Design method of automatic moving feeding frame of base material longitudinal cutting device

A technology of automatic movement and design method, applied in the direction of winding strips, thin material handling, sending objects, etc., can solve problems such as instability, cutting speed cannot be increased, and cannot work normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 The automatic moving discharge rack of the substrate longitudinal slitting equipment is characterized in that it includes a sensor, an automatic adjustment device, a power mechanism, a transmission mechanism, and an adjustment mechanism; the sensor is electrically connected to the automatic adjustment device, and the automatic adjustment device It is electrically connected with the power mechanism, and the power mechanism is connected to the moving mechanism through the transmission mechanism, and the moving mechanism is fixedly connected with the discharge rack 1 . It uses the electrical automatic control system to transmit the signal to the servo motor to drive the precision transmission to drive the unwinding frame 1 to move automatically to realize the constant distance between the surface of the unwinding shaft substrate and the unwinding guide roller, to ensure constant tension of the cutting substrate 3, and to improve Slitting speed.

[0018] In an ...

Embodiment 2

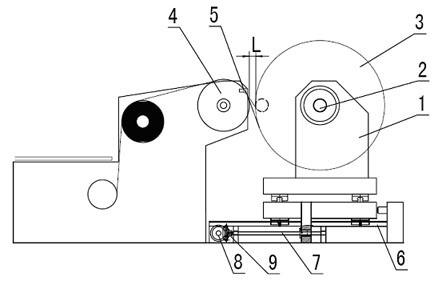

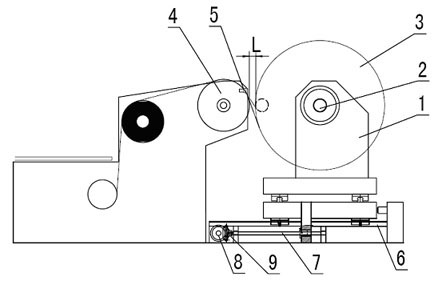

[0019] Example 2 as figure 1 As shown, the detection photoelectric head 5 is fixed on the unwinding guide roller 4? ? ,

[0020] The detection photoelectric head 5 is electrically connected to the variable-range automatic logic controller PLC, and the variable-range automatic logic controller PLC is electrically connected to the transmission servo motor 8. The servo motor 8 is connected to the ball screw 7 through the bevel gear 9, and the ball screw Pay 7 to be connected with sliding track 6 transmissions by screw nut. The nut of the ball screw 7 is fixedly connected with the sliding track bracket. There is a pulley at the bottom of the sliding track bracket. The pulley slides on the sliding track 6 to drive the fixed discharge rack 1 and the unwinding air shaft 2 on the sliding track bracket. Cut substrate 3 moves.

[0021] When unwinding, through the detection of the photoelectric head 5, the electrical signal is transmitted to the PLC to compare with the original set v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com