Digital straightening method and straightening machine

A leveling machine and leveling technology, applied in the field of leveling machines, can solve the problems of affecting the production efficiency of automatic production lines, taking a long time, consuming many sheets, etc., and achieve the effect of low modification cost, remarkable use effect and simple debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

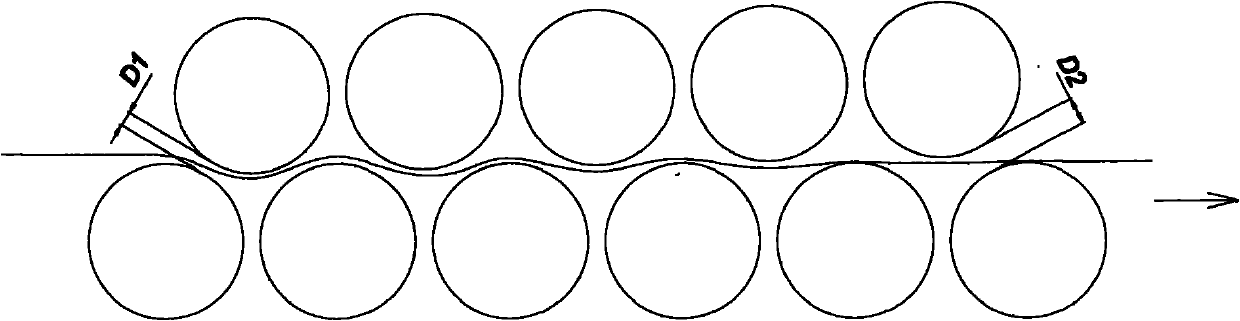

[0030] Assuming that the width of the plate to be leveled is W, the thickness is T, and the yield limit is δs, the leveling machine is equipped with a first roller group adjustment device for adjusting the feeding gap D1 and a second roller group adjustment device for adjusting the discharging gap D2. Roller adjustment device. For fast and precise leveling of the sheet, the following steps can be implemented:

[0031] First, input the identification data of the sheet into the computer: width W, thickness T and yield limit δs to retrieve the empirical parameter values for leveling of the corresponding sheet in the database. Such an empirical parameter value may be a set of data consisting of a value A and a value B, wherein the value A corresponds to the size of the feeding gap D1, and the value B corresponds to the size of the discharge gap D2.

[0032] Second, the computer reads the state value A' of the feed gap sensor used to measure the feed gap D1, and the state value ...

