Ladder type stress ring synthetic diamond mold

A technology for synthesizing diamonds and prestressed rings, applied in the application of ultra-high pressure processes, etc., can solve problems such as low production efficiency, uneven material of large-sized products, cracking and failure, etc., to improve quality and production efficiency, and improve working stress Conditions, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

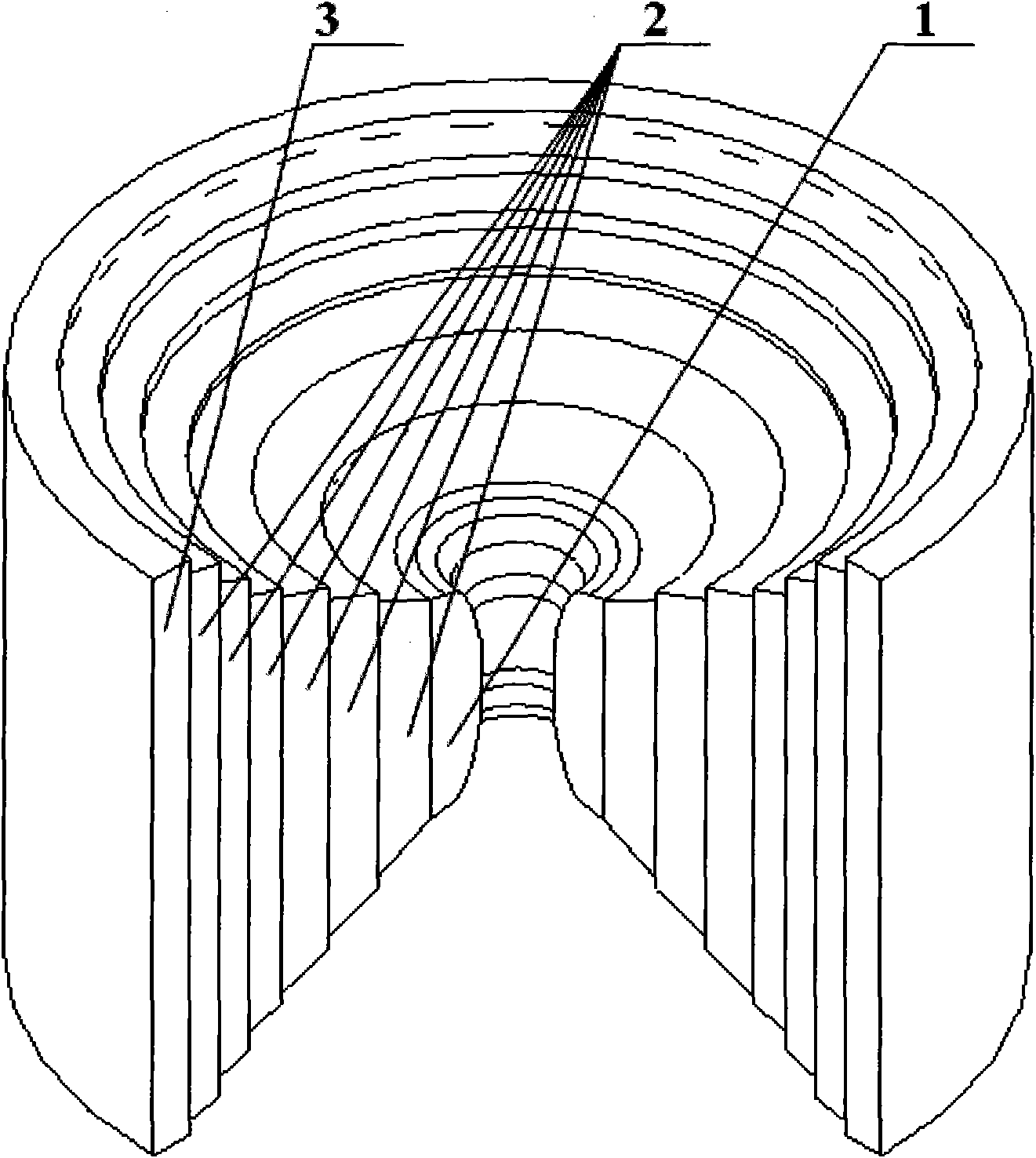

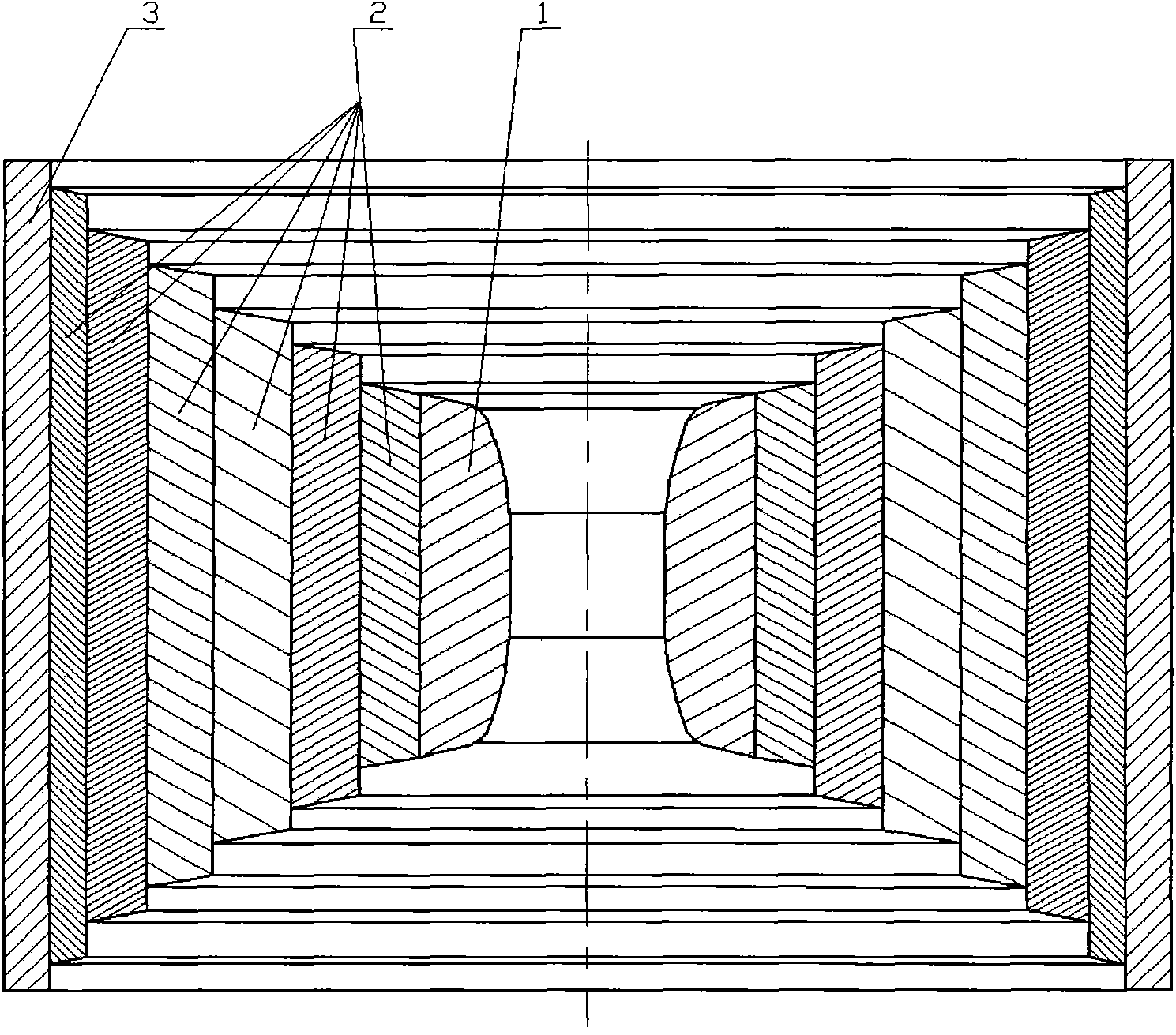

