Stitching-starting thread-drawing device for automatic thread-cutting sewing machine

A sewing machine and sewing thread technology, applied in sewing machine components, tension devices, sewing equipment, etc., can solve the problems of not meeting the needs of use, poor appearance, complicated mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

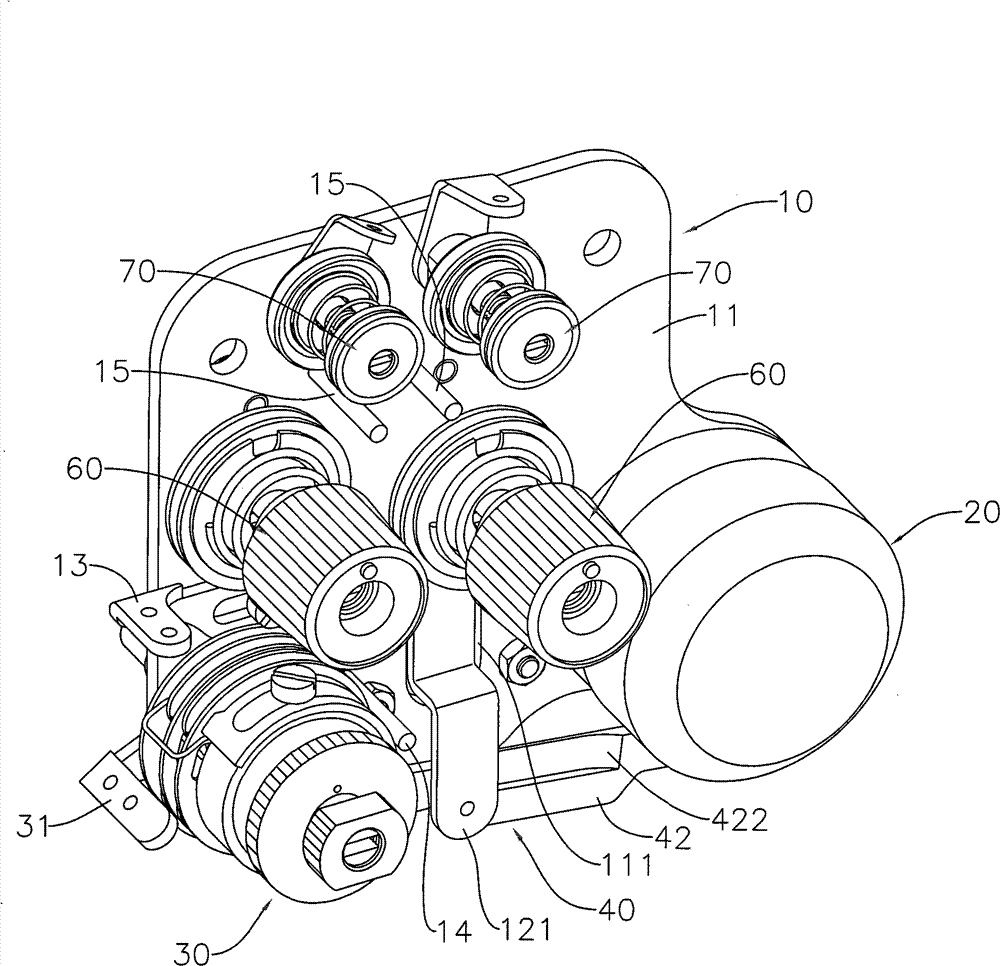

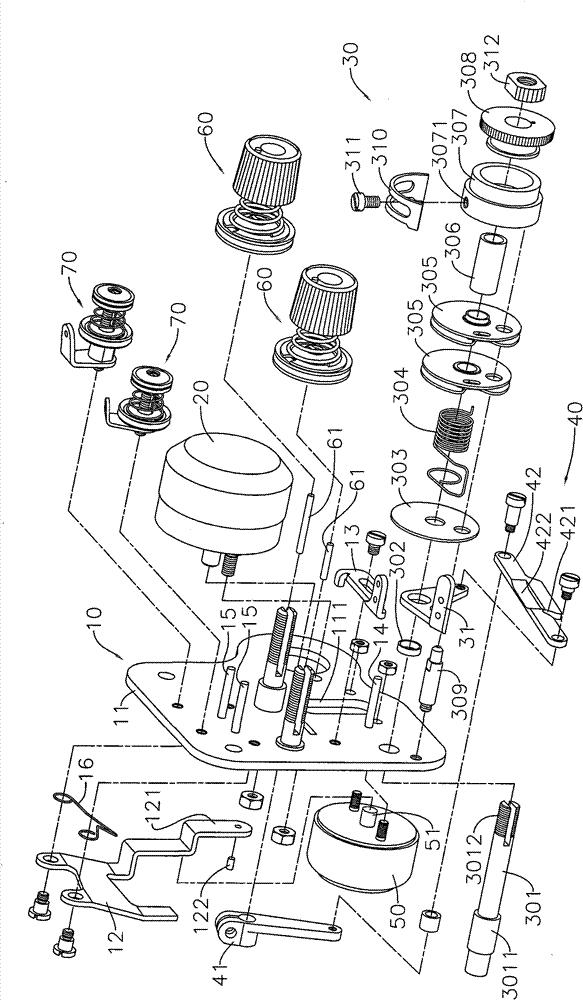

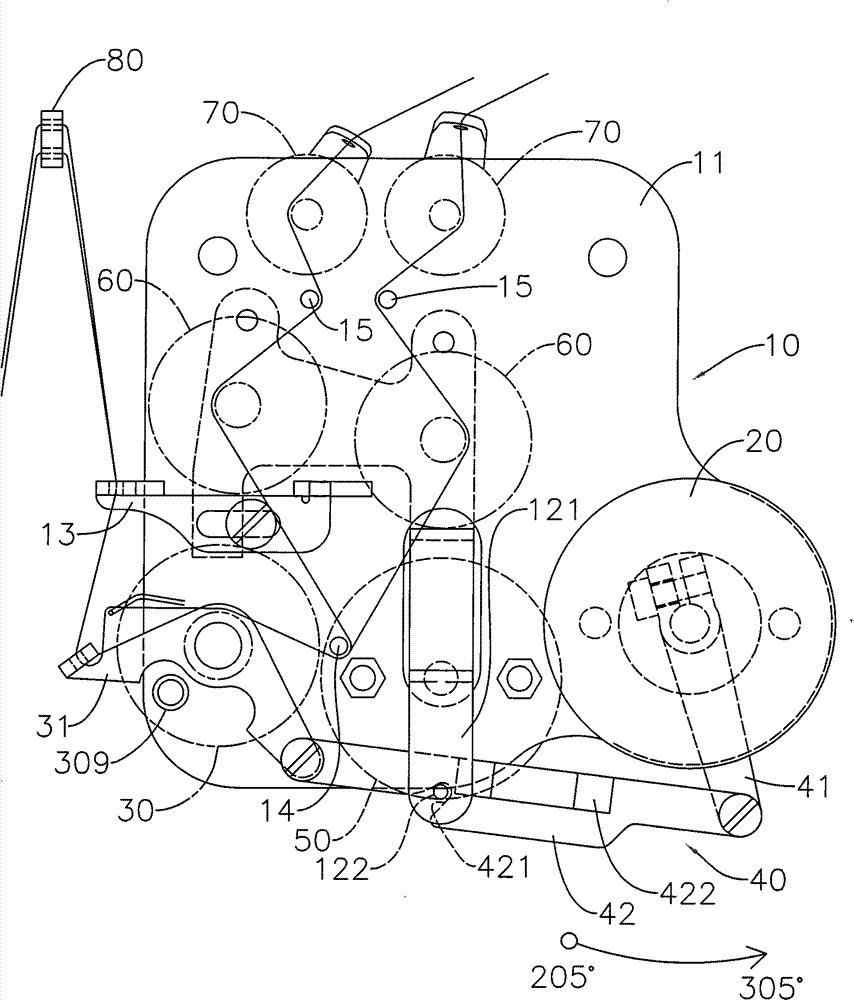

[0047] The embodiment of the present invention takes the double-needle model as an example, and when it is applied to the single-needle model, it only needs to remove the passage-related components of the left needle thread or the right needle thread, and the principle is the same; please refer to Figures 1 to 4, the present invention is A thread-starting and thread-drawing device of an automatic thread-cutting sewing machine, the thread-starting and thread-drawing device of the sewing machine comprising:

[0048] A seat body 10, the seat body 10 includes a base plate 11, a thread loosening operating plate 12, an adjustment line hanger 13 and at least two wire posts 14, 15, the base plate 11 is provided with a slot 111, the thread loosening actuating plate 12 is movably combined with the rear side of the base plate 11, and one end of the thread loosening actuating plate 12 forms a continuously bent extension arm 121, and the extension arm 121 is passed through the opening slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com