Overcurrent detection for droplet ejectors

An injector and circuit technology, applied in printing, printing devices, etc., can solve problems such as inoperability and damage to ink nozzles, and achieve the effect of preventing indirect damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

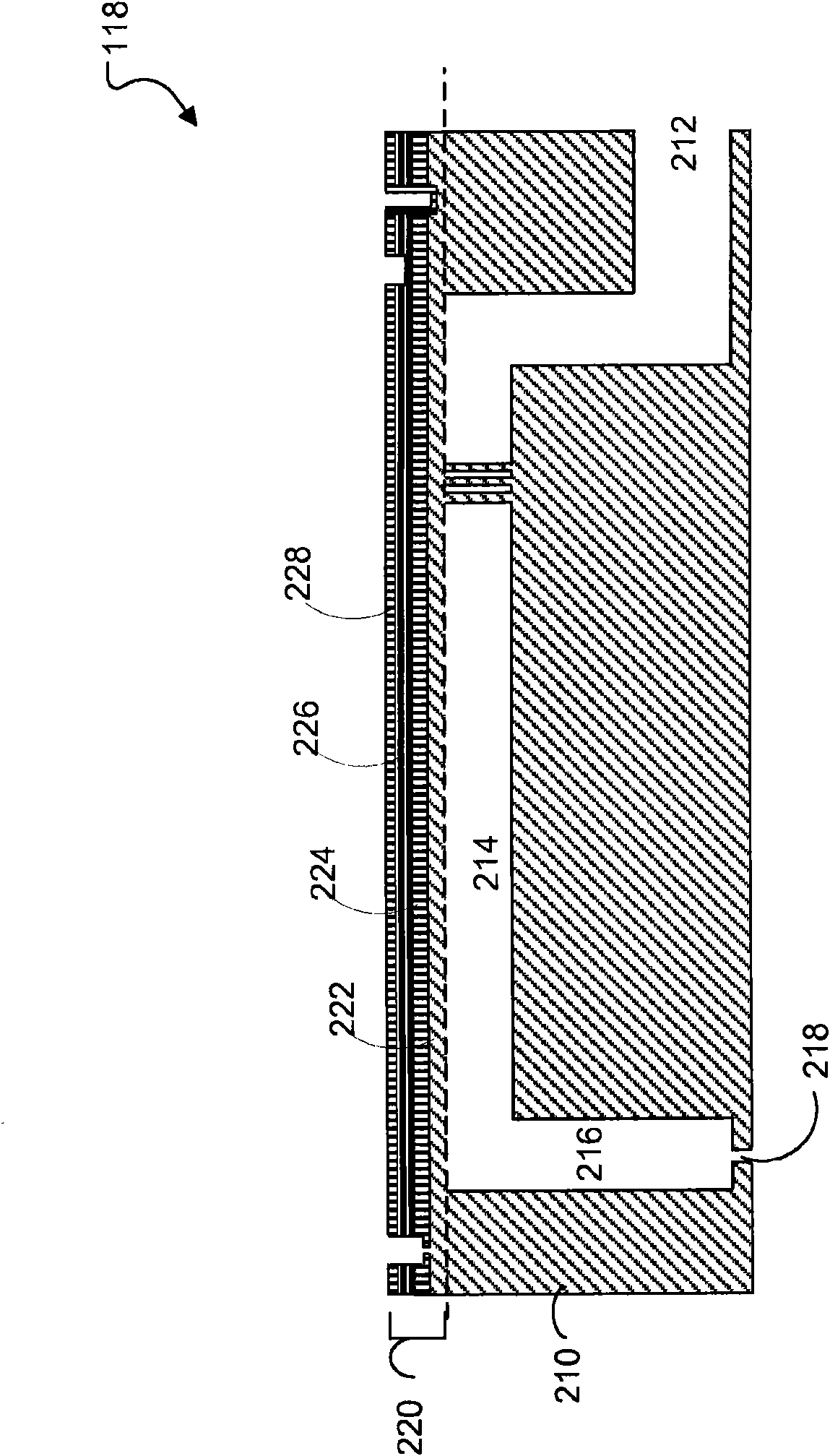

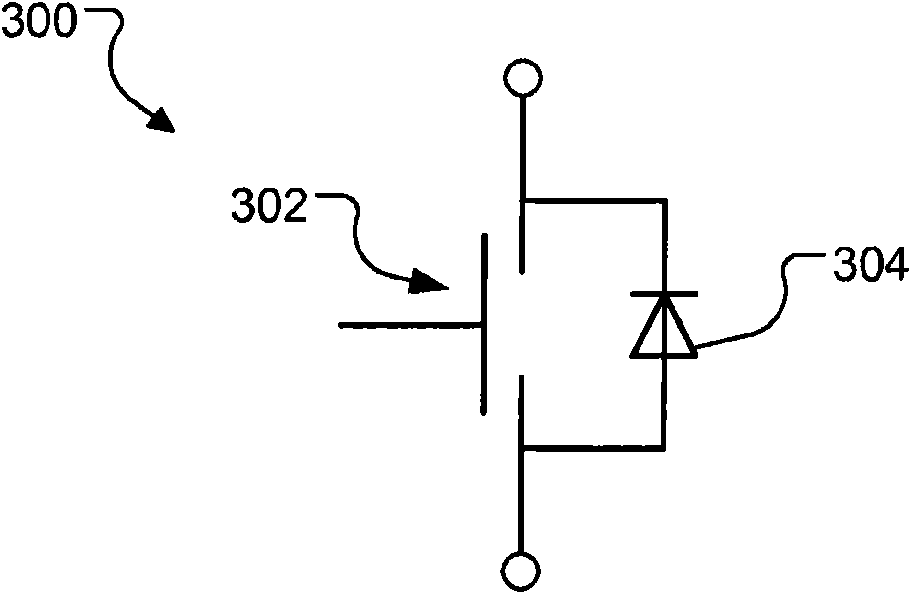

[0018] Although an ink-based printer system is described below, the concepts are also generally applicable to other microelectromechanical systems (MEMS-based) devices that include driven piezoelectric layers, and are particularly applicable to fluid ejection systems that eject fluid.

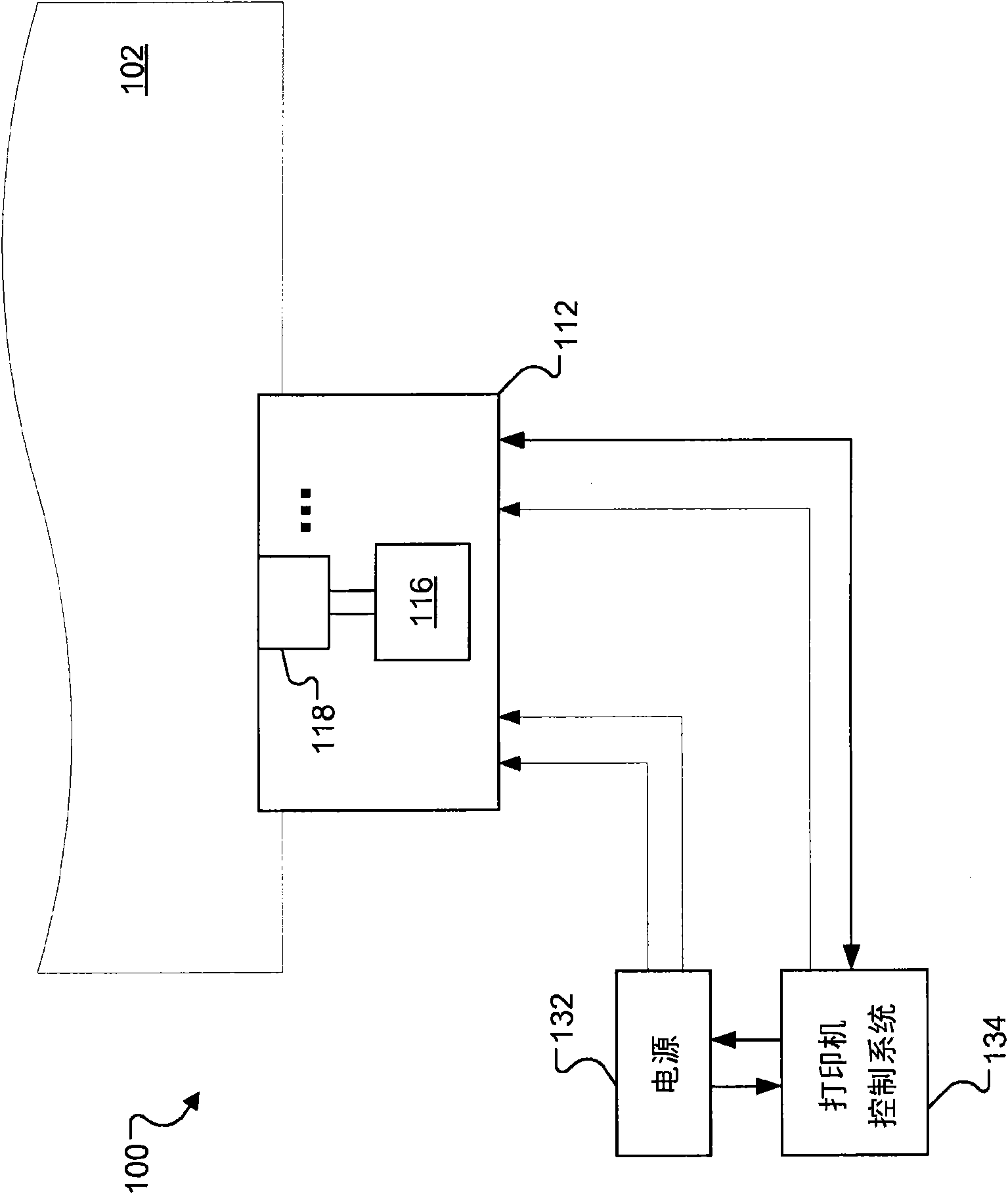

[0019] figure 1 A schematic plan view of an exemplary fluid ejection system, such as printer unit 100, is shown. Printer unit 100 includes one or more fluid ejectors, such as one or more printheads 112 . The printhead 112 may deposit a fluid material (eg, ink) onto a receiving surface 102 (eg, a recording medium, such as paper, or a substrate undergoing integrated circuit fabrication). In some embodiments, the printhead 112 and / or the receiving surface 102 can move or translate relative to each other such that fluid can be deposited at different locations on the receiving surface 102 . For example, the flat and flexible receiving surface 102 (eg, paper) can be translated by one or more roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com