Laser machining tool having expanded work space

A technology of laser processing machine and laser processing head, which is applied in the direction of laser welding equipment, metal processing equipment, manufacturing tools, etc., to achieve the effect of reducing space requirements and high synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

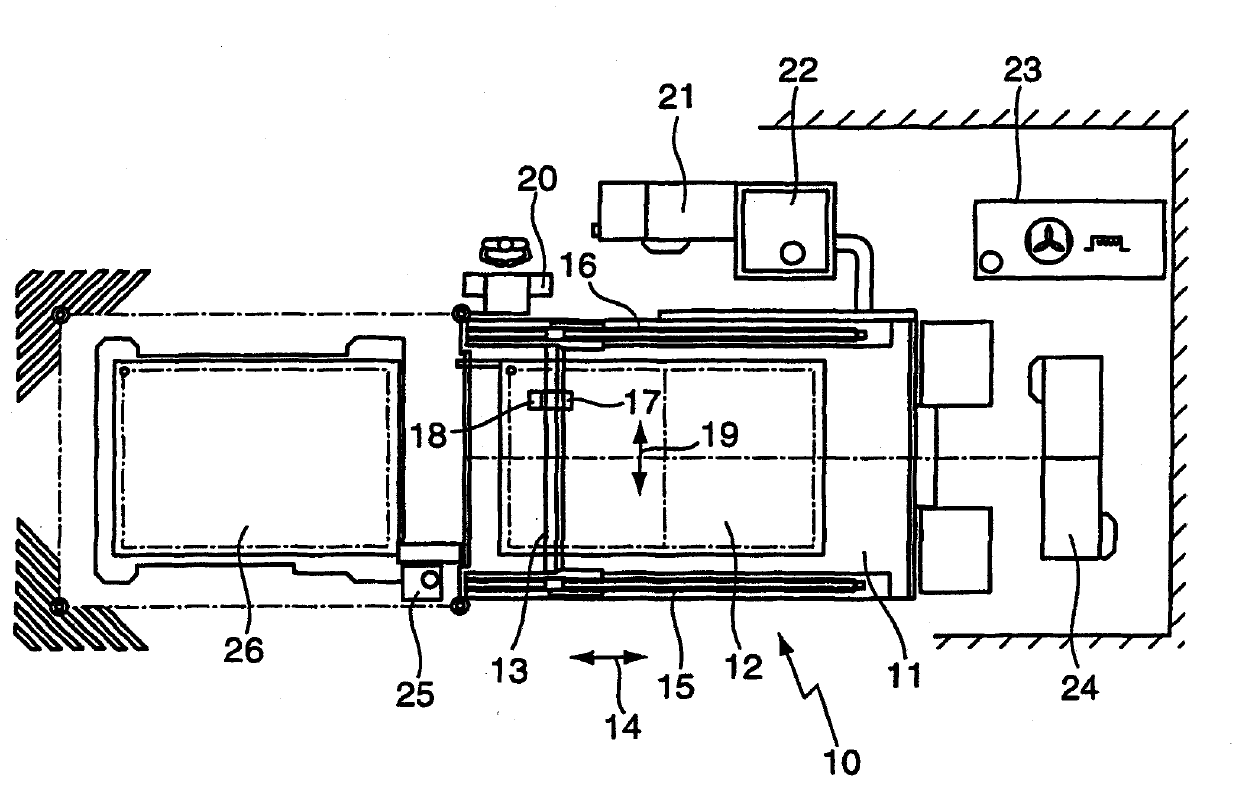

[0035] figure 1 A laser processing machine 10 is shown with a workpiece holder 11 on which a workpiece 12 is arranged. A support structure 13 in the form of a gantry is arranged above the workpiece 12 . The support structure 13 is movable along the guides 15 , 16 in the direction of the double arrow 14 . Here, the carrier structure 13 is driven by a linear drive. The device causing the movement in the direction of the double arrow 14 is called the (tool) shaft. Laser processing heads 17 , 18 are arranged on both sides of the carrier structure 13 . The laser machining head is movable relative to the carrier structure 13 in the direction of the double arrow 19 . The device which brings about the movement in the direction of the double arrow 19 is likewise called the (tool) shaft. Since the laser processing heads 17 , 18 are arranged on both sides of the carrier structure, a maximum working area is achieved. In particular, workpieces can be machined which have substantially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com