Device and method for x-ray examination of an object for material defects by means of x-rays

A material defect, X-ray technology, used in X-ray tube parts, material analysis using radiation, X-ray tubes, etc., can solve problems such as rising, inability to obtain information on objects, and high cost of computed tomography equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

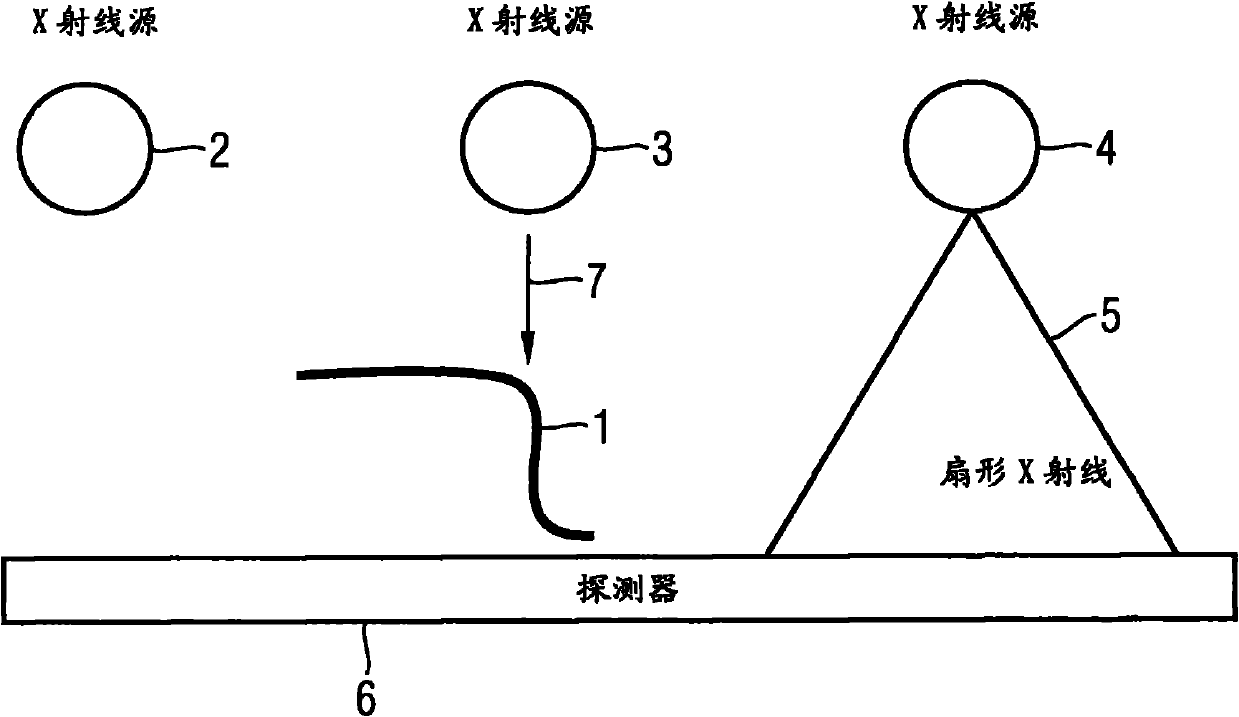

[0030] figure 1 A section of object 1 to be examined is shown. These are, for example, metal components consumed in vehicles. The assembly is moved in the z-direction, ie in the direction of the drawing plane (for example by means of a conveyor belt not shown) and irradiated there with the test radiation. exist figure 1 In the conventional system shown in , three conventional X-ray sources 2 to 4 are used for the examination of objects. These x-ray sources 2 to 4 generate x-rays 5 , for example fan beams. During the x-ray recording, the x-rays transmitted through the object 1 to be examined are recorded by the detector 6 . That is, projections can be registered by means of which the material properties of the object 1 can be deduced.

[0031] as in figure 1 Conventional X-ray tubes used in X-ray tubes mainly consist of a vacuum chamber with an outer casing, which contains a cathode and an anode. The cathode here works as a negative electrode, which sends electrons to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com