Double-inlet atomizing spray head for making snow

A technology of atomizing nozzles and double inlets, which is applied in applications, making ice, household utensils, etc., to achieve the effects of easy disassembly and washing, simple structure, and high snowmaking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

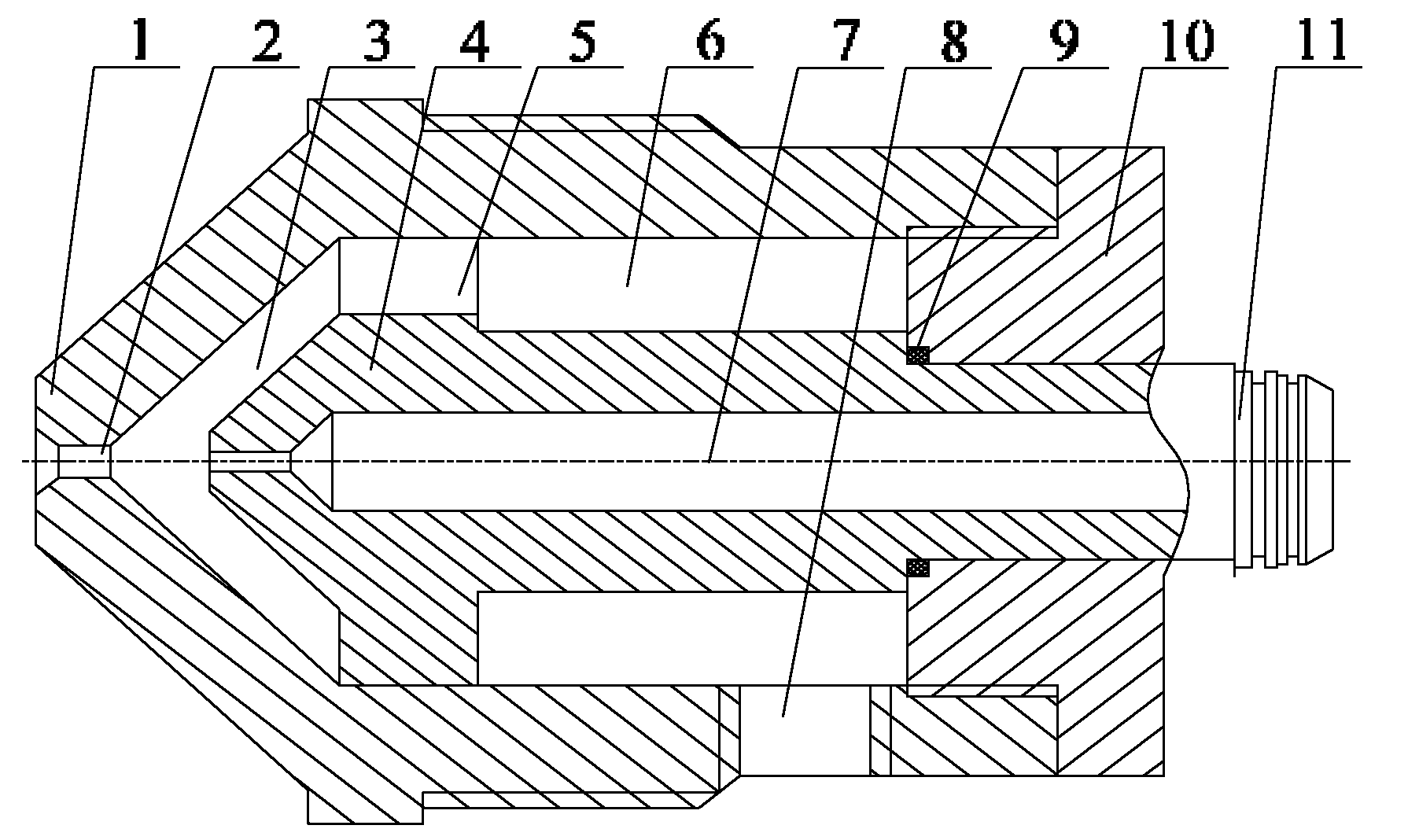

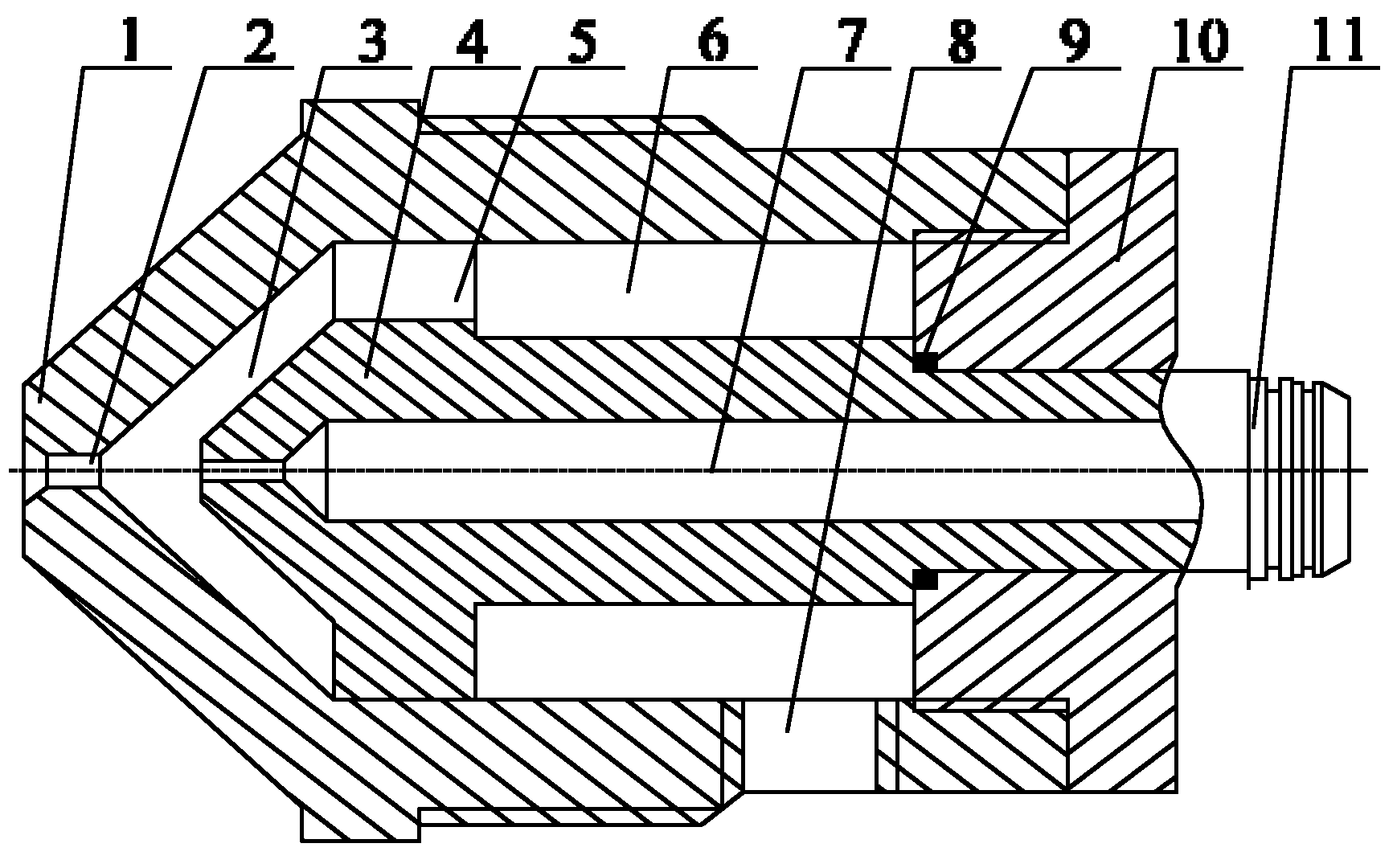

[0011] Below in conjunction with accompanying drawing, the present invention is described in more detail:

