Vacuum cutting method and device for vacuum suction of anode mud from cell bottom

A vacuum suction, anode slime technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of affecting the quality of metal deposition on the cathode plate, polluting the new electroplating solution, and returning the anode slime to turbidity, etc. Violation of tank workers, elimination of effects, and effects of eliminating the effects of misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

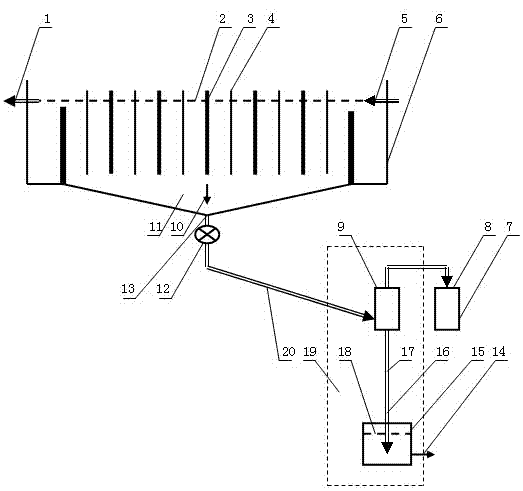

[0043] Embodiment one: A vacuum cutting device for single-point vacuum suction of anode slime from the bottom of the tank

[0044] figure 1 It is a vacuum cutting device for single-point vacuum suction of anode sludge from the bottom of the tank, and is composed of an electrowinning tank 6 , a vacuum separation device 19 and a vacuuming device 7 . The anode slime 10 in the electrowinning cell 6 is vacuumed from the anode slime outlet 13 provided at the bottom 11 of the bucket-shaped chamber through a vacuum valve 12 and a vacuum separation device 19 .

[0045] It can be seen that the electrowinning cell 6 is a small electrowinning cell with only one bucket-shaped chamber bottom 11 . The slope of the tank bottom 11 of the bucket-shaped chamber is greater than the angle of repose of the anode slime 10 in the new electrowinning solution 5 , and the anode slime 10 falling off the anode plate 3 tends to gather at the anode slime outlet 13 . When the deposition layer of the anod...

Embodiment 2

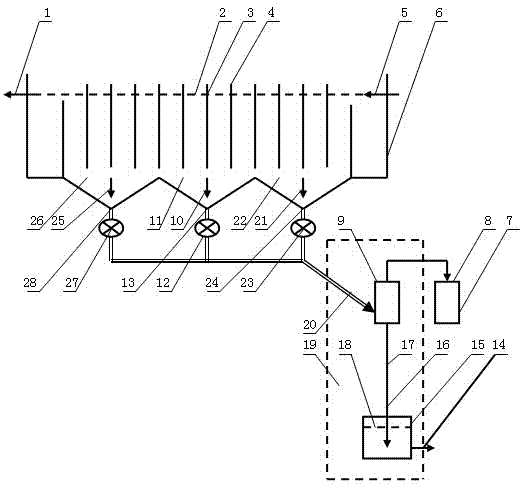

[0050] Embodiment two: A vacuum cutting device for vacuuming anode slime from multiple points at the bottom of the tank

[0051] figure 2 It is a vacuum cutting device for multi-point vacuum suction of anode slime from the bottom of the tank, consisting of an electrowinning tank 6, a vacuum separation device 19 and a vacuuming device 7. When adopting a large-scale electrowinning cell scheme, it is better to implement the vacuum cutting process of vacuuming the anode slime from multiple points at the bottom of the cell.

[0052] Since the size of the large electrowinning tank 6 is too large, if a single bucket-shaped chamber bottom structure is adopted, the total height of the electrowinning tank may be too high, resulting in a significant increase in the manufacturing cost of the electrowinning tank. figure 2 The electrowinning cell 6 shown is provided with three bucket-shaped chamber bottoms 11, 22 and 26, and the bottom slopes of all bucket-shaped chamber bottoms are gr...

Embodiment 3

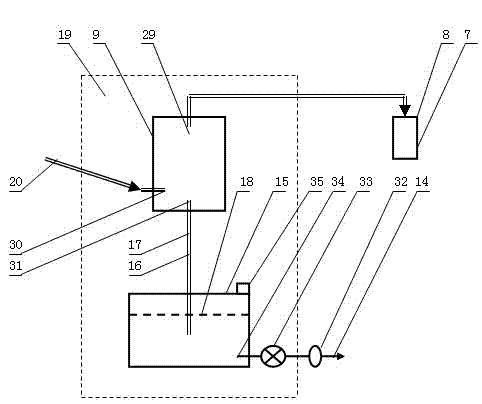

[0055] Embodiment three: one Anode Slime Vacuum Separation Device

[0056] image 3 It is a vacuum separation device for anode slime, which is composed of a vacuum liquid receiving device 9, a gravity sludge discharge device 16 and a liquid sealing device 15, and the vacuum system used is a water ring vacuum pump system. Compared with the conventional vacuum separation device, it is superior in that the height of the upper end of the gravity sludge discharge pipe 17 is set to be lower than the height of the bottom of the electrowinning tank 6 . Usually, the liquid sealing device 15 is arranged at a place 5-10 meters lower than the bottom of the electrowinning tank. This setting can make full use of the potential energy of the liquid surface 2 of the electrowinning tank, which is beneficial to reduce the vacuum force of the vacuum device 7 , and especially effectively prevents the deposition of the anode slime 10 in the vacuum tube 20 . Although it is theoretically feasible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com