Model test system for sandy soil liquefaction and flowing

A model test, sand and soil technology, applied in teaching models, educational appliances, instruments, etc., can solve the problems of non-discovery, blindness, lack, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

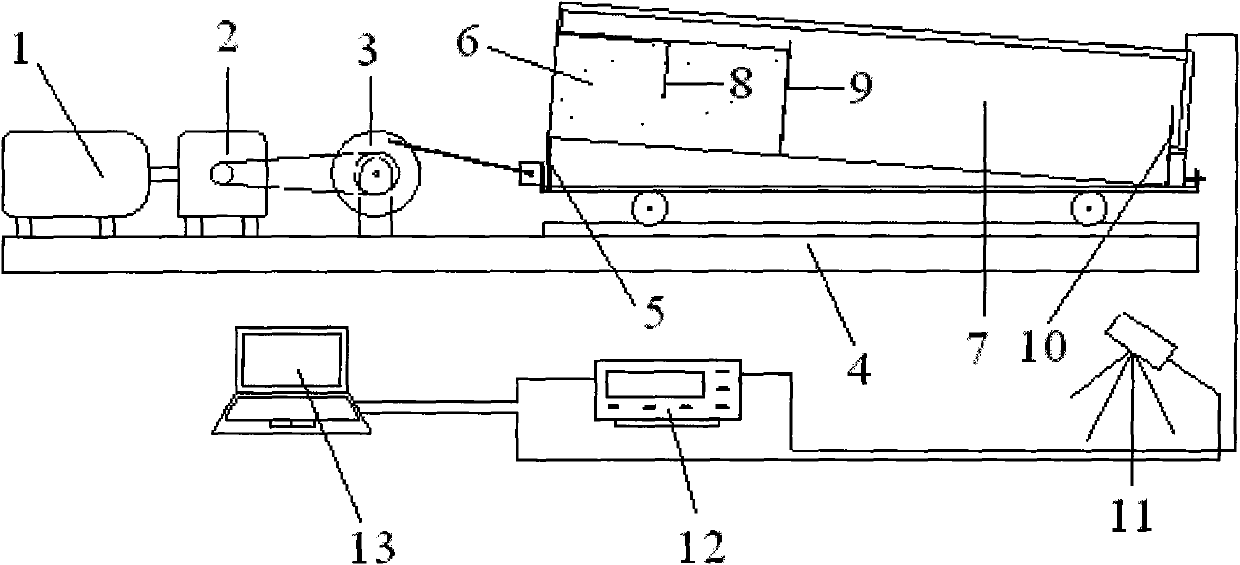

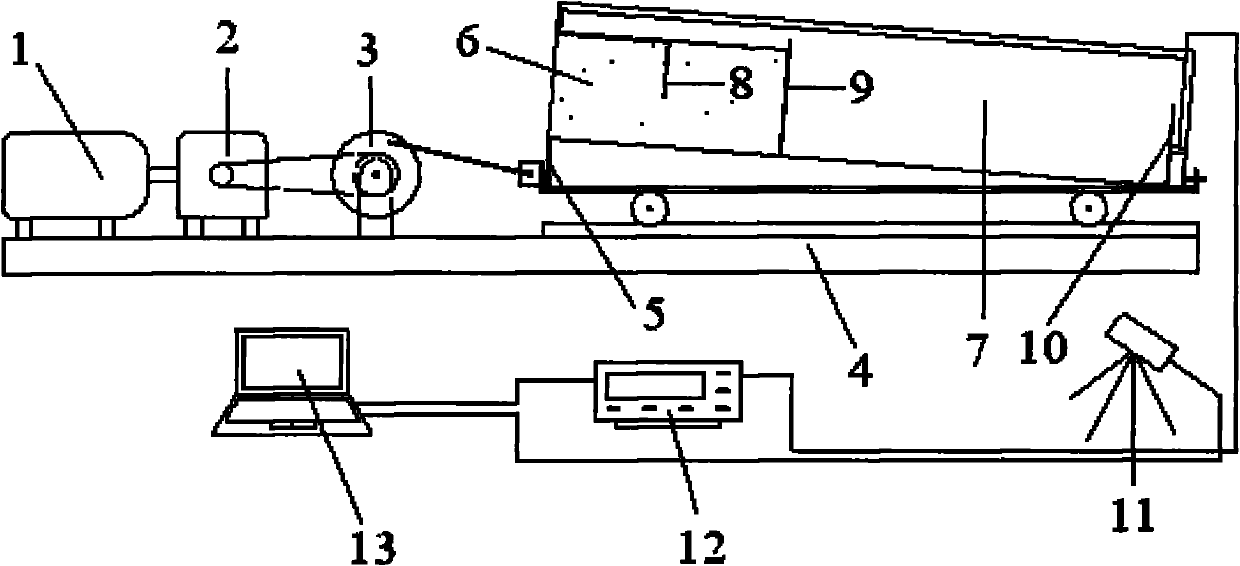

[0017] A model test system for sand liquefaction flow, its structure is as follows figure 1 As shown, the system includes a motor 1, a worm reducer 2, a slider crank mechanism 3, a base 4, a screw support 5, an inner connection box 6, a model box 7, a hole pressure sensor 8, an inner connection box baffle 9, a force measuring Baffle plate 10, digital camera 11, dynamic strain acquisition instrument 12 and computer 13, motor 1 is connected with worm reducer 2, worm reducer 2 is connected with crank slider mechanism 3 through a belt, and one end of crank slider mechanism 3 is connected with base 4 , a directional guide rail is installed under the base 4, and the pulley of the worm reducer 2 has three kinds of pitch circle diameters, which can realize three speeds of 60r / min, 120r / min or 180r / min at the crank end, so that the base 4 can realize 1Hz, 2Hz or The vibration frequency is 3Hz. At the same time, the crank radius is designed to be adjustable. The adjustment range is 20-7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com