Method and device for burning coal slime in circulating fluidized bed boiler

A technology of circulating fluidized bed and coal slime, which is applied in the direction of fluidized bed combustion equipment, combustion method, fuel burned in a molten state, etc., can solve the problems of low combustion efficiency and unusability, and achieve the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

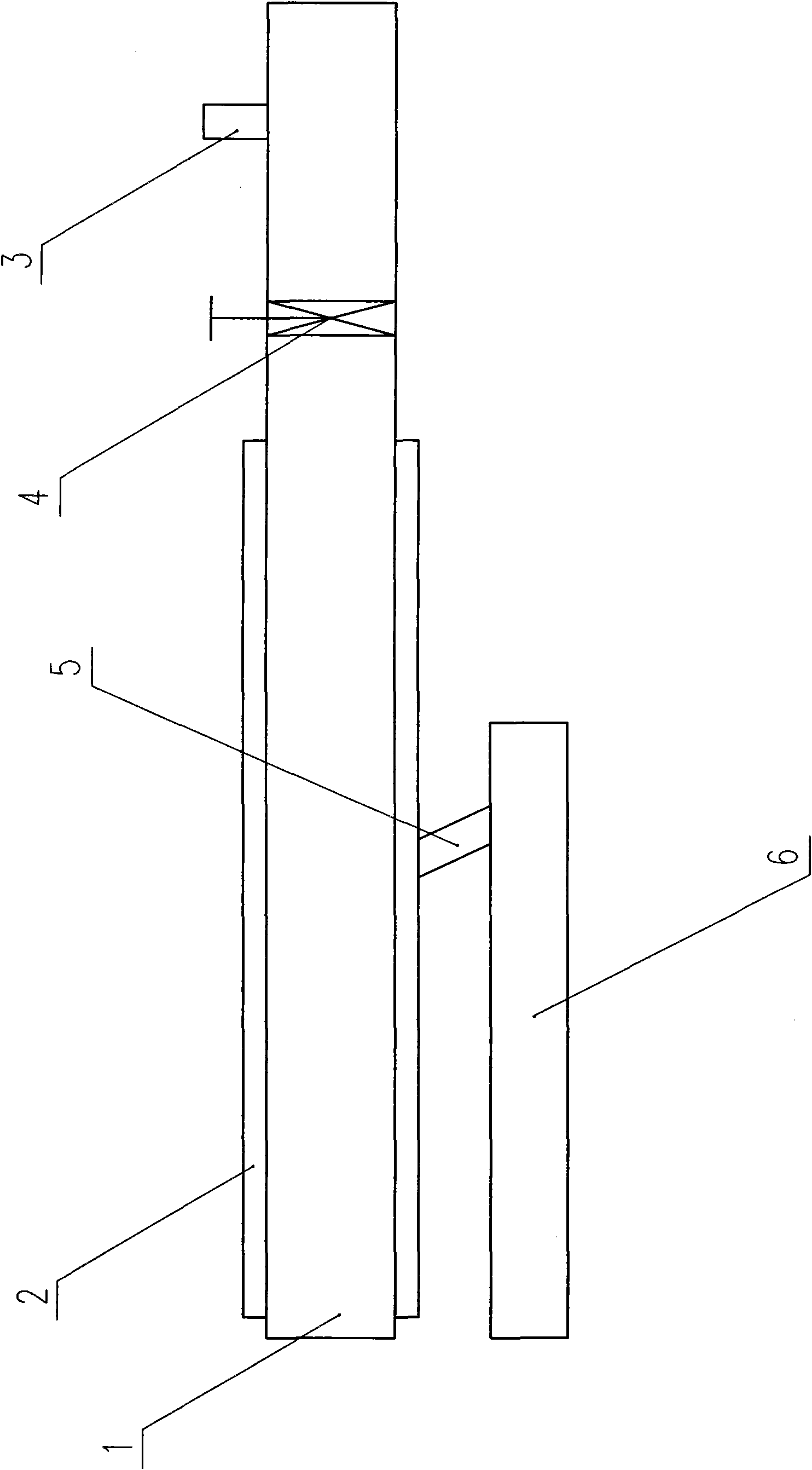

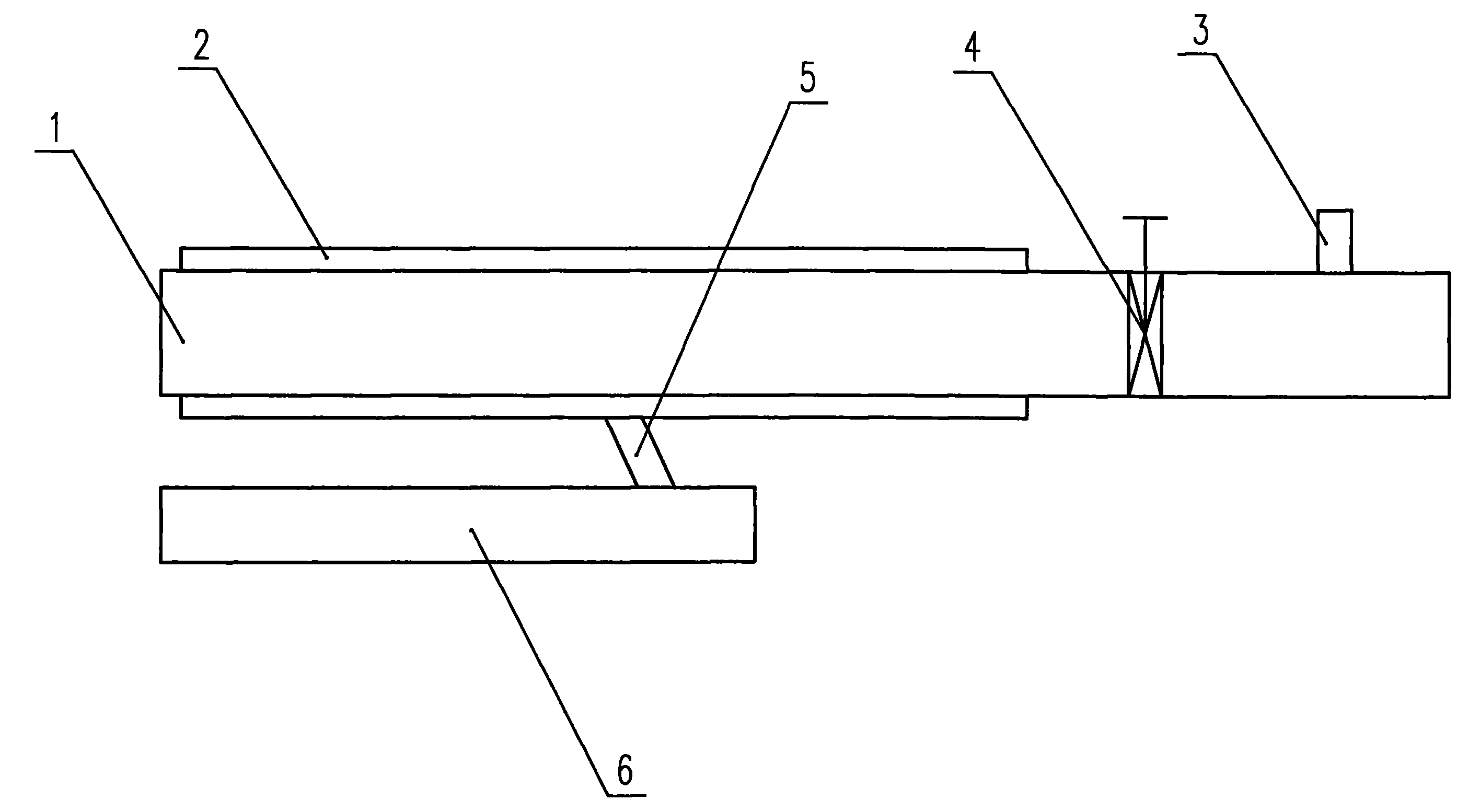

[0014] The method of burning coal slime in a circulating fluidized bed boiler, the process of this method is: the coal slime in a paste state is sent to the dense phase area at the lower part of the furnace of the circulating fluidized bed boiler, and is used in the circulating fluidized bed boiler The coal slime high-pressure atomizing air duct 6 of the coal slime burning device breaks the falling coal slime into fine particles and spreads them into the furnace, and the coal slime is mixed with the rising flue gas and circulating materials in the furnace to burn.

Embodiment 2

[0016] A device for burning coal slime in a circulating fluidized bed boiler, its composition includes: a coal slime delivery pipe 1, a coal slime shut-off valve 4 is installed on the described coal slime delivery pipe, and the described coal slime delivery pipe is cooled by the coal slime The wind connecting pipe 5 is connected to the coal slime high-pressure atomizing air pipe 6.

Embodiment 3

[0018] A device for burning coal slime in a circulating fluidized bed boiler, its composition includes: a coal slime delivery pipe 1, a coal slime shut-off valve 4 is installed on the described coal slime delivery pipe, and the described coal slime delivery pipe is cooled by the coal slime The wind connecting pipe 5 is connected to the coal slime high-pressure atomizing air pipe 6.

[0019] In the device for burning coal slime in a circulating fluidized bed boiler, a cleaning water pipe 3 is provided on the coal slime delivery pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com