Special blowing device and special blowing method for dry sand-grinding and dust-removing complete equipment

A technology of blowing device and complete set of equipment, applied in chemical instruments and methods, solid separation, sieve and other directions, can solve the problems of unsolved powder method environment, inability to produce, pollution, etc., achieve novel structure design, improve service life, The effect of improving sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

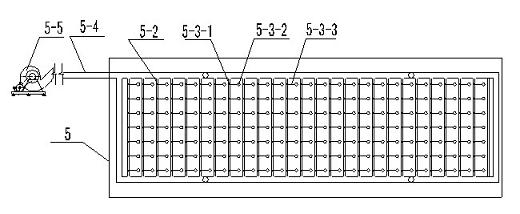

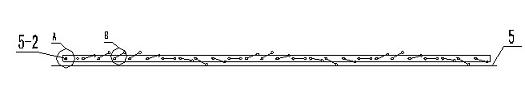

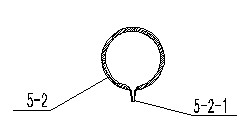

[0018] Embodiment 1: with reference to attached Figure 1-4 . Dry sand grinding and dust removal equipment special blowing device, which includes a fan, the blowing device is composed of multiple rows of air ducts 5-2, facing the surface of the screen 5-1, there are multiple blowing nozzles on the multi-rows of air ducts 5-2 5-2-1, the multi-row air duct 5-2 communicates with the air outlet of the fan 5-5 through the main air duct 5-4.

[0019] The multiple rows of air ducts are divided into 2 groups or more, and the number of each group of air ducts is 2 or more, and the air inlets of each air duct are connected and controlled by a control valve to blow or not.

Embodiment 2

[0020] Embodiment 2: with reference to attached Figure 5 . On the basis of Example 1, the special vibrating screen mechanism for the dust-free dry sand making system includes a vibrating screening mechanism 5. The vibrating screen in the vibrating screening mechanism 5 is composed of three layers of screens, and the three layers of screens are in the form of The distance is distributed up and down and the apertures of the three layers of screens are different, and they become smaller from top to bottom. A blowing device is arranged above the surface of the third layer of screens, and the blowing device is composed of multiple rows of air ducts 5-2, There are multiple blowing nozzles 5-2-1 on the multi-row air duct 5-2 facing the screen 5-1, and the multi-row air duct 5-2 passes through the main air duct 5-4 and the fan 5-5 air outlet Connected, the multi-row air ducts are divided into 2 groups or more than 2 groups, and the number of air ducts in each group is 2 or more, and...

Embodiment 3

[0022] Embodiment 3: On the basis of Embodiment 1 and 2, the blowing method of the special air blowing device for the complete set of equipment for dry sand grinding and dust removal, it comprises a blower fan, and in the blowing device, multiple rows of air ducts constitute 5-2 facing the screen cloth 5-1, There are a plurality of blowing nozzles 5-2-1 on its multi-row air duct 5-2, and the multi-row air duct 5-2 communicates with the blower fan 5-5 air outlet through the main air duct 5-4, and the multi-row air duct is divided into 2 or more groups, the number of air ducts in each group is 2 or more, the air inlets of each group of air ducts are connected, and the time controller or program controller controls the valve to control whether it blows or not, forming a sequential cycle of blowing Or cross hair.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com