Corrosion resistant paint for the inner surface of radiator and preparation method thereof

An internal anti-corrosion and radiator technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of limited epoxy resin, reduced production efficiency, and slow surface drying speed, and achieve strong adhesion, reduced energy consumption, and coating surface dry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

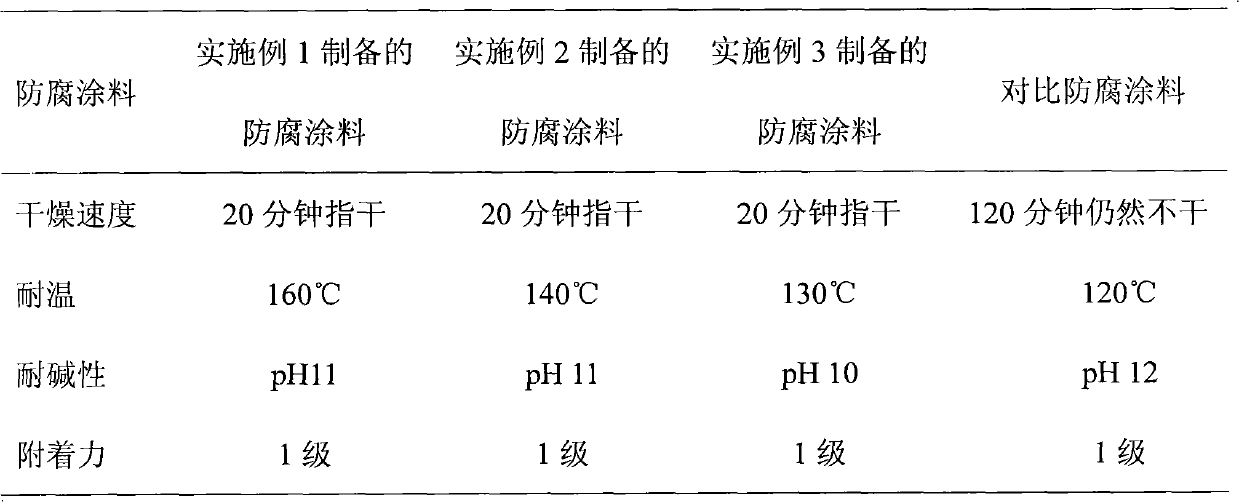

Examples

Embodiment 1

[0038] An internal anti-corrosion coating for radiators, the components are in parts by weight: modified acrylic resin: 48, pigment: 12, filler: 15, thinner: 19, auxiliary agent: 1.5, and other resins: 4.5.

[0039] The pigments are titanium dioxide and soft black, wherein the titanium dioxide is 11 parts by weight and the soft black is 1 part by weight.

[0040] The filler is calcined aluminum silicate and talcum powder, wherein the calcined aluminum silicate is 12 parts by weight and the talc powder is 3 parts by weight.

[0041] The diluent is butyl acetate and xylene, wherein the butyl acetate is 12 parts by weight and the xylene is 7 parts by weight.

[0042] The auxiliary agent is fumed silica.

[0043] The other resins are 618 epoxy resins.

[0044] The preparation method of anticorrosion coating in the above-mentioned radiator is as follows:

[0045] (1) Preparation of modified acrylic resin:

[0046] ① Prepare raw materials for preparing modified acrylic resin: re...

Embodiment 2

[0054] An internal anti-corrosion coating for radiators, the components are, in parts by weight, modified acrylic resin: 40, pigment: 12, filler: 15, thinner: 30, auxiliary agent: 1, and other resins: 2.

[0055] The pigment is nanometer iron red.

[0056] The filler is calcined aluminum silicate and kaolin, wherein the calcined aluminum silicate is 10 parts by weight and the kaolin is 5 parts by weight.

[0057] Described diluent is butyl acetate, ethyl acetate, ethanol and butanol, wherein, butyl acetate is 10 parts by weight, ethyl acetate is 10 parts by weight, butanol is 5 parts by weight, ethanol parts by weight is for 5.

[0058] The auxiliary agent is fumed silicon dioxide and organic bentonite, wherein the weight part of fumed silicon dioxide is 0.5, and the weight part of organic bentonite is 0.5.

[0059] The other resins are modified silicone resin and 852 amino resin, wherein the modified silicone resin is 1,852 amino resin is 1 by weight.

[0060] The preparat...

Embodiment 3

[0070] An internal anti-corrosion coating for radiators, each component is, by weight, modified acrylic resin: 50, pigment: 10, filler: 12, diluent: 20, auxiliary agent: 3, other resin: 5.

[0071] The pigment is titanium dioxide.

[0072] The filler is calcined aluminum silicate.

[0073] Described diluent is butyl acetate.

[0074] The auxiliary agent is fumed silica.

[0075] The other resins are 618 epoxy resin and 852 amino resin, wherein the 618 epoxy resin has 4 parts by weight, and the amino resin has 1 part by weight.

[0076] The preparation method of anticorrosion coating in the above-mentioned radiator is as follows:

[0077] (1) Preparation of modified acrylic resin:

[0078] ① Prepare raw materials for preparing modified acrylic resin: reaction material A and reaction material B;

[0079] The reaction material A is composed of: methyl methacrylate: 32, methyl acrylate: 32, butyl acrylate: 4.5, diluent: 31.5 in parts by weight; the diluent in the reaction mat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap