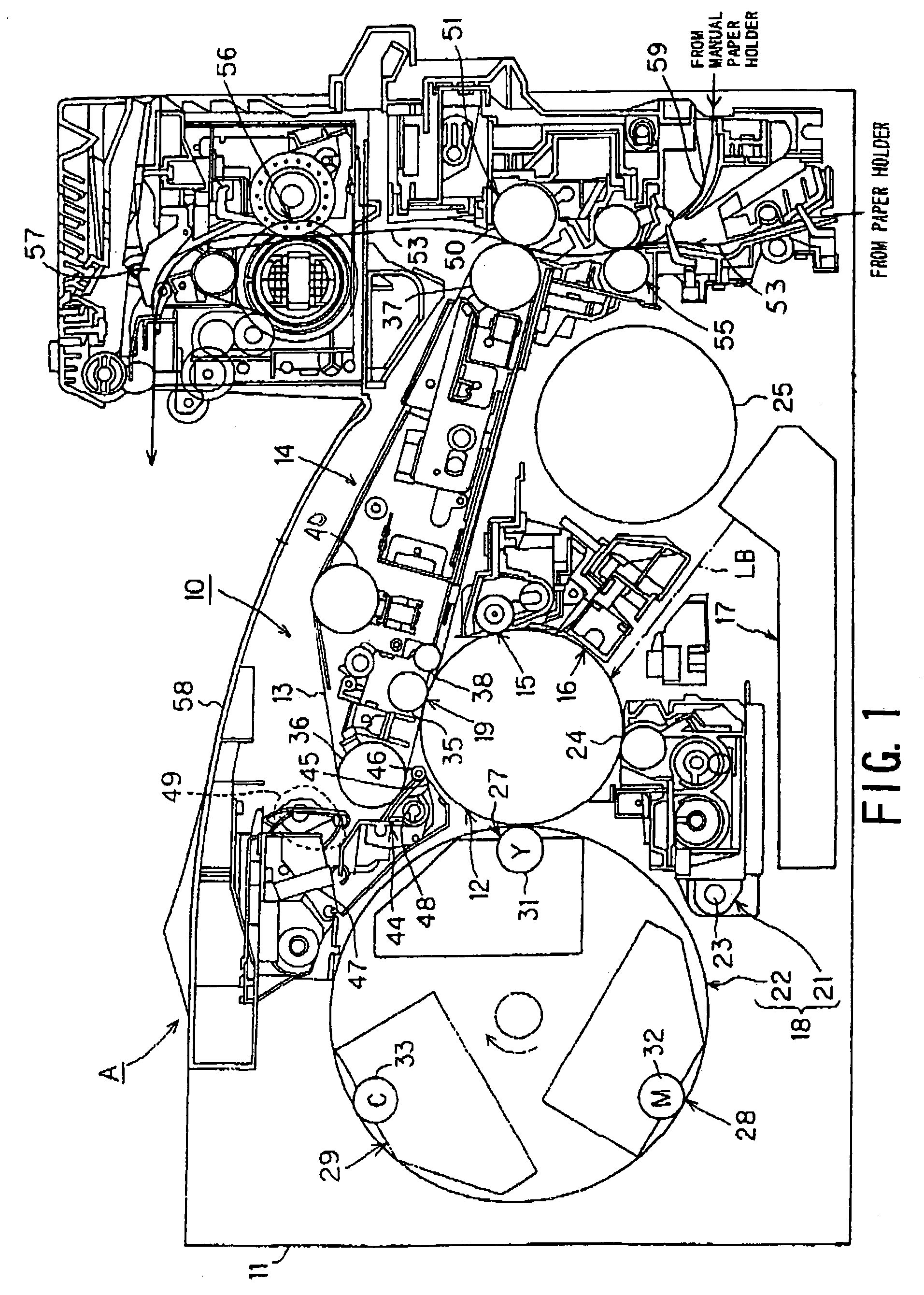

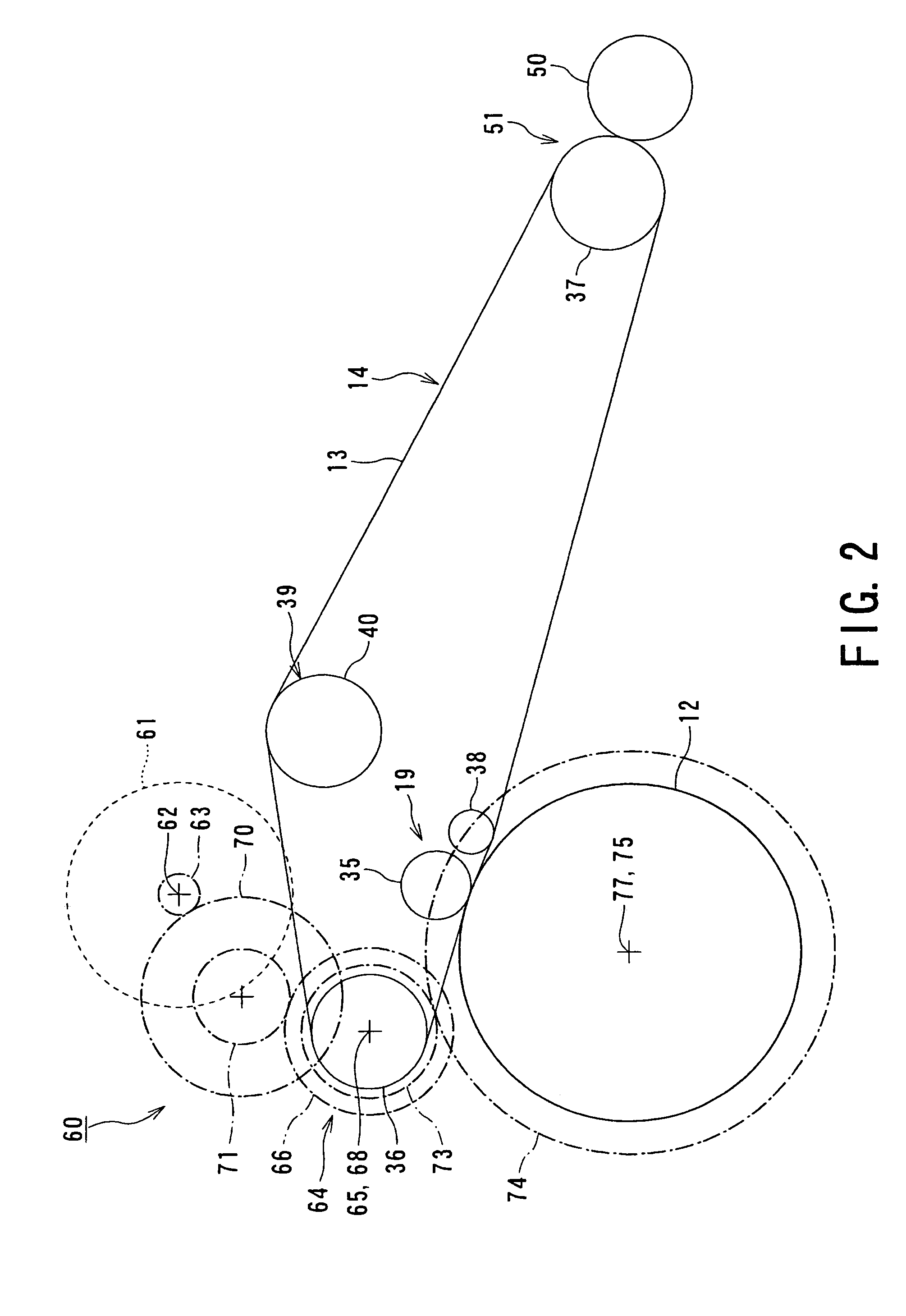

Apparatus for producing images

InactiveUS7130563B2Improve matching accuracyImprove driving accuracyElectrographic process apparatusCorona dischargeDrive shaftDrive motor

Owner:KK TOSHIBA +1

Method of designing member of spline wheel contour, spline surface contour and cam periphery of roller-type wave-motion

ActiveUS20170002913A1Improve accuracyImprove driving efficiencyGearingGearing elementsCamMirror image

A method for designing a spline surface contour of a roller-type wave-motion includes of the steps of slicing radial movement track of a roller between a cam and a spline aperture and circumference rotation track at equal proportion at equal time intervals to sequentially obtain circle centers and points of tangency of the track circles during movement of the roller; connecting the points of tangency to form a unit cam circumference segment of a cam periphery in order to draw and form a single-sided tooth flank contour; and forming a correspondent side tooth flank contour by mirroring and projecting the single-sided tooth flank contour. A method of forming a spline wheel contour and a method of forming a cam periphery are obtained.

