Working station for transaction system, and working method and material loading and unloading methods thereof

A transaction system and workstation technology, applied in the field of pipeline transmission system, can solve the problems of affecting transaction time, complicated control, large friction, etc., and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

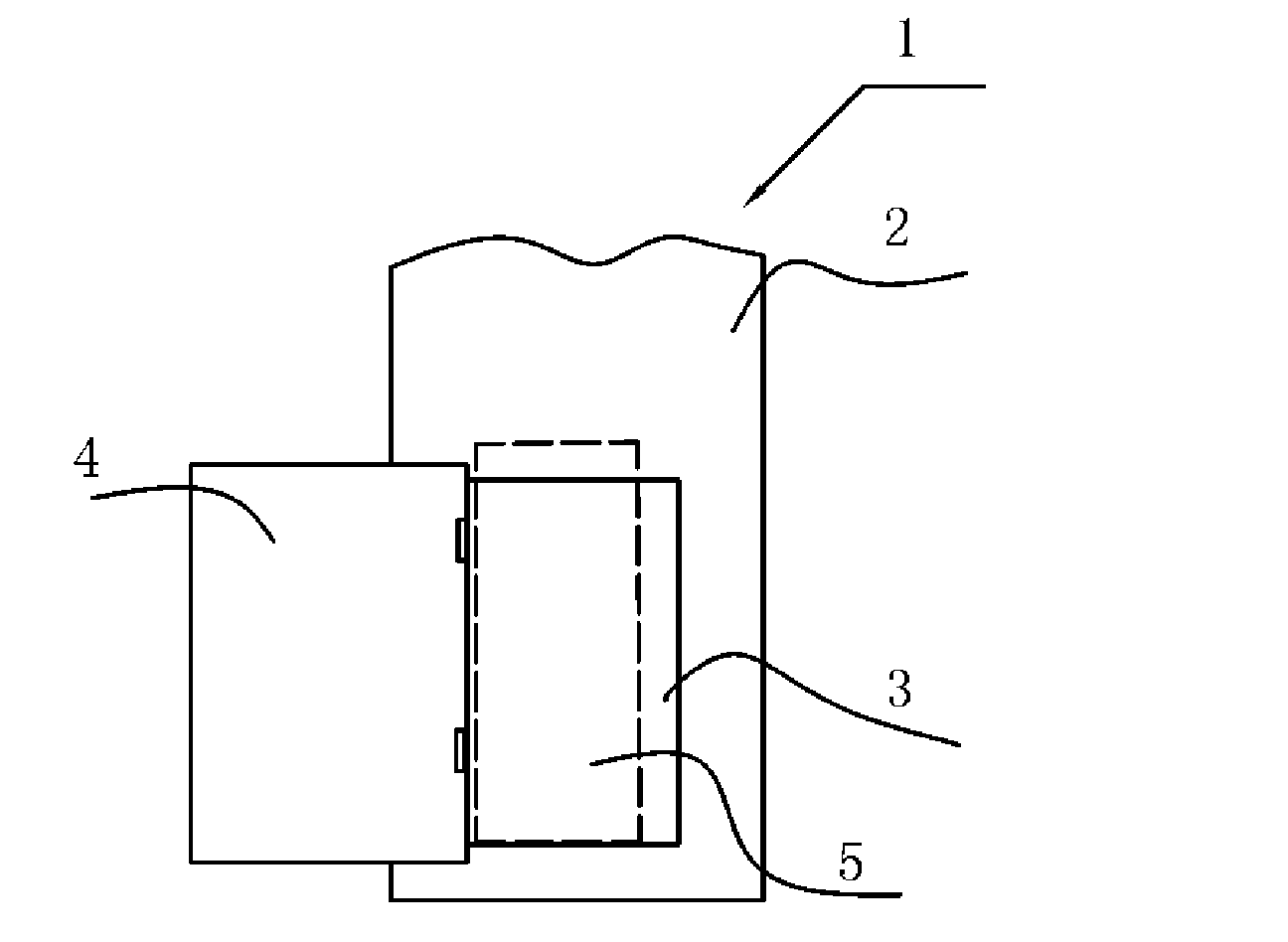

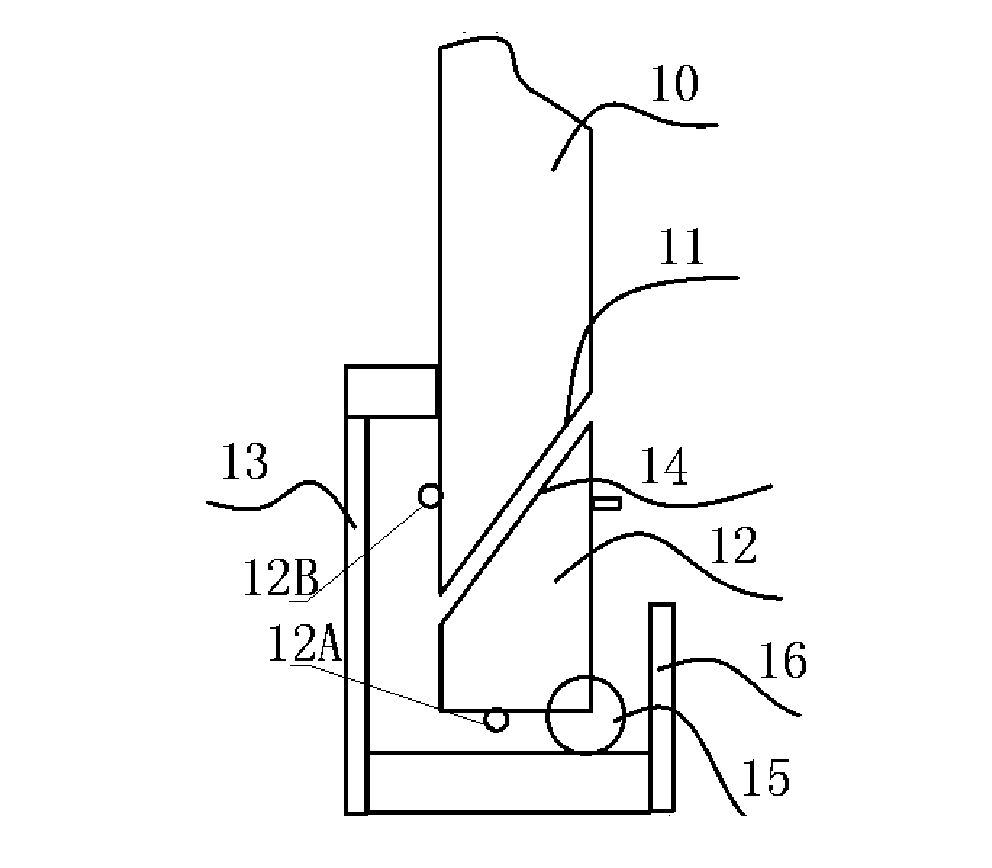

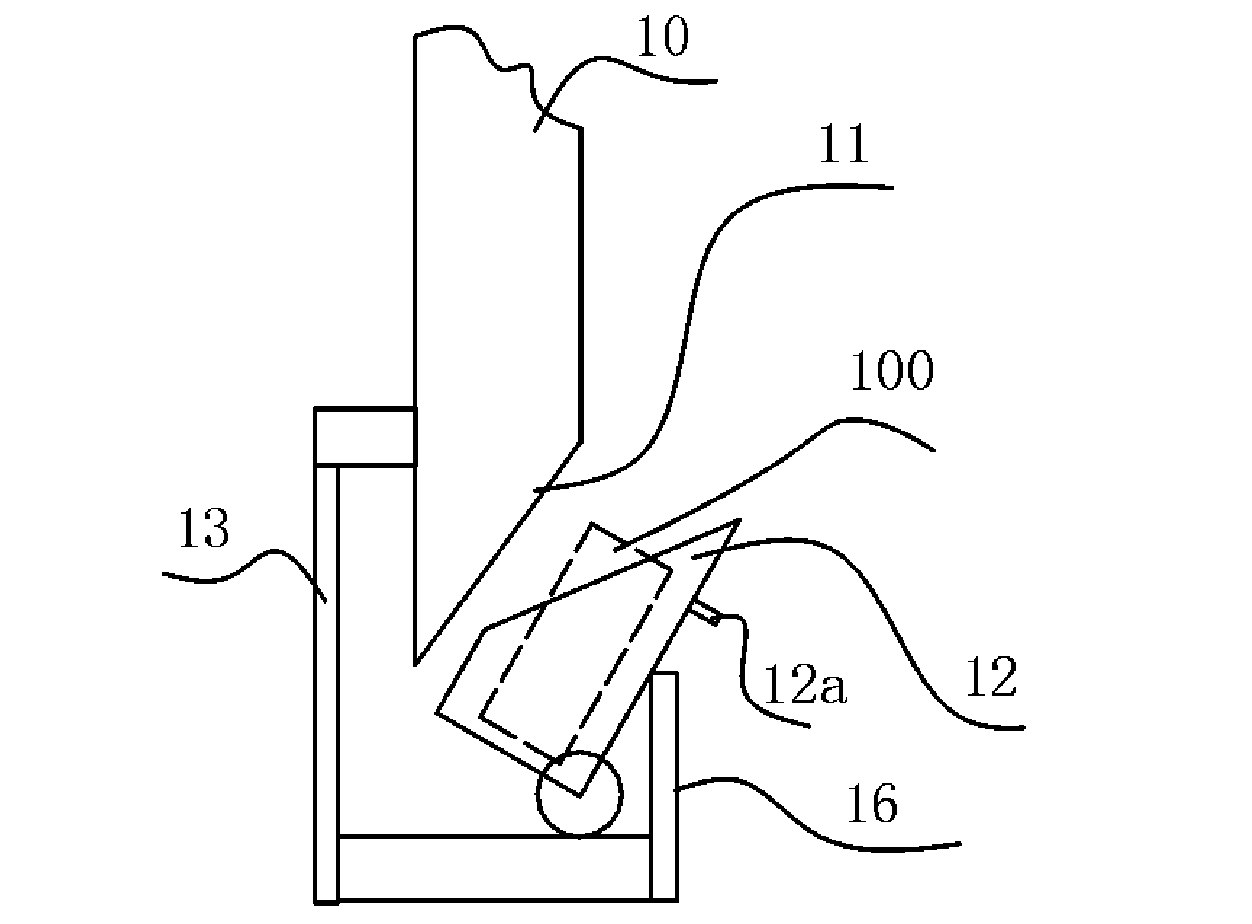

[0136] Such as figure 2 , image 3 As shown, the trading system workstation of the embodiment of the present invention includes a vertical pipeline 10, a port 11 is provided at the lower end of the vertical pipeline 10, and a container 12 is pivotally connected to the port 11 at the lower end of the vertical pipeline. The container is pivotally connected to the frame body 13 through a pivot shaft 15, the vertical pipe 10 is fixed on the frame body 13, the upper end of the container has an opening 14, and the opening 14 at the upper end of the container is connected to the frame body 13. The port 11 at the lower end of the vertical pipe is adapted, wherein the port 11 