Adhesive composition, adhesive and optical film

A technology of adhesive and composition, which is applied in the field of optical film, can solve problems that cannot be solved, and achieve the effect of suppressing light leakage and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0074] The first embodiment of the present invention is an adhesive composition characterized by containing the following components (A), (B1) and (C) or the following components (A), (B2) and (C) Or following (A), (B1), (B2), (C) component.

[0075] (A) 100 parts by weight of a (meth)acrylate polymer having a weight average molecular weight of 200,000 to 2,500,000,

[0076] (B1) 1 to 100 parts by weight of a reactive (meth)acrylate polymer having a weight average molecular weight of 30,000 to 1,500,000 and having an ethylenic double bond in the side chain,

[0077] (B2) 1 to 50 parts by weight of a polyene compound having two or more ethylenic double bonds in one molecule,

[0078] (C) 0.01 to 50 parts by weight of a polythiol compound having two or more mercapto groups in one molecule.

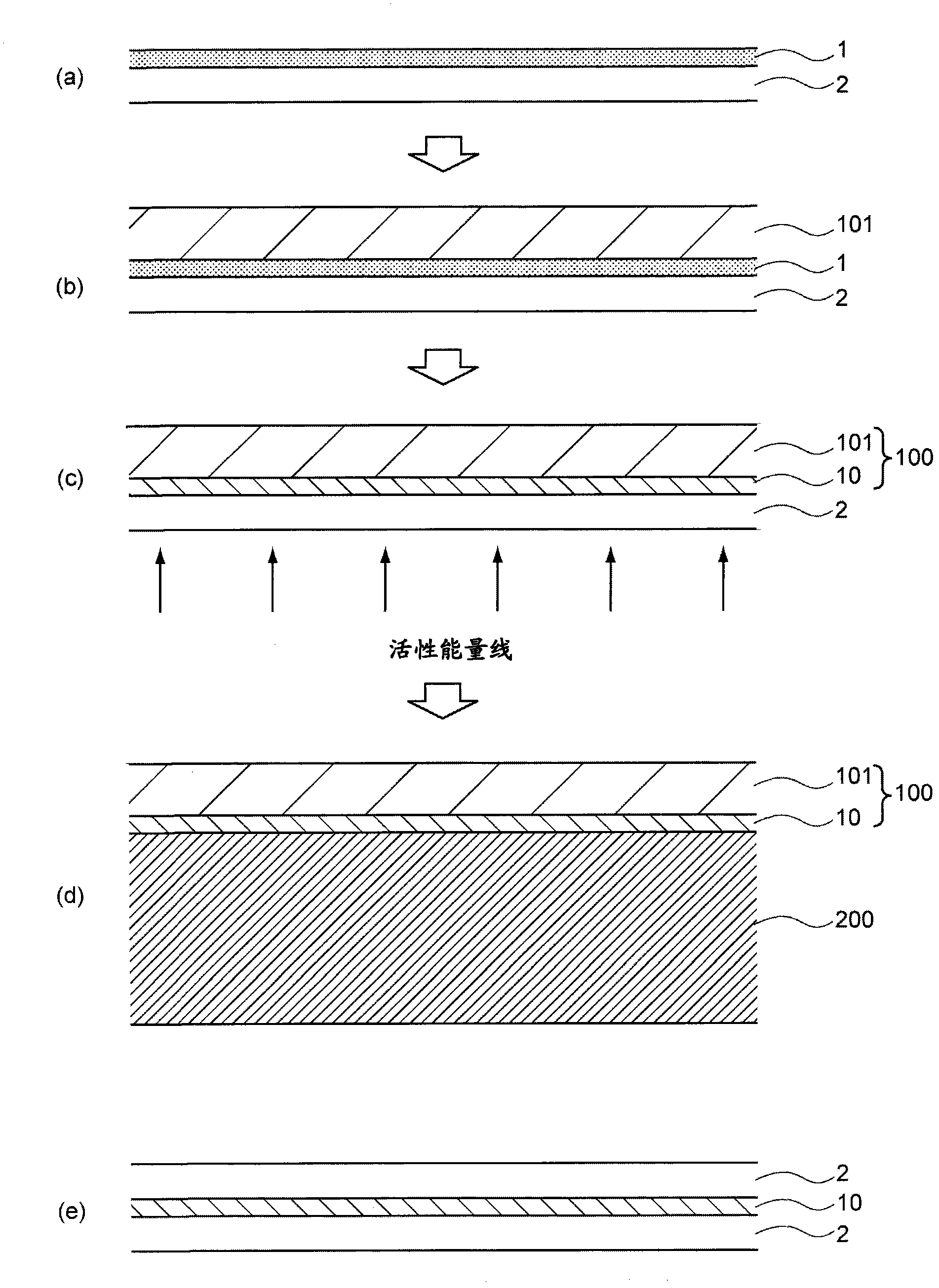

[0079] that is to figure 1 Adhesive composition 1 used as an example in (a)-(e).

