Composite sliding seat matched with guide rail of machine tool

A composite, sliding seat technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve problems such as single form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

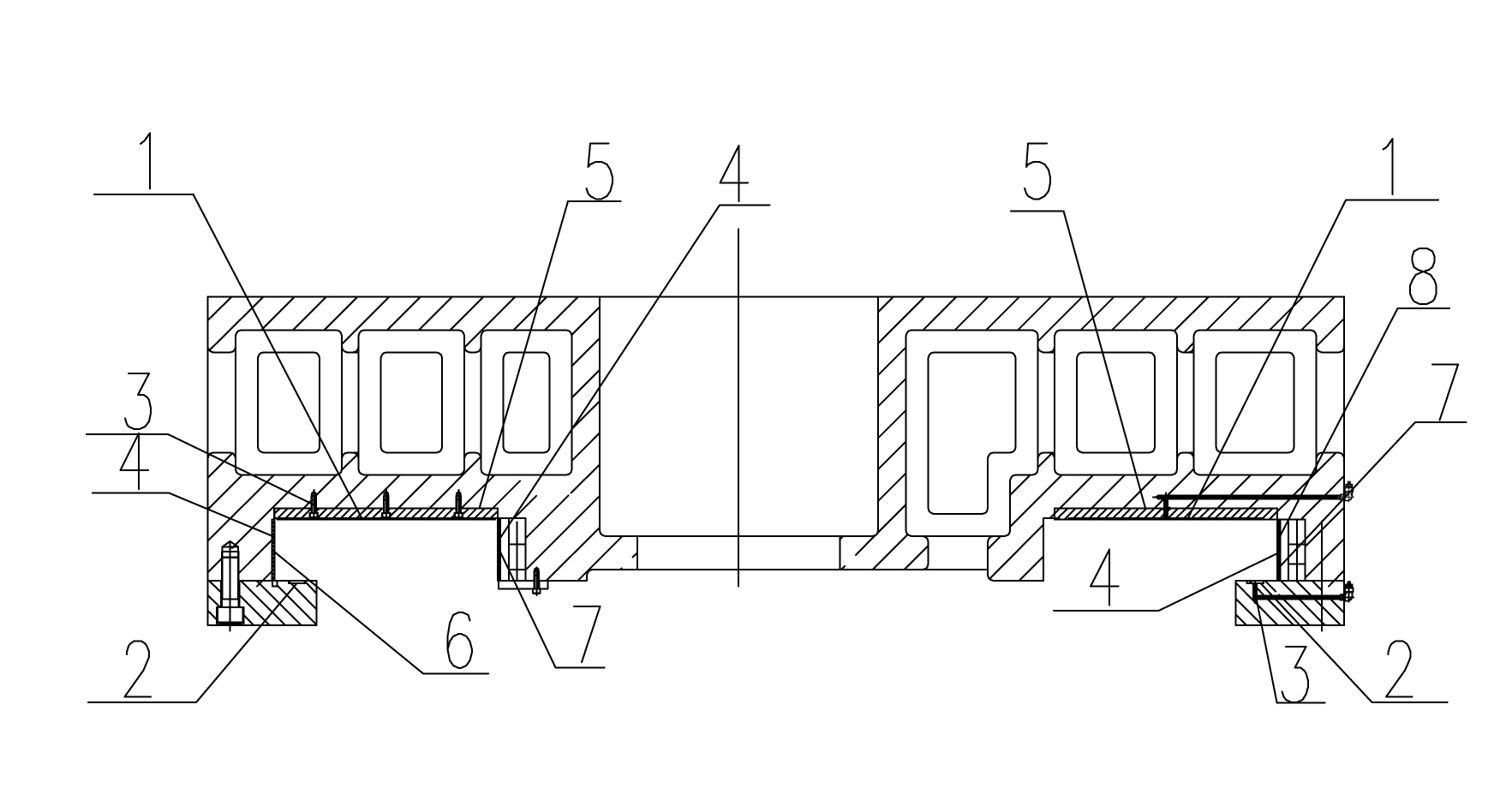

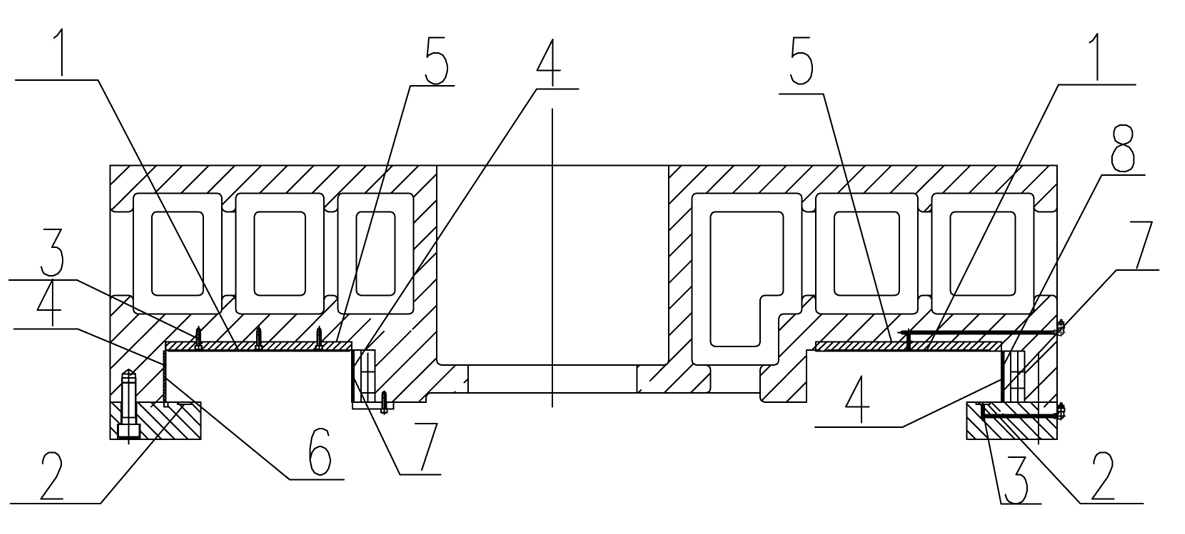

[0015] Such as figure 1 As shown, the present invention relates to a composite sliding seat that cooperates with machine tool guide rails. The sliding seat includes an upper supporting surface 1, a lower pressing plate surface 2 and side surfaces. The upper supporting surface 1 and the lower pressing plate surface 2 of the sliding seat are separated There is an oil cavity 3 for forming a static pressure fit between the guide rail and the sliding seat, and a plastic-coated layer 4 is provided on the side. The upper support surface 1 and the lower pressure plate surface 2 of the sliding seat are provided with an oil chamber 3, which is matched with the guide rail in the form of static pressure, so that there is no direct contact between the sliding seat and the working surface of the guide rail, basic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com