Embodiment 2

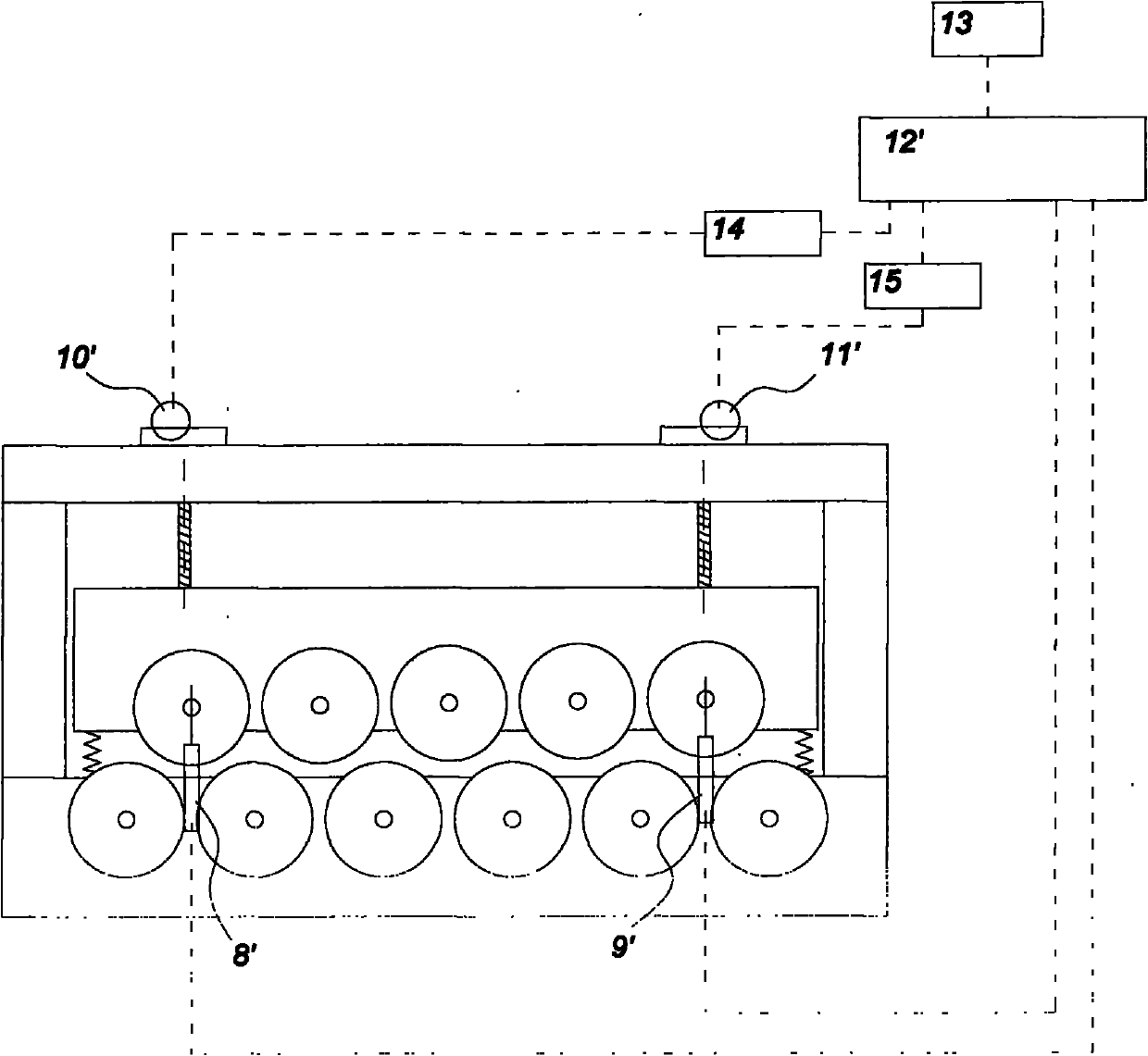

[0037] The numerical control leveling machine of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0038] Such as figure 2 As shown, the CNC leveling machine of this embodiment consists of a frame 1, an upper leveling roller group 2, a lower leveling roller group 3, a first roller group adjustment device 4, a second roller group adjustment device 5, a first spring 6, and a second roller group adjustment device. Two springs 7, feed gap sensor 8, discharge gap sensor 9, first motor 10, second motor 11, PLC12 and computer 13 constitute.

[0039]Among them, the frame 1, the upper leveling roller group 2, the lower leveling roller group 3, the first roller group adjustment device 4, the second roller group adjustment device 5, the first spring 6, and the second spring 7 constitute the prior art. Leveling machine. The feeding gap D1 at the feeding end between the upper leveling roller group 2 and the lower level...