Owner:PRODRIVES & MOTIONS +1

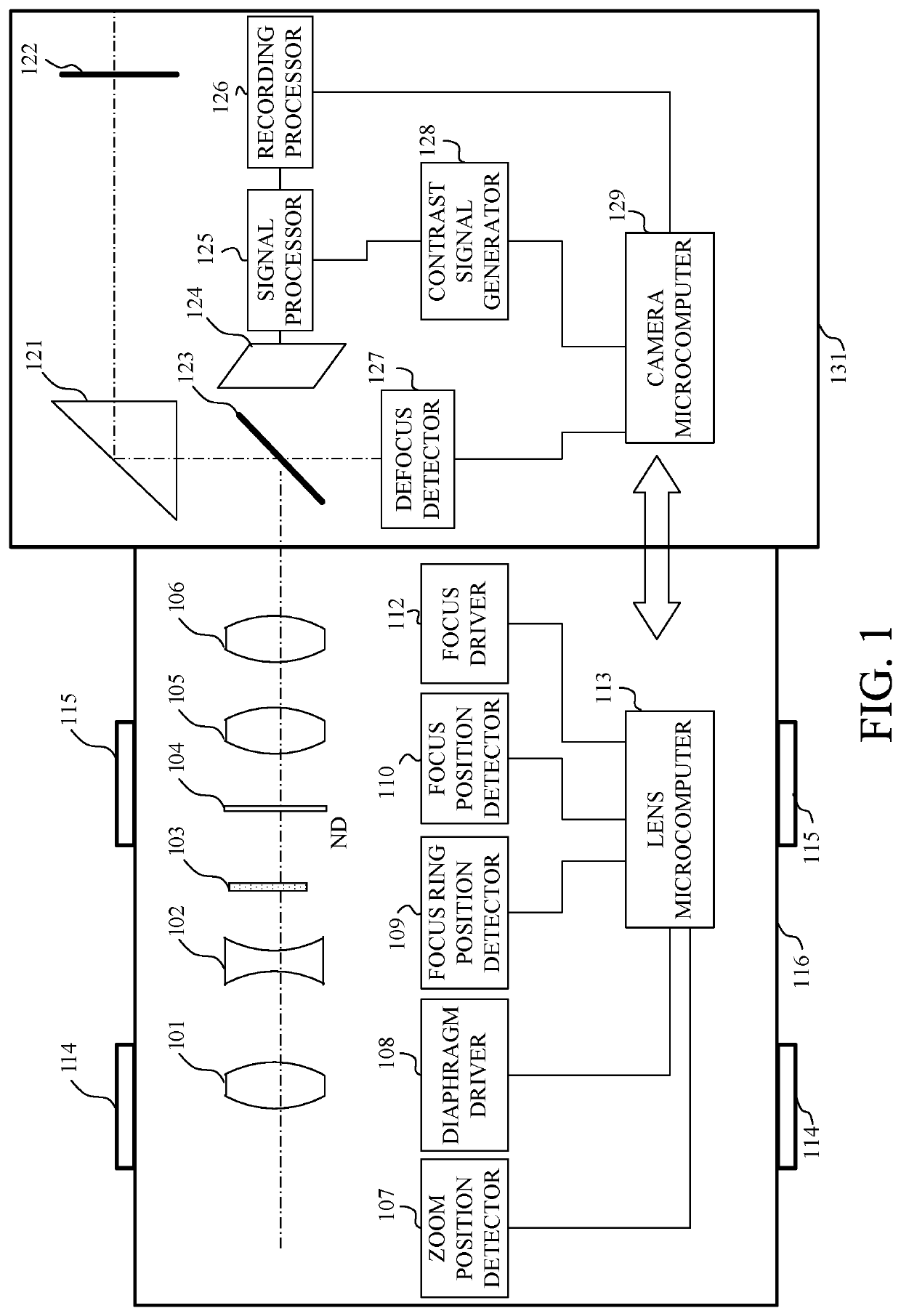

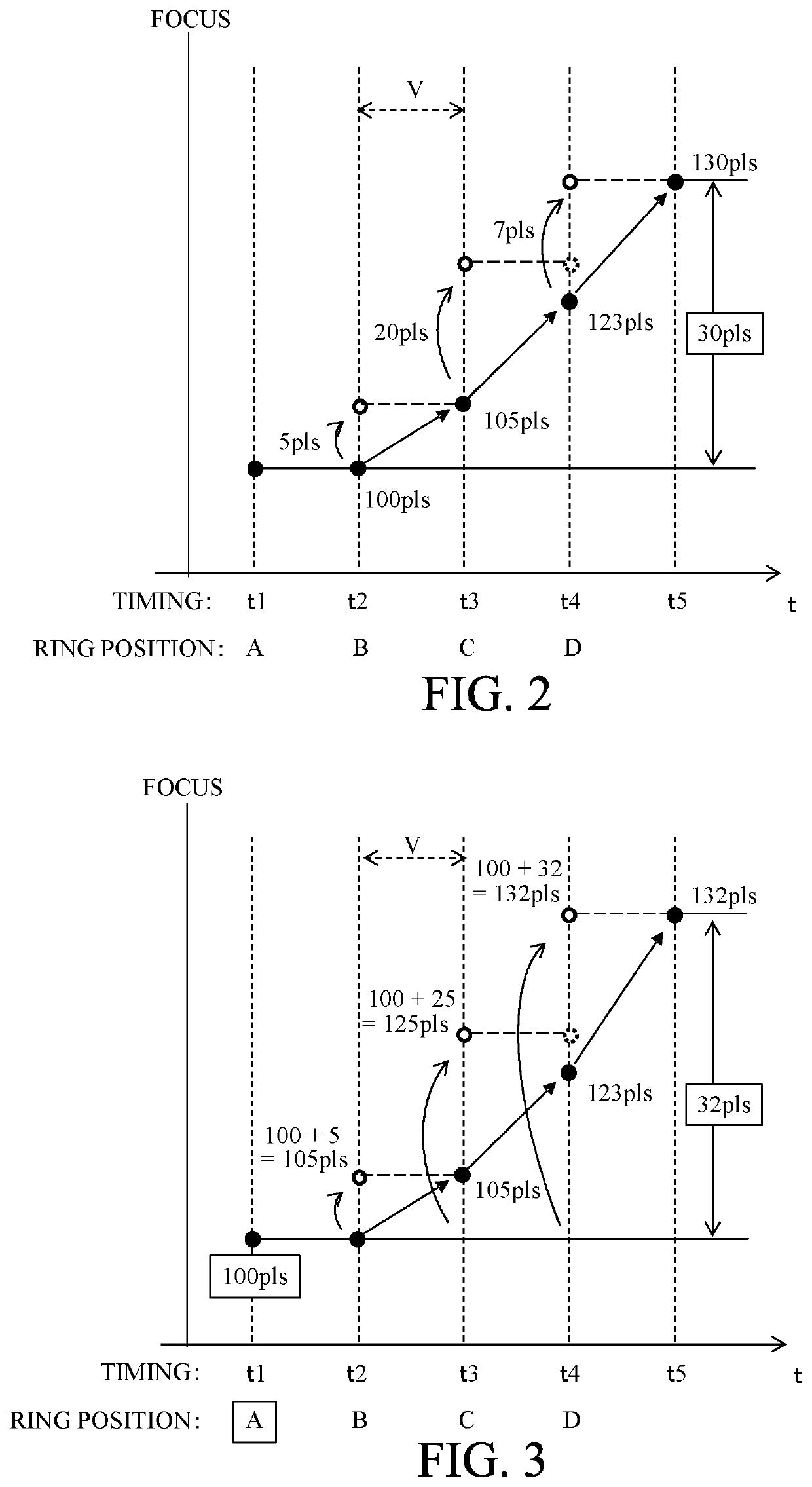

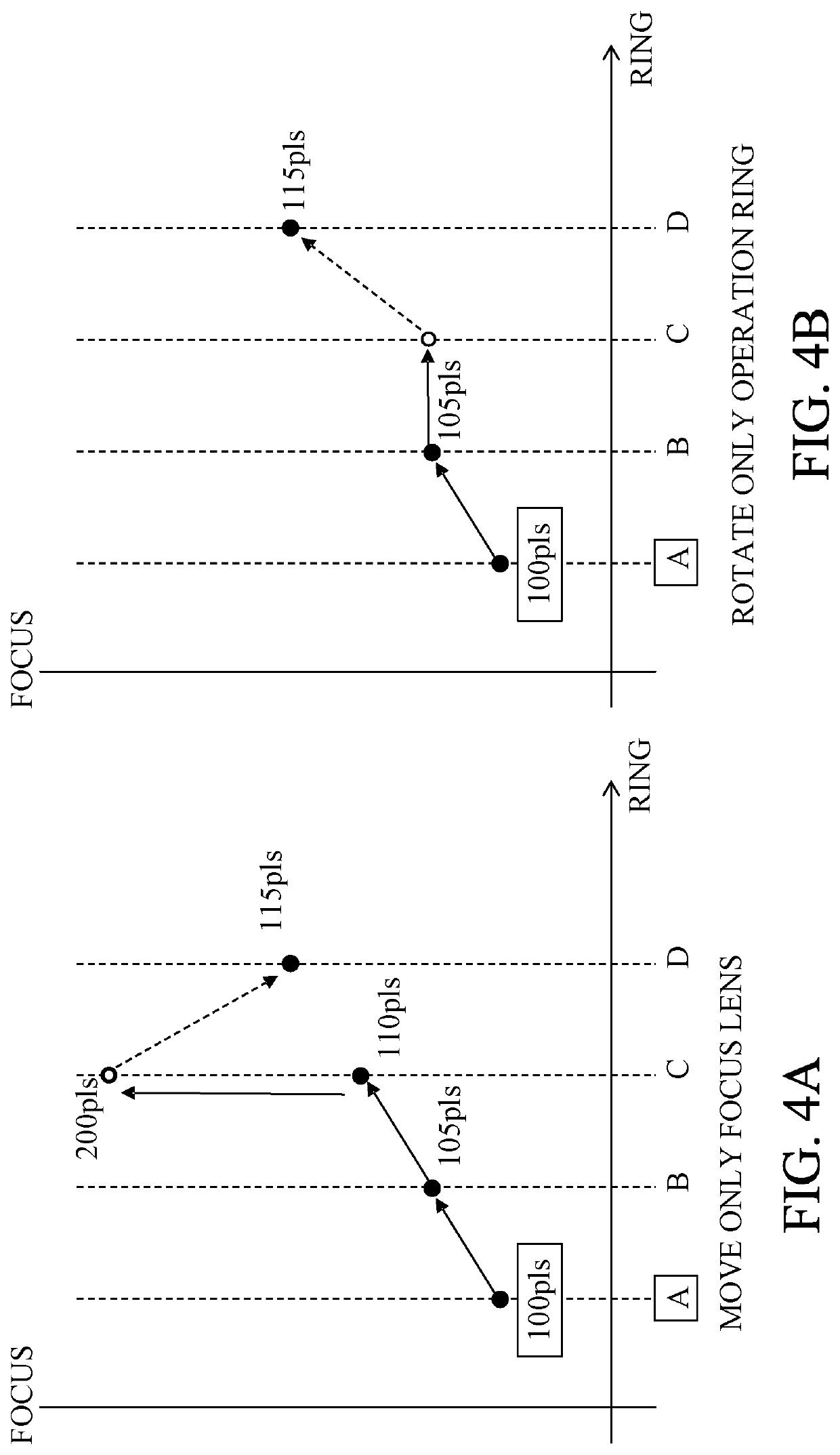

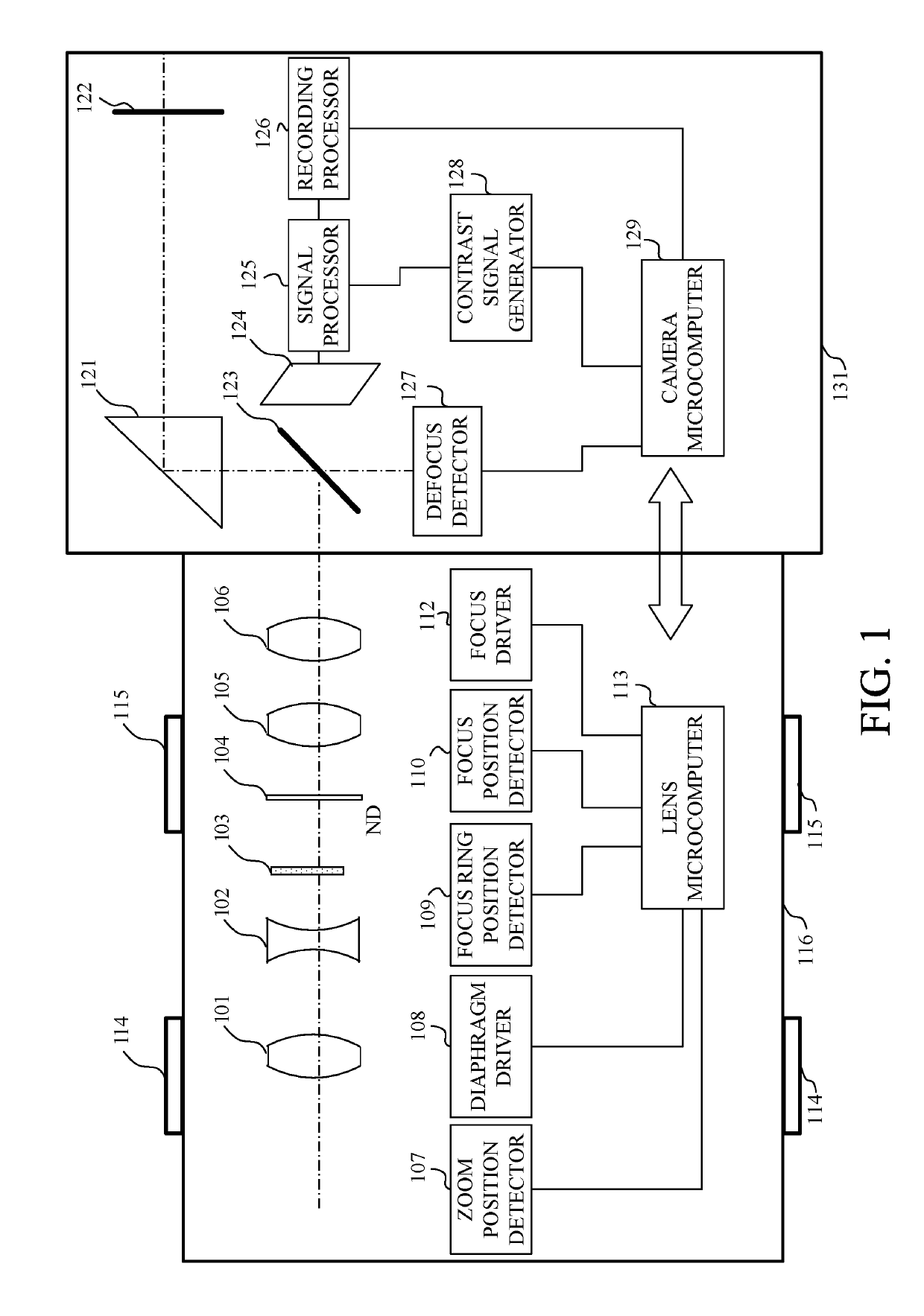

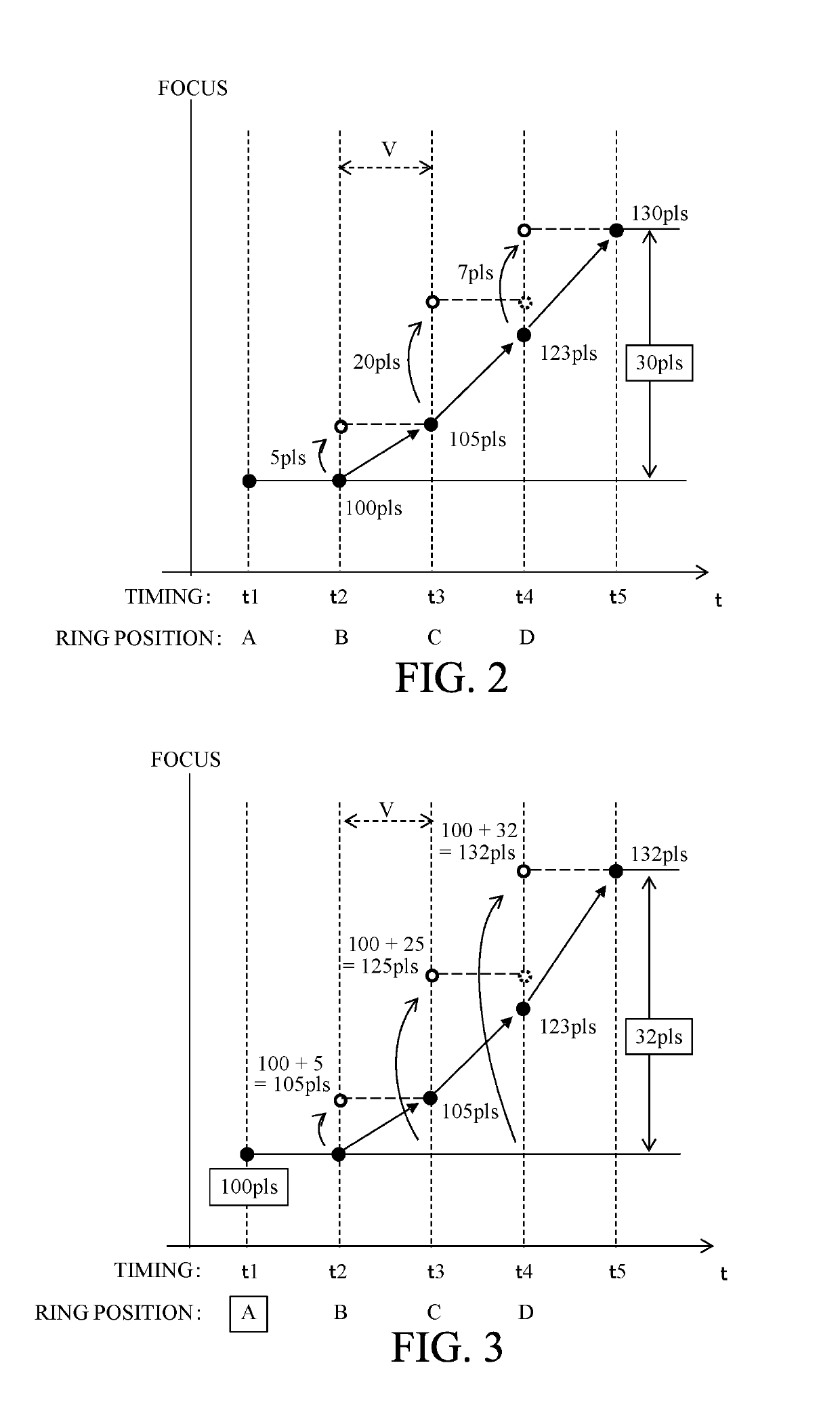

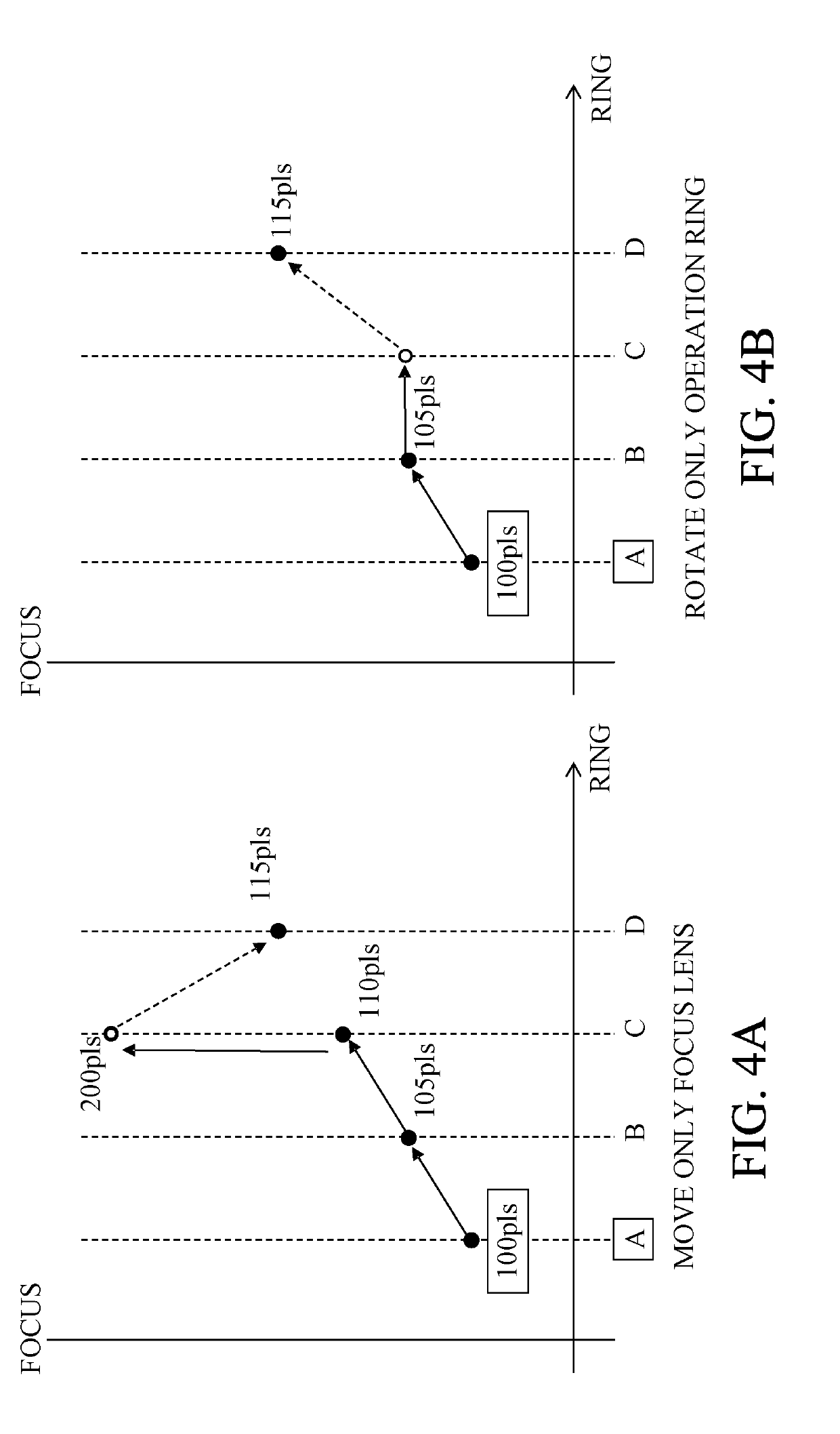

Control apparatus, optical apparatus, and control method for optical apparatus

ActiveUS11002940B2Improve driving accuracyTelevision system detailsProjector focusing arrangementControl theoryPhysics

A control apparatus is used for an optical apparatus that includes a movable optical element, an operation ring that is endlessly rotatable, and a driver configured to drive the optical element. The control apparatus includes an operation start detector configured to detect a start of an operation of the operation ring, and a drive controller configured to control the driver. The drive controller sets a rotational position of the operation ring and the position of the optical element to a ring reference position and an optical element reference position respectively when the start of the operation of the operation ring is detected. The drive controller controls the driver in accordance with a drive amount of the optical element calculated with an operational amount of the operation ring from the ring reference position, and the optical element reference position.

