Deployable reflecting surface device under traction drive of rope

A traction drive, reflective surface technology, applied in the field of machinery, can solve the problems of difficult deployment speed and stability, low storage rate, complex structure, etc., achieve the advantages of profile precision adjustment, overcome excessive deployment speed, and have wide application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

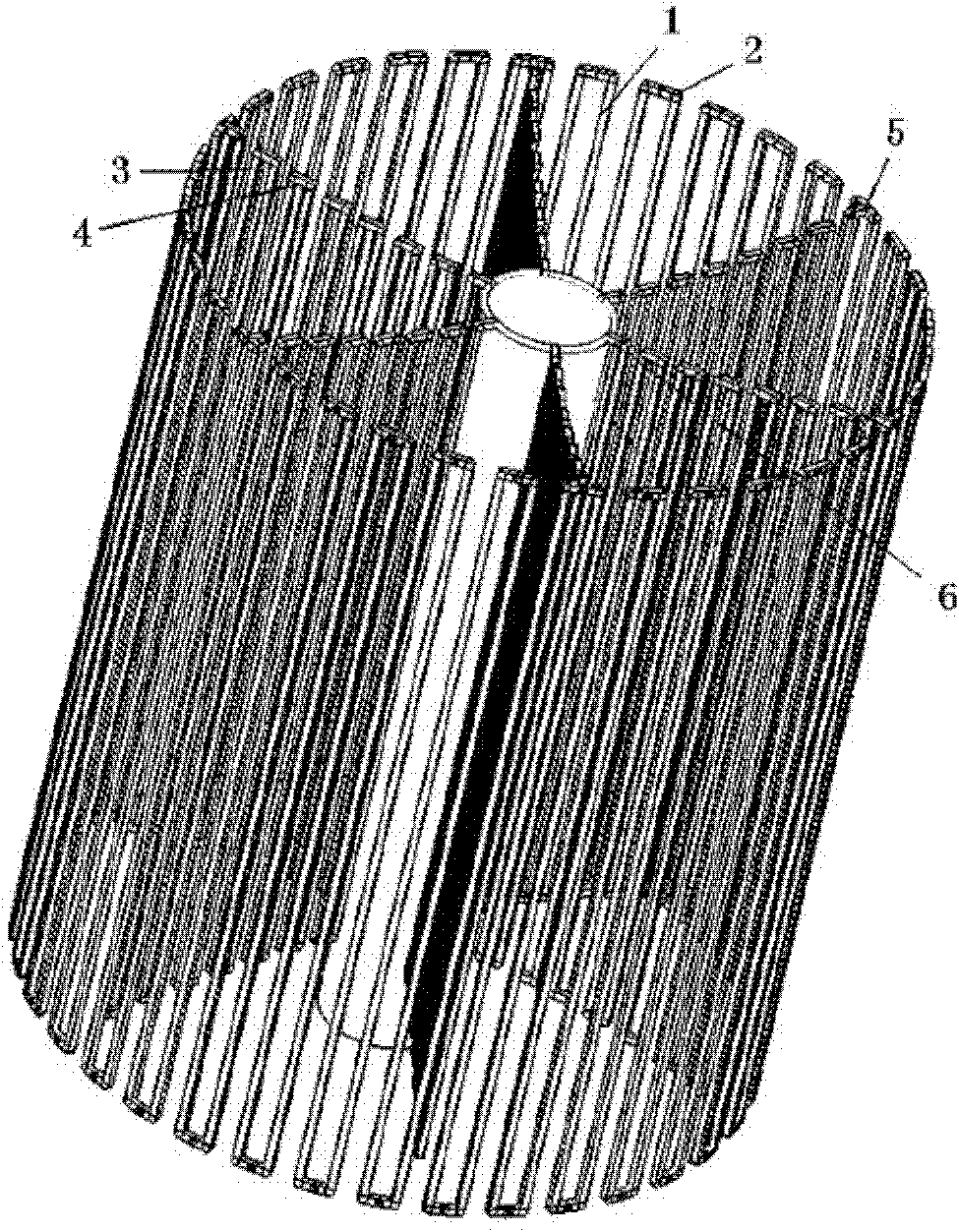

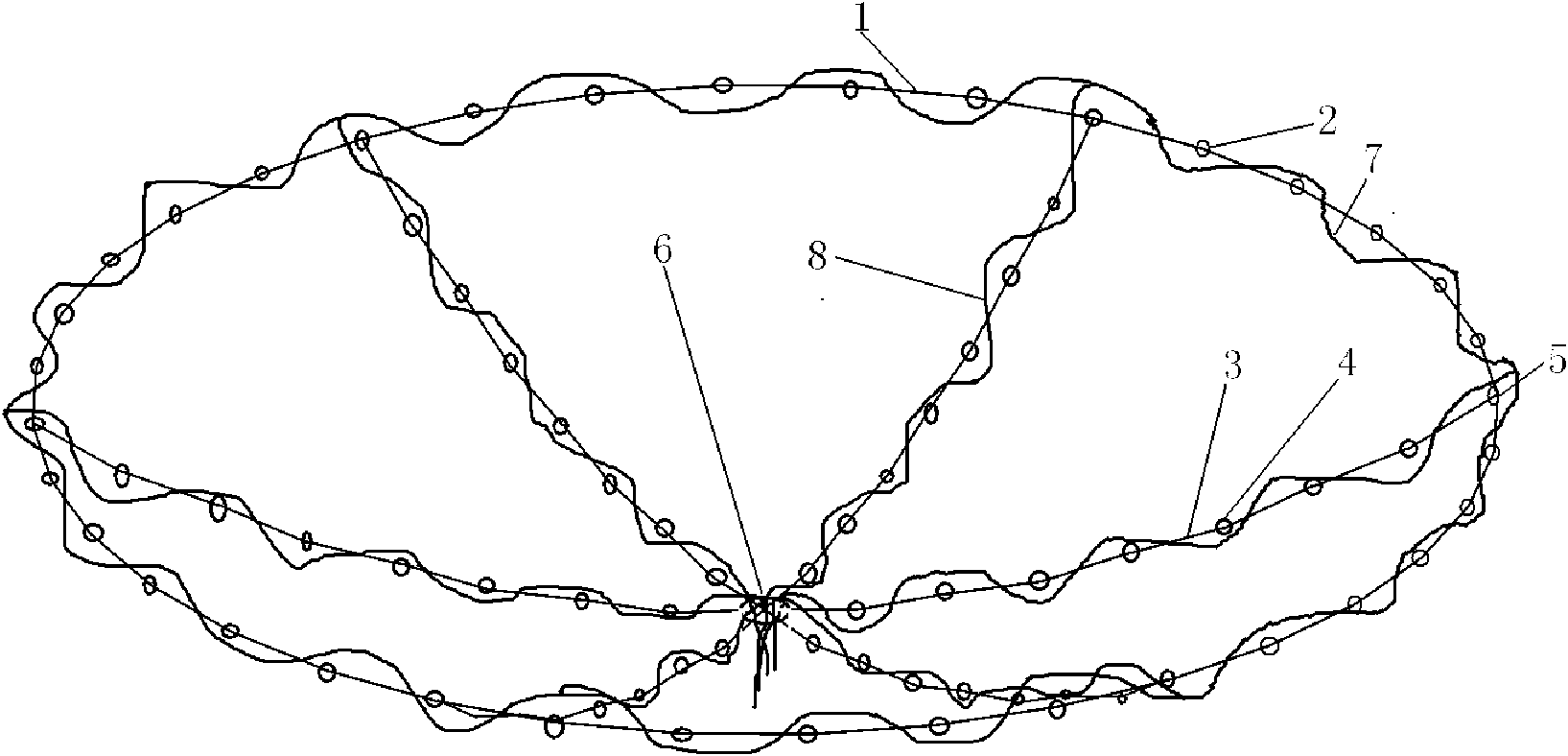

