Device for automatically wiping outer surface of vacuum tube of solar heat collector

A technology for solar collectors and automatic wiping, which is applied to solar collectors, solar collector safety, solar thermal devices, etc., can solve problems such as reducing transparency and affecting heat absorption efficiency, and achieves increased wiping frequency and simple structure , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

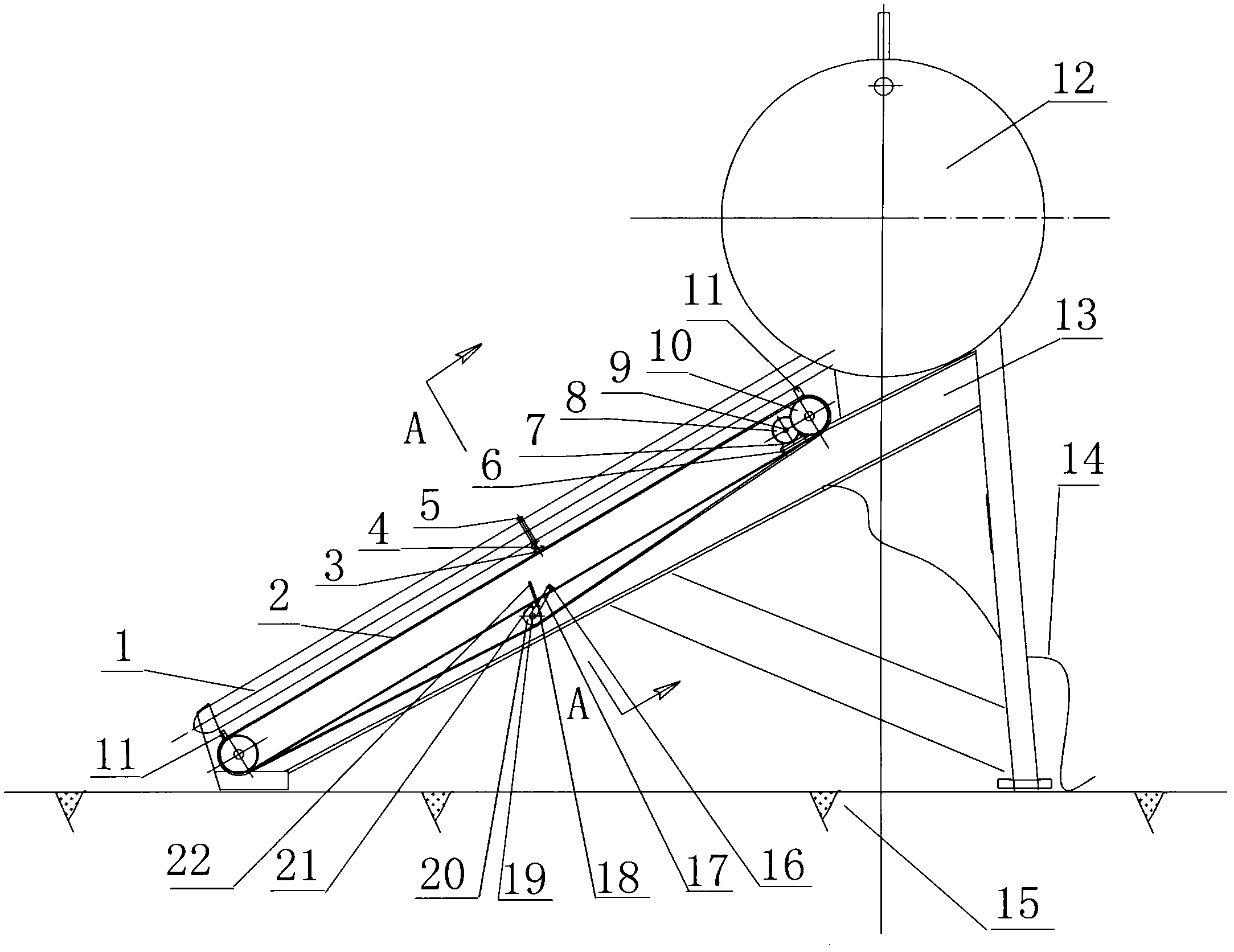

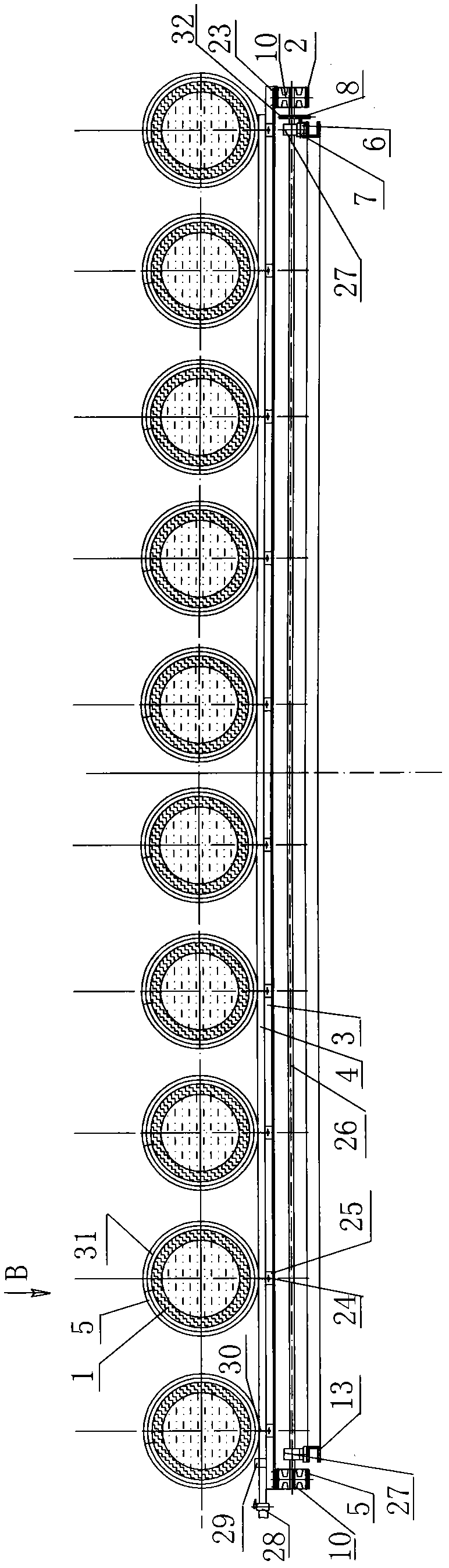

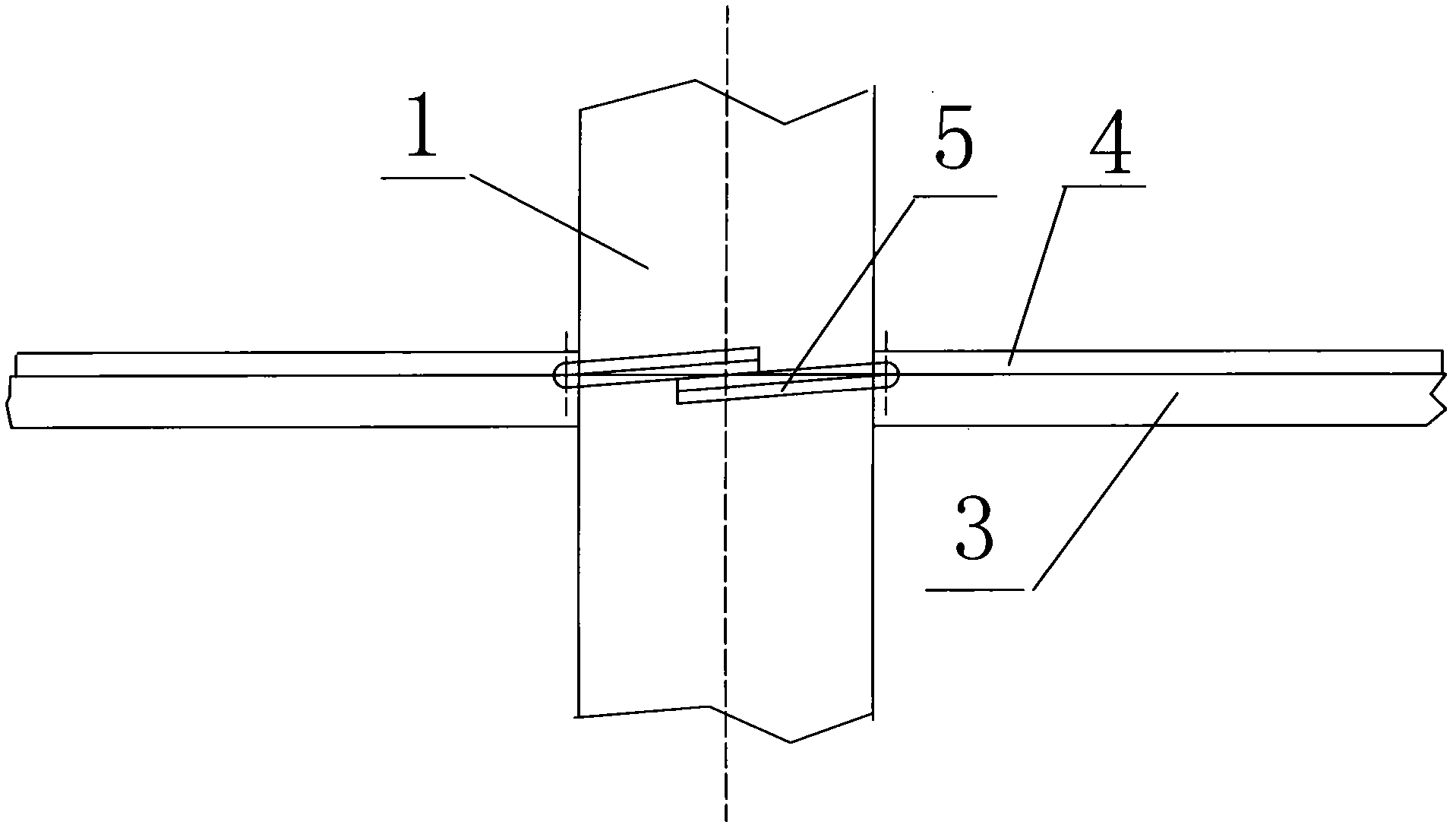

[0016] Accompanying drawing is a kind of specific embodiment of the present invention. The automatic wiping device for the outer surface of the solar heat collector vacuum tube is characterized in that it includes a reversible motor 7 installed on the bracket 13, and the reversible motor 7 is connected with the wiping device installed on the vacuum tube 1 through a mechanical transmission. Described mechanical transmission device comprises the driving gear 8 that is installed on the reversible motor 7 output shafts, and a spring clip 9 is installed on the driving gear 8, and the driving gear 8 is meshed with the driven gear 32, and the driven gear 32 is installed on the rotating shaft 26, rotates Bearing shaft seat 27 and toothed belt pulley 10 are installed at the two ends of shaft 26, bearing shaft seat 27 is installed on the support 13 by bolt 33, limit plate 11 is installed at both ends of support 13, toothed belt wheel 10 is equipped with toothed Belt 2, the toothed belt ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap