Heavy rail scaling apparatus and method

A sizing, heavy rail technology, applied in the field of rolling equipment, can solve the problems of difficult maintenance, waste of funds and resources, affecting heavy rails, etc., and achieve the effects of improving the precision of sizing, prolonging service life, and avoiding accidental damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

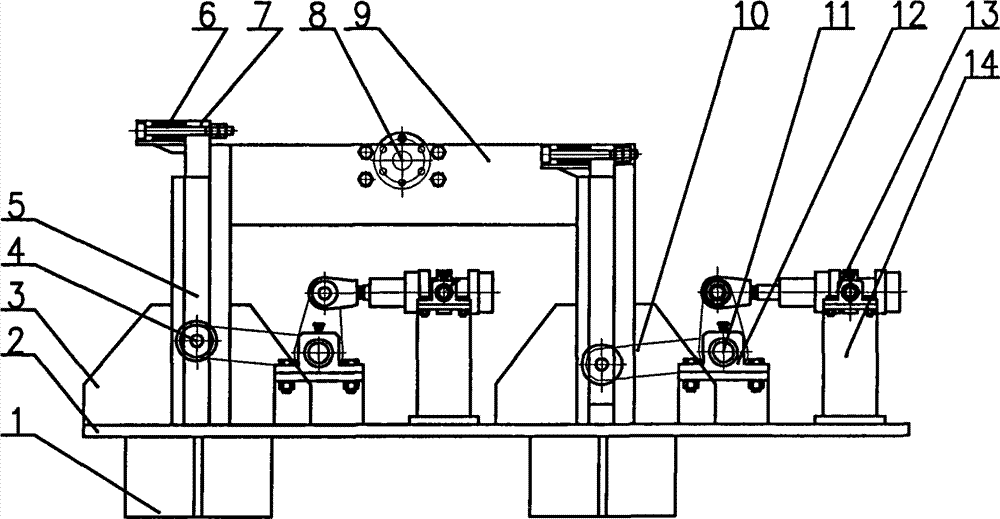

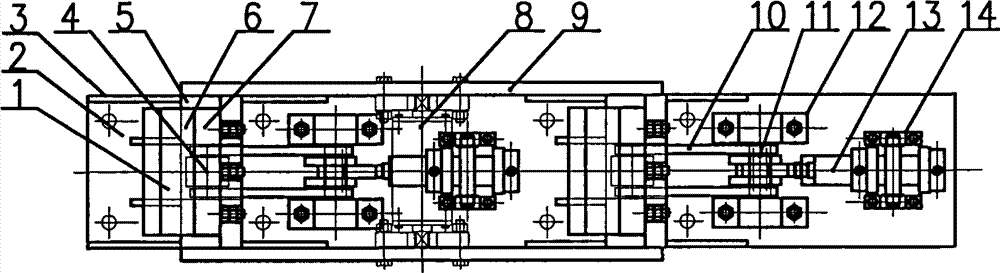

[0030] The present invention will be further described below in conjunction with accompanying drawing.

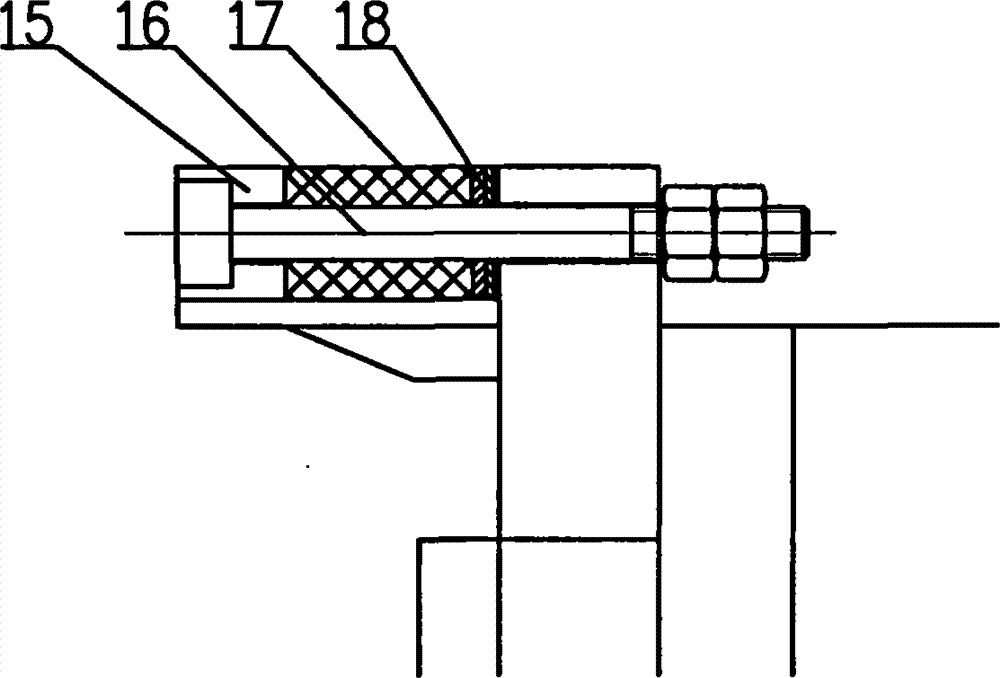

[0031] As can be seen from the accompanying drawings, the heavy rail sizing device of the present invention is mainly composed of four parts: a collision head lifting system, a transmission system, a frame and a detection switch. The bumping head lifting system includes a lifting plate 7 and a bumping head 6; the transmission system includes an electro-hydraulic push rod 13, a swing rod seat 12 and a swing rod 10 with a top wheel 4; the frame includes a column 5, a bottom plate 2 and a connecting column 5 and Ribs 3 of the base plate 2 .

[0032] The electro-hydraulic push rod 13 is used as the power source of the sizing device, and its push rod speed is 15mm / s; the stroke is 30mm; the pulling force is 3300N. The swing link 10 adopts an "arm bend" structure, and the length ratio of the front section to the rear end is 2:1. The lifting distance of the head bump is 60mm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com