Thin film single-face cleaning mechanism

A technology for cleaning mechanisms and films, applied in cleaning methods and utensils, cleaning methods using tools, and thin material handling, etc., can solve problems such as film wrinkles, dust removal roller adhesion, and film conveying cannot maintain a tensioned state, and achieve structural Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

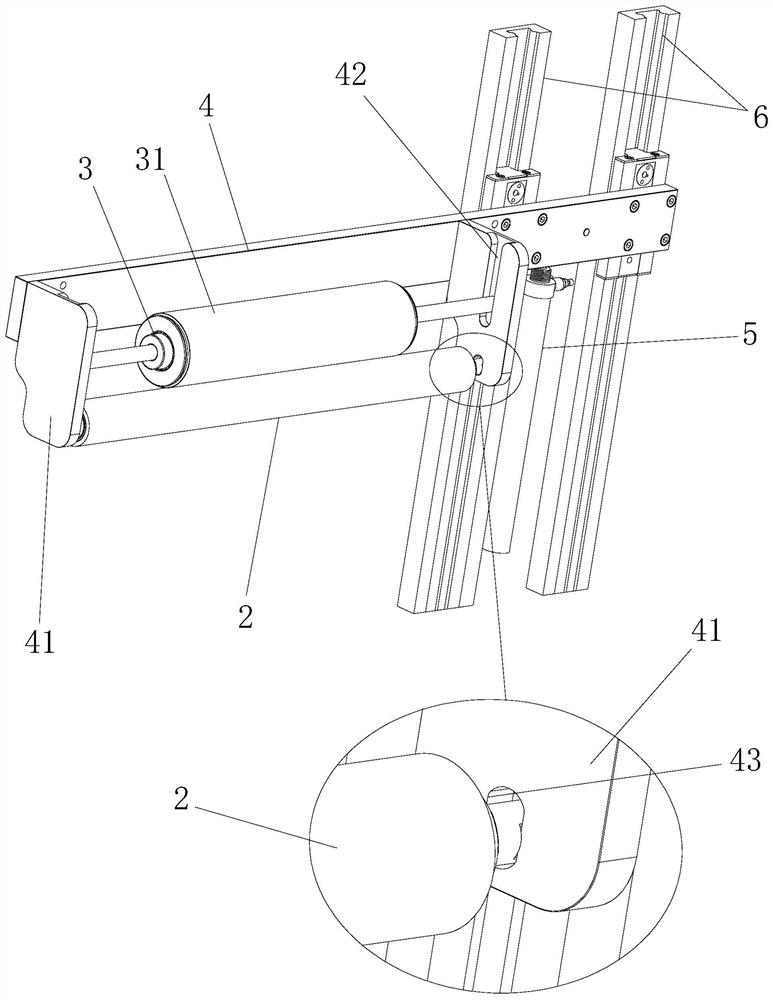

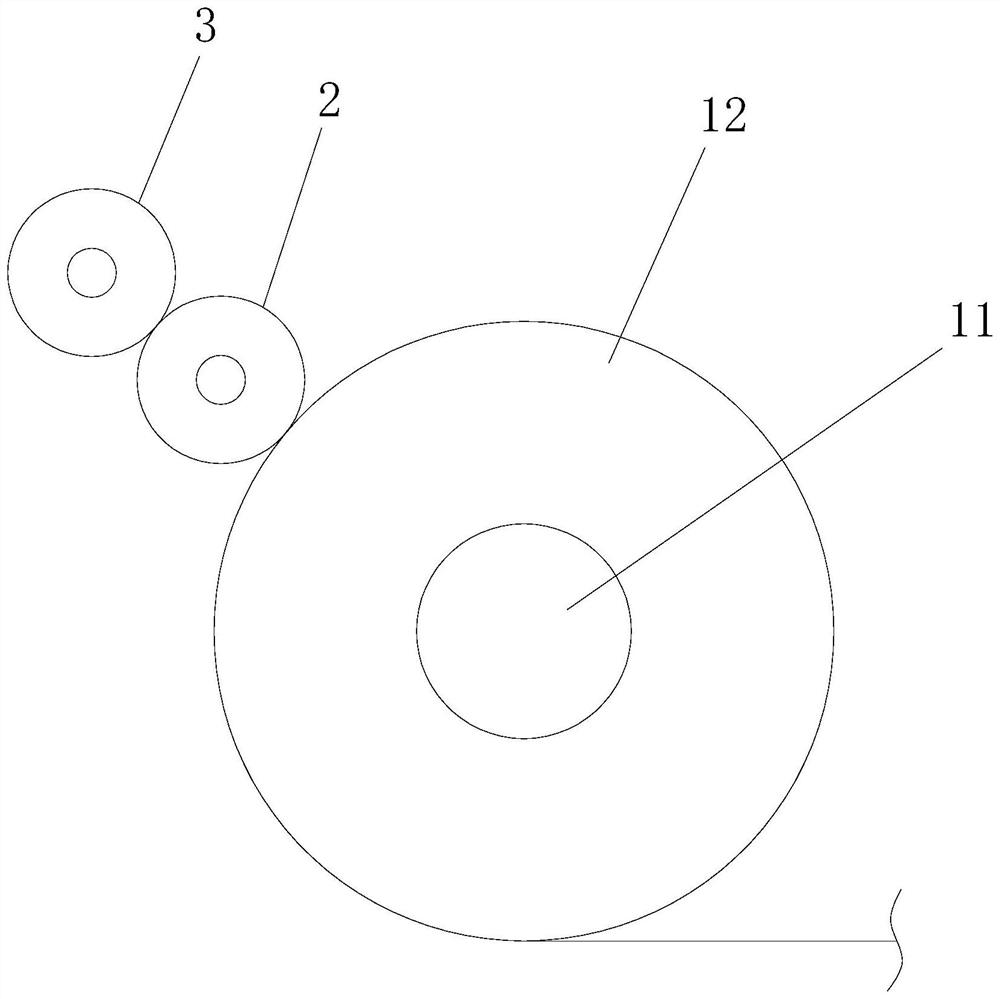

[0021] Embodiment one, such as Figure 1-2 As shown, a film single-sided cleaning mechanism includes a lifting mechanism, a dust removal roller 2 and a cleaning roller 3. The dust removal roller 2 is preferably a rubber roller with certain viscosity, and the cleaning roller 3 is wound with a tearable sticky paper 31 .

[0022] The lifting mechanism includes a guide rail 6, a cylinder 5, and a support 4 driven by the cylinder 5 to move along the guide rail. Two support plates 41 are fixed on the support 4. The support plate 41 has a support hole 43 for the