Owner:CANON KK

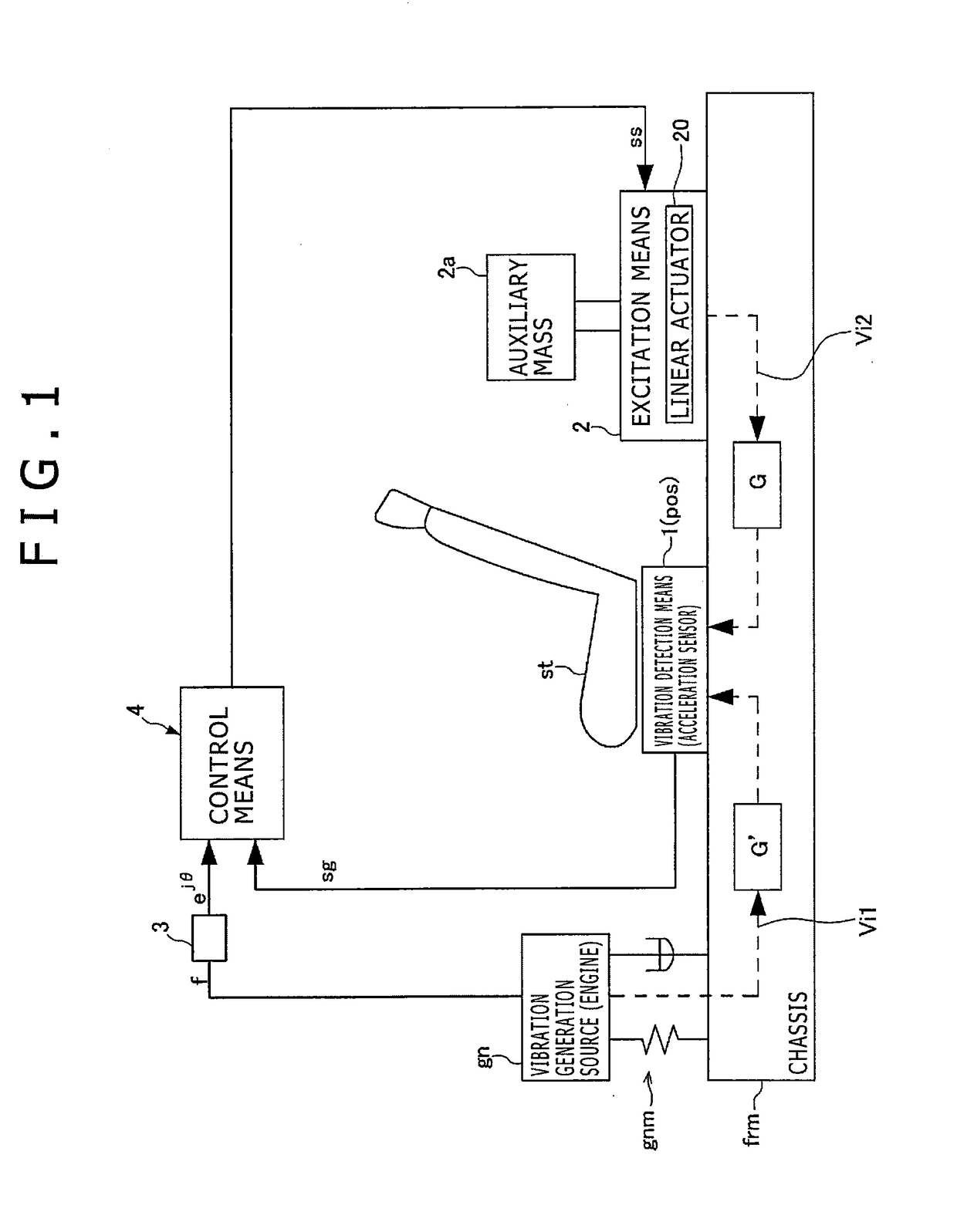

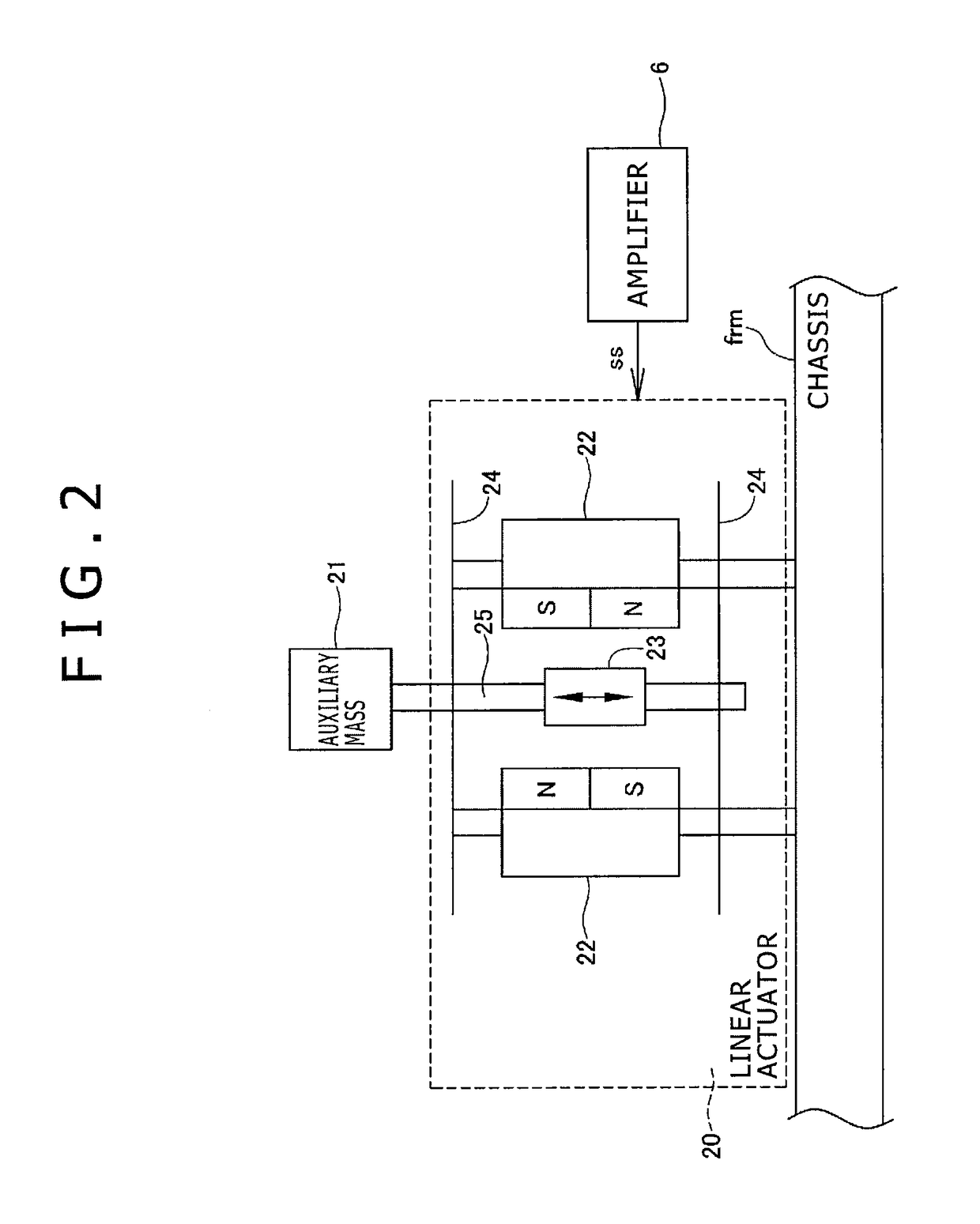

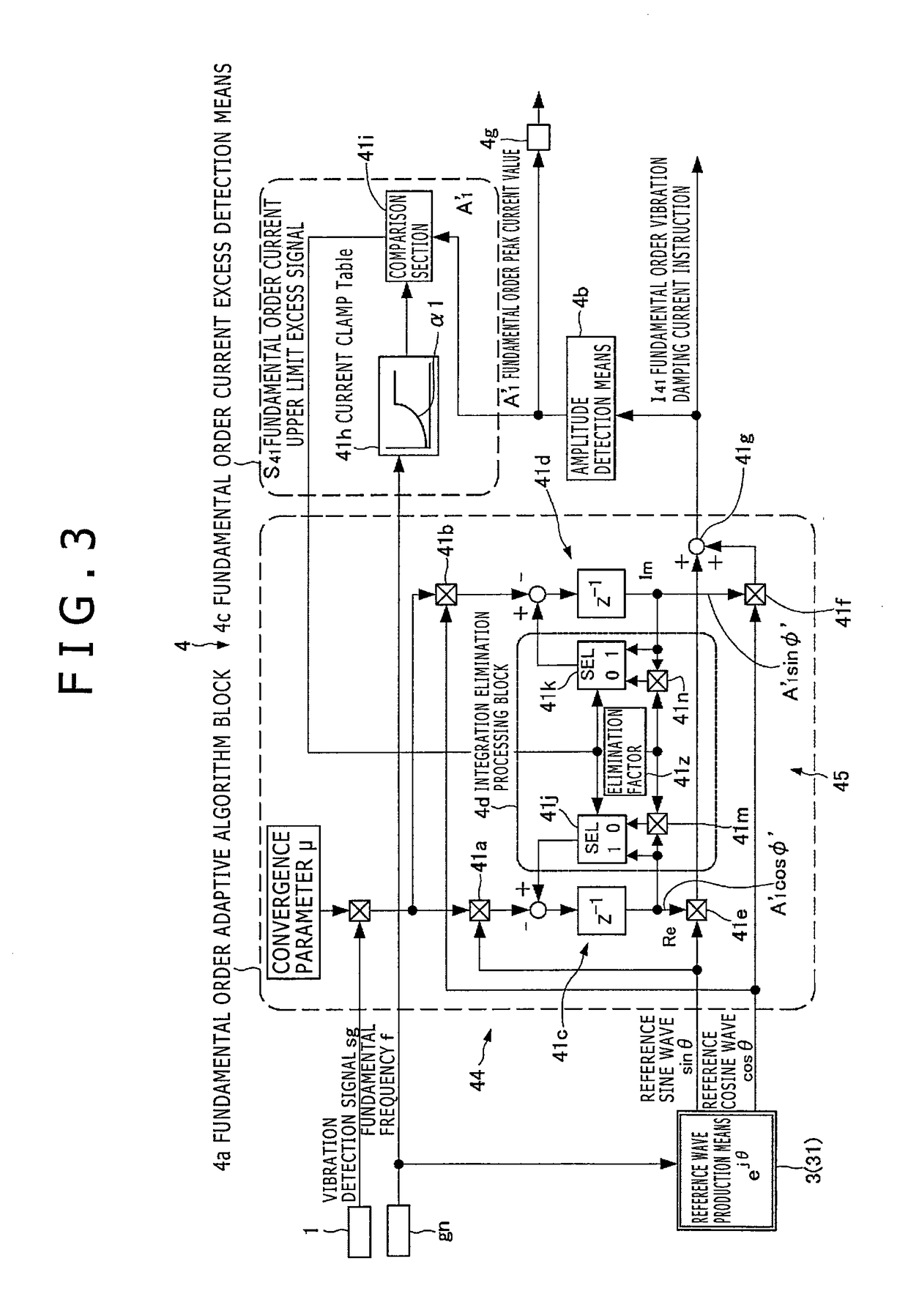

Vibration damping apparatus, electric actuator driving apparatus and vehicle

ActiveUS8471502B2Increased durabilityImprove reliabilityAC motor controlDC motor speed/torque controlAdaptive filterFundamental frequency

A vibration damping apparatus including reference wave production section that produces a reference wave; a fundamental order adaptive algorithm block that calculates fundamental order adaptive filter factors from a vibration detection signal and the reference wave and produces a fundamental order vibration damping current instruction; an amplitude detection section that calculates a peak current value of the fundamental order vibration damping current instruction; and a fundamental order current excess detection section that derives a fundamental order current upper limit value from the fundamental frequency to produce a fundamental order current upper limit excess signal that is output to the fundamental order adaptive algorithm block, which revises the fundamental order adaptive filter factors in a direction in which the vibration damping current instruction is limited within a range.

