Shutting door for dry-type slag-discharging machine

A technology of dry slag discharger and shut-off door, which is applied in the direction of lighting and heating equipment, which can solve problems such as operating environment, personal safety hazards, affecting the cooling effect of the coke block core, and difficulty in transporting large coke blocks, and achieves maintenance The effect of low cost, smooth transportation and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

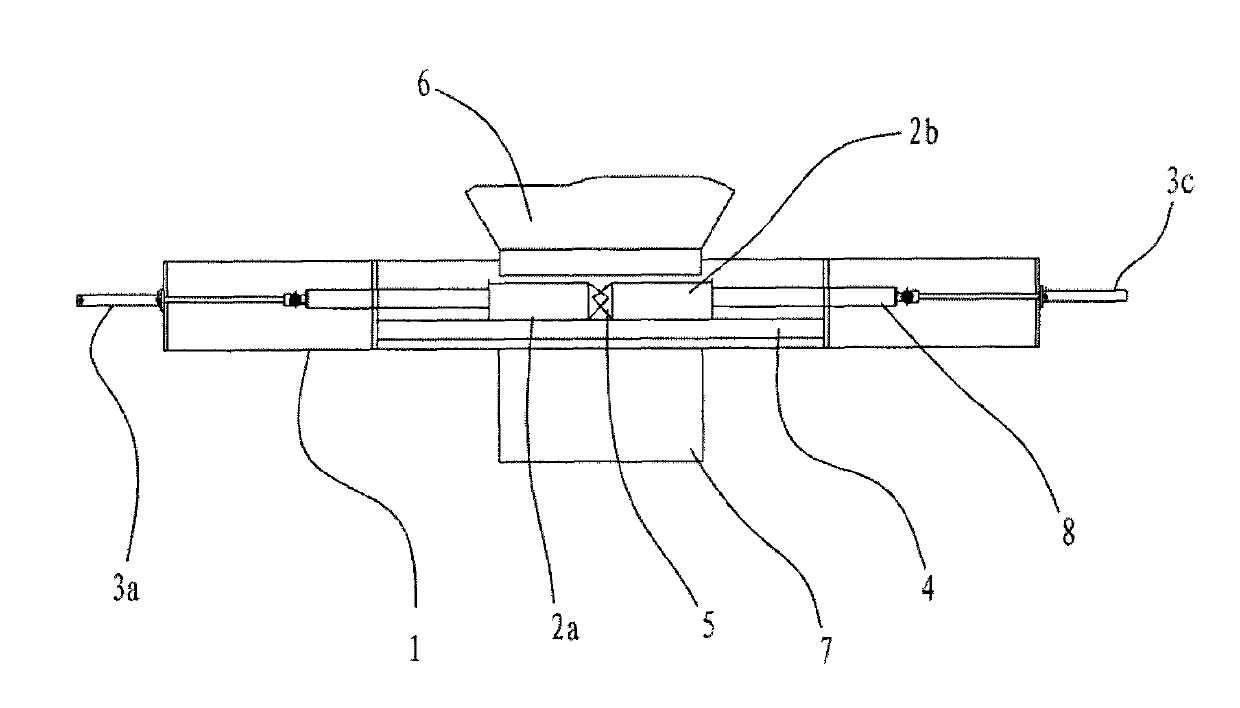

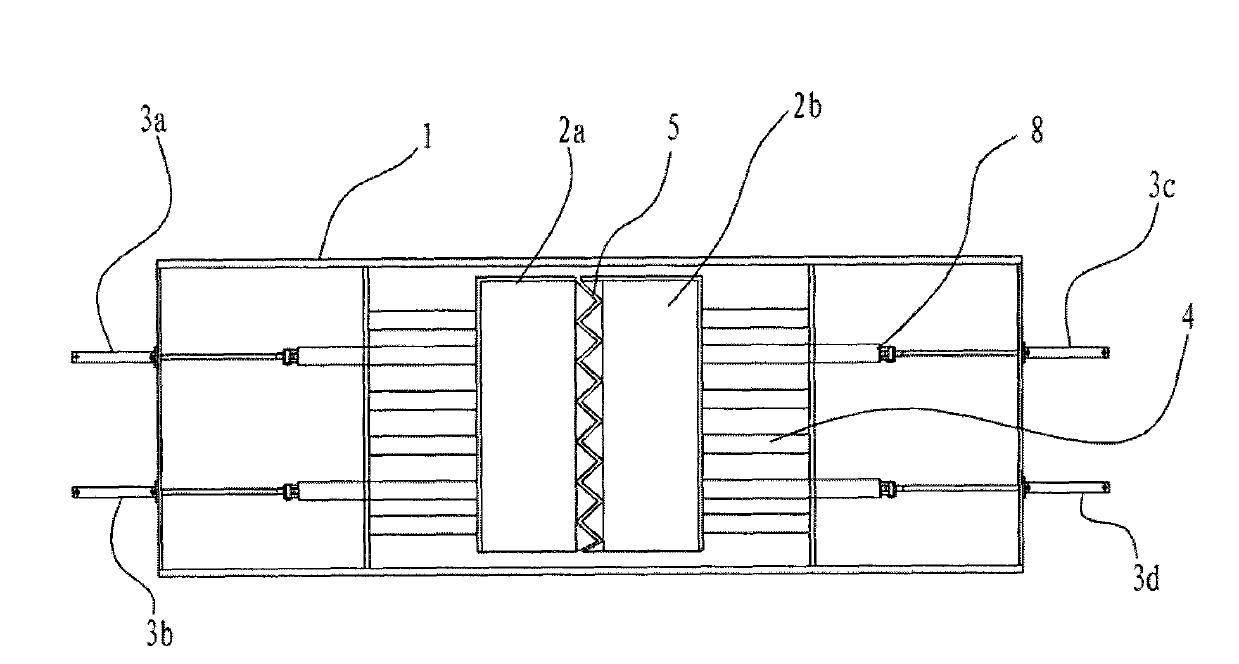

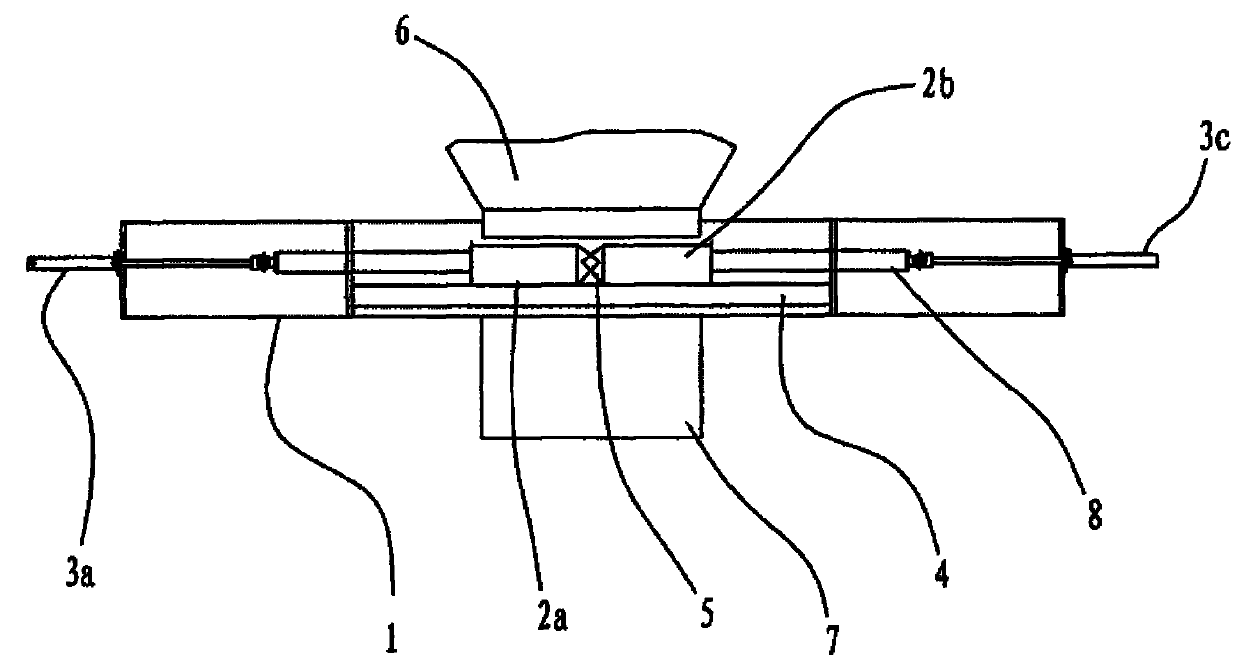

[0023] Such as figure 1 , figure 2 As shown, the best implementation mode of the shut-off door for the dry-type slag discharger of the present invention, the door seat 1 of the shut-off door device is installed between the slag hopper 6 and the dry-type slag discharger 7 . The door seat 1 is provided with left and right door panels 2a, 2b running opposite to each other horizontally. The left and right door panels 2a, 2b are installed on the horizontal track 4. Between the horizontal track 4 and the door seat 1 is a fixed rigid body. The left and right door panels 2a, 2b are respectively connected to the first driving mechanism 3a, the second driving mechanism 3b, the third driving mechanism 3c, and the fourth driving mechanism 3d through the connecting rod 8. The first drive mechanism 3 a , the second drive mechanism 3 b , the third drive mechanism 3 c , and the fourth drive mechanism 3 d can be driven electrically or hydraulically, and are fixed on the door seat 1 . In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com