Grinding, collecting and refrigerating system capable of recycling kitchen garbage used as forage

A technology for smashing kitchen waste and garbage, which is applied to cleaning methods and utensils, cleaning hollow objects, building components, etc. The effect of pollution-free recycling and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

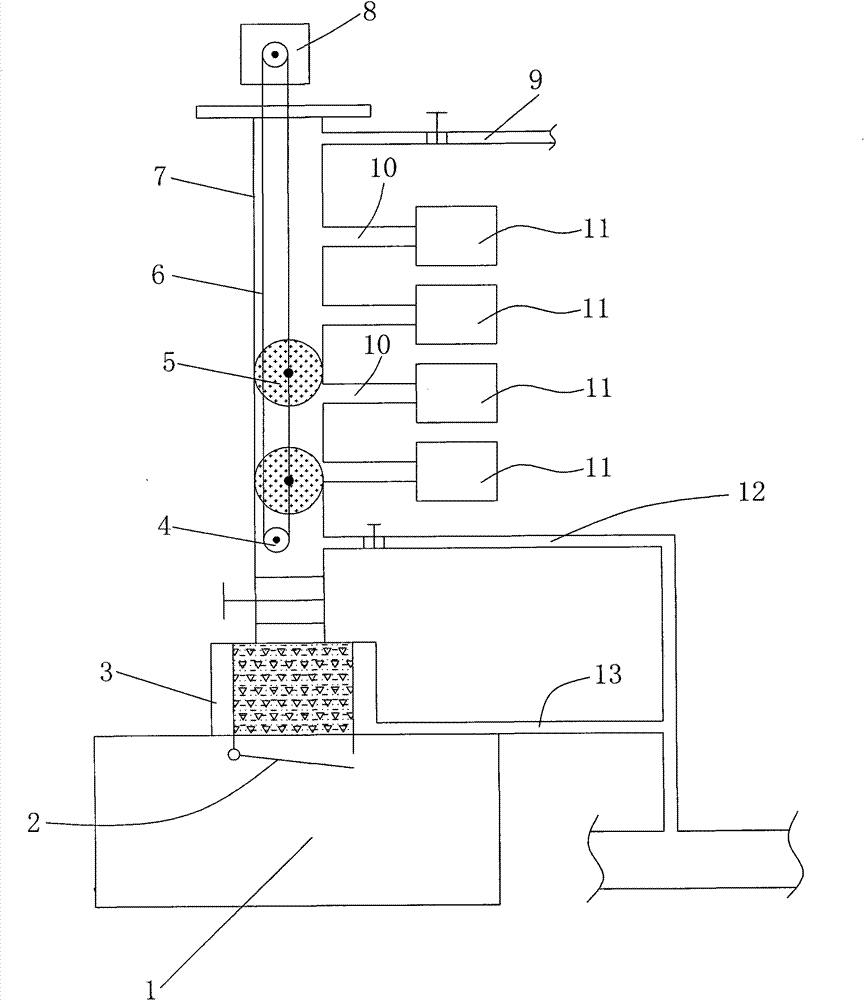

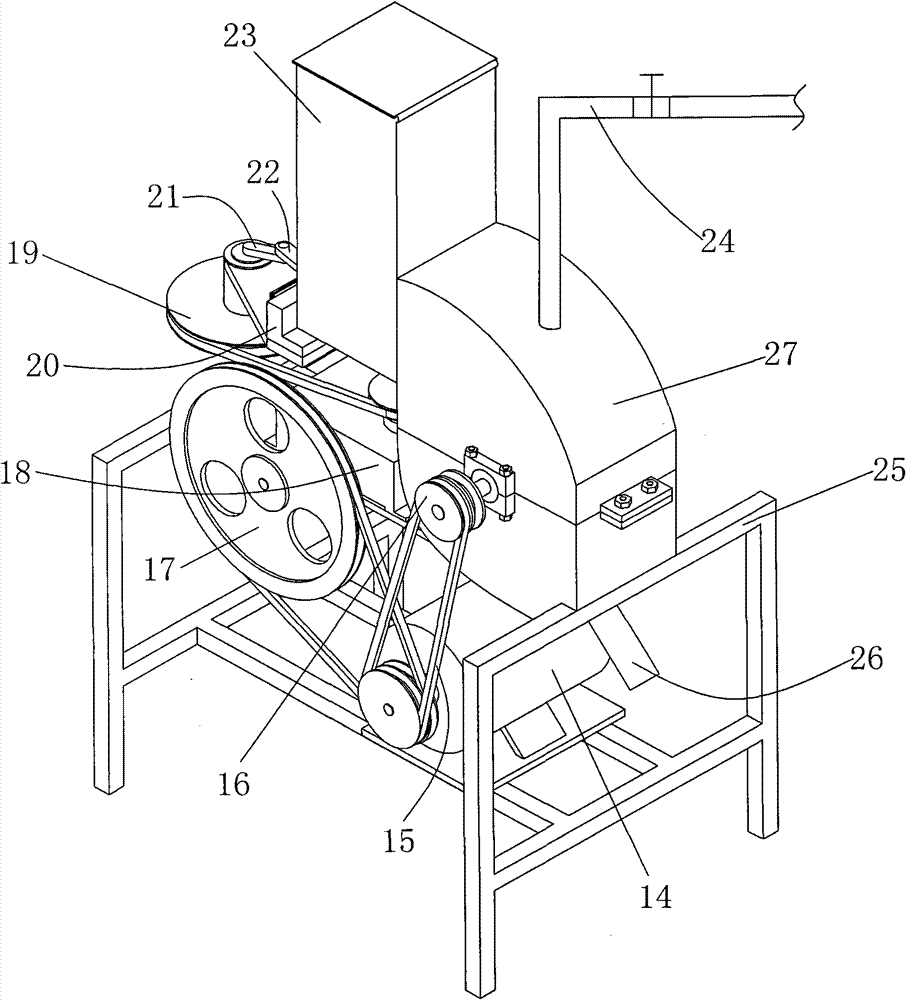

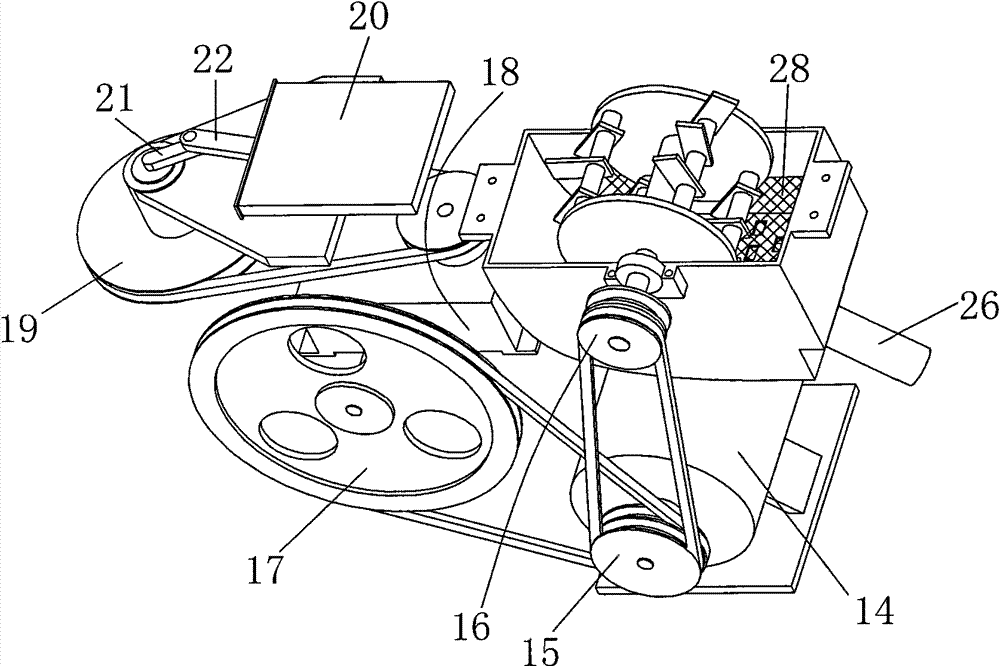

[0027] Such as Figure 1 to Figure 7 The shown crushing, collecting and refrigeration system for food waste that can be recycled as feed includes a garbage crushing device 11, a garbage recycling pipeline and a garbage recycling refrigeration device 1, and the garbage recycling pipeline includes a vertically arranged top-to-bottom through The main pipe 7 and the laterally arranged branch pipes 10 are a plurality of top-to-bottom arranged pipes arranged on each floor, and each floor is equipped with a branch pipe 10, and each branch pipe 10 One end is connected with the main pipeline 7, and the other end is connected with the garbage crushing device 11. The garbage recovery and refrigeration device 1 is located at the bottom outlet of the main pipeline 7. After being pulverized by the garbage crushing device 11, the food waste enters the main pipeline 7 through the branch pipeline 10 , and then sent from the main pipeline 7 into the garbage recovery and refrigeration device 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com