Owner:SINFONIA TECHNOLOGY CO LTD

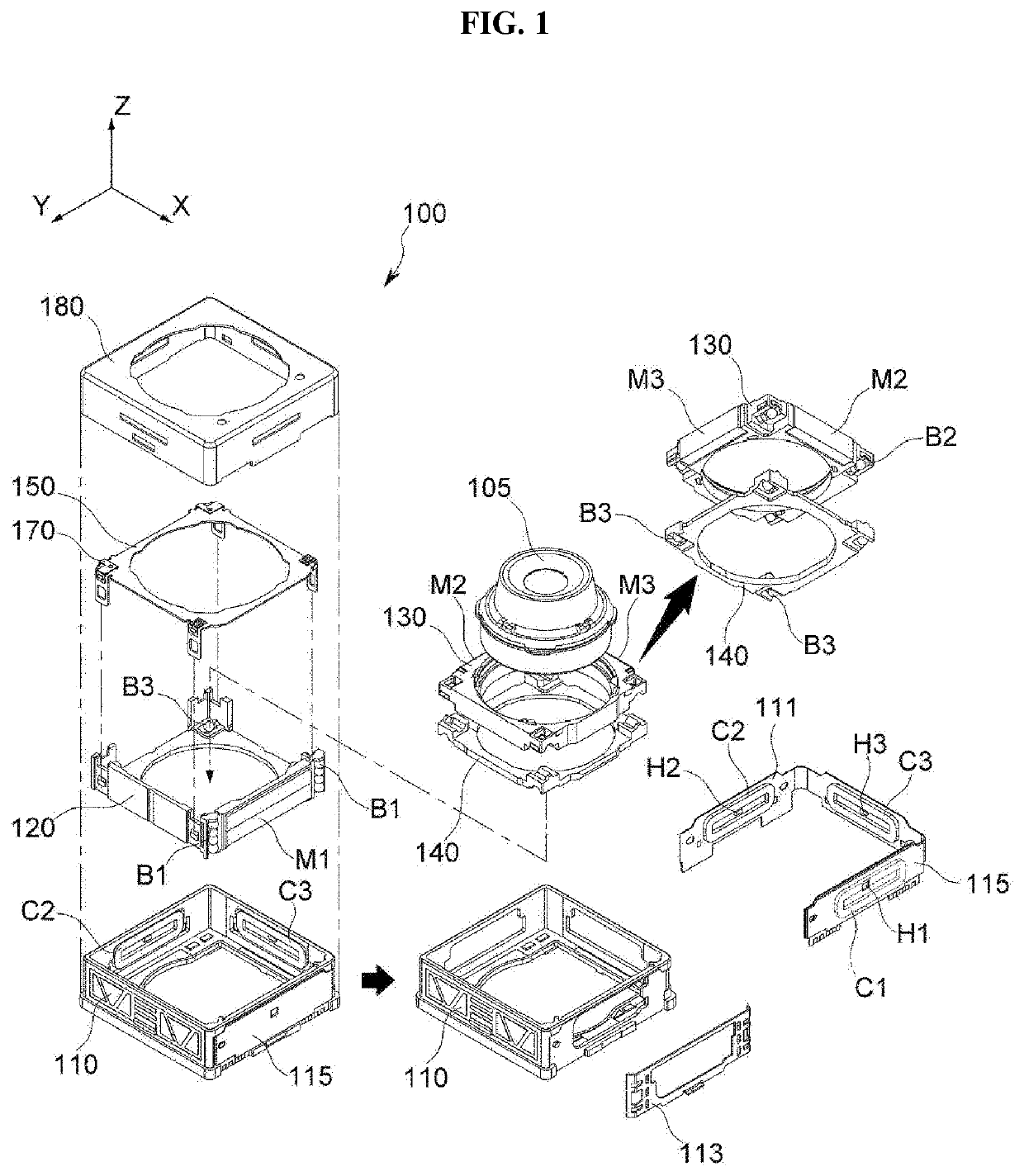

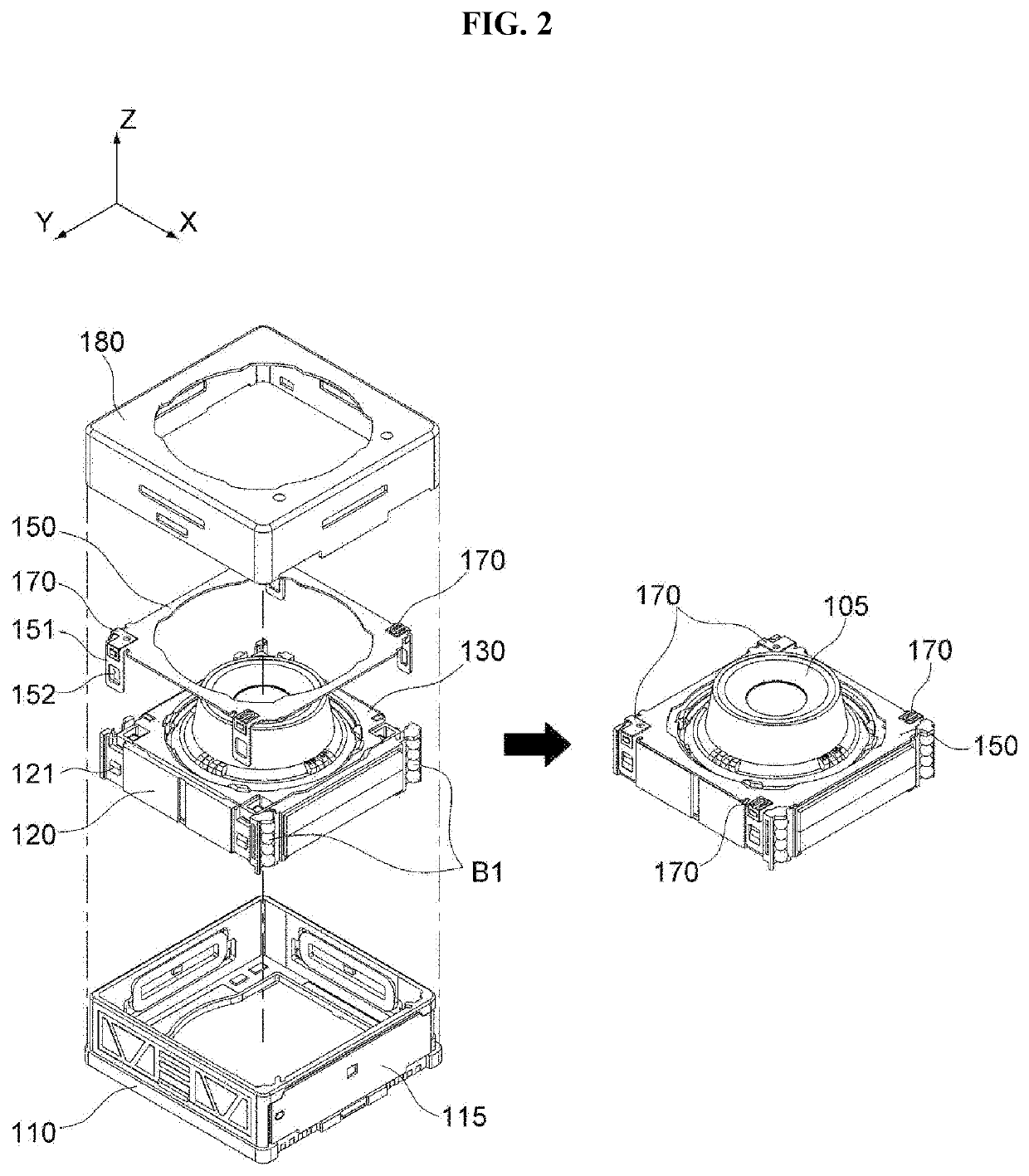

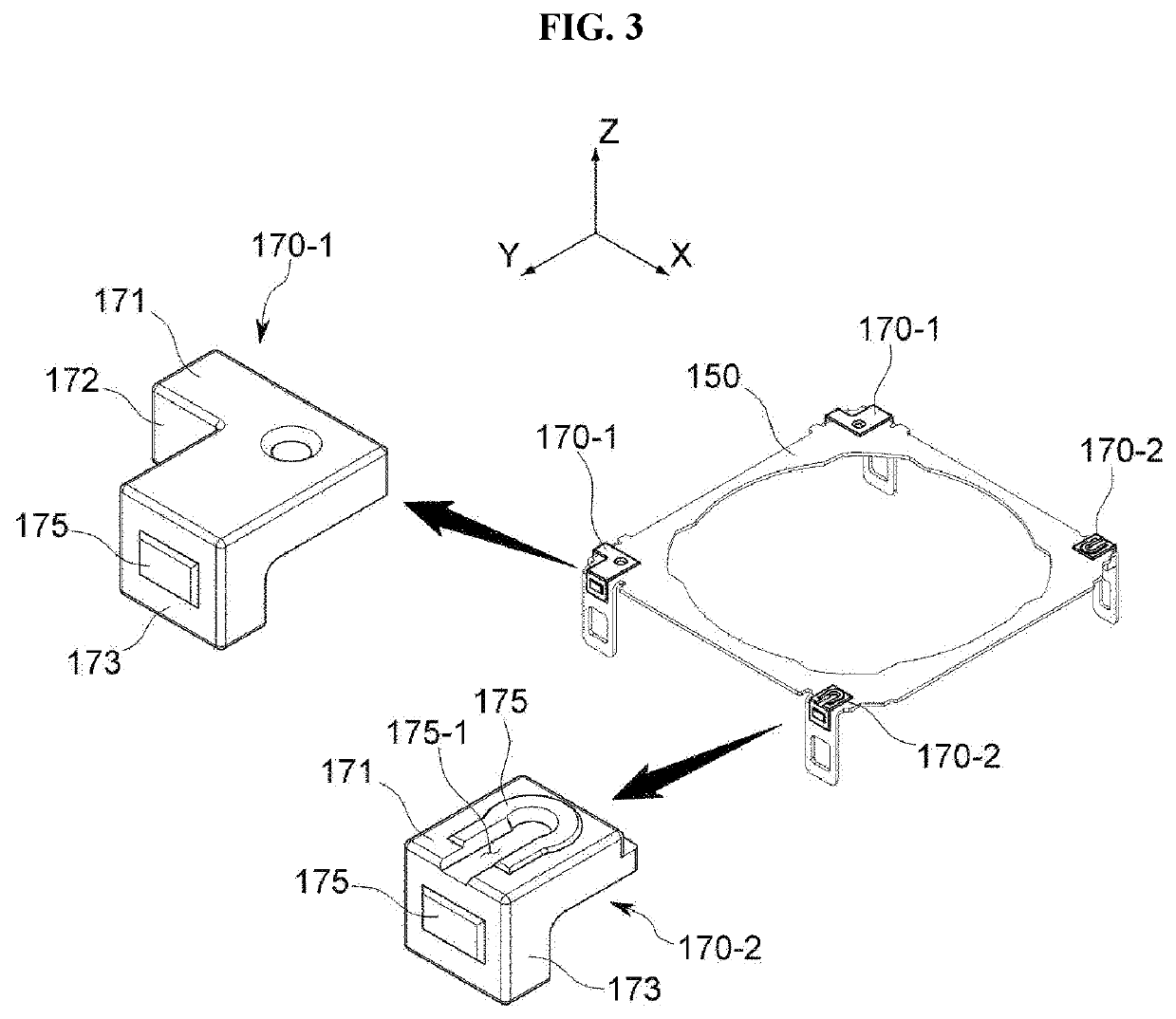

Damper and actuator for camera including same

ActiveUS20220163089A1Minimising external influenceReduce shockSpringsProjector focusing arrangementInterior spaceOptical axis

An actuator for a camera according to an embodiment includes a base having an inner space formed therein, a carrier provided inside the base and configured to move in at least one direction among an optical axis direction, a first direction perpendicular to the optical axis and a second direction perpendicular to the optical axis and the first direction; and a damper provided to the carrier or the base and configured to have a shape extending in two or more directions among the optical axis direction, the first direction and the second direction.

