Power-free double-chain seat transport line

A conveying line and seat technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high cost and complex conveying line structure, and achieve the effect of simplifying the structure and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

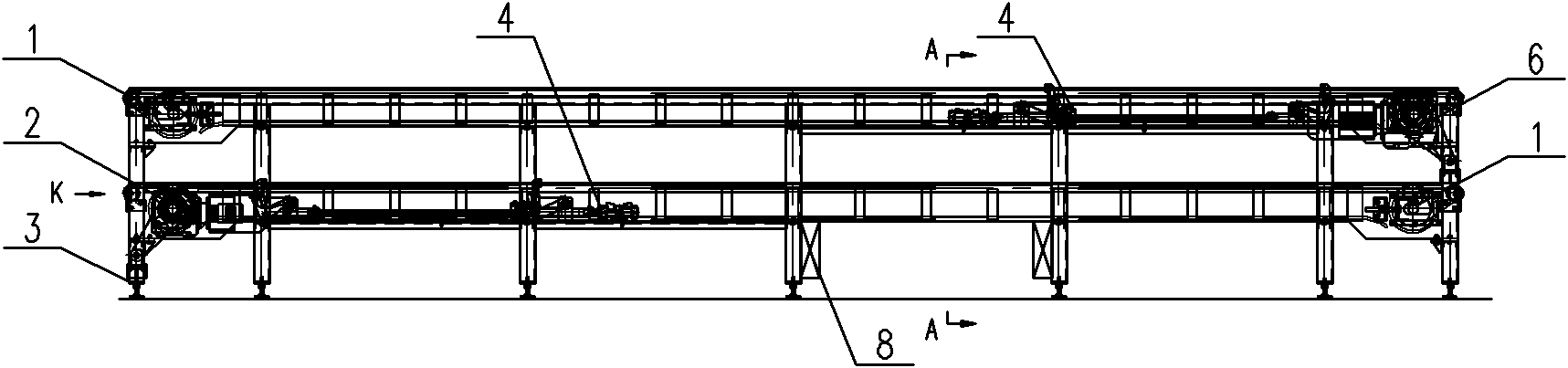

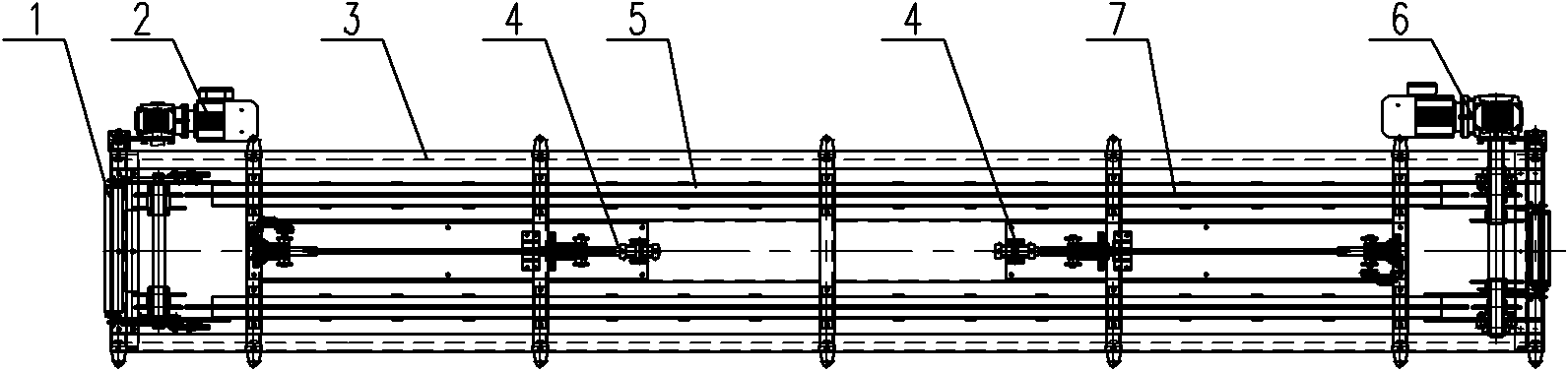

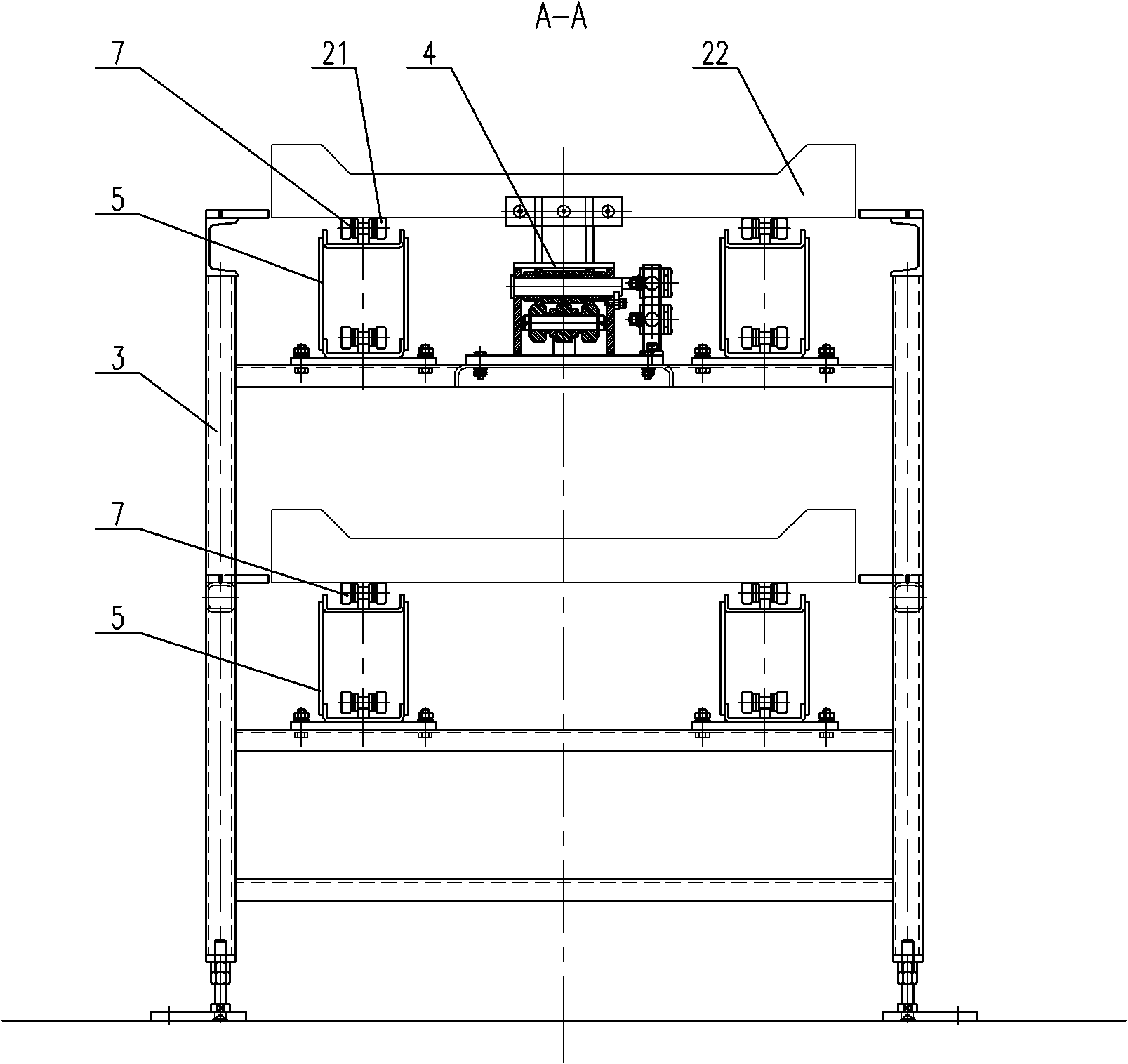

[0016] Such as Figure 1 to Figure 10 As shown, it includes tensioning device 1, lower driving device 2, frame 3, stopper 4, chain rail 5, upper driving device 6, chain 7, air circuit unit 8, cylinder 9, first cylinder joint 10, first Mounting seat 11, first baffle assembly 12, limit block 13, limit block mounting seat 14, connecting rod 15, second cylinder joint 16, second mounting seat 17, second baffle assembly 18, chute 19, Walking wheel 20, roller 21, tray 22, front solid seat tray 221, rear solid seat tray 222 and connecting piece 23 etc.

[0017] Such as Figure 1 ~ Figure 4 As shown, the present invention is an accumulative double-chain seat conveyor line, which includes a frame 3 divided into upper and lower layers. The upper and lower layers of the frame 3 are respectively provided with double-chain conveyors with opposite running directions, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com