Method for manufacturing and processing paper

A processing method and technology of base paper, which are applied in the field of papermaking to achieve the effects of strong waterproof ability, strong tensile ability and strong oil resistance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

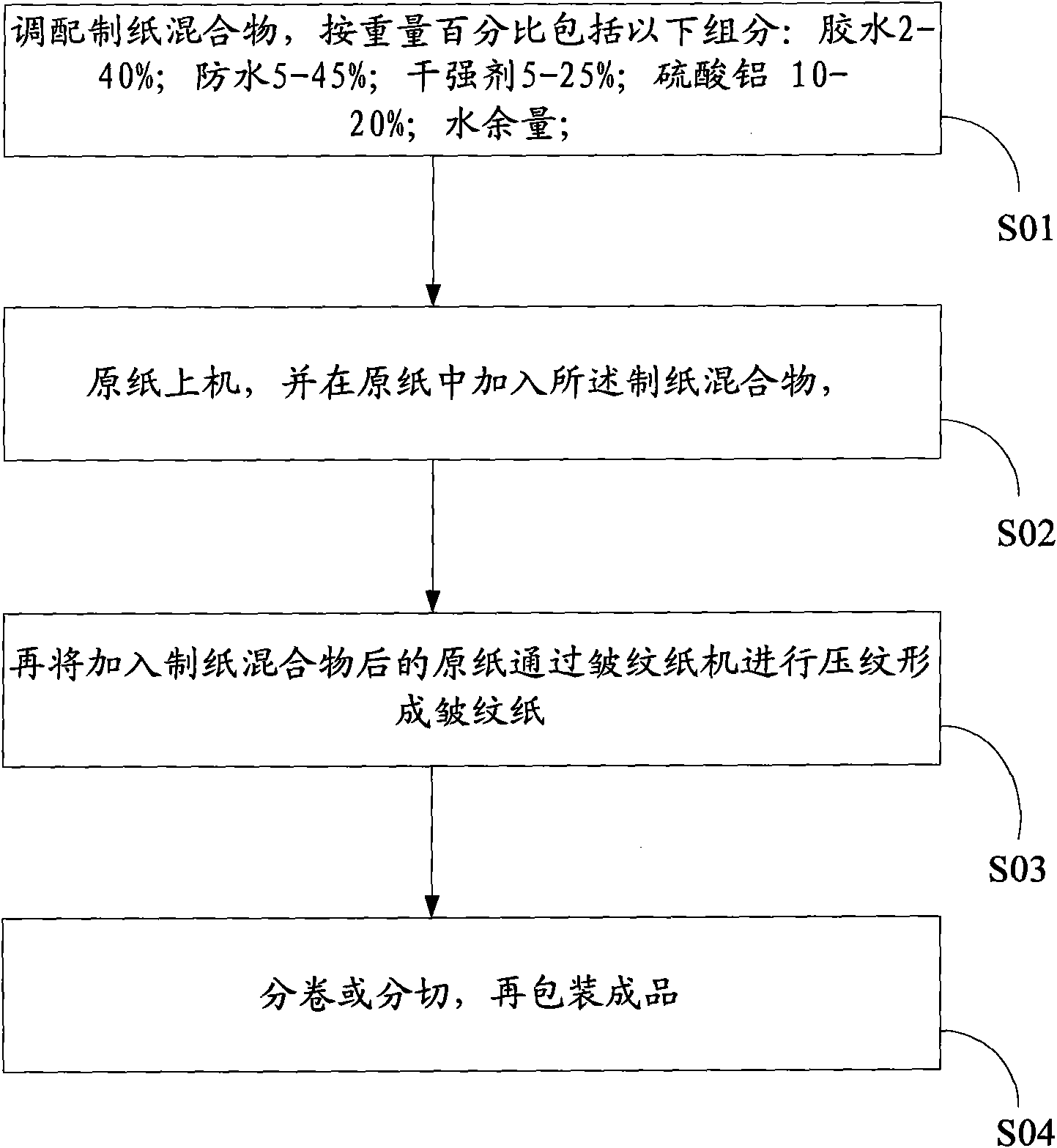

Method used

Image

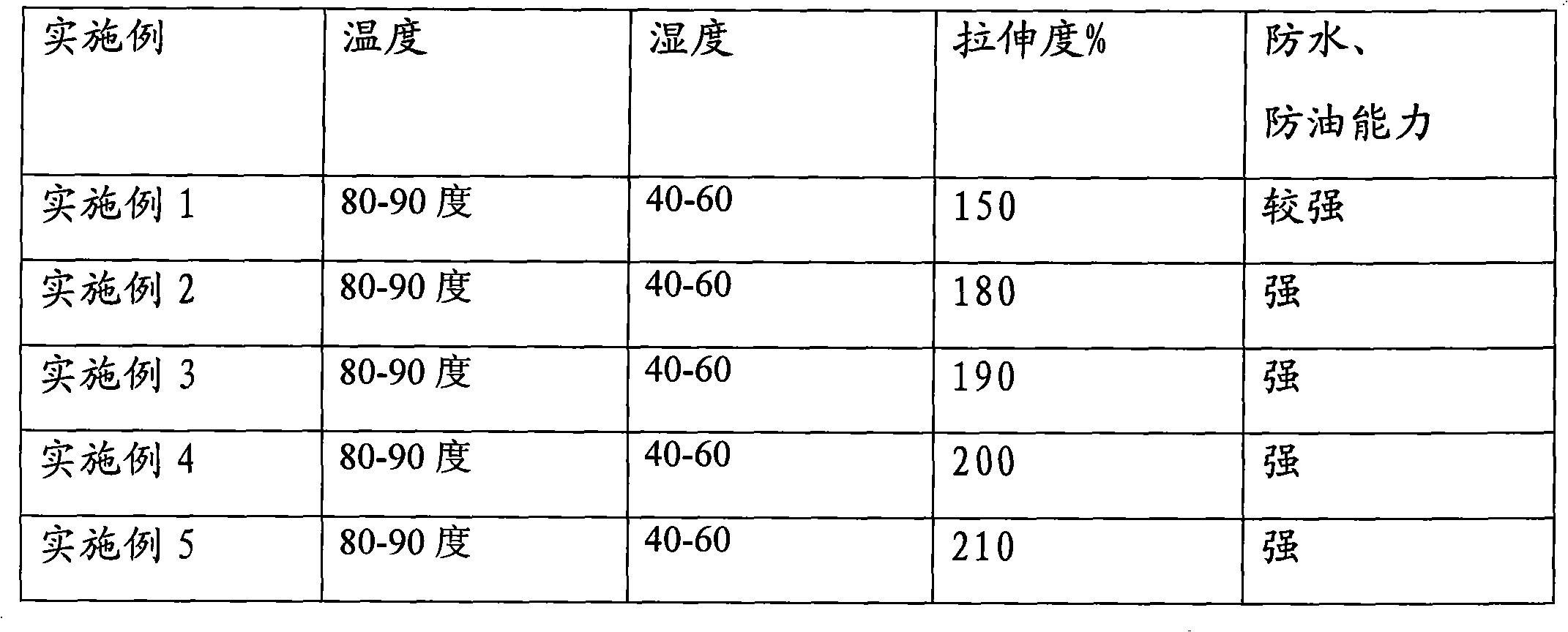

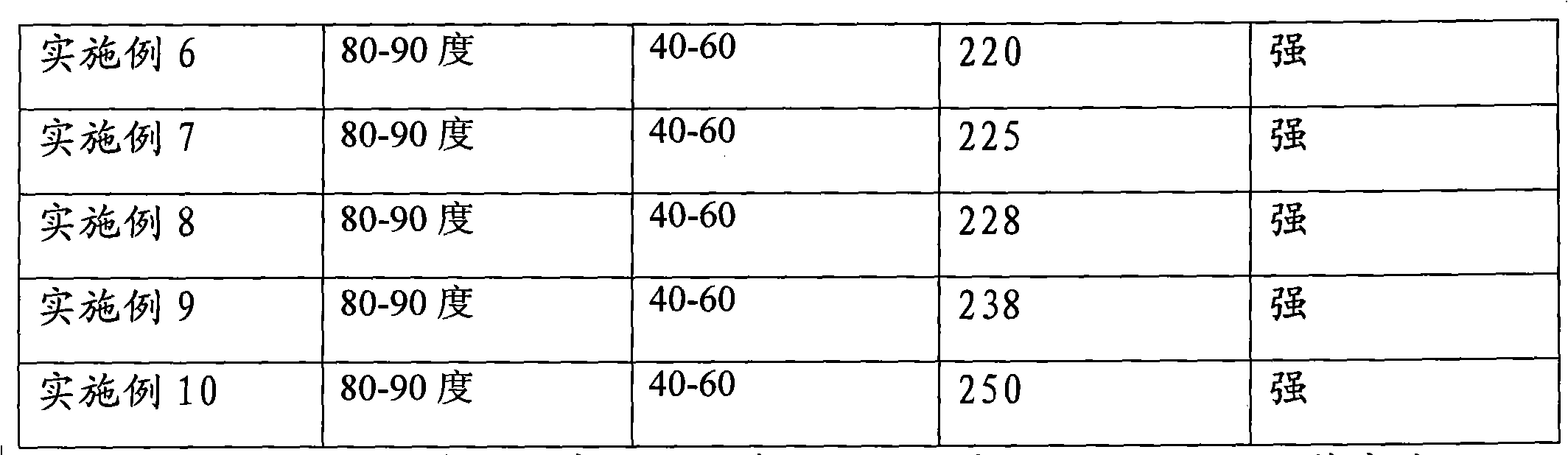

Examples

Embodiment 2

[0023] Example 2: The papermaking mixture includes the following components: glue 2Kg; waterproof 8Kg; dry strength agent 10Kg; aluminum sulfate 16Kg; water 64Kg.

Embodiment 3

[0024] Example 3: The papermaking mixture includes the following components: glue 7Kg; waterproof 5Kg; dry strength agent 13Kg; aluminum sulfate 18Kg; water 57Kg.

Embodiment 4

[0025] Example 4: The papermaking mixture includes the following components: glue 3Kg; waterproof 14Kg; dry strength agent 5Kg; aluminum sulfate 12Kg; water 66Kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com