Owner:JAHWA ELECTRONICS

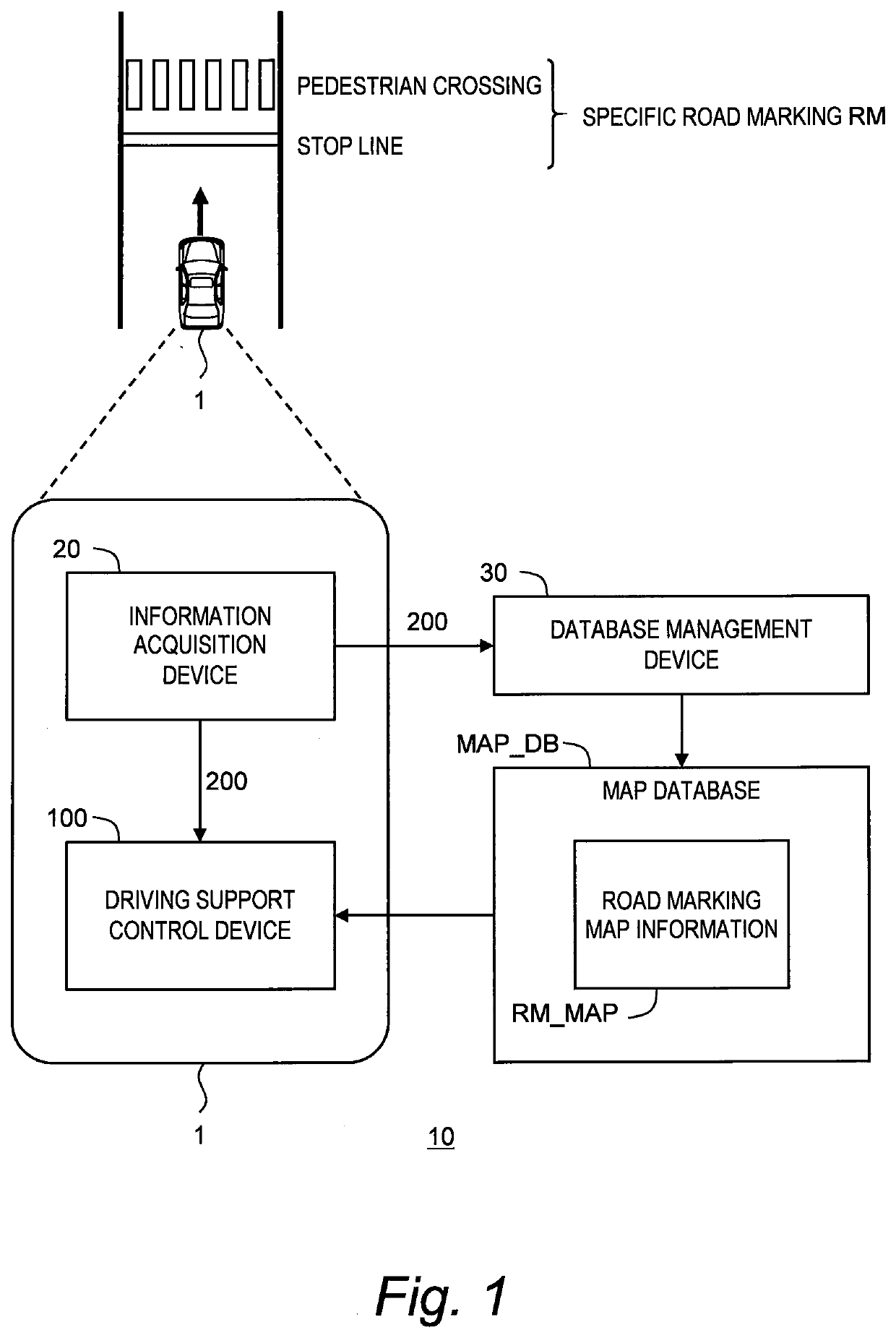

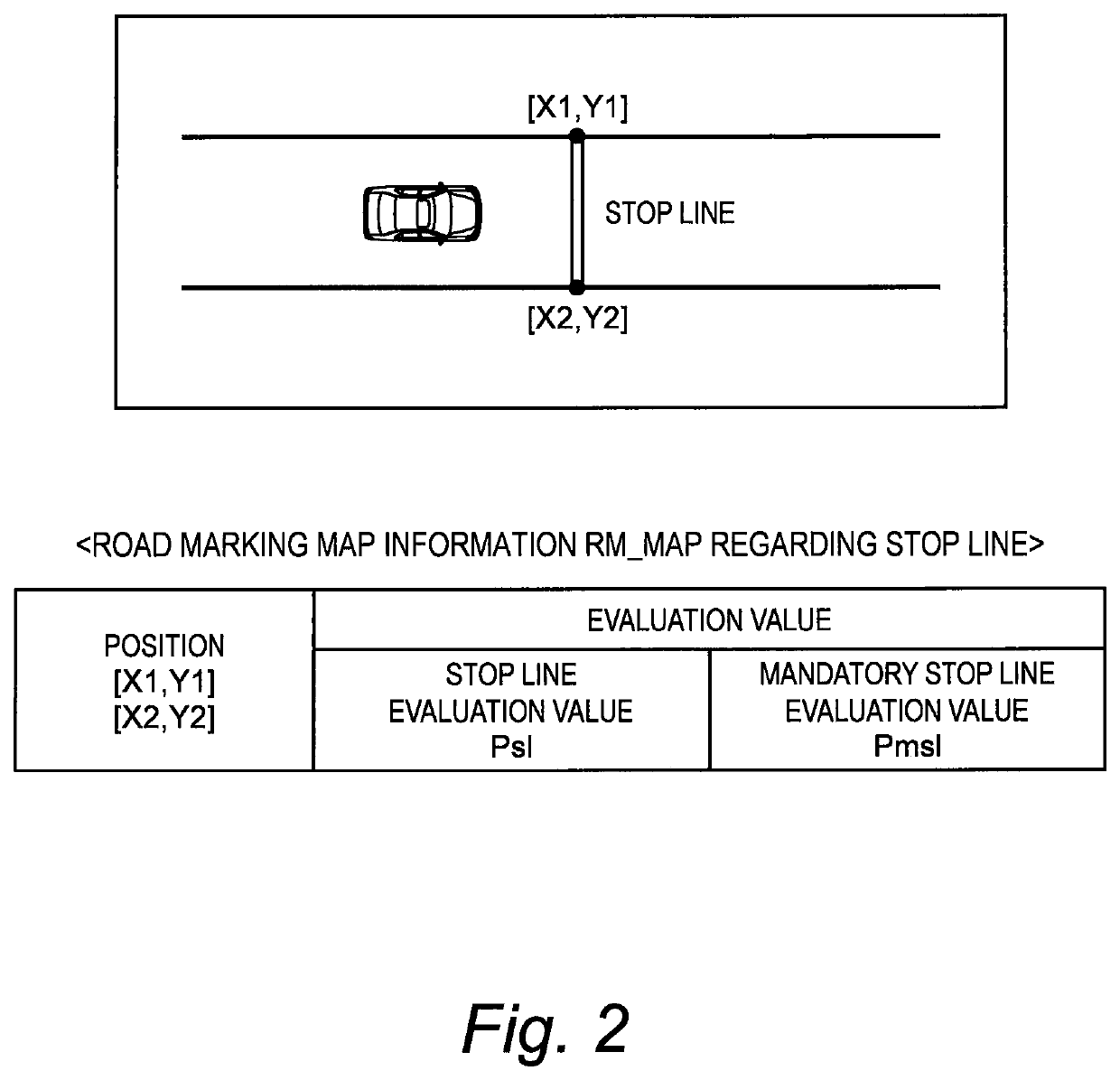

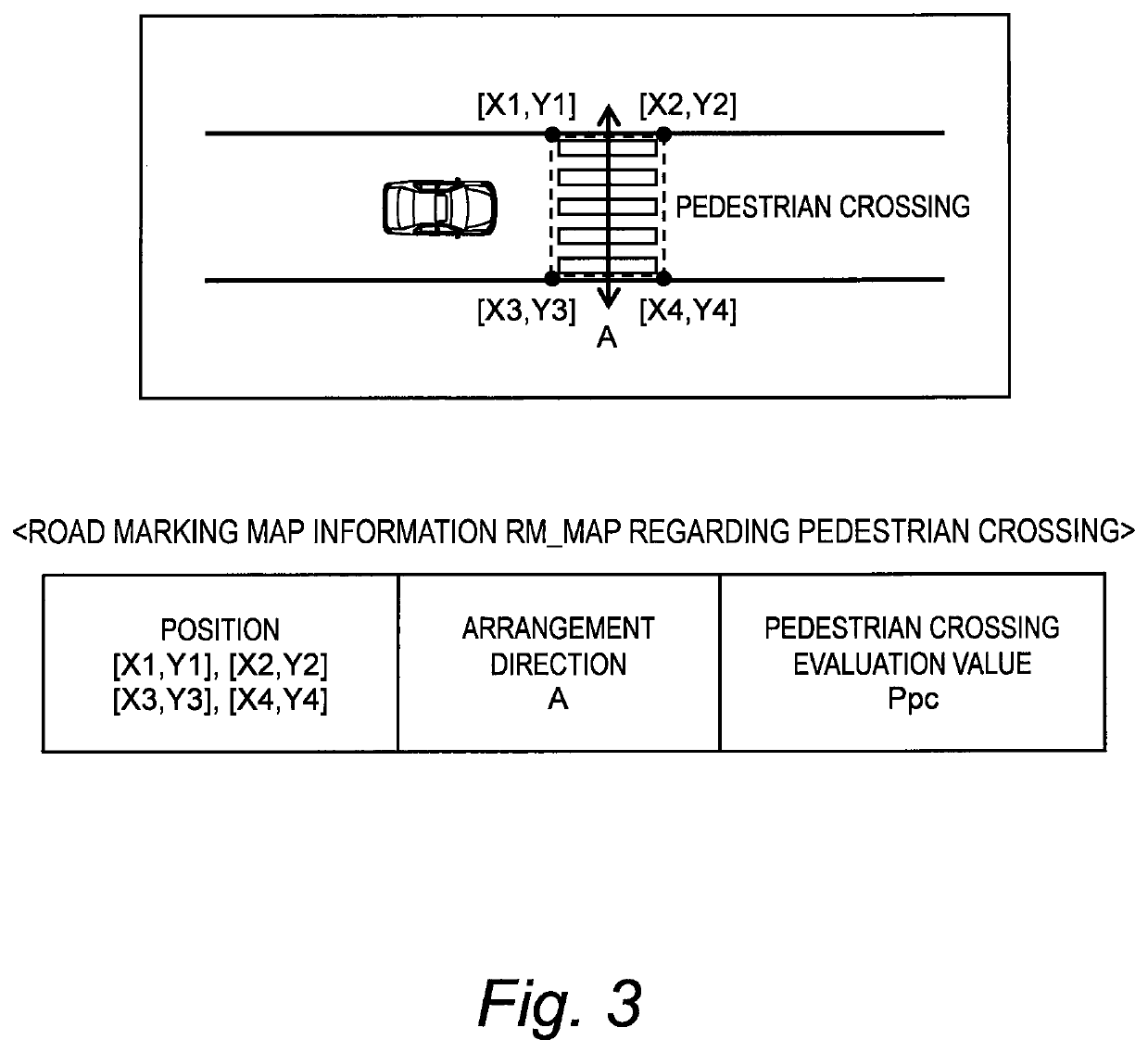

Map information system

ActiveUS20200109953A1Improve accuracyImprove driving accuracyInstruments for road network navigationCharacter and pattern recognitionVehicle behaviorEngineering

A map information system includes a database management device configured to manage a map database used for vehicle driving support control. The map database includes road marking map information that indicates a position of a specific road marking including at least one of a stop line and a pedestrian crossing. The database management device is further configured to: detect a road marking candidate being a candidate for the specific road marking around a vehicle; recognize vehicle behavior of at least one of the vehicle and another vehicle in a period when passing the road marking candidate; determine, based on the vehicle behavior, an evaluation value that indicates certainty of the road marking candidate being the specific road marking; and register the road marking candidate having the evaluation value equal to or higher than a threshold, as the specific road marking, in the road marking map information.