[0080] Hereinafter, the first embodiment of the present invention will be specifically described with r...

no. 2 Embodiment approach

[0234] The second embodiment of the present invention is an adhesive, characterized in that the adhesive is formed through the following steps (1) to (3):

[0235] (1) The preparation is characterized by containing the following (A), (B1), (C) components or the following (A), (B2), (C) components or the following (A), (B1), (B2) ), (C) the operation of the adhesive composition of composition;

[0236] (A) 100 parts by weight of a (meth)acrylate polymer having a weight average molecular weight of 200,000 to 2,500,000,

[0237] (B1) 1 to 100 parts by weight of a reactive (meth)acrylate polymer having a weight average molecular weight of 30,000 to 1,500,000 and having an ethylenic double bond in the side chain,

[0238] (B2) 1 to 50 parts by weight of a polyene compound having two or more ethylenic double bonds in one molecule,

[0239] (C) 0.01 to 50 parts by weight of a polythiol compound having two or more mercapto groups in one molecule,

[0240] (2) A process of applying ...

no. 3 Embodiment approach

[0289] A third embodiment of the present invention is an optical film comprising an adhesive layer containing the adhesive of the second embodiment on a film substrate, wherein the adhesive layer has a The thickness is a value within a range of 1 to 100 μm.

[0290] Below, refer to figure 1 A third embodiment of the present invention will be described in detail.

[0291] 1. Membrane substrate

[0292] As the film base material 101 of the optical film 100 of this invention, if it is a film base material used for an optical film, it will not specifically limit.

[0293] For example, optical films used for liquid crystal displays, such as a polarizing plate, a polarizing layer protective film, a viewing angle expansion film, an antiglare film, and a retardation plate, etc. are mentioned.

