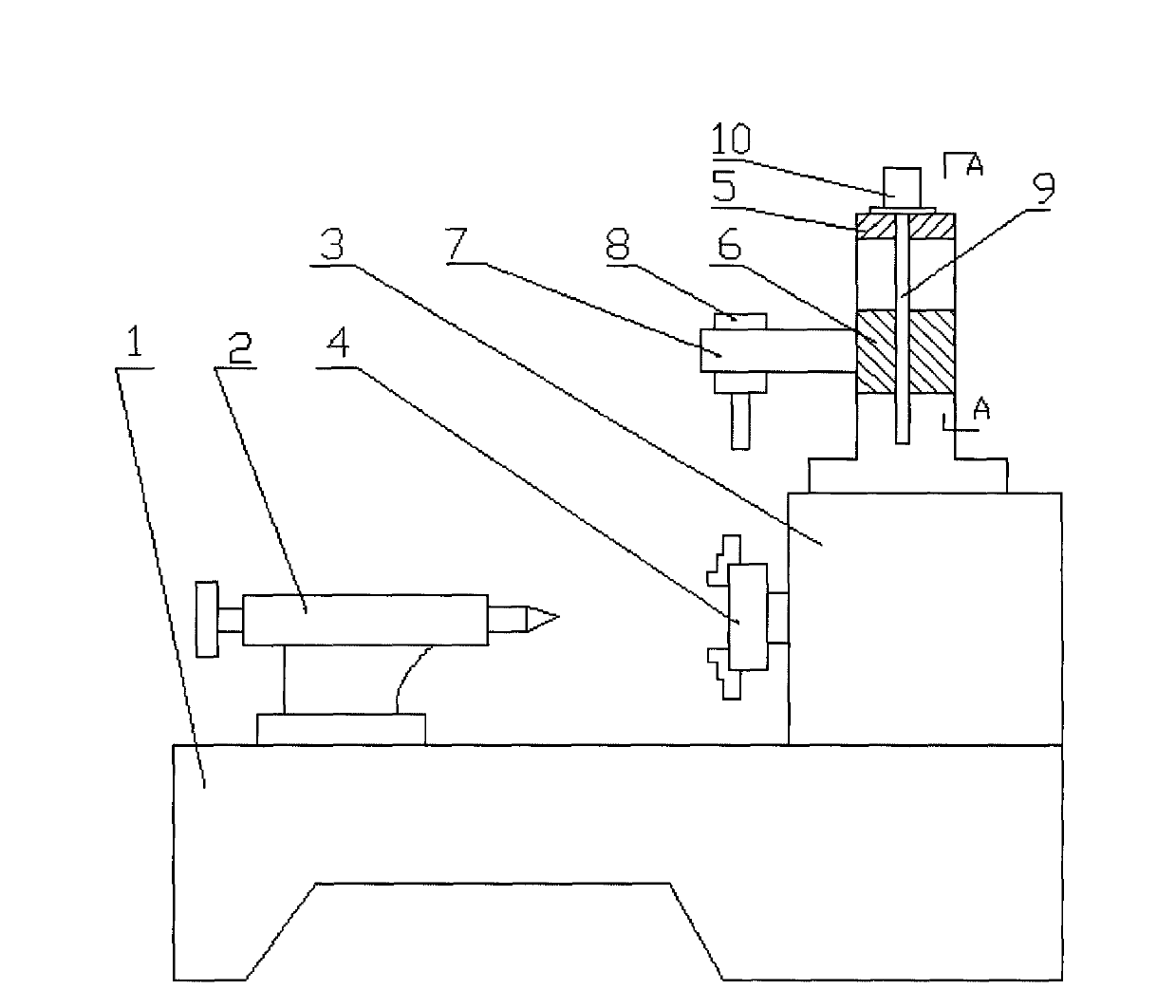

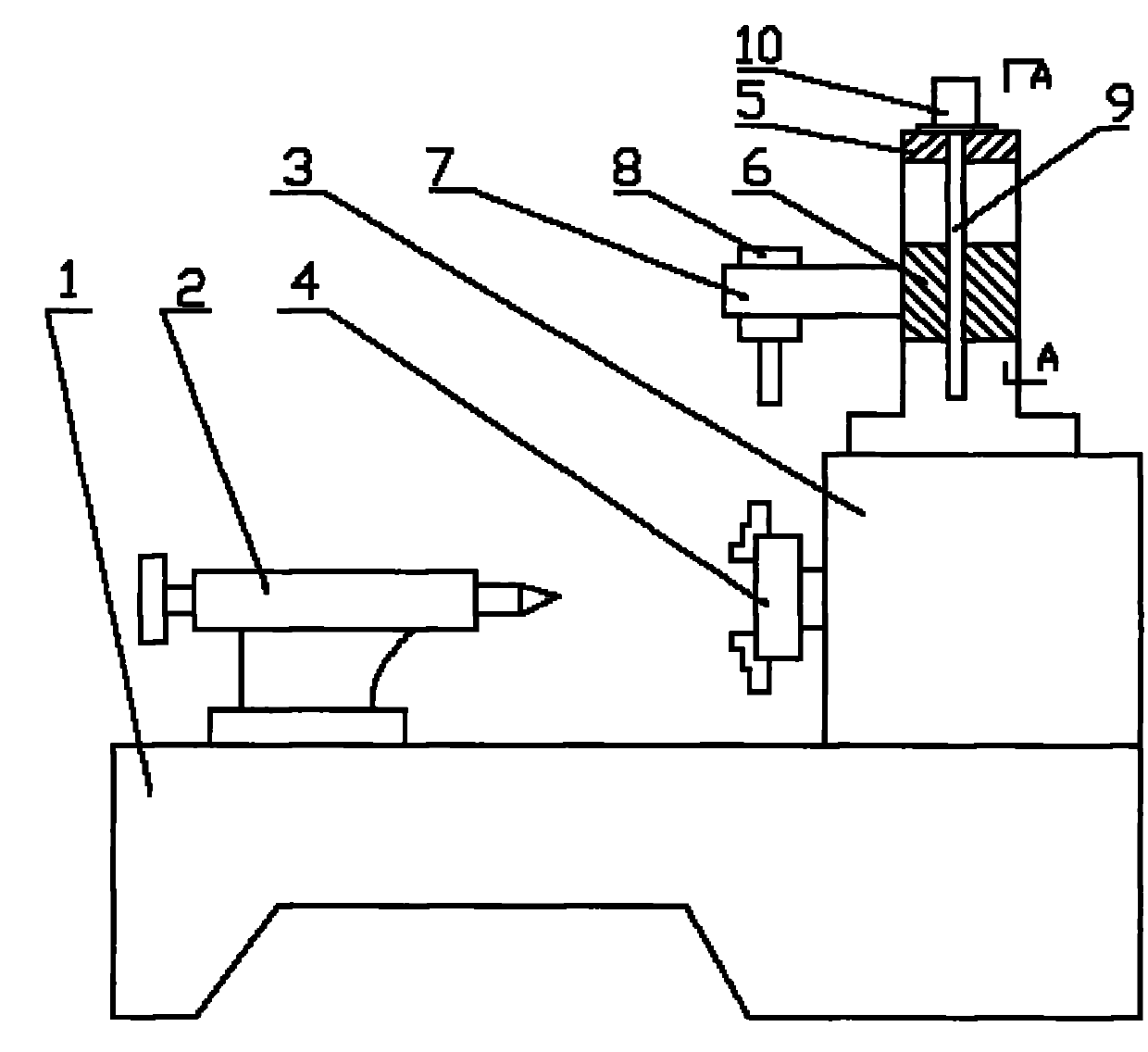

Novel horizontal lathe with functions of automatically clamping and loosening chuck

An automatic clamping and horizontal lathe technology, applied in the field of horizontal lathes, can solve problems such as complex structure, low production efficiency, and easy failure, and achieve the effect of overcoming complex structure, high production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] According to the assembly process of the horizontal lathe, the bed (1), tailstock (2), headstock (3), and chuck (4) are assembled into a standard ordinary horizontal lathe, and the portal column (5) is used The bolts are fixedly installed on the bedside box (3), the slide block (6) is installed in the middle of the opening of the portal column (5), the cantilever (7) is fixedly connected with the slide block (6) in an appropriate manner, and the Install and fix the air wrench (8) on the cantilever (7) in an appropriate manner, install and fix the air motor (10) on the top of the portal column (5), connect the upper end of the lead screw (9) to the air motor (10) The output shaft of the output shaft is fixedly connected in an appropriate manner, and the other end is connected with the slide block (6) by thread fit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com