Owner:TOYOTA JIDOSHA KK

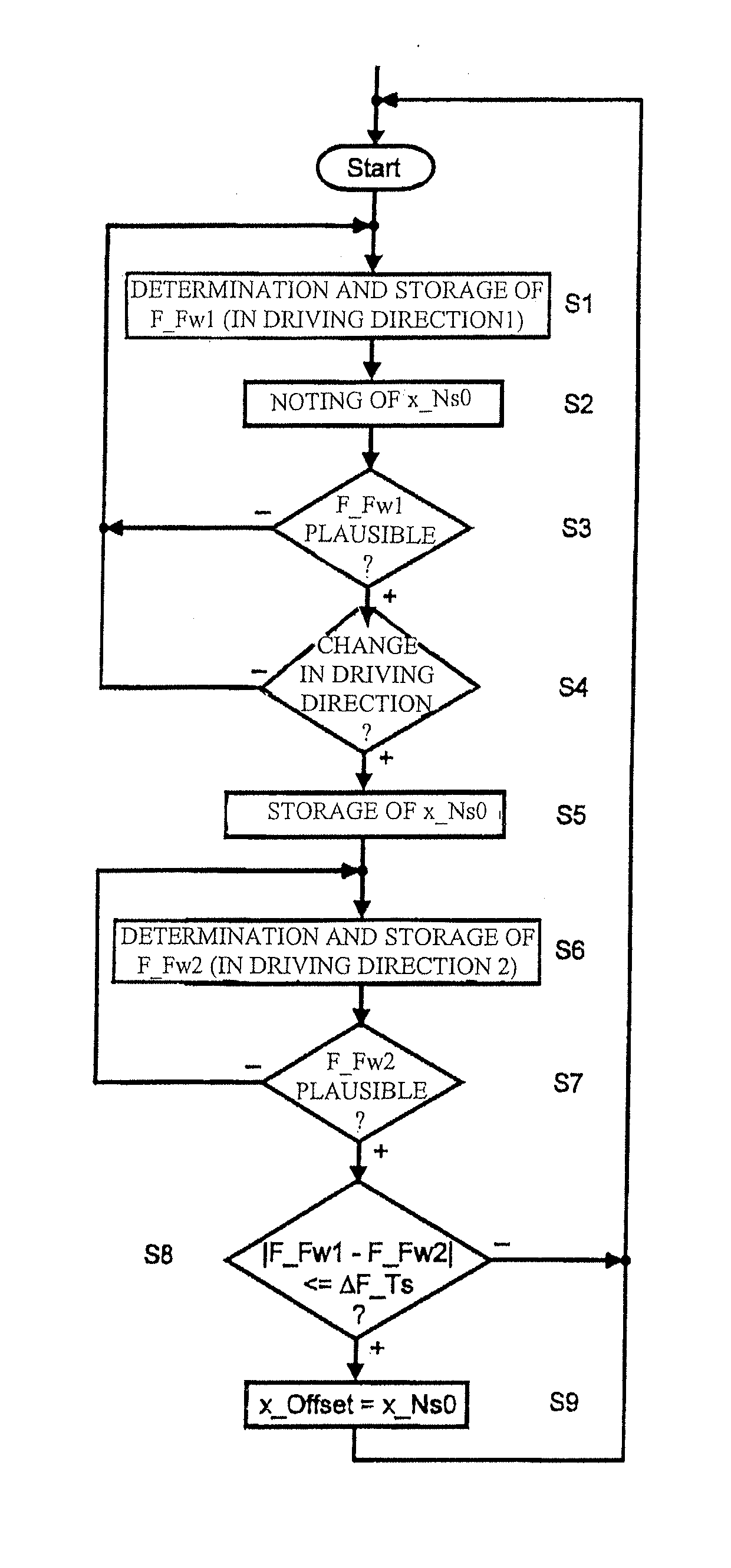

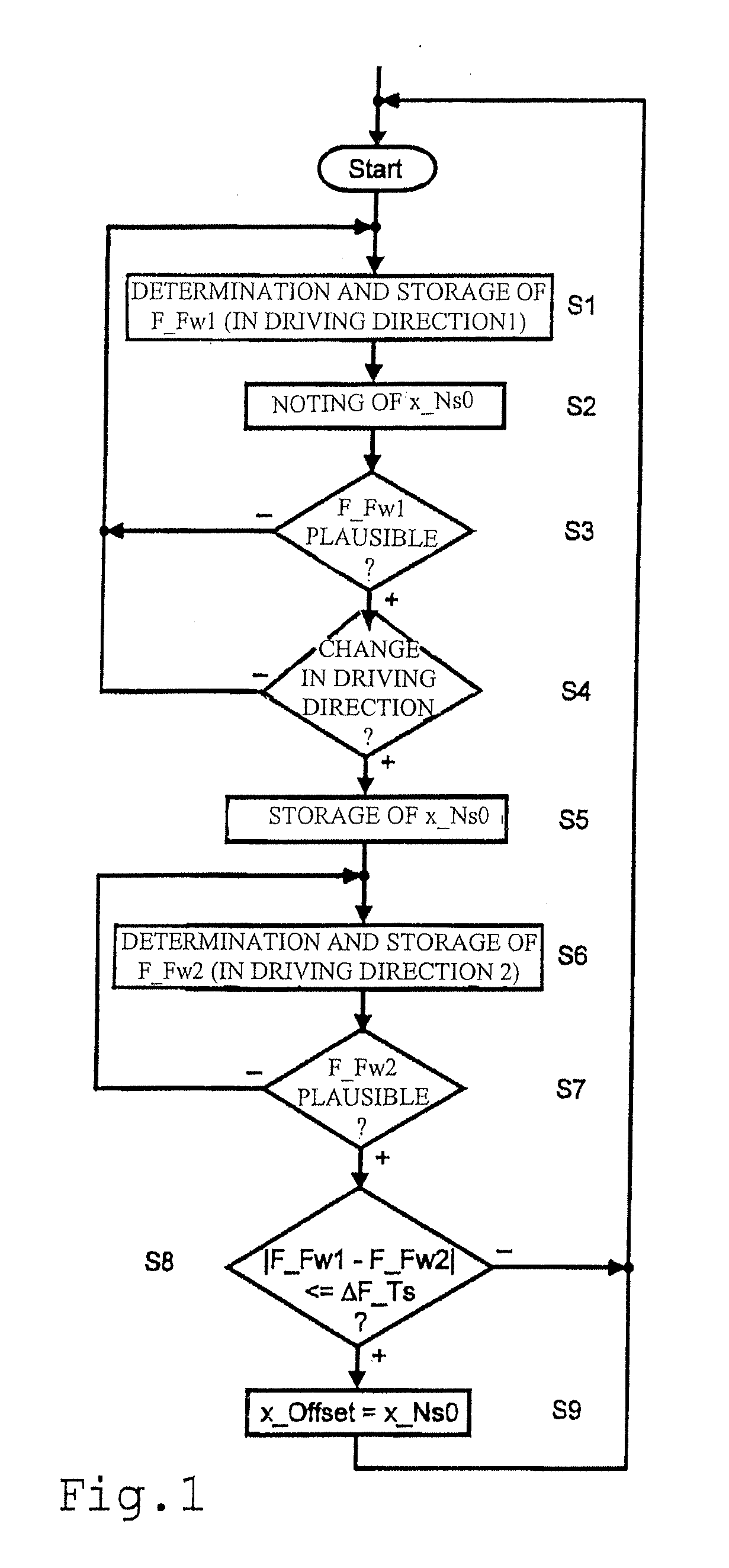

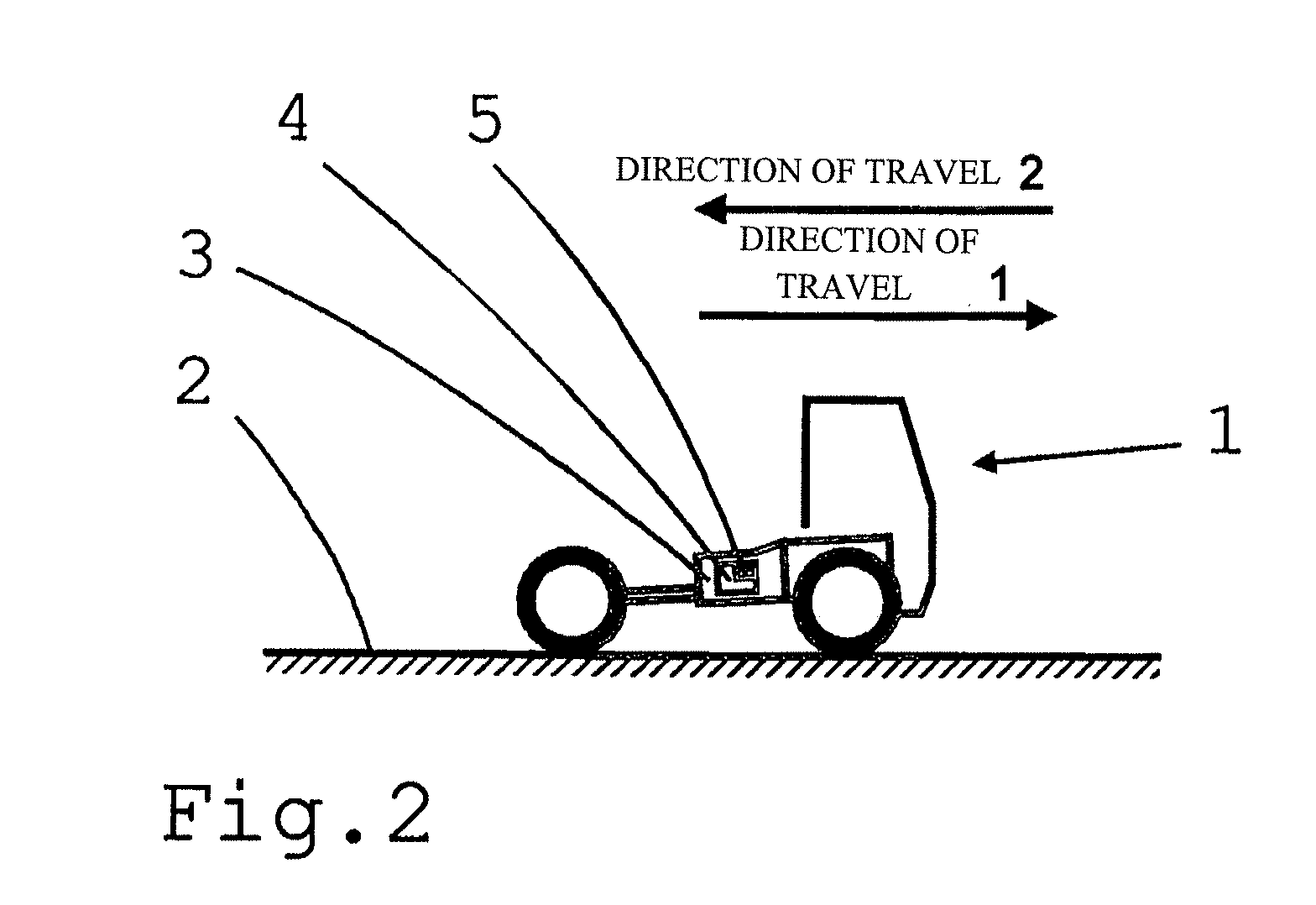

Method for calibrating a slope sensor

InactiveUS20120065835A1Improve driving accuracyVehicle testingMachine part testingElectrical resistance and conductanceResistance force

A method for automatically determining a current offset value for the zero-point correction of a vehicle inclination sensor including the steps of while driving in a first driving direction, the current driving resistance is determined repeatedly, without regard to the sensor and stored temporarily, and a current raw signal value of the sensor is noted. Upon a change in the driving direction, the last-noted raw signal value is stored temporarily and while driving in the second driving direction. The current driving resistance is determined repeatedly, without regard to the sensor and stored temporarily. Then, if the difference between the two stored driving resistances agree with a tolerance threshold, the noted raw signal value is stored as the offset value for the zero-point correction of the inclination sensor.