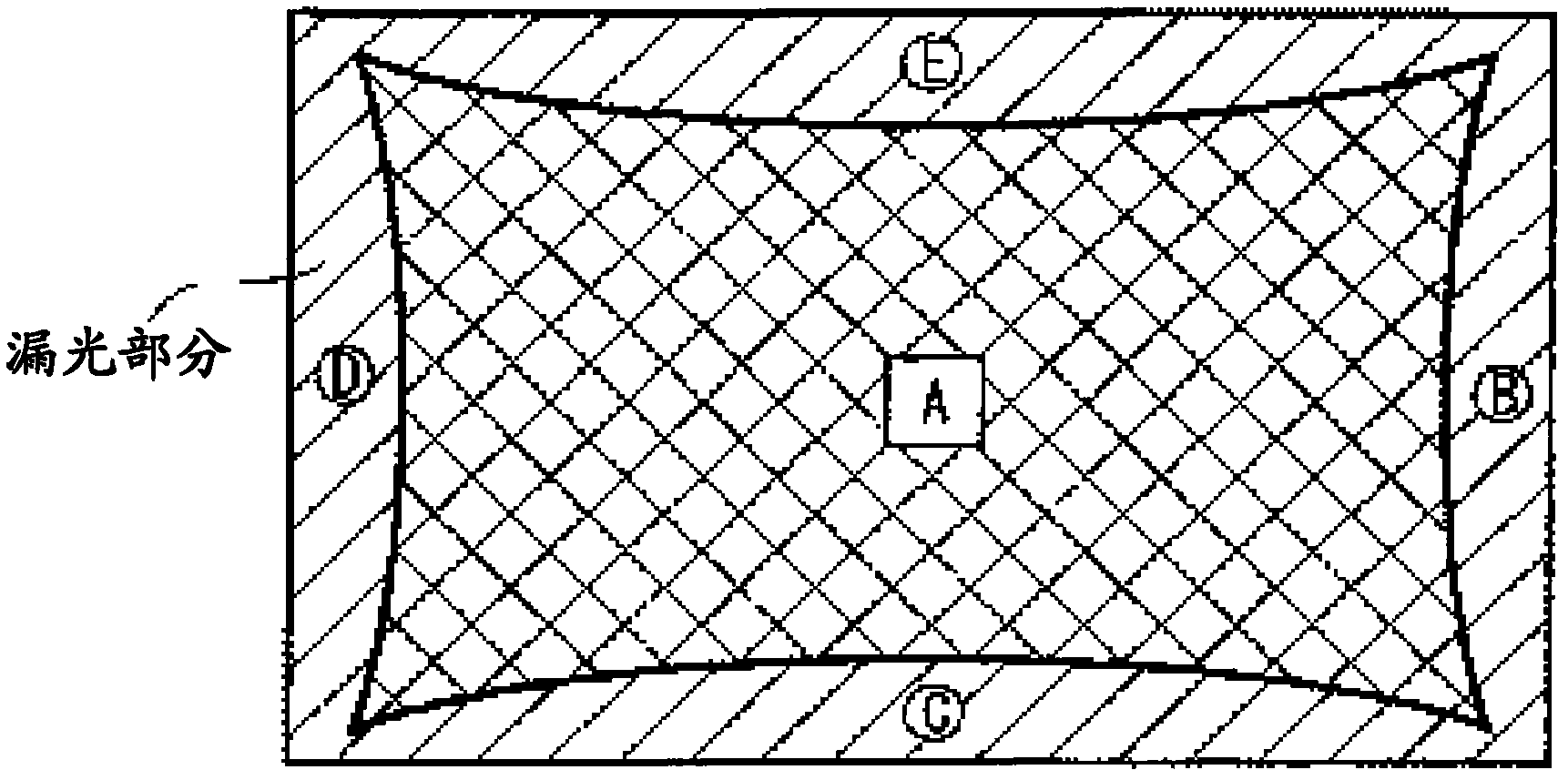

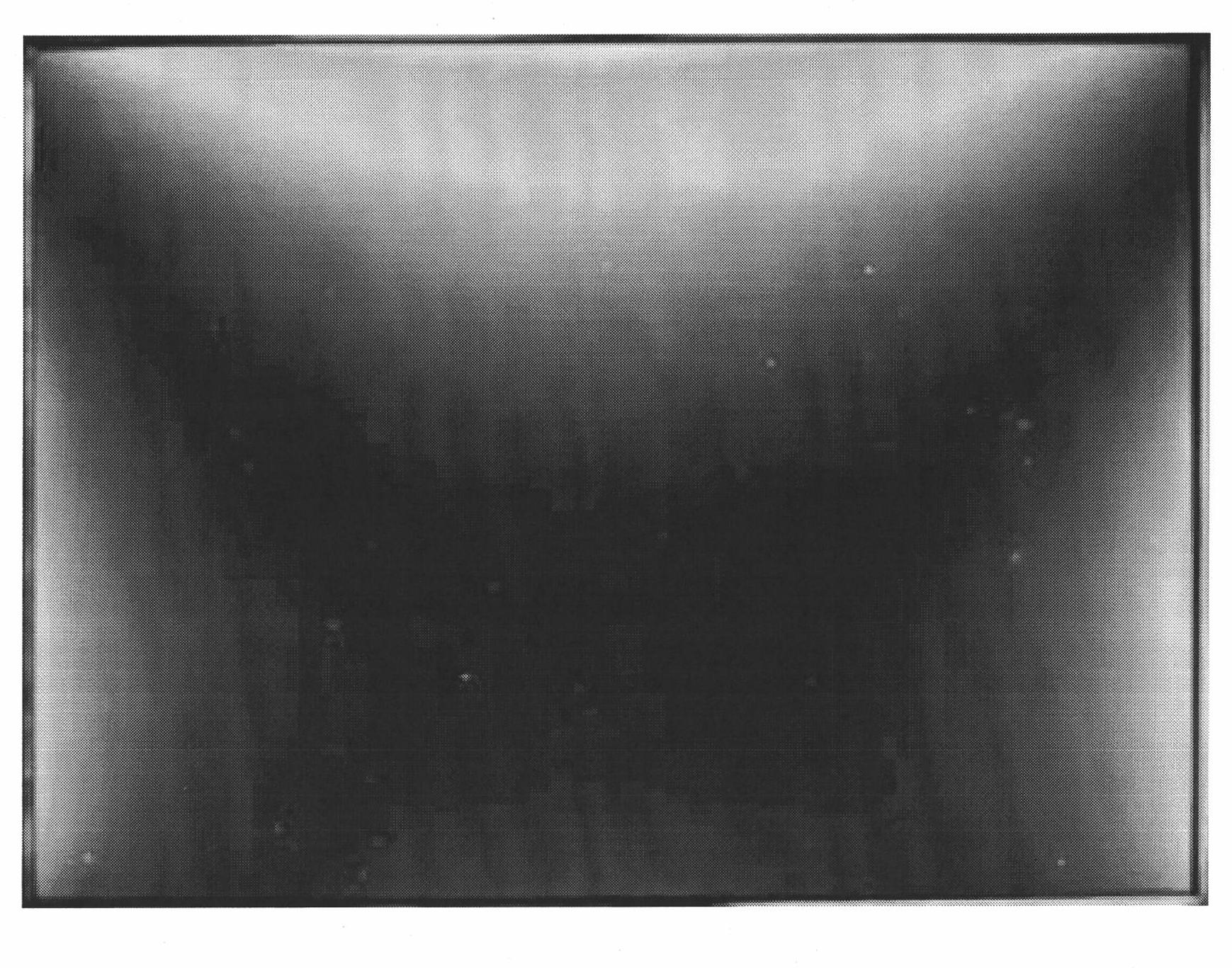

[0294] In particular, as long as it is the optical film of the present invention, even when the film base material is a polarizing plate, the occurrence of light leakage can be effectively s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com