Method for obtaining a stiffening cross member for a vehicle frame and cross member obtained with such method

A beam and frame technology, applied in the field of vehicle frames, can solve problems such as optimizing the production cost of beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

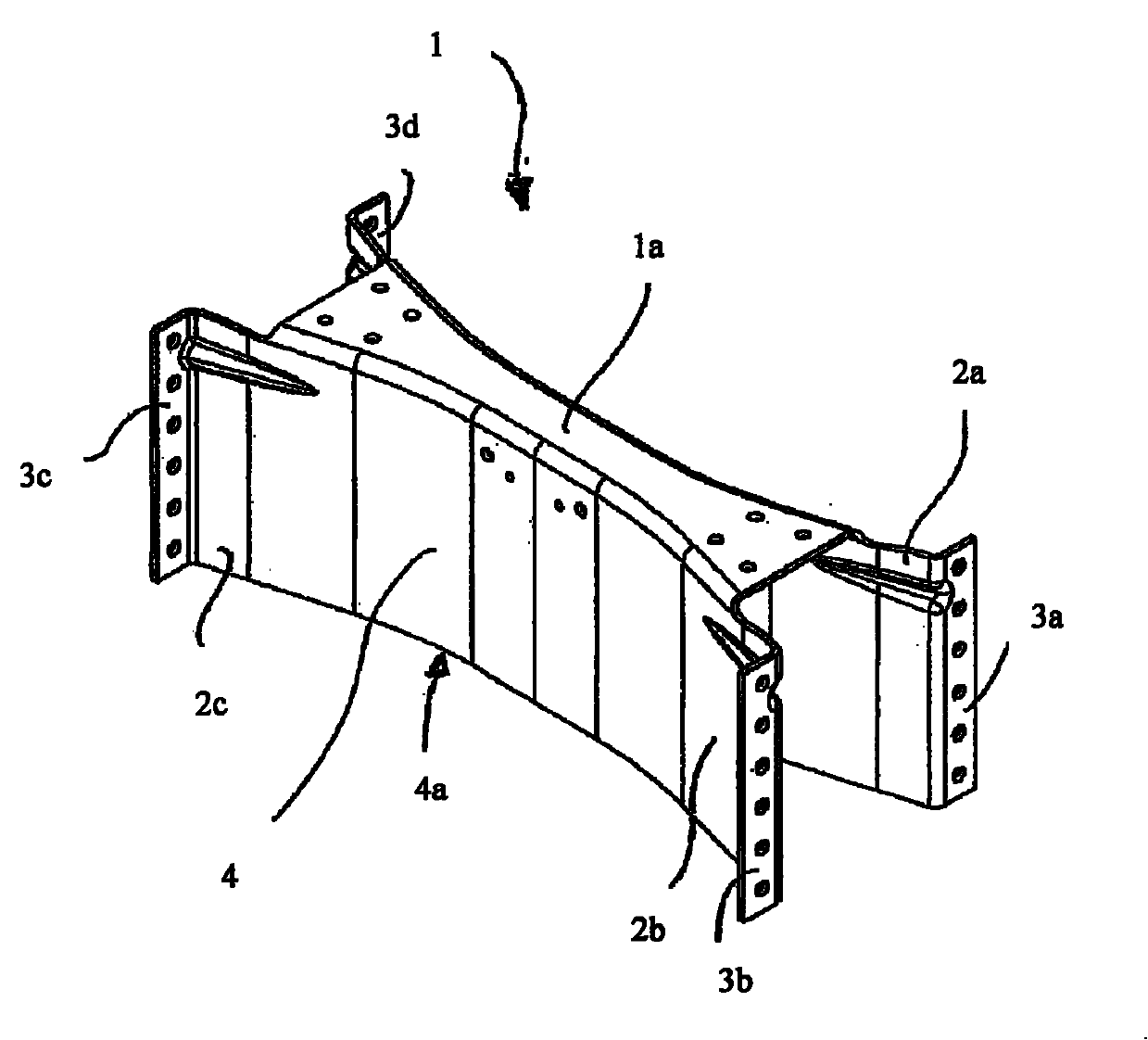

[0026] Refer to attached figure 1 , the beam 1 according to the invention comprises a main body 1a connected at each end to a flange 2a, 2b, 2c, 2d respectively.

