Grain sorting suction pen

A technology of crystal grains and pen holder, which is applied in the improvement field of sorting suction pens, can solve the problems of suction nozzle suction and the like, and achieve the effect of increasing energy consumption and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

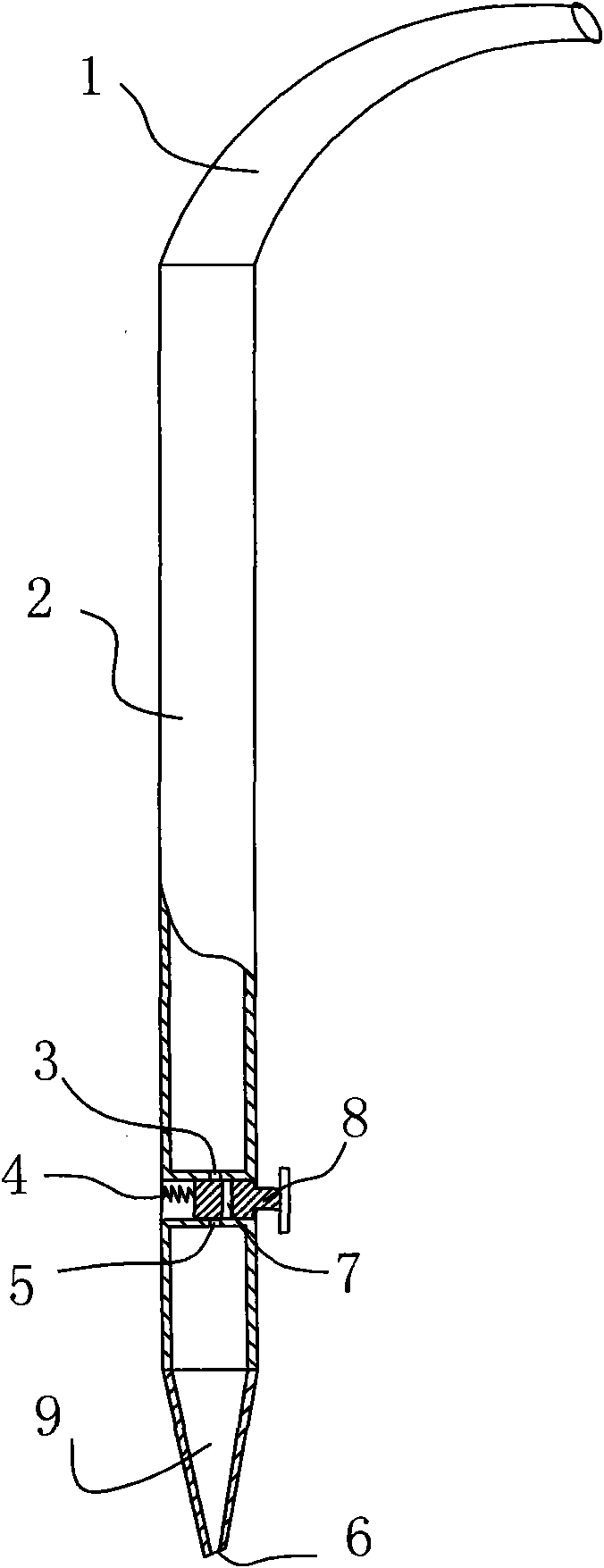

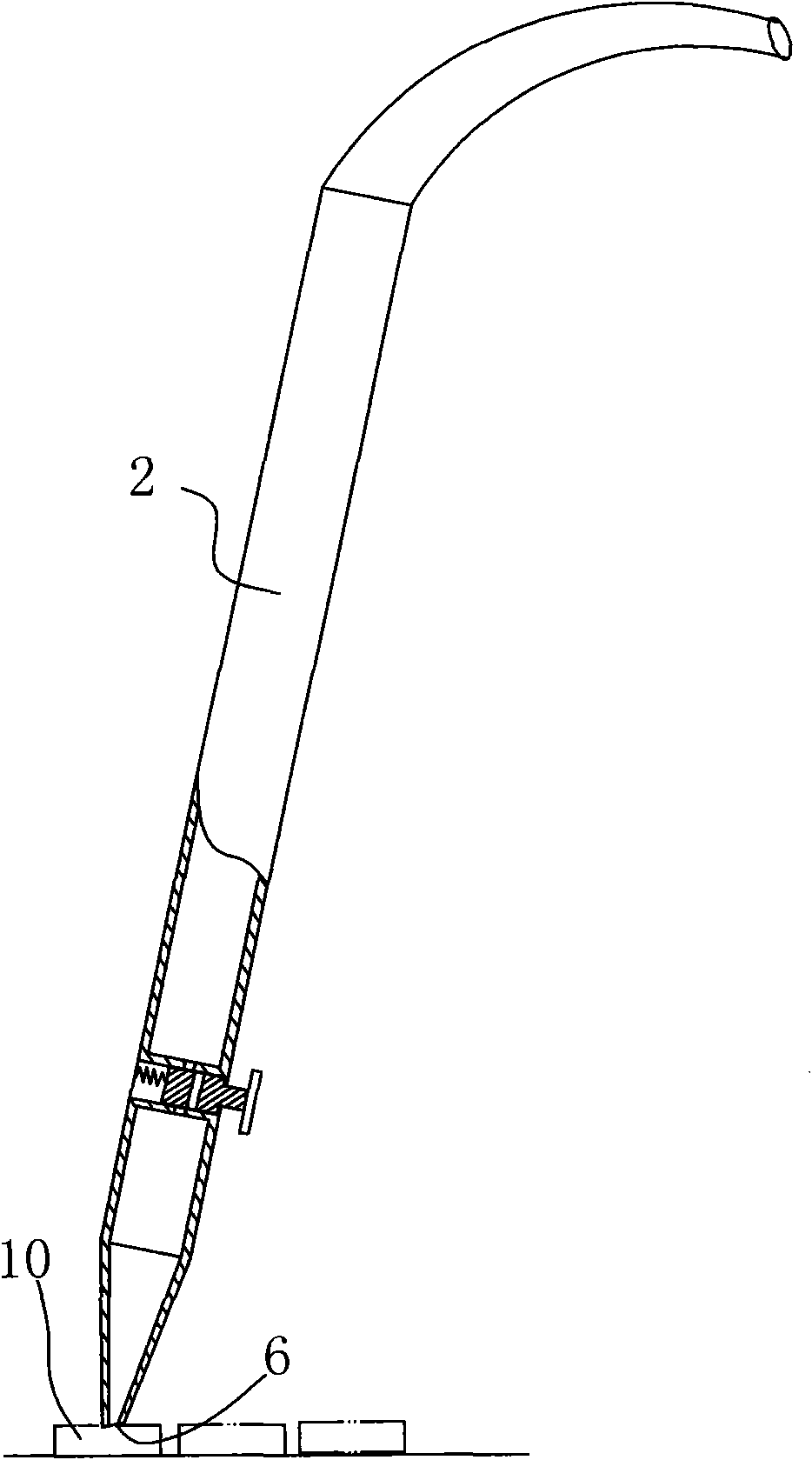

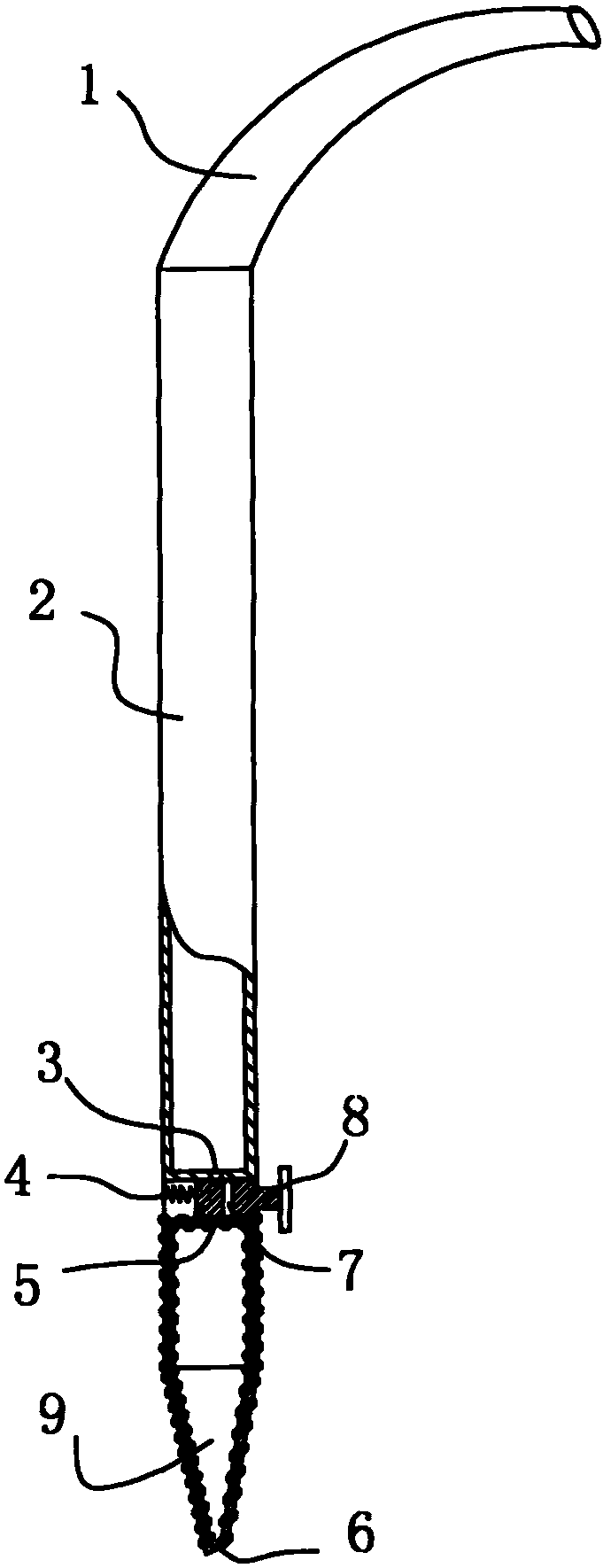

[0014] The present invention as figure 1 As shown: it includes a hollow pen holder 2, an air pipe 1 connected to the tail end of the pen holder 2, and a suction nozzle 6 arranged at the head end of the pen holder 2, and a press-type air valve is provided at a distance of 2-4 cm from the suction nozzle 6 on the shaft of the pen holder 2, The end surface of the suction nozzle 6 forms an included angle of 45-70° with the horizontal plane.

[0015] It also includes a tapered nib 9 , which is fixedly connected to the suction nozzle 6 , and is pivotally connected to the pen holder 2 in an airtight manner, so that the nib 9 can rotate relative to the pen holder 2 .

[0016] The push type air valve includes a cylindrical button 8 with a radial through hole 7 and a spring 4, and the penholder 2 is provided with a circular air valve chamber that is transverse to the section of the penholder 2, and the air valve chamber is set There are an upper hole 3 and a lower hole 5, the button 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com