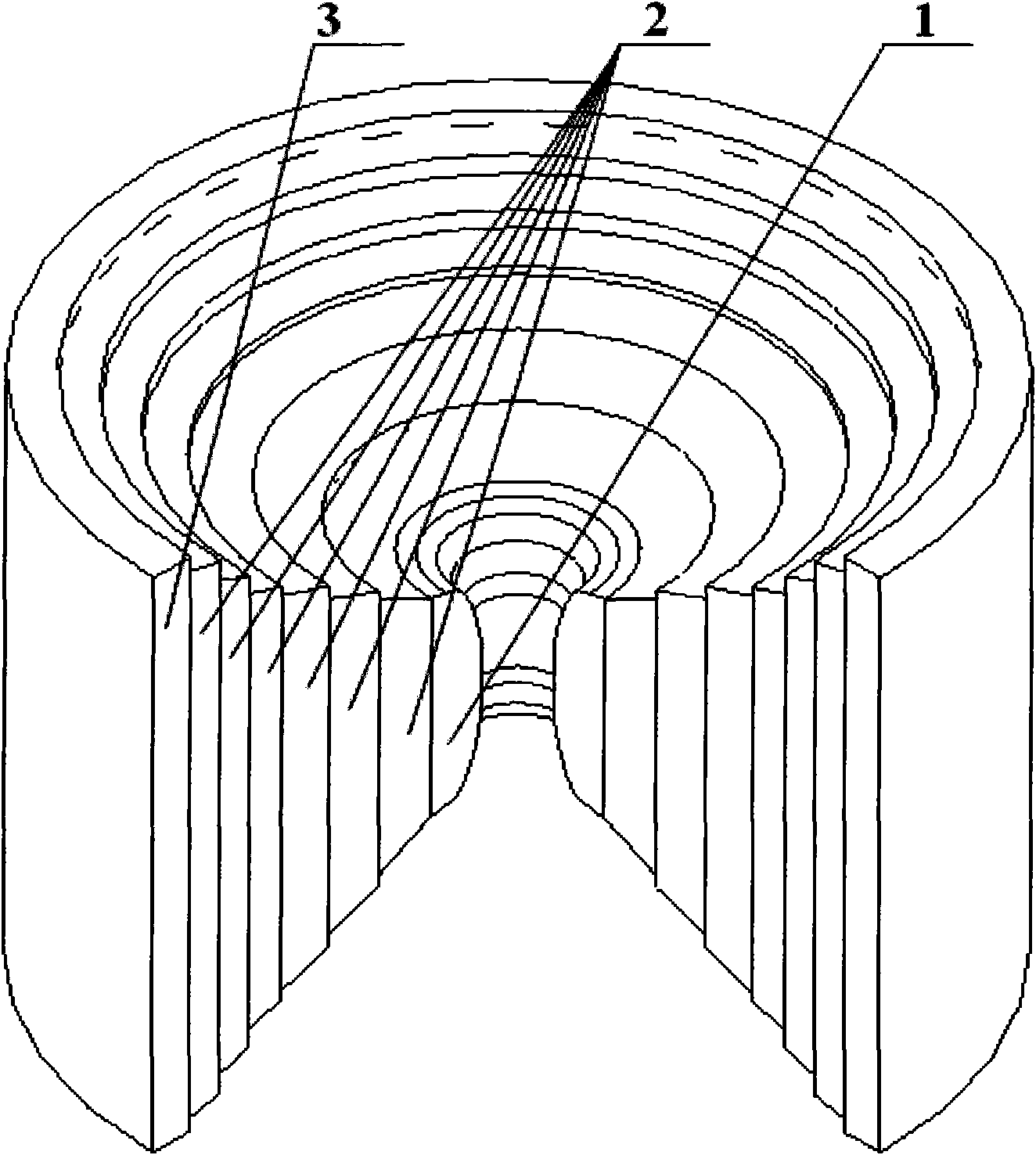

[0013] The stepped prestressed ring synthetic diamond mold of the present invention is composed of a pressure cylinder 1, a prestressed ring 2, and a protection ring 3. The pressure cylinder 1 is matched with the stepped prestressed ring mold, and the axial height of each layer of the prestressed ring 2 is stepped. , the inner layer is low and the outer layer is high, and the upper and lower end surfaces of the prestressing rings 2 of each layer are inclined surfaces with low inner and outer high, with an inclination angle of 2° to 15°; the protective ring 3 plays a role of safety protection.

[0014] In practical application, the materials of cylinder 1, prestressing ring 2 and protection ring 3 can be selected and determined according to the requirements of diamond synthesis; and then the materials of prestressing ring 2 can be selected and determined according to the requirements of diamond synthesis and the size of internal pressure. The number of layers, the number of laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com