at the lower end of the vertical pipe is an inclined port; the container 12 is a pipe section with a closed bottom and an inclined opening at the upper end, and the inside of the pipe section There is an accommodating space for containing an object 100 (such as a transmitter) to be sent or received; the containe...

Embodiment 2

[0146] In order to realize automatic control and enable the container to be opened automatically, on the basis of the first embodiment, in this embodiment, the workstation further includes a driving mechanism for driving the container to turn over and reset.

[0147]In this embodiment, the pivot shaft is fixed at the bottom of the container; the driving mechanism includes a power device (not shown) fixedly connected to the pivot shaft. The power device is a stepping motor, and the precise control of the rotation angle of the container can be realized by adopting the stepping motor. The power unit may also include a motor and a gear transmission mechanism connected to the motor.

[0148] The drive mechanism drives the receptacle to flip open, presenting the opening of the receptacle in front of the operator, which not only facilitates the operation, but also serves as a reminder to the operator, making the entire operation appear more humane.

Embodiment 3

[0150] When the workstation receives the transmitter, the transmitter falls by gravity along a transfer conduit connected to the vertical conduit of the workstation, thereby creating a positive air pressure inside the workstation. In order to prevent the container 12 pivotally connected to the port 11 at the lower end of the vertical pipe from accidentally rotating and opening under the action of the positive air pressure, this embodiment is based on the above-mentioned embodiments. The system workstation also includes means for maintaining said receptacle closed.

[0151] Such as Figure 5 , Figure 6 and Figure 7 As shown, in the embodiment of the present invention, the locking device for keeping the container in a closed state is a lock device 214 installed at the closing position between the container and the pipeline. The lock device includes a lock slot provided on the vertical pipe 11 and a lock tongue 214 provided on the container 12, when the container 12 is close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com