end of the dust removal roller to be inserted. The support hole 43 A U-shaped support groove 42 is arranged above, and the end of the cleaning roller 3 is placed in the support groove 42 . The two ends of the dust removal roller 2 are respectively inserted into the support holes on the two support plates, and can rotate therein. The two ends of the cleaning roller 3 are placed in the support grooves 42 on the two support pla...

Embodiment 2

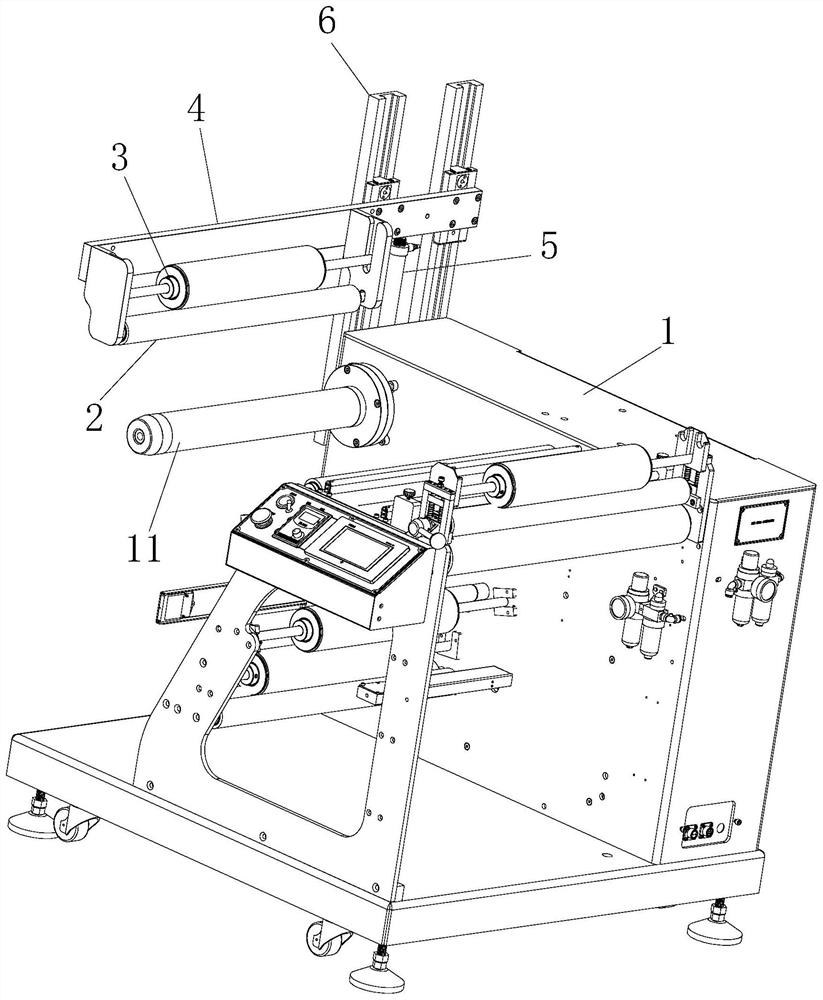

[0027] Embodiment two, such as image 3 As shown, a film conveyor 1 with a film single-sided cleaning mechanism, the film conveyor 1 is provided with a discharge roller 11 wrapped with a film 12, and one side of the film conveyor 1 is fixedly connected with a pair of winding rollers wrapped around the discharge roller. 11 A cleaning mechanism for dust removal on the outer surface of the outermost film. The cleaning mechanism is the film single-side cleaning mechanism in the first embodiment above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com