Embodiment 3

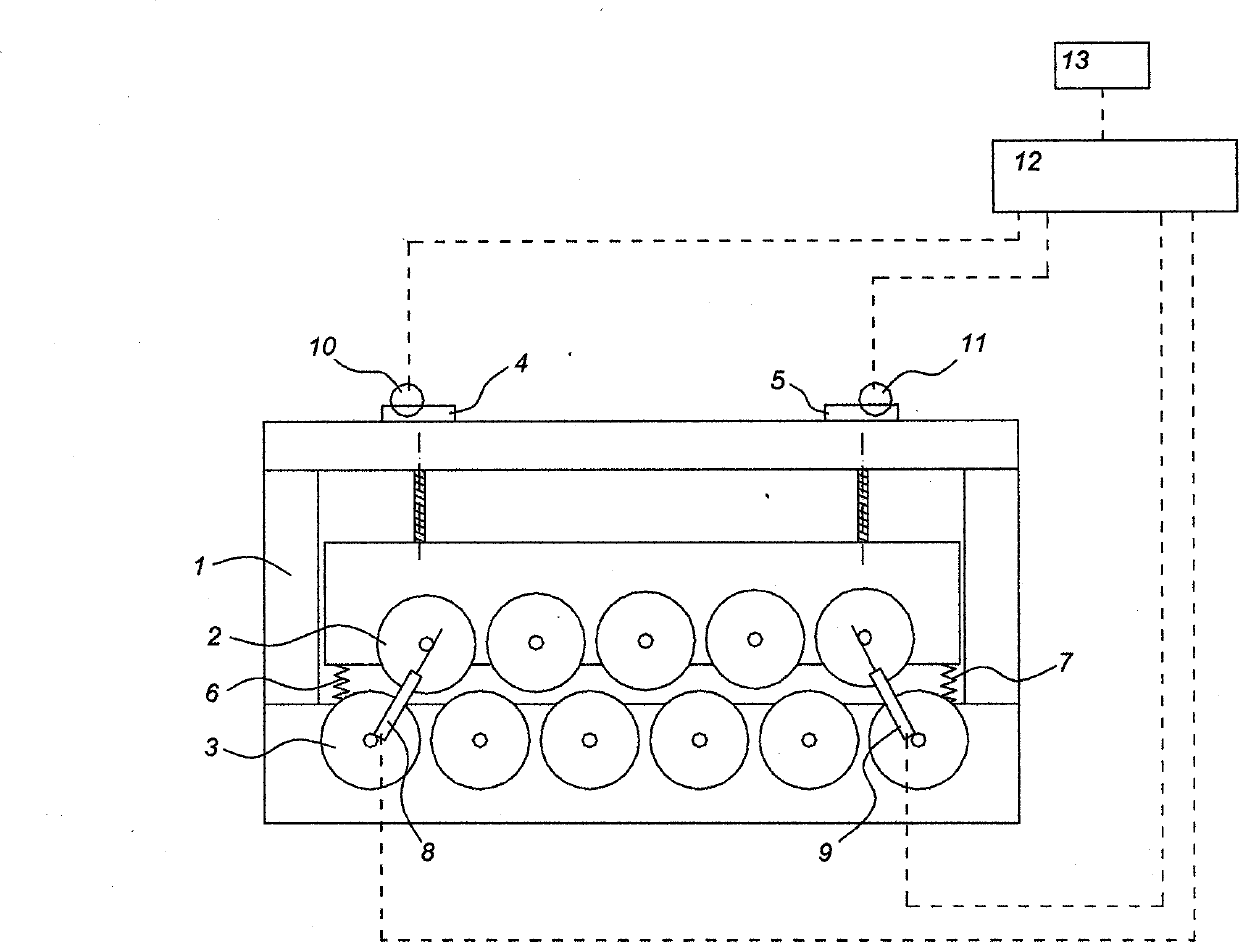

[0044] Such as image 3 As shown, the difference between this embodiment and Embodiment 2 is that: the feed gap sensor 8' and the discharge gap sensor 9' are installed vertically, rather than the oblique installation of Embodiment 2. The first motor 10' and the second motor 11' are variable frequency motors, the first motor 10' is connected to the corresponding port of the PLC12' through the first frequency converter 14; the second motor 11' is connected to the PLC12' through the second frequency converter 15 on the corresponding port.

[0045] The feeding gap sensor 8' is vertically installed, and the measured result is the length of the projection of the feeding gap D1 in the vertical direction. It is easy to know that there is a one-to-one correspondence between the length of the projection and the feeding gap D1. The above-mentioned projected length values can then also be used as status values for the feed gap sensor 8 ′.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com