Absorbing type refrigerator

An absorption refrigerator and absorption liquid technology, applied in refrigerators, adsorption machines, refrigeration components, etc., can solve the problems of energy saving and cooling water temperature reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

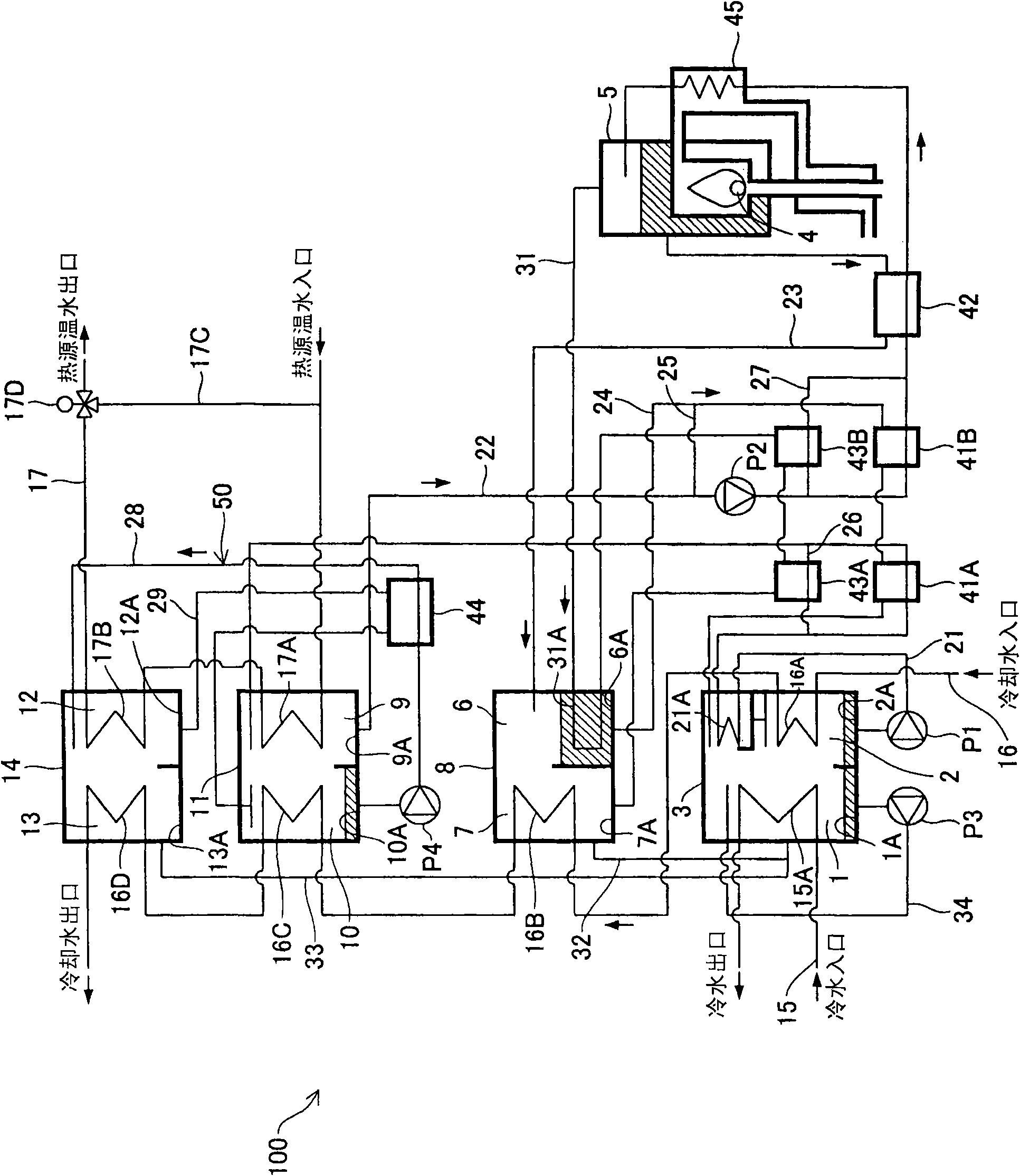

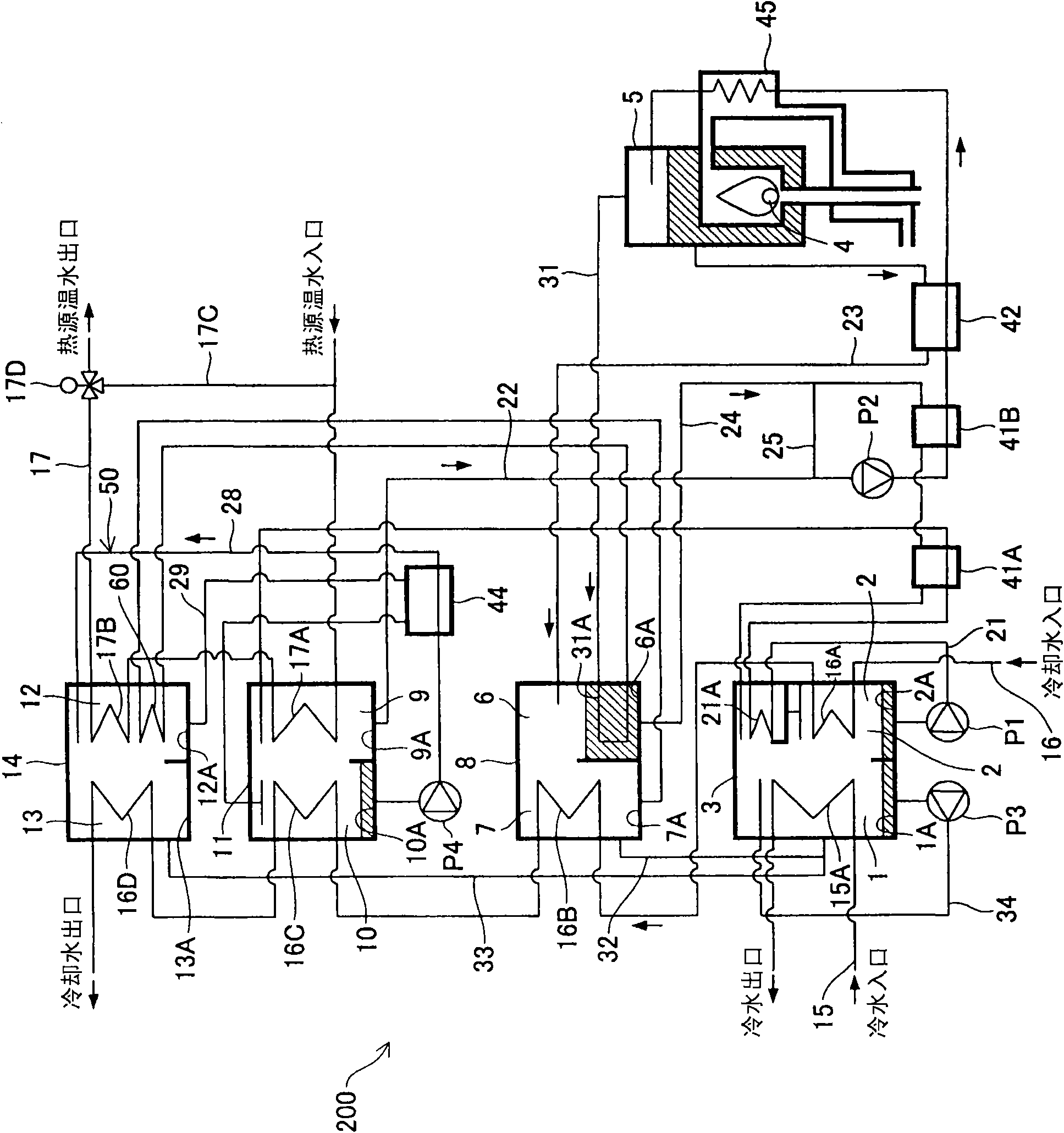

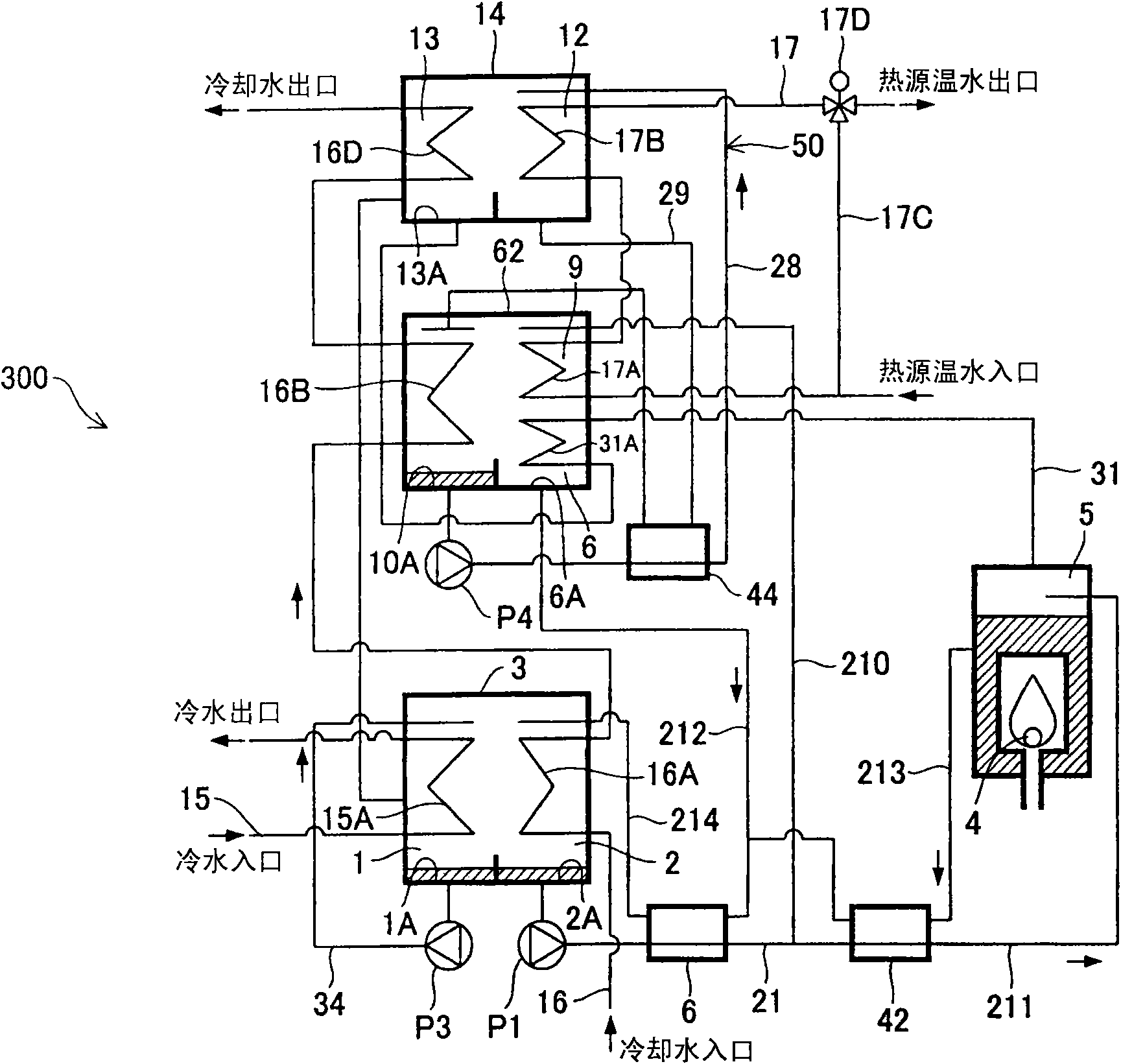

[0019] figure 1 It is a schematic configuration diagram of an absorption chiller (absorption chiller) 100 according to the present embodiment. The absorption chiller 100 is an absorption chiller using water as a refrigerant and lithium bromide (LiBr) aqueous solution as an absorption liquid.

[0020] Such as figure 1 As shown, the absorption cold and warm water machine 100 has: an evaporator 1; a first absorber 2 arranged side by side with the evaporator 1; an evaporator absorber cavity 3 that accommodates the evaporator 1 and the first absorber 2; The high-temperature regenerator 5 of the combustor 4; the low-temperature regenerator 6; the first condenser (condenser) 7 arranged side by side with the low-temperature regenerator 6; the low-temperature regenerator condensing the low-temperature regenerator 6 and the first condenser 7 Device chamber 8; a heat source w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com