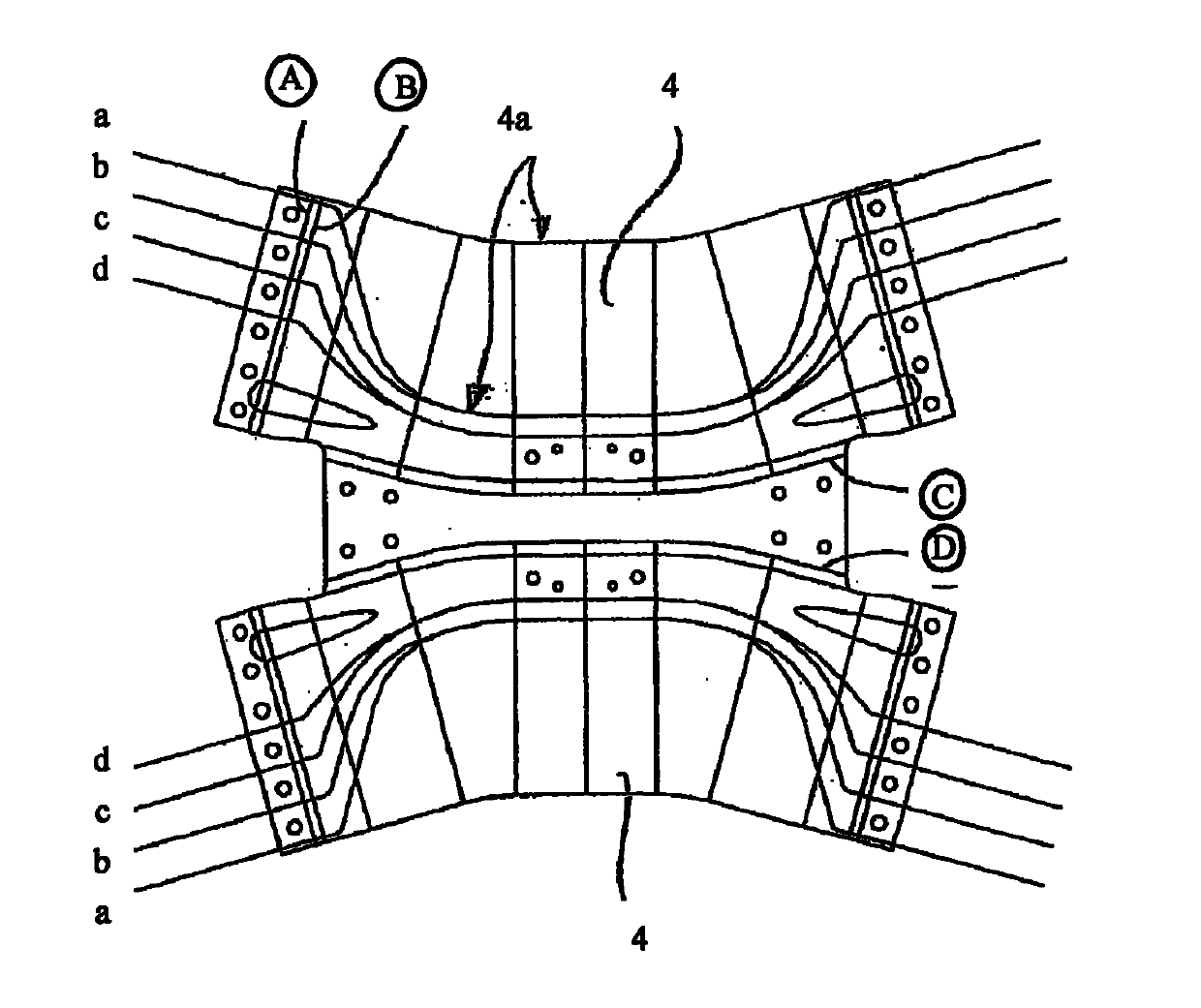

[0027] like Figure 4 As shown in the example of , the cross member 1 is assembled with the side members 11 and 12 of the vehicle frame through the flanges 2a, 2b, 2c, 2d.

[0028] back to figure 1 In this case the beam has a main body 1a, characterized in that the bottom edge 4a of the side part 4 is almost solid.

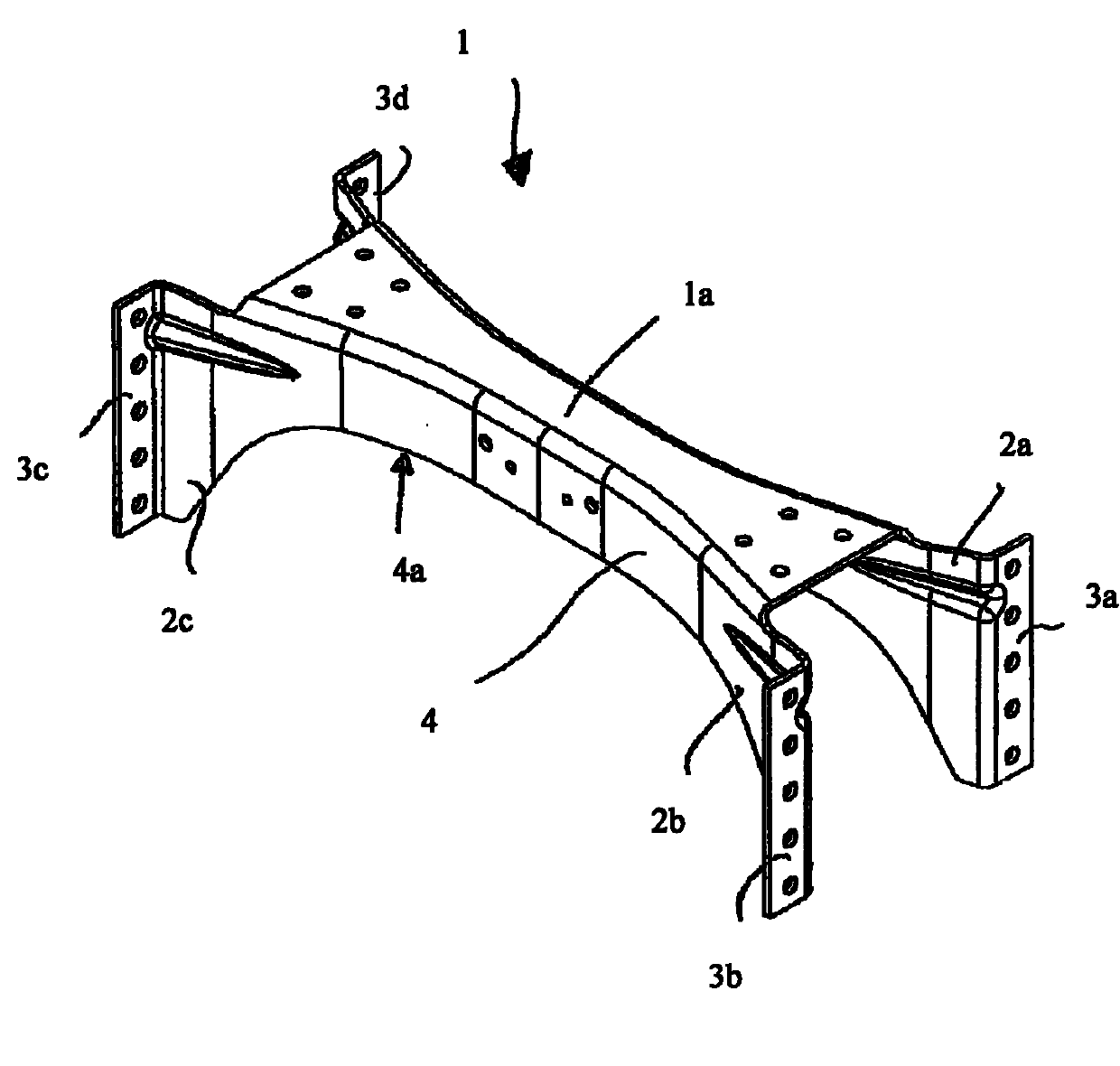

[0029] Compared figure 1 and figure 2 It can be seen that the bottom edge 4a of the side part 4 of the beam can be further flared outwards, making the main body 1a of the beam thinner.

[0030] The main body 1a of the cross beam has different shapes according to the weight of the cross beam installed on the vehicle frame, so that the materials used can be optimized and the weight of the cross beam itself can be reduced.

[0031] The presently described beam 1 is made of a single piece having a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com