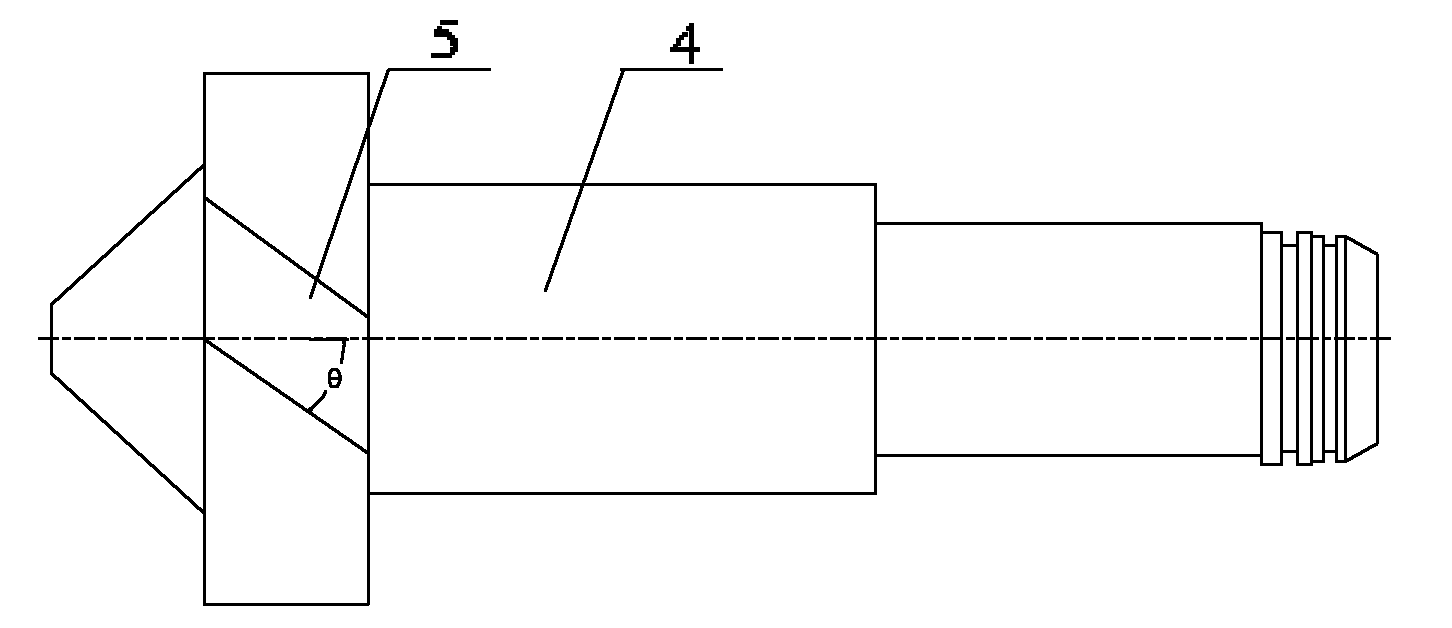

[0012] to combine figure 1 and figure 2 , the present invention is mainly composed of nozzle cap 1, inner cone 4, sealing ring 9, nozzle seat 10 and the like. The inner cone 4 is the most important part of the nozzle. Its front end is in the shape of a truncated cone, and a compressed gas outlet hole is drilled in the center, and the outlet hole communicates with the air flow chamber 7; 4-6 water flow guide grooves 5 are set up, and the center line of the flange is 45°-50° to ensure that the water flow passing through the guide grooves has a tendency to rotate; the end of the inner cone 4 is processed with several ring grooves , it is connected with the gas pipeline coming from the air compressor as the gas coupling head 11. The top of the nozzle cap 1 is in the shape of a truncated cone, with a nozzle hole 2 of 1mm in the center. The nozzle cap 1 is tapped with int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com