Low-temperature internal recycling steam engine

A steam engine and internal circulation technology, which is applied to steam engine devices, mechanical equipment, engine components, etc., can solve problems such as high emissions, unfavorable use, complex structure, etc., and achieve the effects of reducing energy consumption, saving heat energy, and low boiling point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

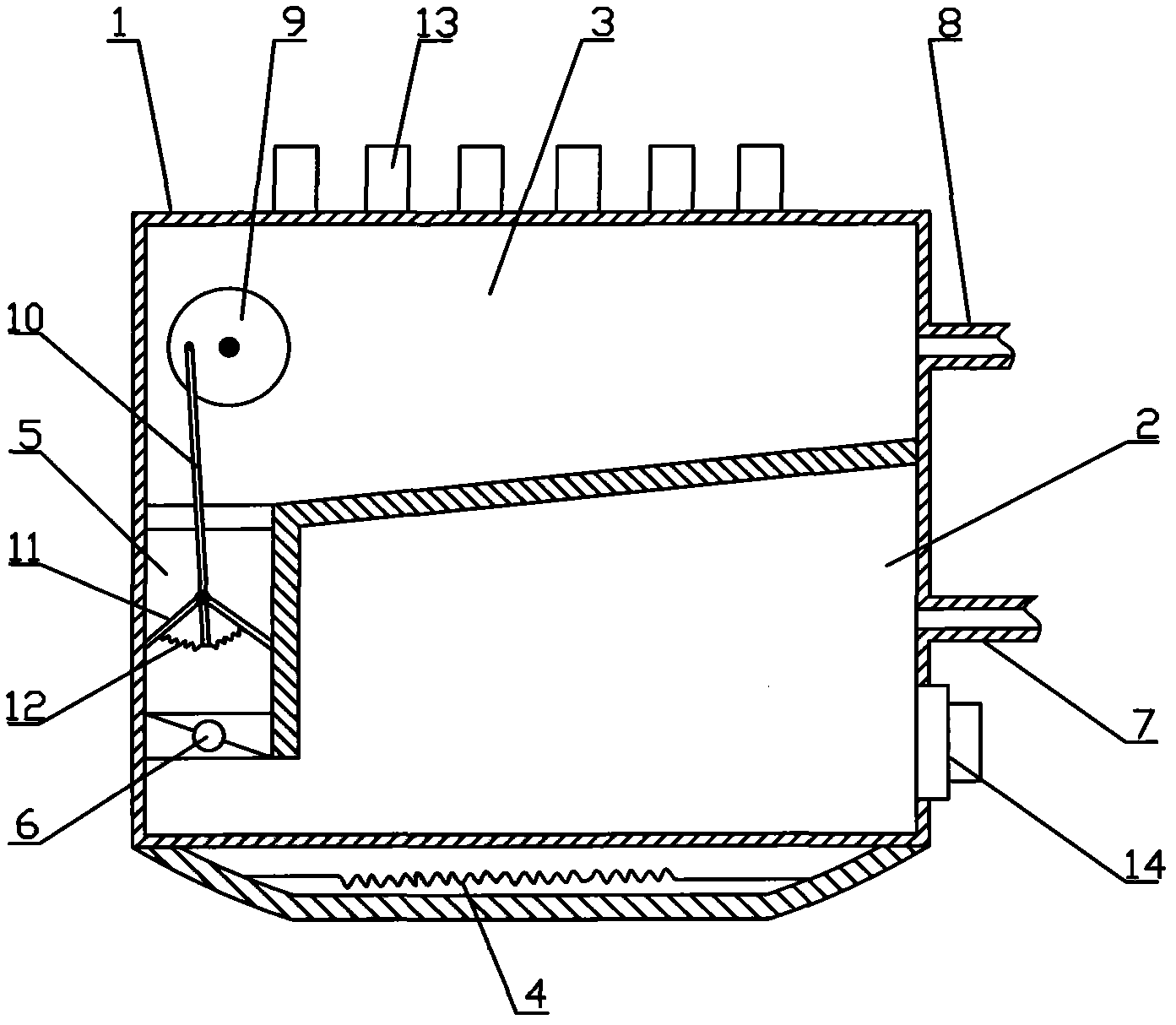

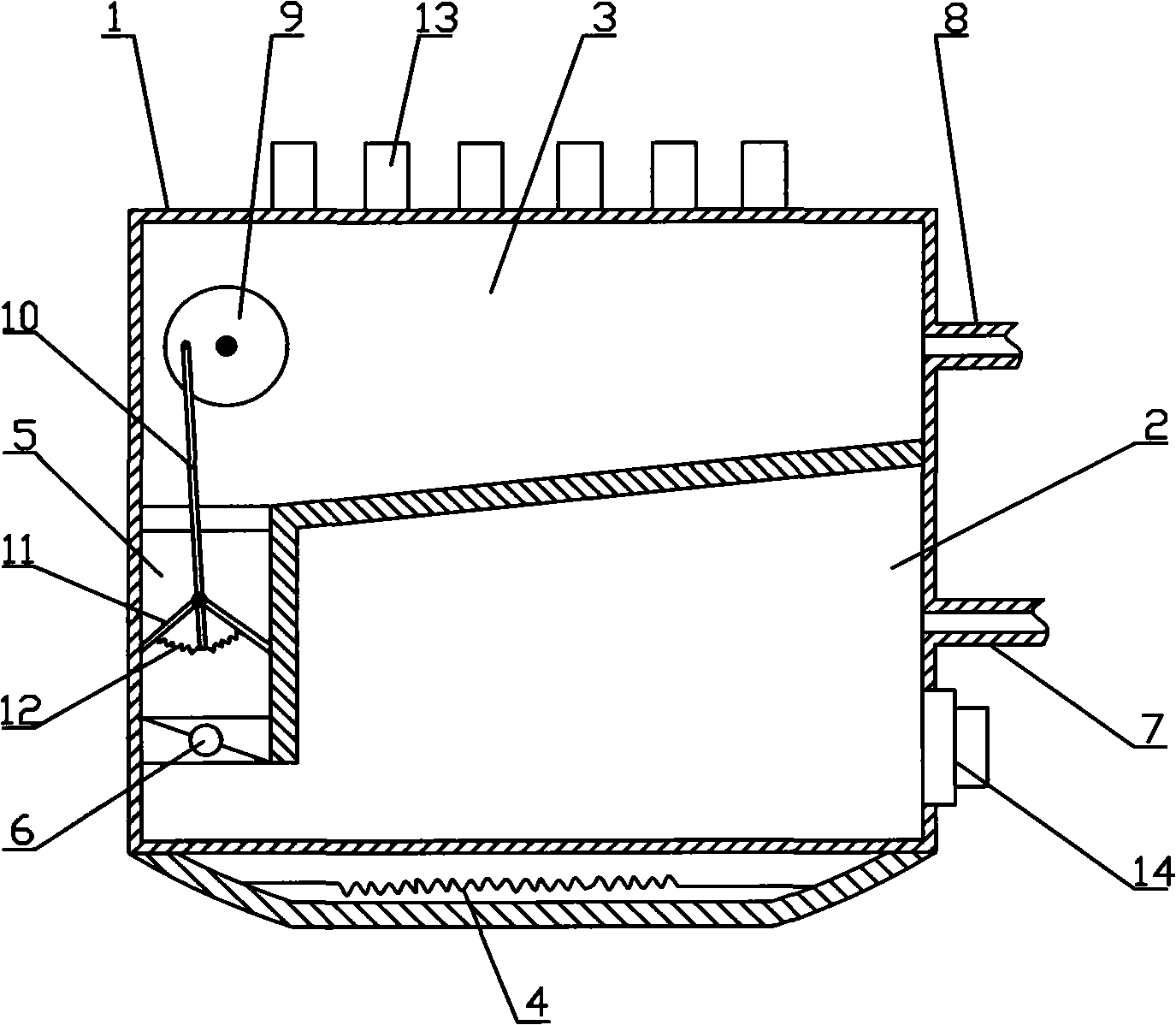

[0011] Such as figure 1 As shown, this embodiment is a low-temperature internal circulation steam engine, which mainly includes a steam engine steam supply system. The steam engine steam supply system mainly includes a casing 1, and the casing 1 is provided with a vaporization chamber 2 and a cooling chamber 3. The vaporization chamber 2 A heating device 4 is provided at the bottom, and a return pipe 5 is provided between the vaporization chamber 2 and the cooling chamber 3. A hydraulic device is provided in the return pipe 5, and a check valve 6 is also provided under the hydraulic device. The vaporization chamber 2 and The cooling cavity 3 is also respectively provided with a steam inlet pipe 7 and a steam outlet pipe 8 which communicate with the cylinder of the steam engine. The hydraulic device mainly includes a turntable 9 arranged on the casing 1. The turntable 9 is connected to the power output shaft of the steam engine. A push rod 10 is connected to any eccentric posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com