Process method and equipment for constructing ground source heat pump well

A soil source heat pump and construction technology technology is applied in the field of ground source heat pump construction technology to achieve the effects of low cost, good application effect and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

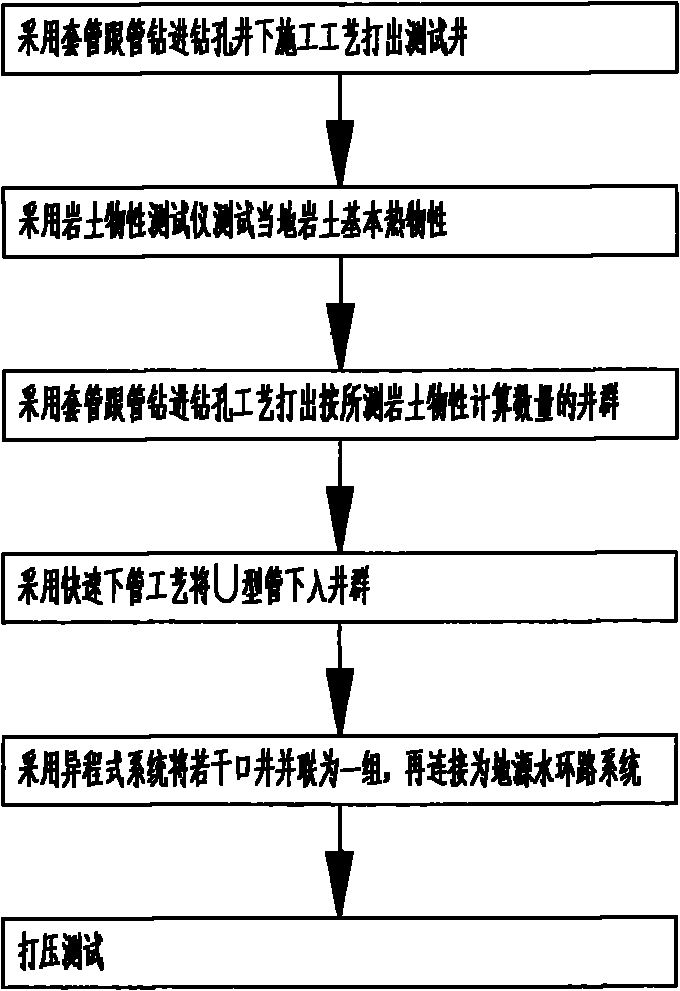

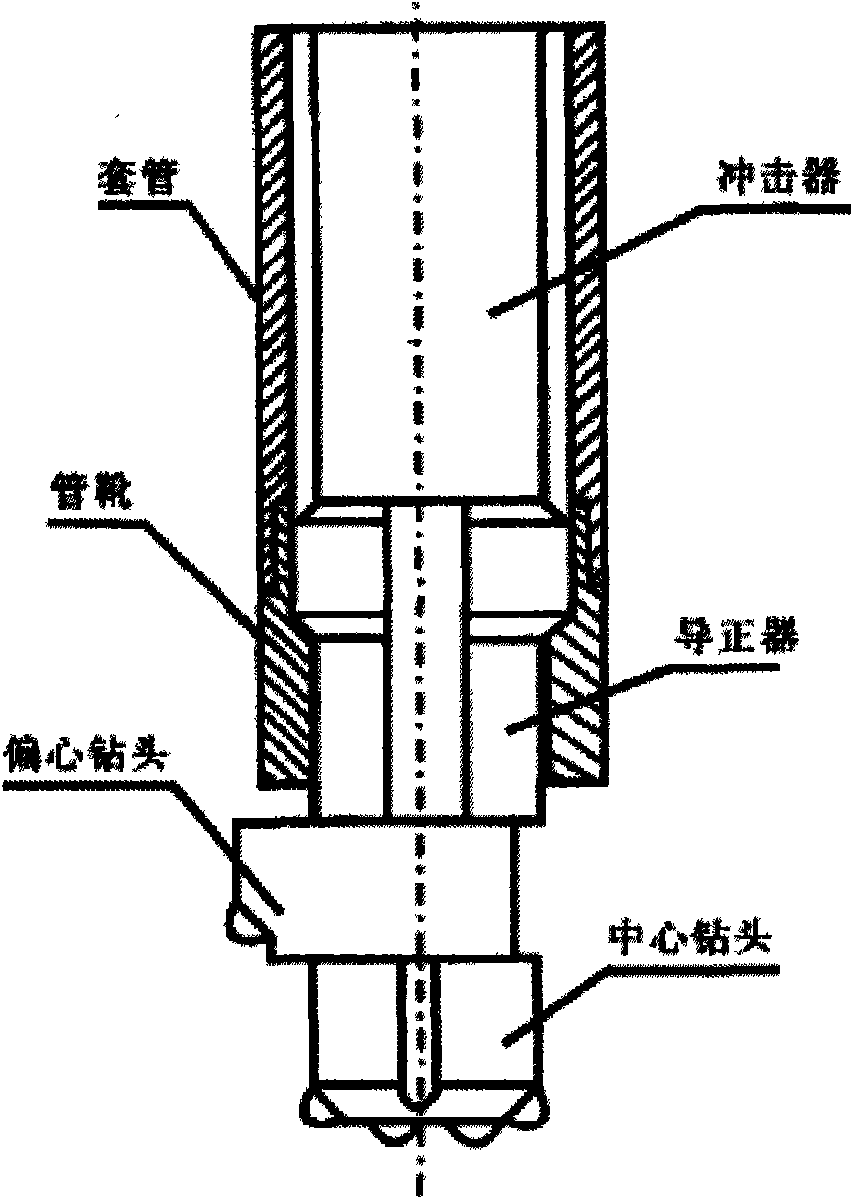

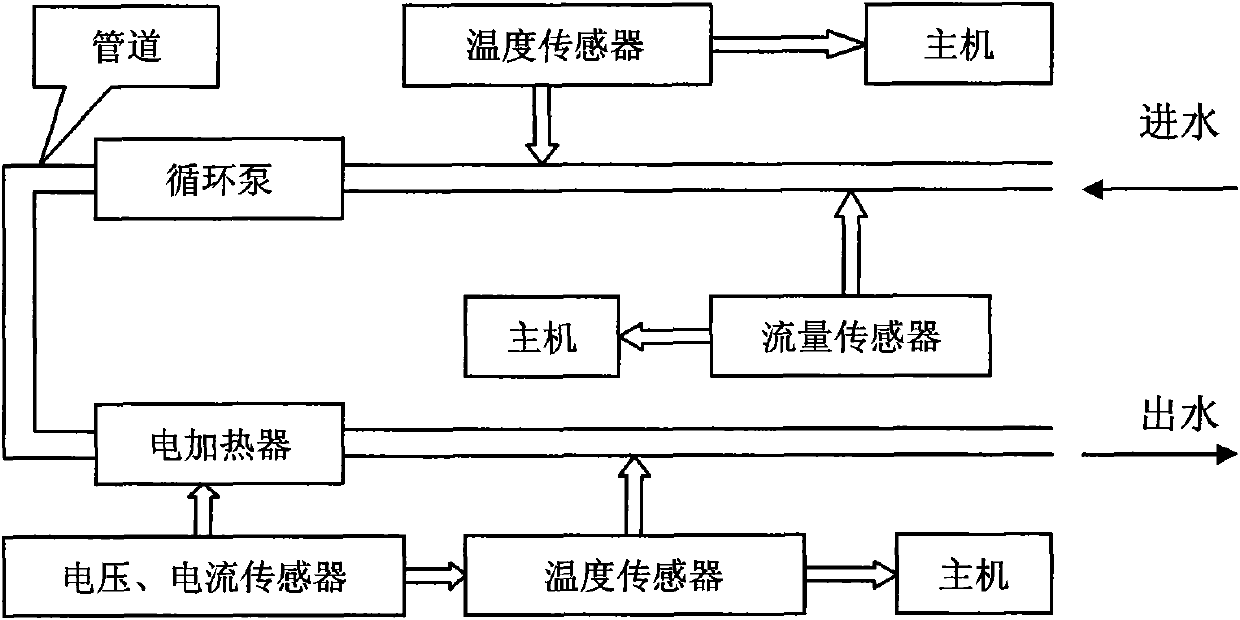

[0029] figure 2 It is a structural schematic diagram of the single-eccentric three-piece casing and pipe drilling tool used in the casing and pipe drilling drilling construction of the key process equipment of the present invention, image 3 It is a schematic diagram of the principle of geotechnical thermal physical property testing.

[0030] The specific description of the present invention is: a soil source heat pump ground source well construction process and equipment, the construction process and steps are as follows:

[0031] (1) The test well is drilled by using the casing and pipe drilling downhole construction technology;

[0032] (2) Use a geotechnical property tester to test the basic thermophysical properties of the local rock and soil;

[0033] (3) Use the casing and pipe drilling technique to excavate the well group with the number calculated according to the measured rock and soil physical properties;

[0034] (4) Run the U-shaped pipe into the well group by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com