Battery system and method for determining battery module voltages

A battery system and battery technology, applied in the field of battery systems, to achieve the effect of avoiding indirect damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

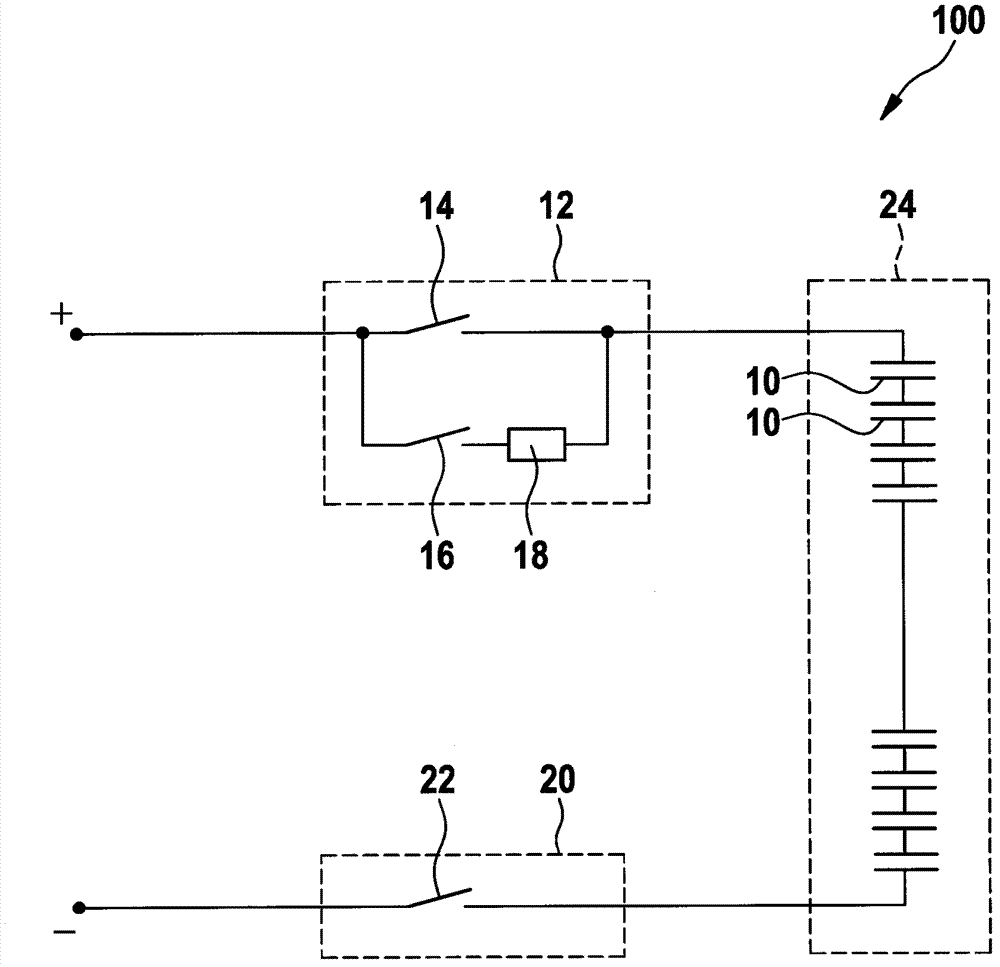

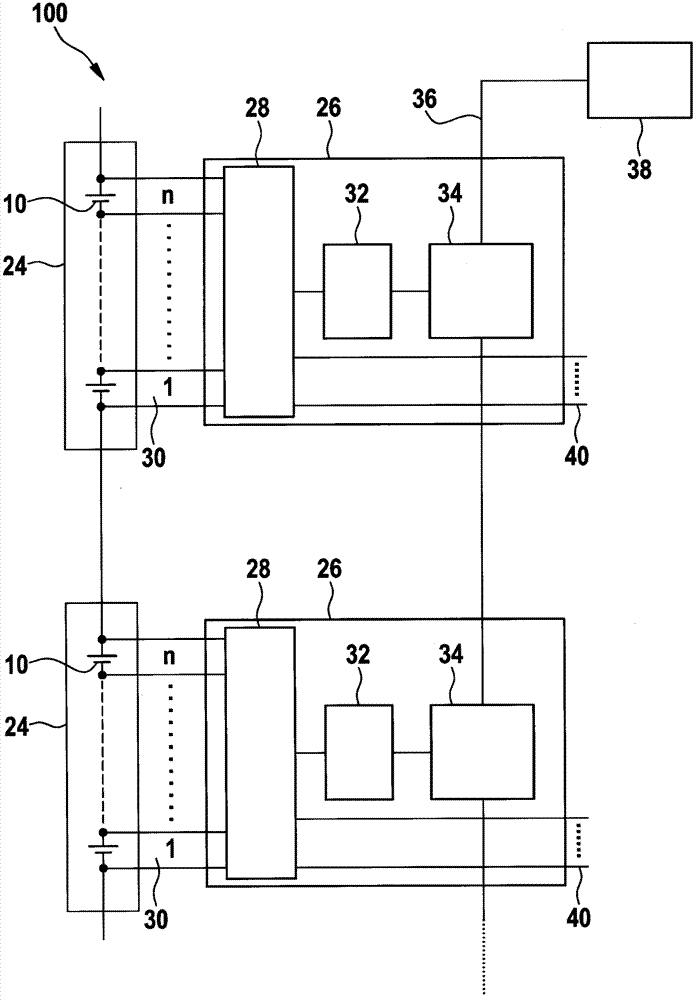

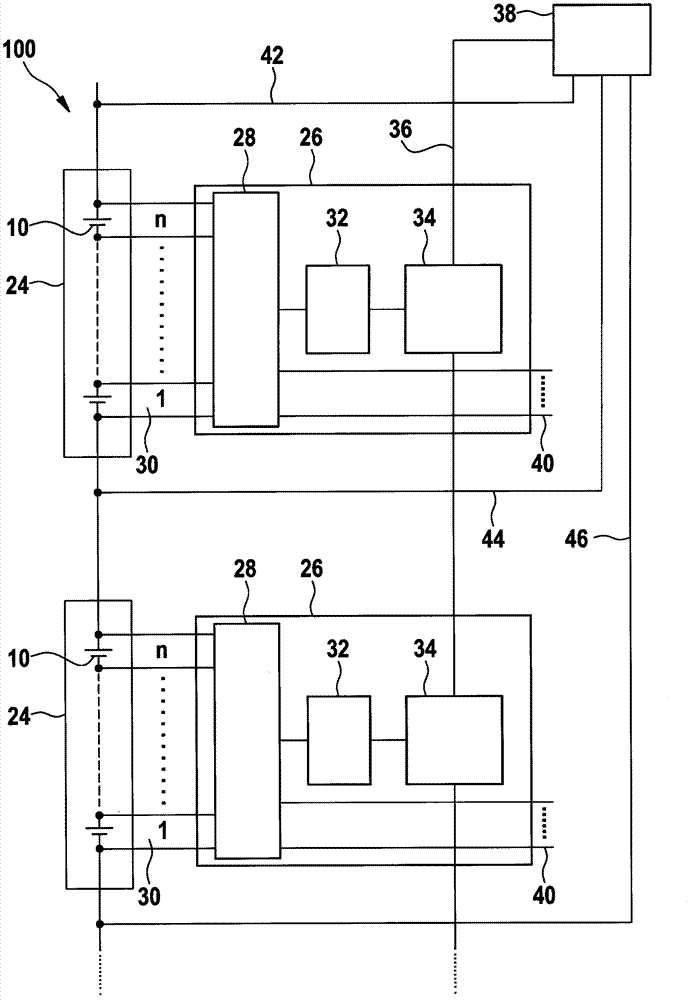

[0031] image 3A battery system 100 according to a first preferred embodiment variant of the invention is shown. A plurality of battery cells 10 are connected in series and are each integrated in a module 24 . In the multiplexer 28 , the cell voltages of the individual battery cells 10 are collected there and fed via an analog-to-digital converter 32 and a gateway 34 into a common communication bus 36 . The voltage analysis is carried out by microcontroller 38 in a known manner.

[0032] exist image 3 Two modules 24 each having a plurality of battery cells 10 are shown by way of example. Embodiments not shown, however, can also connect a plurality of modules 24 in series with each other or additionally in parallel.

[0033] Module measurement leads 42 , 44 , 46 are associated with each module 24 . The module measuring lines 42 , 44 , 46 tap the voltage applied to the individual modules 24 and feed it to a central control unit, in the exemplary embodiment a microcontrolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com