Floating unloading type device for loosening blade on main shaft

A spindle and tool loosening technology, which is applied in the direction of positioning device, clamping, support, etc., can solve the problems of affecting, reducing the accuracy of the spindle and service life, etc., and achieve the effect of simple overall structure and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

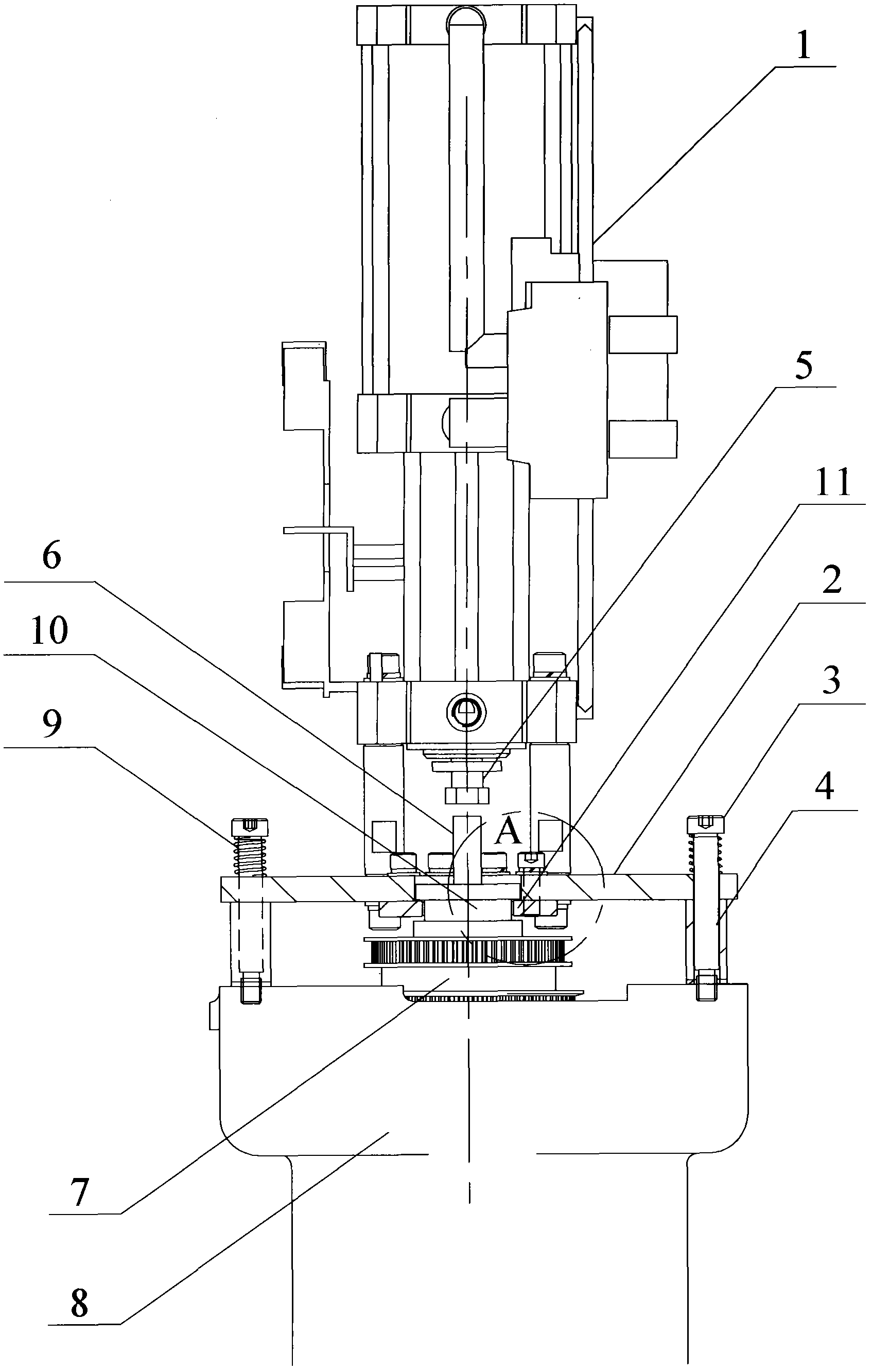

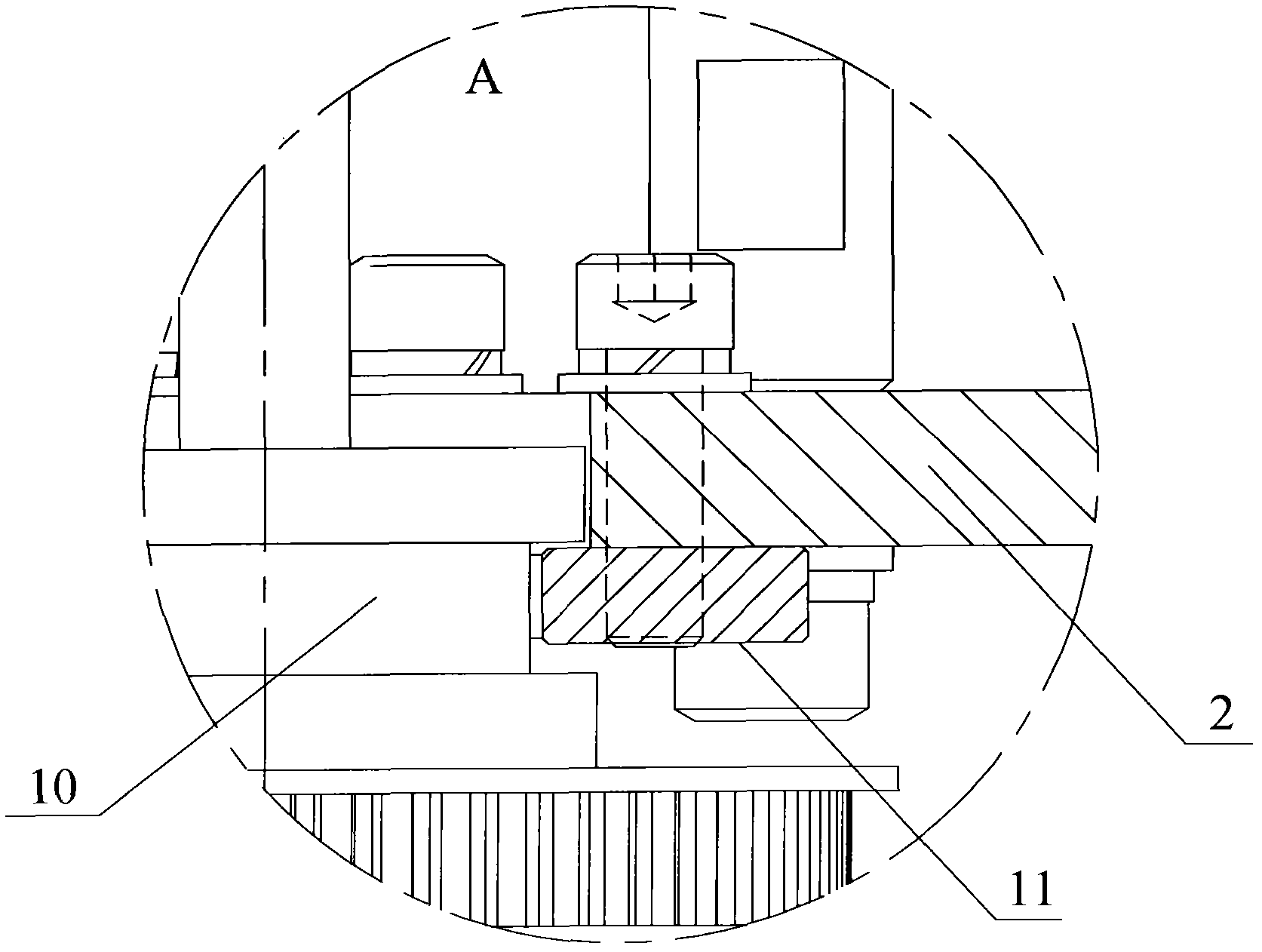

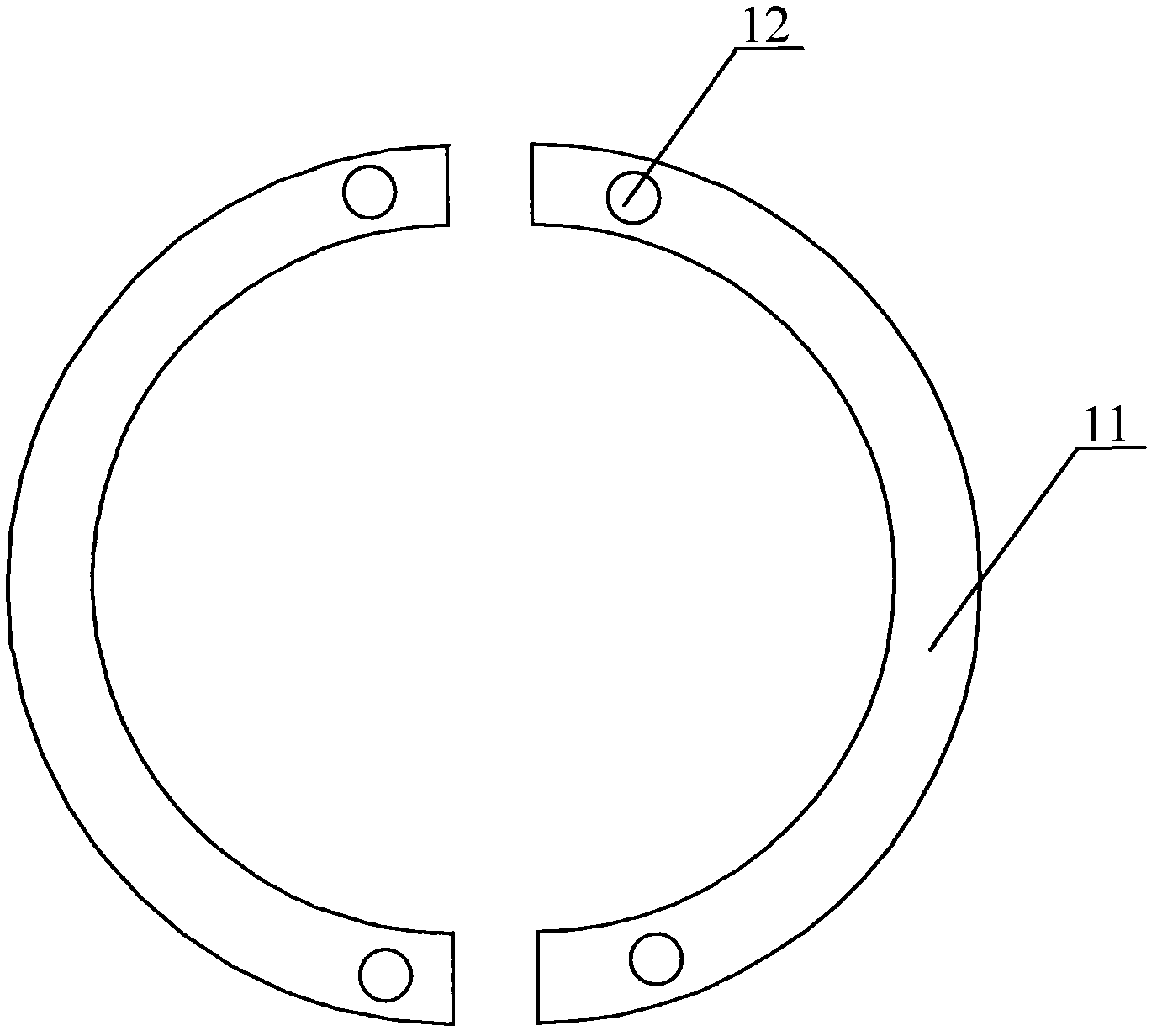

[0018] like figure 1 , 2 As shown, the pressurized cylinder 1 of the present invention is provided with a pressurized cylinder piston rod 5 that can freely expand and contract along the vertical direction, and the interior of the main shaft housing 8 is equipped with a freely rotatable main shaft 7 . The broach rod 6 used for grasping and releasing the tool is arranged inside the main shaft 7, and can move up and down along the central axis of the main shaft 7 to compress and relax the butterfly spring. The end of the broach rod 6 corresponding to the booster cylinder piston rod 5 protrudes outside the spindle housing 8, and the central axis of the broach rod 6 is on the same line as the central axis of the booster cylinder piston rod 5. On a straight line, to ensure that the broach bar 6 can be right at the end of the broach bar 6 when moving down quickly.

[0019] A booster cylinder load-bearing plate 2 is also fixed by screws on the booster cylinder 1, which ensures that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com