Pressing tool for sliding bearing of crankcase cover

A technology for sliding bearings and crankcase covers, which is applied in the field of fixtures and fixtures, can solve the problems of sliding bearings that are prone to offset, difficult to meet consistent production, and long time spent on alignment, so as to ensure accuracy and consistent production , the simple effect of counterpoint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

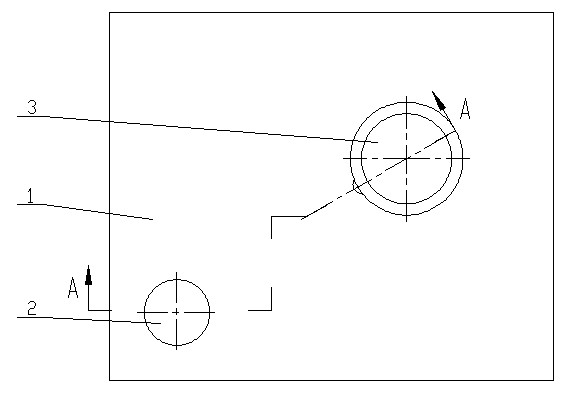

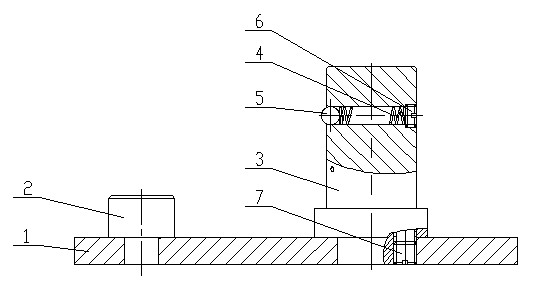

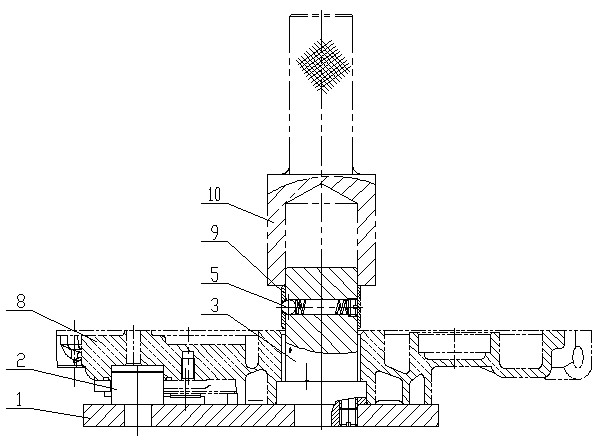

[0013] Such as figure 1 , figure 2 As shown, the present invention is made of components such as base plate 1, first positioning pin 2, second positioning pin 3, spring 4, steel ball 5 and screws, wherein base plate 1 is a rectangular plate structure, and the left front corner of base plate 1 is vertically provided with The first positioning pin 2, the lower end of the first positioning pin 2 extends into the base plate 1, the lower end surface of the first positioning pin 2 is flush with the bottom surface of the base plate 1, and the first positioning pin 2 is fixedly connected with the base plate 1. A second locating pin 3 is vertically arranged at a position to the right of the middle part of the base plate 1. The lower part of the second locating pin 3 is integrally formed with an annular boss, and the lower end of the second locating pin 3 extends int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com