Horizontal template steel structure bracket

A technology of steel structure and formwork, applied in the direction of formwork/formwork/work frame, house structure support, house structure support, etc., can solve the problems of high production and use costs, inconvenient disassembly and assembly of formwork brackets, poor adaptability, etc. To achieve the effect of convenient production and construction, shortened turnaround time and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

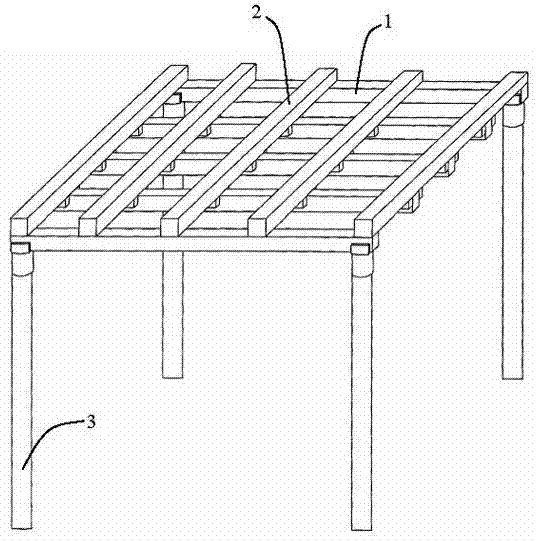

[0030] The horizontal formwork steel structure bracket of the present invention, the main beam and the secondary beam are all made of steel beams, the structural connection is simple and reasonable, and it is not easy to be damaged. It can be turned over more than a hundred times under normal use. Square and other brackets have a long service life.

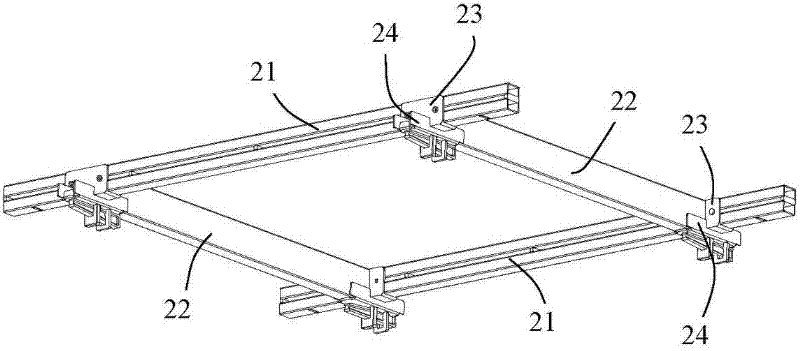

[0031] See figure 2 , which is an overall elevation angle schematic diagram of the horizontal formwork steel structure bracket of the present invention, the horizontal formwork steel structure bracket includes two main beams 21, two secondary beams 22, four movable heads 23 and four primary and secondary beam joints 24. The main beam 21 and the secondary beam 22 intersect perpendicularly so that the bracket forms a rectangular shape. Wherein, each main beam 21 is fixedly connected with two movable heads 23 , and the primary and secondary beam joints 24 are arranged on the lower side of the movable heads 23 and correspond to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com