Novel pump body of large sized radial variable plunger pumps

A technology of variable plunger and pump body, which is applied in the field of new type pump body of large radial variable plunger pump, which can solve problems such as limited processing conditions, difficult processing, easy leakage, etc., and achieve tolerance matching optimization, performance improvement and system optimization , The effect of reducing the cost of transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

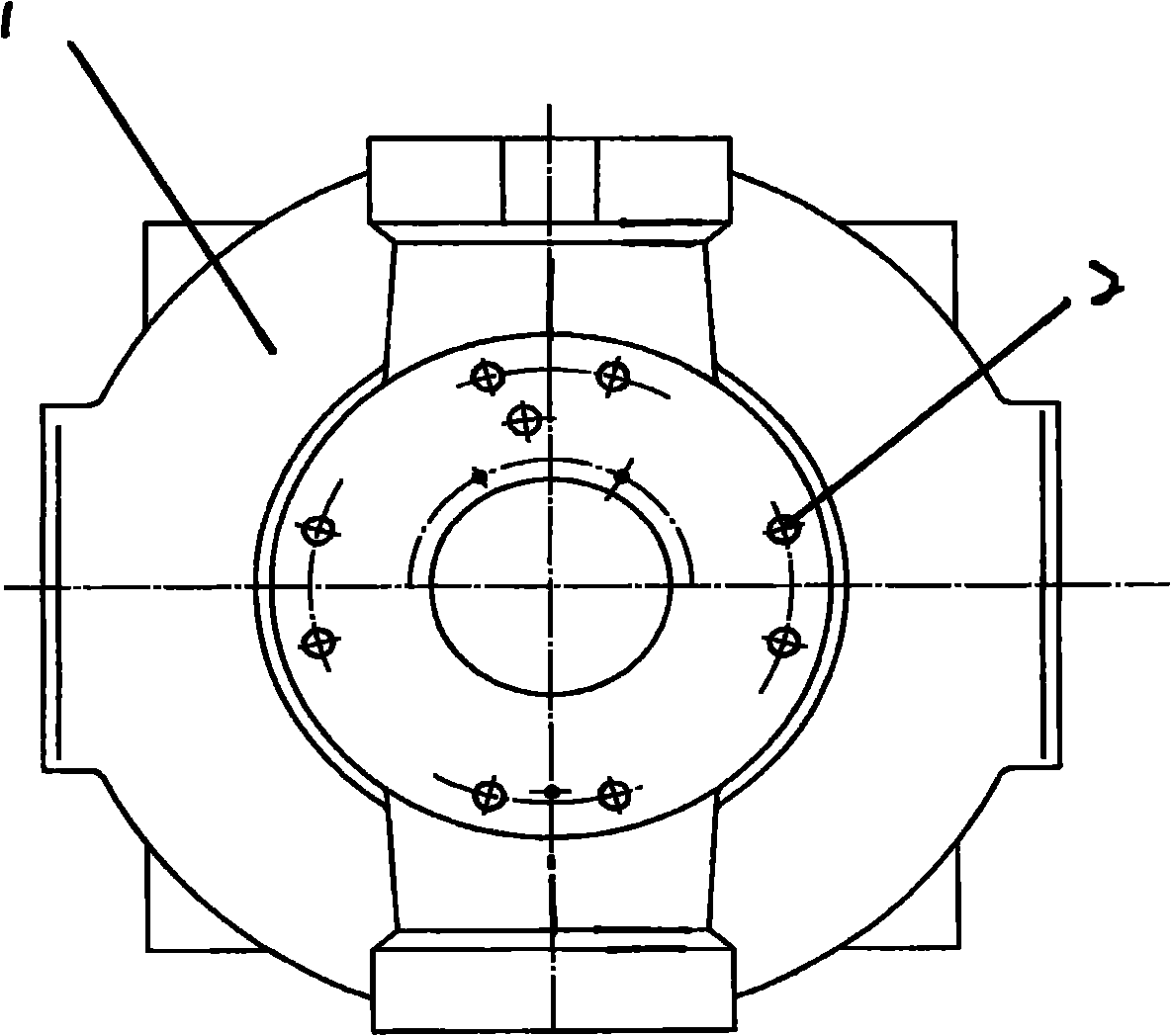

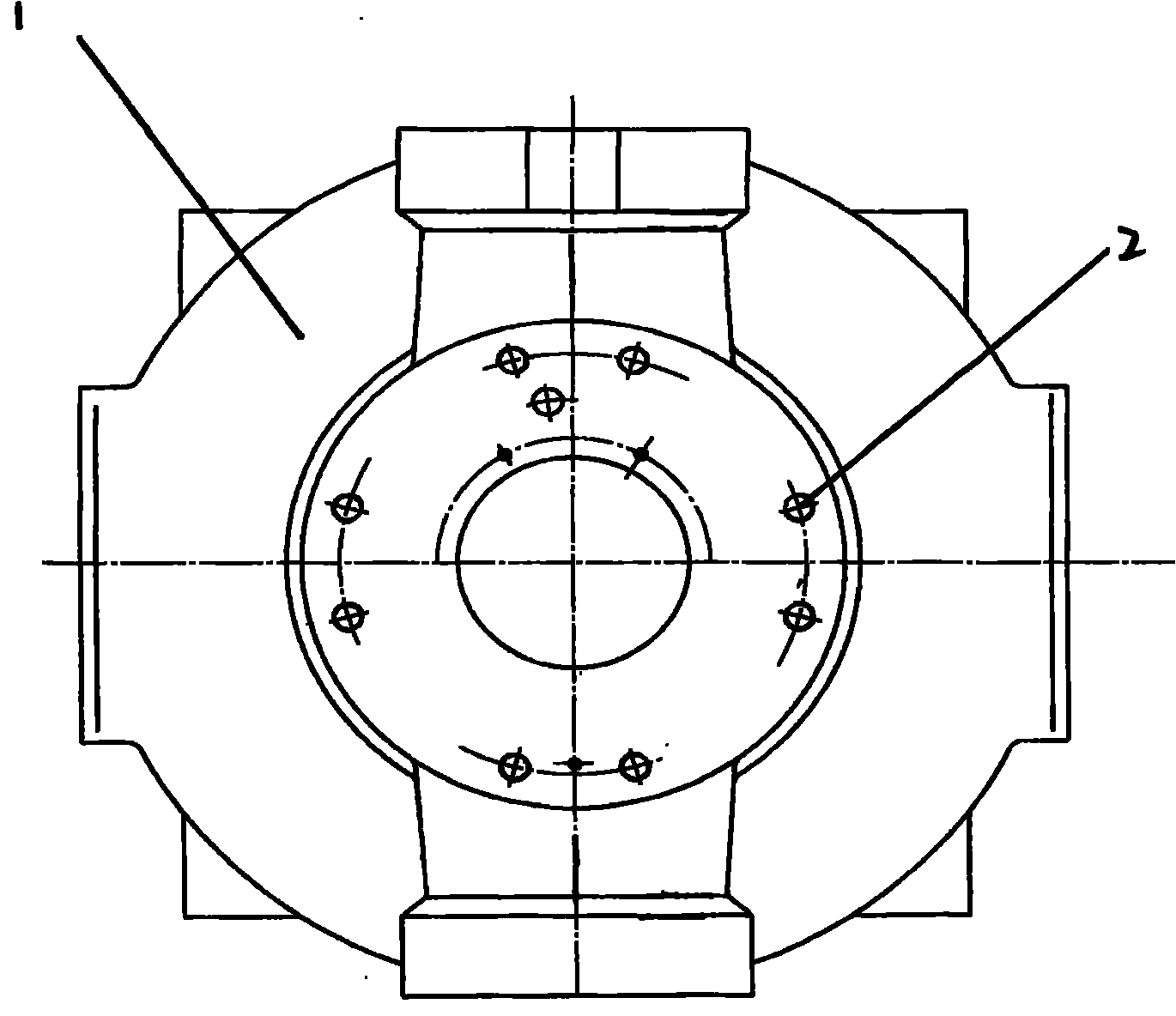

[0012] refer to figure 1 , on the integral pump body (1), the passive pump mounting screw hole (2) is designed. Use the mounting screw hole (2) of the passive pump to connect to another radial piston pump of the same specification or a smaller specification to meet the large flow requirements of the overall oil supply. At the same time, the output pressure and flow of the two pumps can be adjusted separately to adapt to the The different working conditions of the whole system, combined with the improvement of the transmission shaft and the distribution shaft, can realize the double pump co-drive, and adapt to the graded oil supply and pressure adjustment requirements of the complex hydraulic system of the large radial piston pump. At the same time, the installation space is reduced, Save power.

[0013] The improvement of the pump body in cooperation with the drive shaft and the distribution shaft can realize double-pump co-drive.

[0014] When working, the hydraulic oil ent...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap