Light-emitting diode (LED) plane light source

A technology of LED surface light source and LED chip, which is applied in the field of light source, can solve the problems of not simplifying the production process, and achieve the effects of easy automation, improved processing efficiency, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

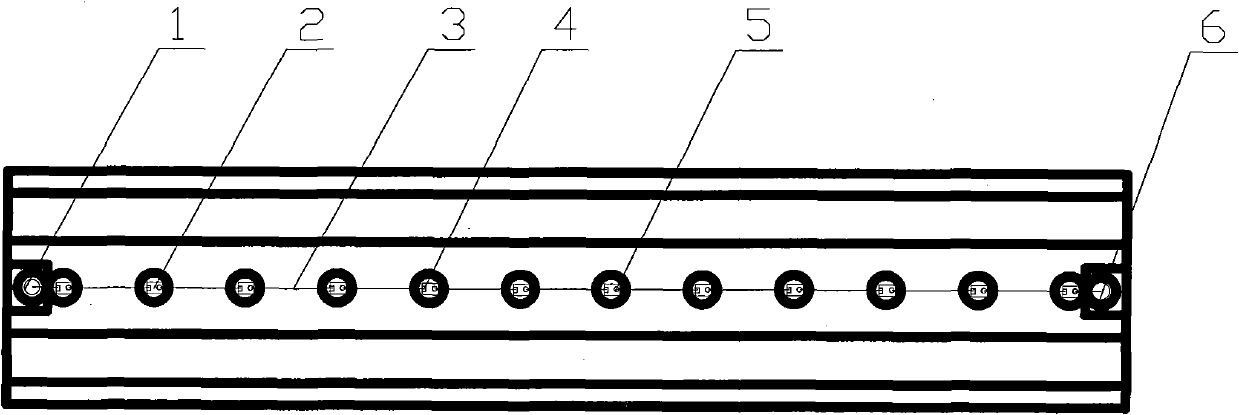

[0023] Embodiment 1 of the present invention, such as figure 1 As shown, the structure of a LED surface light strip strip has: the guide wire first power supply external lead electrode 1; the LED chip 2 of the strip strip; the LED chip positive pad 4 of the strip strip; The negative electrode pad 5 of the LED chip of the chip; the chip connection wire 3 of the positive electrode pad 4 and the negative electrode pad 5 of different LED chips 2 connected in series;

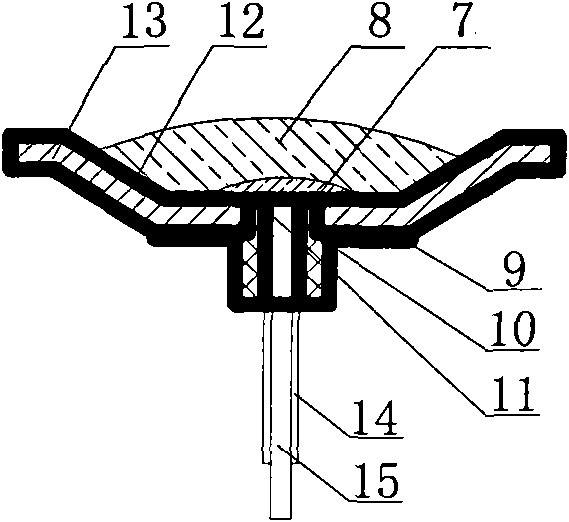

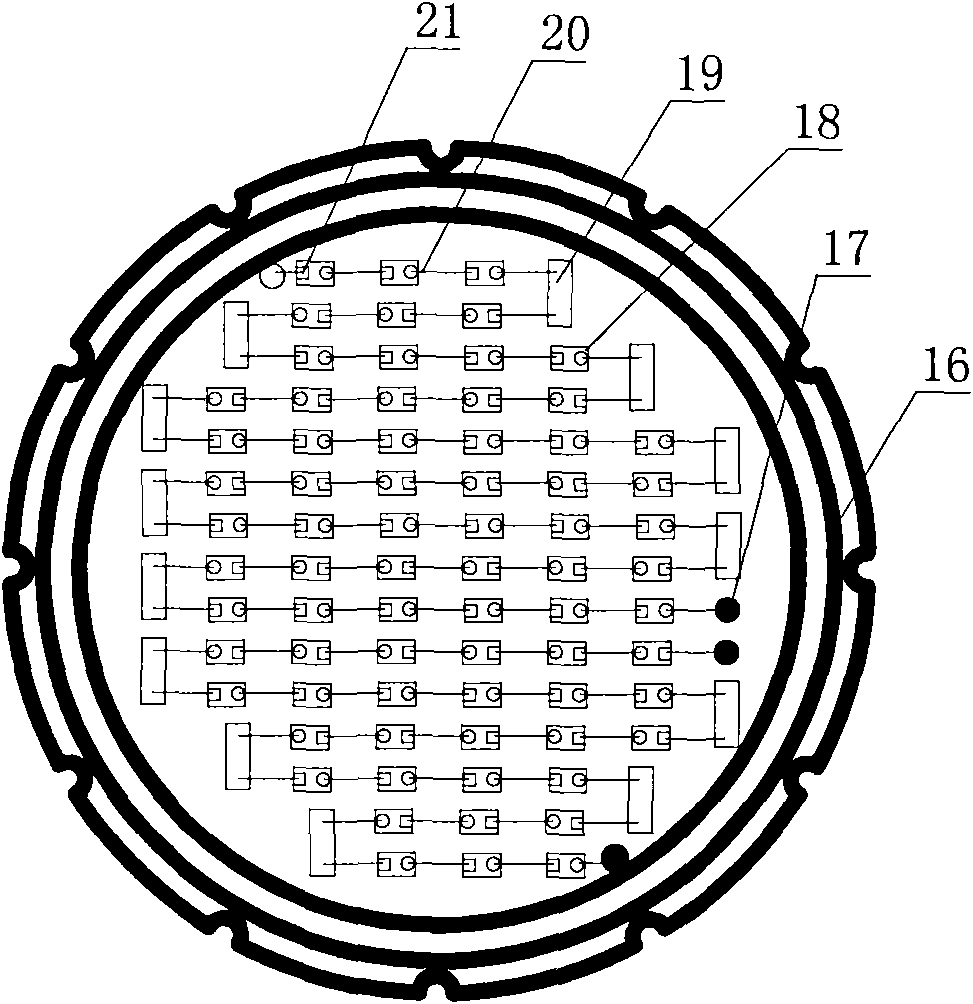

[0024] Such as figure 2 As shown, the mixed phosphor colloidal coating 7 coated on the plate-shaped heat good conductor mirror plate 16 and the LED chip 2 of the strip cloth, wherein the heat good conductor mirror plate 16 can be a mirror aluminum plate or a copper plate nickel-plated Such as metal mirror panels or mirror panels of ceramic materials; and colloid lenses 8 mixed with fluorescent powder colloidal coating 7 strips of cloth; PECC film 9 of strip cloth; electrodes of strip cloth are introduced into insul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap