Concrete frame structure

A frame structure and concrete technology, applied in the direction of building structure, construction, etc., can solve the problems of low ratio, poor energy consumption mechanism, poor ductility, etc., and achieve the effect of good energy consumption mechanism, low structure cost, and reduced structure weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

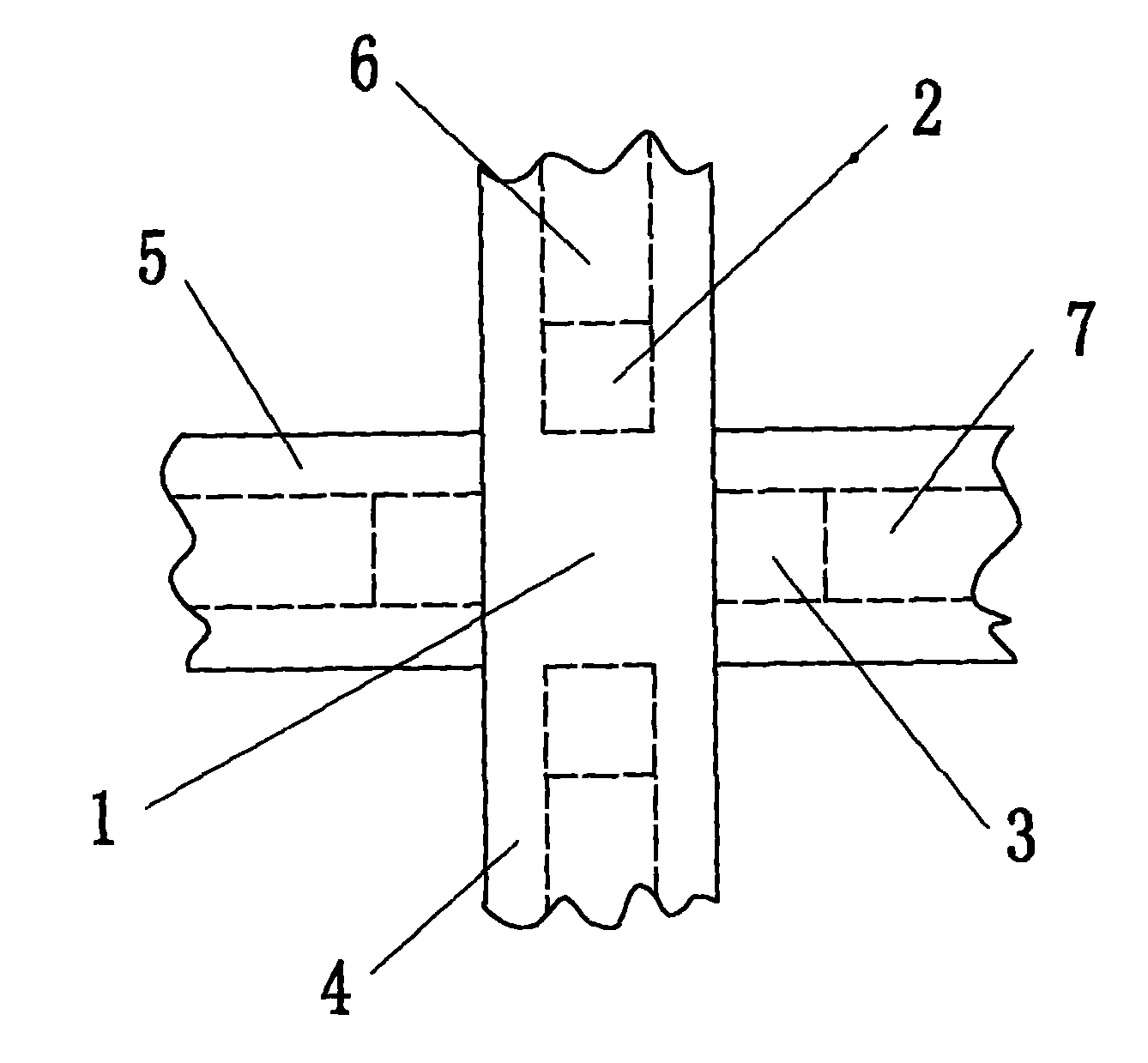

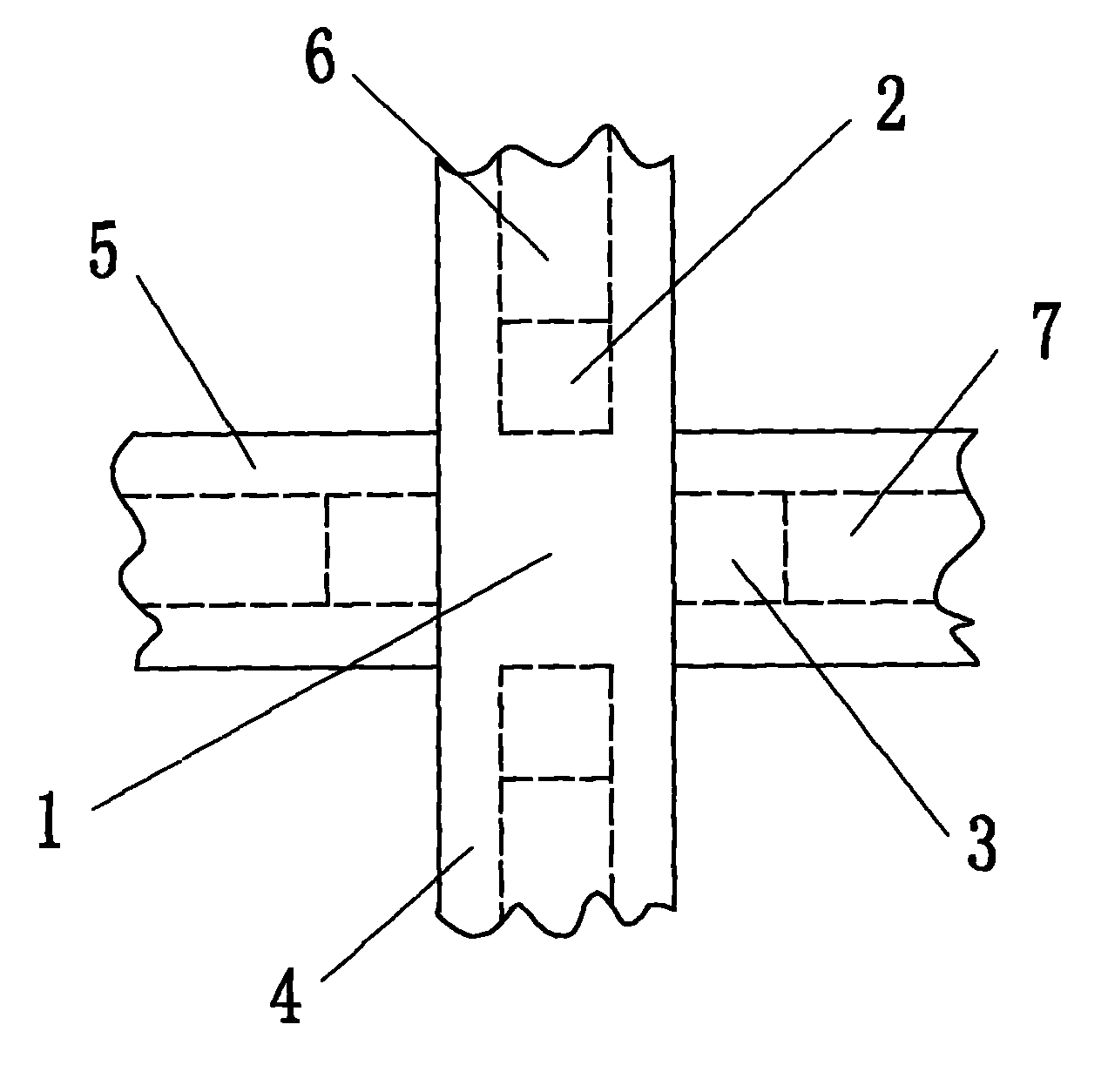

[0031] As shown in the accompanying drawing, it is a partial structural schematic diagram of an embodiment of the concrete frame structure in the present invention, including nodes, columns and beams. In this example, node 1 has tenon 2 protruding vertically and tenon 3 protruding horizontally, column 4 and beam 5 have vertical mortise 6 and transverse mortise 7 respectively, tenon 2 and tenon 3 are respectively connected with vertical The ends of the mortise 6 and the transverse mortise 7 are tightly combined.

[0032] The present invention has multiple implementations, and two preferred ones are now disclosed.

[0033] The first embodiment of the present invention is an assembled integral type: firstly, prefabricated columns 4 with vertical mortises 6 and prefabricated beams 5 with transverse mortises 7 are produced respectively, inside the vertical mortises 6 and transverse mortises 7 , each with two baffles, the vertical mortise 6 and the horizontal mortise 7 are divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com