Design and manufacturing method of inserted aluminum substrate

A finger-inserted, horizontal design technology, applied in the design and manufacture of finger-inserted LED BAR, can solve the problem of low productivity, reduce welding wires, enhance reliability and productivity, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The content of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

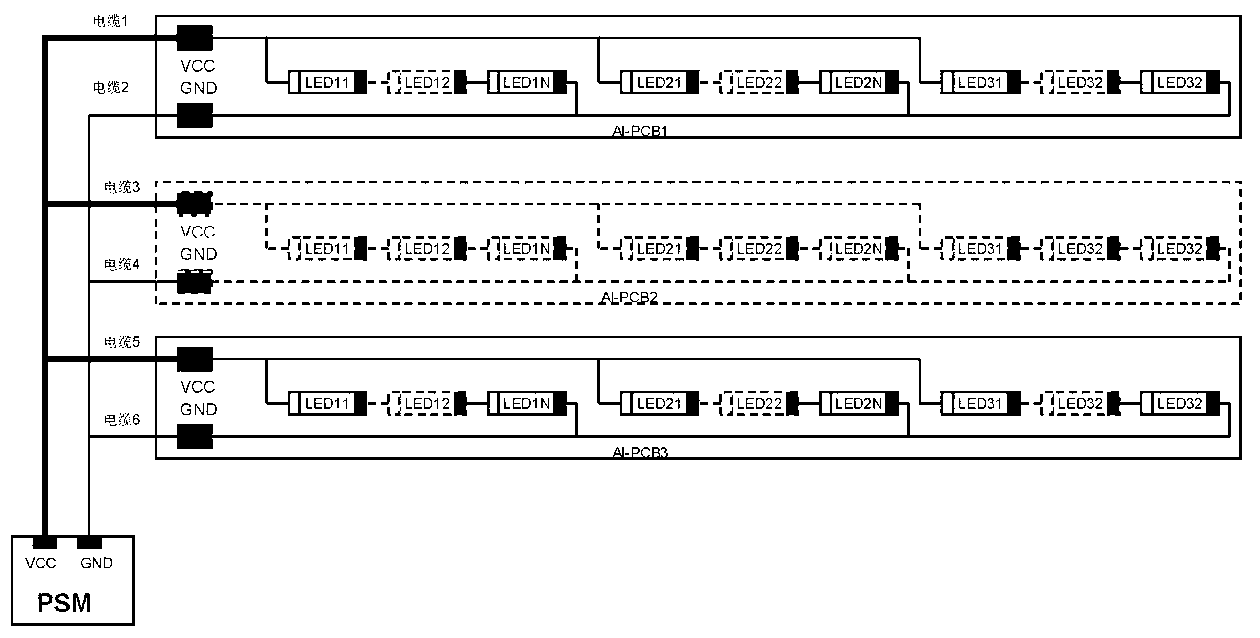

[0029] Such as figure 2 As shown, the schematic diagram of a single finger LED BAR.

[0030] 2 cables are connected to the VCC and GND of the power supply module PSU, and the voltage is connected to the PCB.

[0031] The anodes of LED11, LED21, and LED31 of the first horizontal aluminum substrate are connected to VCC, and the cathodes of LED1N, LED2N, and LED3N are connected to GND. LED11, LED12, and LED1N are connected in series to form one string, LED21, LED22, and LED2N are connected in series to form one string, and LED31, LED32, and LED3N are connected in series to form one string.

[0032] The anodes of LED11, LED21, and LED31 of the second horizontal aluminum substrate are connected to VCC through a jumper 0Ω resistor, and the cathodes of LED1N, LED2N, and LED3N are connected to GND. LED11, LED12, and LED1N are connected in serie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com