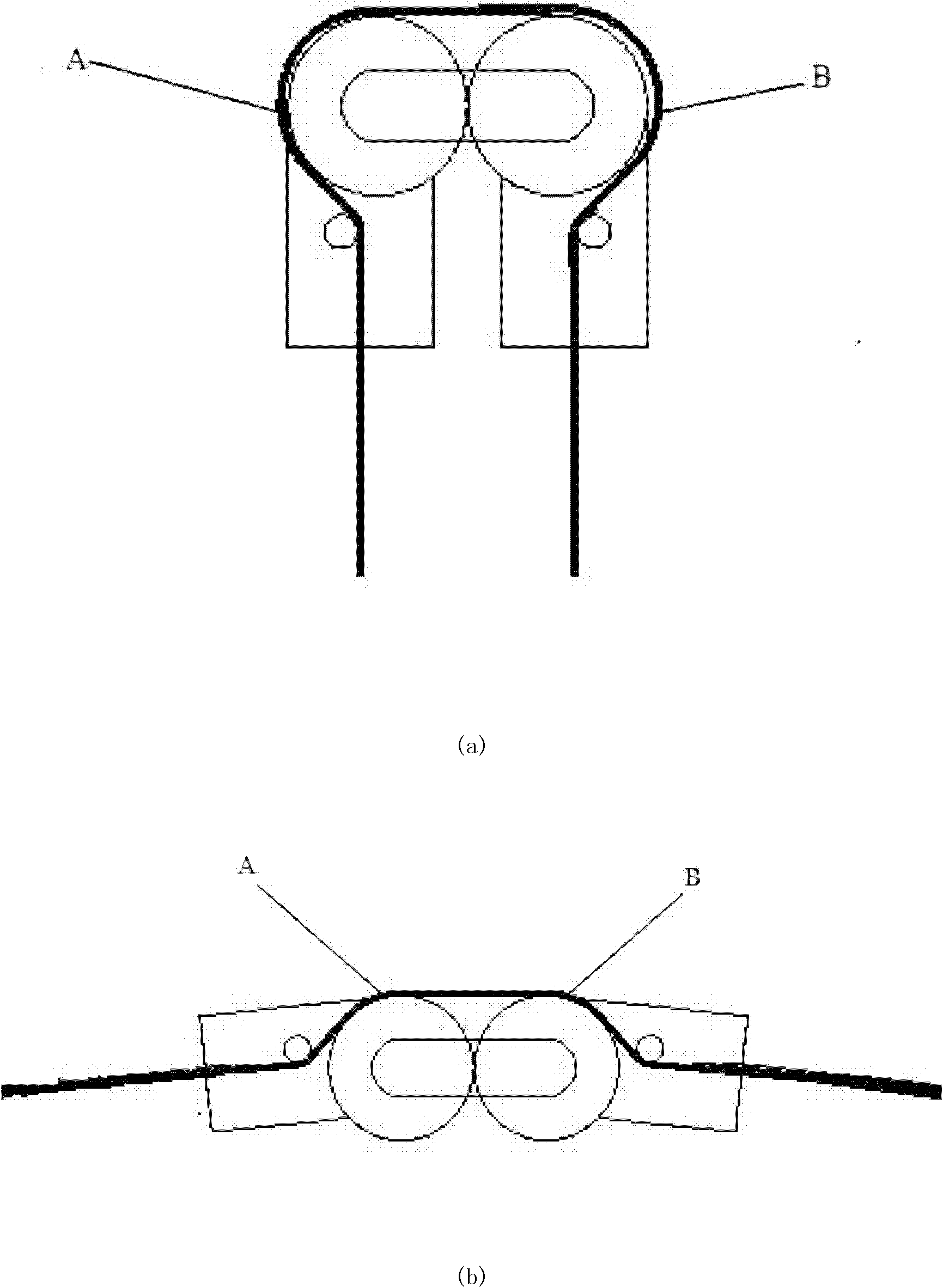

[0030] Such as figure 1 with figure 2 As shown, the present invention includes: foldable ring rod 1, ring rod connection joint 2, foldable rib rod 3, rib rod connection joint 4, ring rib connection joint 5, rib cylinder connection joint 6, hoop traction rope 7, diameter To the traction rope 8. The foldable ring rod 1 and the foldable rib rod 3, the ring rod connection joint 2, the rib rod connection joint 4, the ring rib connection joint 5, the rib cylinder connection joint 6, and the radial traction rope 8 are plural numbers, the specific numbers and geometric dimensions According to the diameter of the unfolding reflective surface, this embodiment adopts six rib structures to support the unfolding ring, but it is not limited to six. These foldable ring rods and foldable rib rods are straight rods to obtain a high storage rate, and the section is hollow to facilitate the smooth passage of the traction rope, while also reducing the mass of the entire device.

[0031] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com