Owner:ZF FRIEDRICHSHAFEN AG

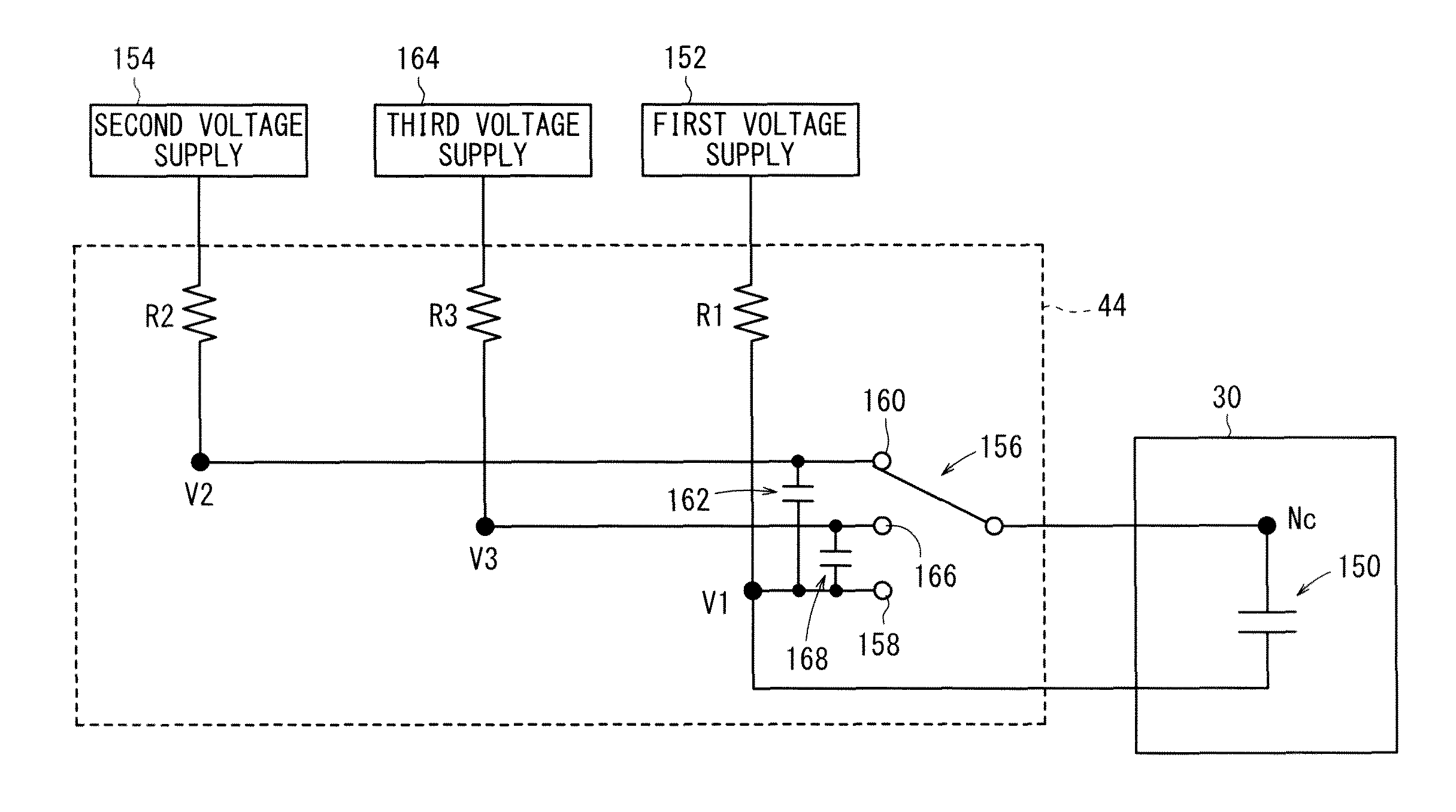

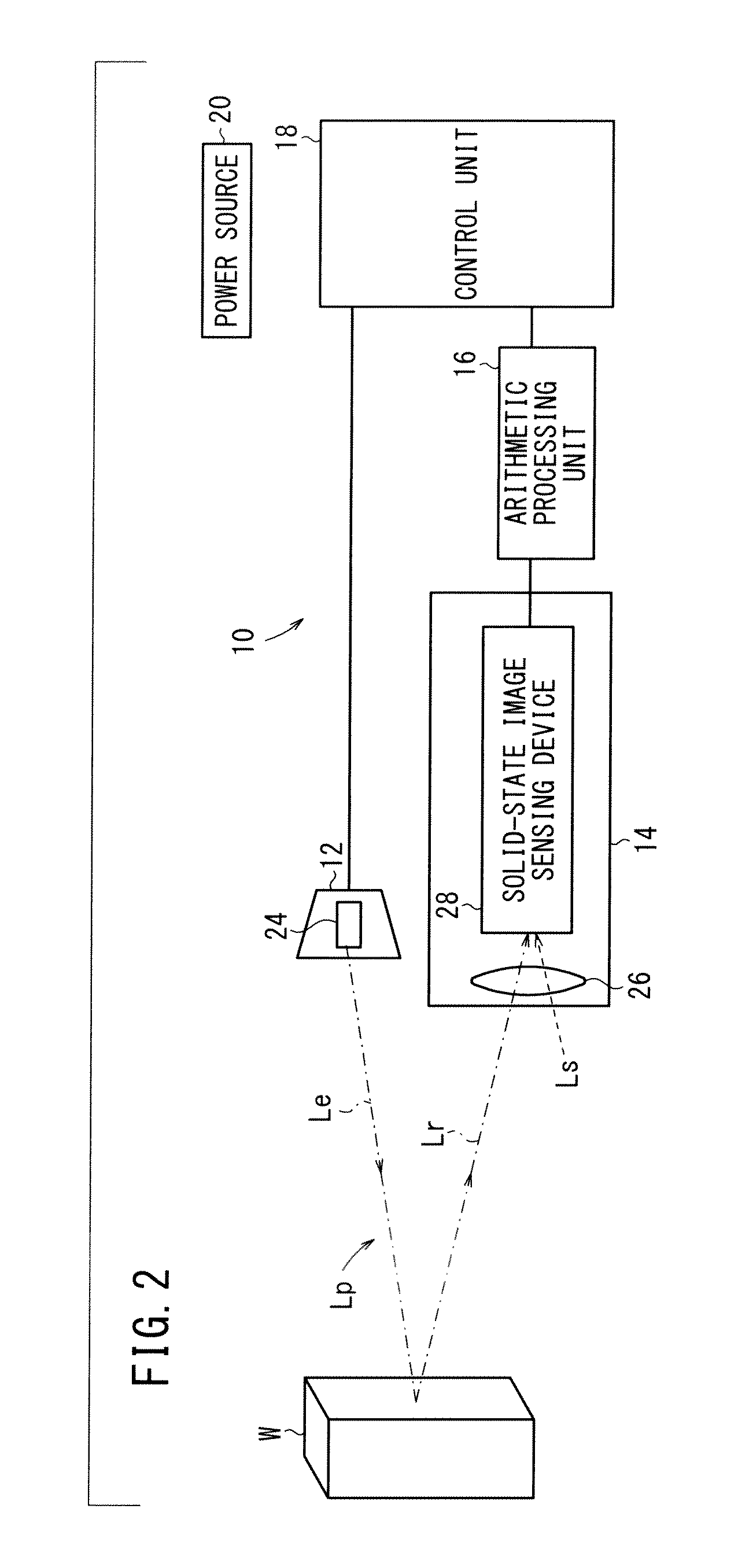

Solid-state image sensing device with a change-over switch

InactiveUS9018573B2Improve driving accuracyIncrease speedTelevision system detailsSolid-state devicesPhotoelectric conversionEngineering

A solid-state image sensing device comprises a unit pixel containing a photoelectric conversion element for detecting a light to generate photoelectrons and at least one electrode for forming an MOS diode structure, a first contact point connected to a first voltage supply for supplying a first voltage to the electrode, a second contact point connected to a second voltage supply for supplying a second voltage higher than the first voltage to the electrode, a first capacitor disposed between the first and second contact points, a change-over switch connected to one of the first and second contact points to selectively switch a voltage applied to the electrode to the first voltage or the second voltage, and pixel drive circuits for driving the change-over switch, thereby alternately applying the first voltage and the second voltage to the electrode to generate, hold, transfer, reset, or discharge the photoelectrons.

Owner:HONDA MOTOR CO LTD

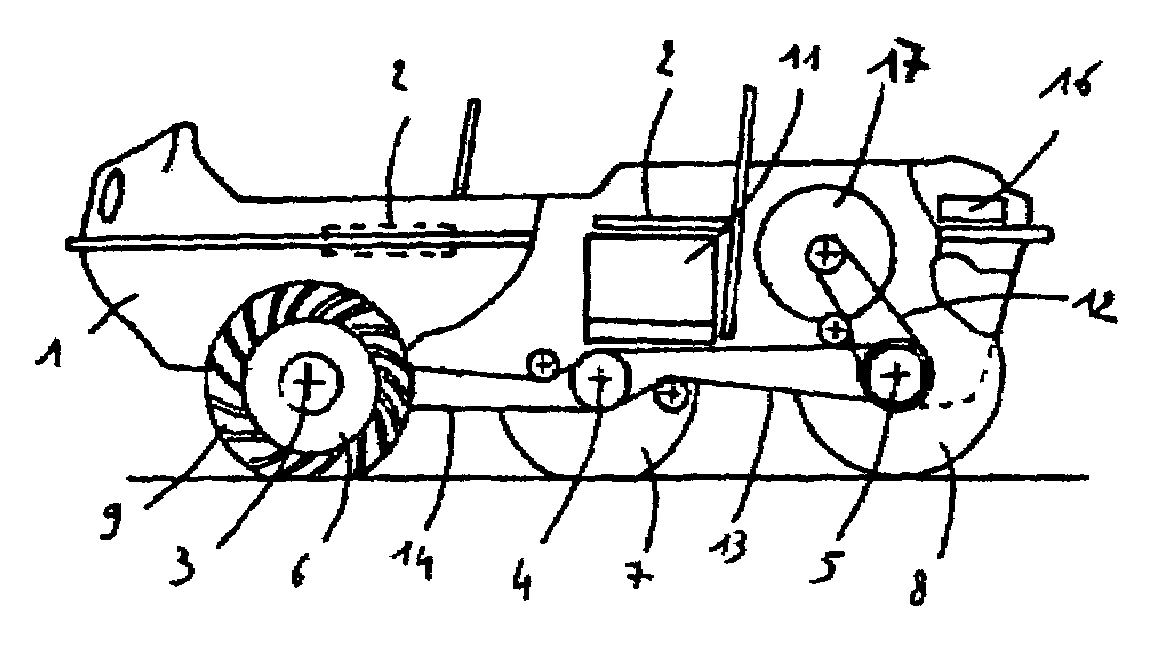

Amphibious off-road vehicle

InactiveUS20060186840A1Reduce noise levelImprove mobilityAC motor controlSynchronous motors startersControl signalBuggy vehicle

The invention concerns an off-road vehicle, in particular of the amphibious type, having a left wheel-train (6, 7, 8) and a right wheel-train, arranged to propel the vehicle on both land and water, propulsion resources (10) to drive the said wheel trains, and mobile control resources (15) capable of supplying at least one control signal as a function of their position. The said propulsion resources include a first electric motor capable of driving the left wheel-train, a second electric motor capable of driving the right wheel-train, and synchronisation resources (16) to synchronise the two electric motors as a function of the control signal.

Owner:HEULIEZ SA

Control apparatus, optical apparatus, and control method for optical apparatus

A control apparatus is used for an optical apparatus that includes a movable optical element, an operation ring that is endlessly rotatable, and a driver configured to drive the optical element. The control apparatus includes an operation start detector configured to detect a start of an operation of the operation ring, and a drive controller configured to control the driver. The drive controller sets a rotational position of the operation ring and the position of the optical element to a ring reference position and an optical element reference position respectively when the start of the operation of the operation ring is detected. The drive controller controls the driver in accordance with a drive amount of the optical element calculated with an operational amount of the operation ring from the ring reference position, and the optical element reference position.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com